Large-aperture static blasting method and hole plugging device thereof

A static blasting, large-aperture technology, applied in blasting and other directions, can solve the problems of unsuitable underwater static blasting operation, low construction efficiency, low expansion pressure, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The model of the hydraulic reaming drill used in the present invention is: 76-101, produced by Hunan Changsha Heijingang Industrial Co., Ltd.

[0024] The crushing agent used in the present invention is the static crushing agent (SCA crushing agent) produced by Changsha Dongke Building Materials Technology Co., Ltd.

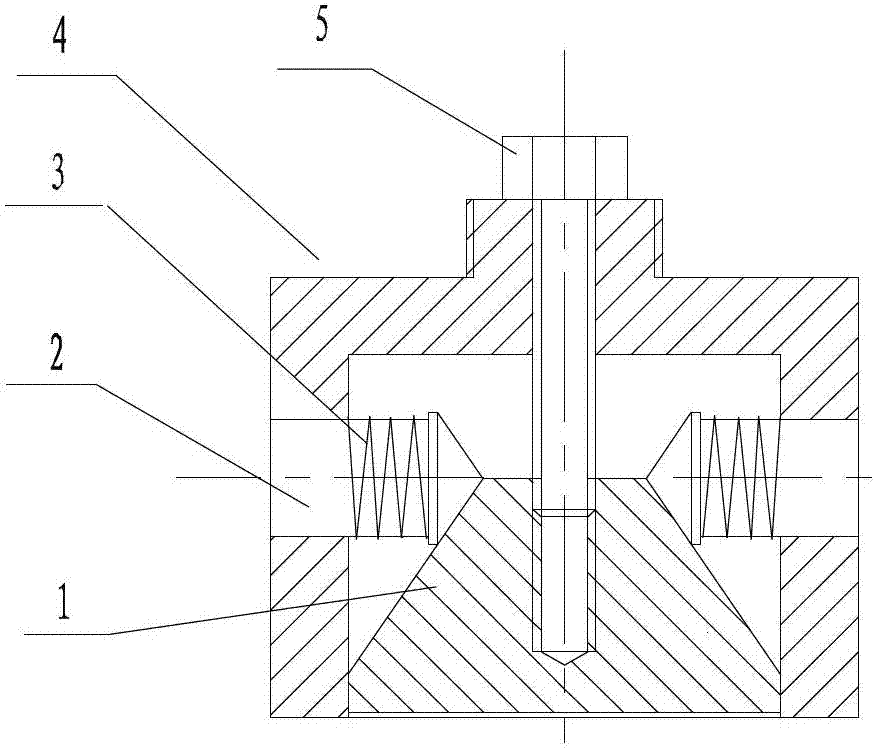

[0025] The hole plugging device of the present invention is a mechanical hole plugging device, which uses four taper pins 2 to clamp the hole wall, and its structure is as follows: figure 2 As shown, it consists of a vertebral body 1, a taper pin 2, a housing 4, a spring 3 and a bolt 5. The vertebral body 1 is arranged inside the housing 4, and four taper pins 2 are located in four holes on the housing 4. The bolts 5 is connected to it through the threads in the vertebral body 1, and the spring 3 is sleeved on the outside of the taper pin 2 and stuck inside the housing 4.

[0026] The bolt 5 is gradually tightened by using a special wrench and an externa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com