Blasting demolition method for cylindrical steel column structure buildings

A steel structure and steel column technology, applied in building construction, construction, building maintenance, etc., can solve the problems of high labor intensity, high strength, explosion shock waves, blasting flying stones, and difficult noise prevention and control, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

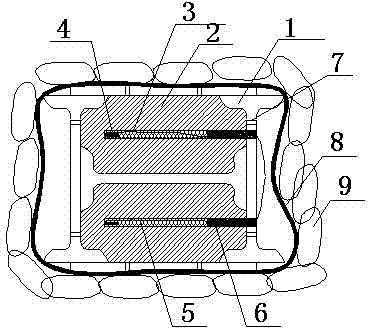

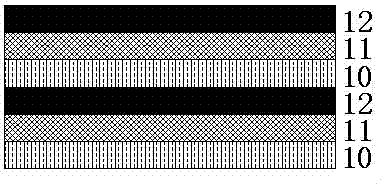

[0024] A method for demolishing a cylindrical steel column structure building by blasting, the steps are: a, pouring concrete 2 inside the column steel structure 1 to be blasted; b, curing of the concrete 2; c, oxygen cutting on the front of the column steel structure 1 Drilling holes 3; d, pre-cutting 7 on the columnar steel structure 1; e, determining the blasting parameters and connecting the charges; f, protection; g, blasting.

[0025] The steps of pouring concrete 2 inside the columnar steel structure 1 to be blasted are as follows: pouring concrete 2 in sections at the side opening of the columnar steel structure 1, and the distance between the openings is preferably 1m~1.5m (depending on whether there are partitions and partitions in the steel column) depending on board spacing). As the pouring height of the columnar steel structure 1 rises, the water-cement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com