Porous Granular Ammonium Fuel Explosive Binder

A technology for ammonium explosives and adhesives, which is used in explosives, non-explosive/non-thermal components, offensive equipment, etc. Sodium toluene sulfonate has problems such as large dust, easy blockage of pipe storage time, etc., to achieve the effect of reducing the ball milling process, low production cost and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1 is composed of the following components by weight percentage, polyacrylamide 1.5%, urea 15%, sodium nitrate 58.5% and water 25%.

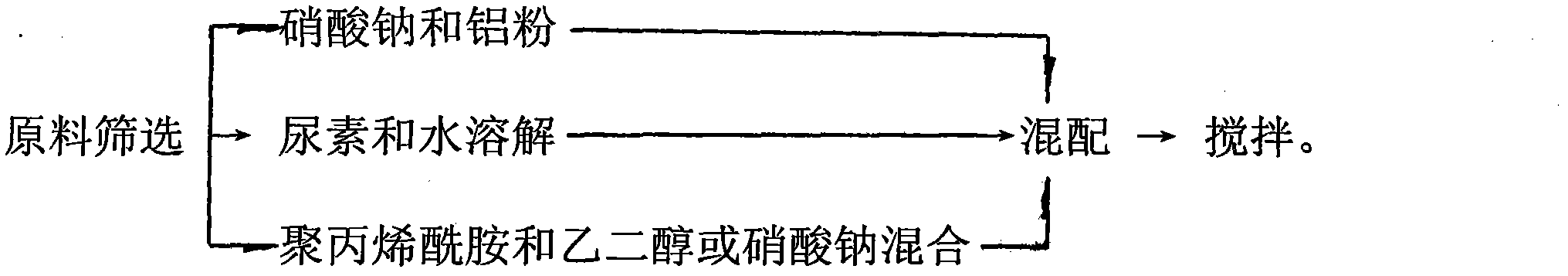

[0013] Its production process includes: raw material screening, urea and water dissolution, polyacrylamide and sodium nitrate mixing, mixing and stirring processes.

[0014] Process description

[0015] 1 Raw material screening, polyacrylamide, urea and sodium nitrate are all industrial products;

[0016] 2 Dissolve urea and water, take urea and water according to the ratio and put them in a stirring container and stir until completely dissolved;

[0017] 3 mix polyacrylamide and sodium nitrate, take polyacrylamide and sodium nitrate according to the proportion and mix evenly;

[0018] 4 Mixing, process 2 and 3 are mixed according to the proportion;

[0019] 5 Stir until evenly mixed.

[0020] The porous granular ammonium oil explosive binder is suitable for on-site mixing and on-site use.

Embodiment 2

[0021] The second embodiment is composed of the following components by weight percentage, polyacrylamide 2%, ethylene glycol 10%, urea 10%, sodium nitrate 48% and water 30%.

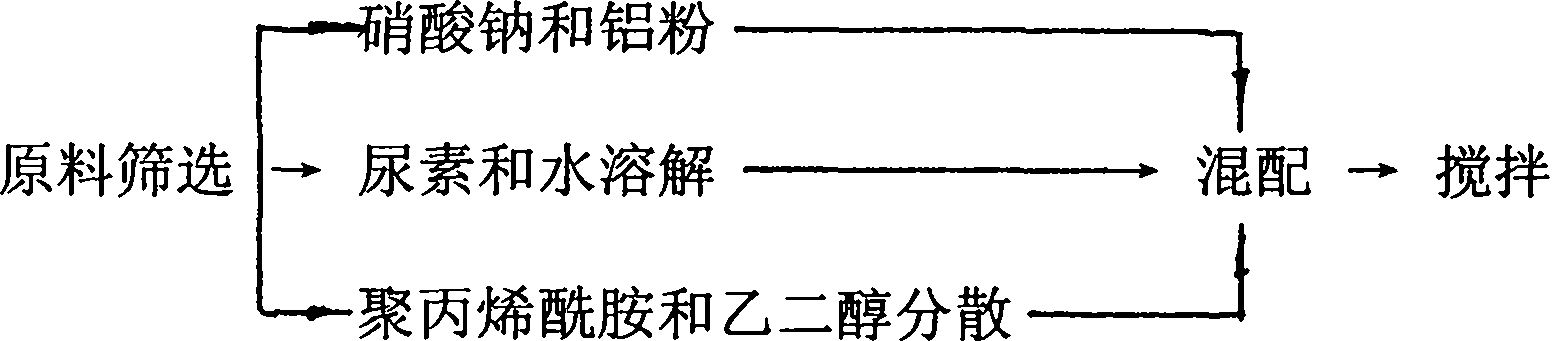

[0022] Its production process includes: raw material screening, urea and water dissolution, polyacrylamide and ethylene glycol mixing, mixing, and stirring processes.

[0023] Process Description

[0024] 1 Raw material screening, ethylene glycol adopts industrial products, and the rest are the same as Example 1

[0025] 2 urea is dissolved in water, same as Example 1;

[0026] 3 Polyacrylamide and ethylene glycol are mixed evenly, and the rest are the same as Example 1;

[0027] 4 mixing, adding steps 2, 3 and sodium nitrate in proportion;

[0028] 5 Stir, same as Example 1

[0029] The porous granular ammonium oil explosive binder is suitable for mixing porous granular ammonium oil explosives below medium hard rock.

Embodiment 3

[0030] The third embodiment is composed of the following components by weight percentage, polyacrylamide 4%, ethylene glycol 15%, urea 10%, sodium nitrate 41%, aluminum powder 10% and water 20%.

[0031] The production process is the same as Example 2 except that 41% of sodium nitrate and 10% of aluminum powder are added in sequence.

[0032] The porous granular ammonium oil explosive binder is suitable for mixing porous granular ammonium oil explosives above medium hard rock.

[0033] Instructions for use: The adhesive can be directly mixed with porous granular ammonium oil explosives, and the proportion is: porous granular ammonium oil explosives 85-95%, binder 5-15%. It can also be mixed and used on site, and its proportion is as follows: 80-90% of porous granular ammonium nitrate, 3-6% of light diesel oil and 5-15% of binder. Light diesel oil adopts No. 0, No. 10, No. -10, No. -20 or No. -35.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com