Safety production process of emulsified granular ammonium oil explosive

A technology for ammonium explosives and safe production, which is applied to explosives processing equipment, explosives, offensive equipment and other directions, can solve the problems of unsafe preparation methods, unpractical operation methods, and high operating labor intensity, and achieves production safety and guarantee. Operational safety, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] In the picture:

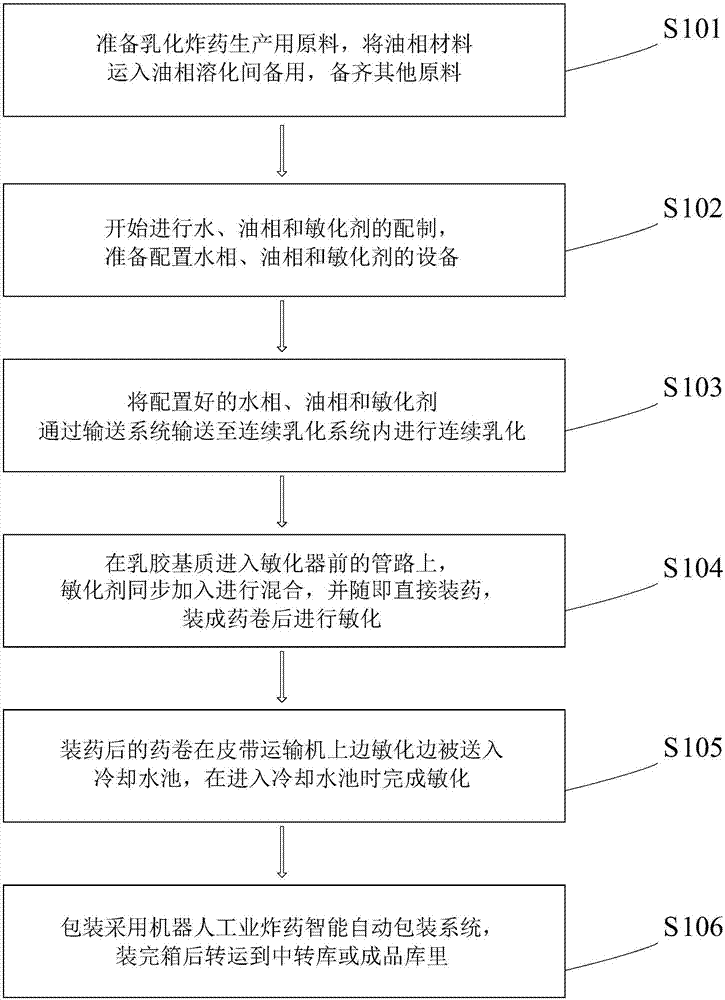

[0034] as attached figure 1 To attach figure 2 shown

[0035] A kind of safe production technology of emulsified granular ammonium oil explosives specifically comprises the following steps:

[0036] S101: Prepare raw materials, transport 300g of oil phase materials into the oil phase dissolving room for standby, transport ammonium nitrate and sodium nitrate into the ammonium nitrate feeding room in a ratio of 1:1 for standby, and mix sodium nitrite and accelerator in a ratio of 1:2 The ratio is transported into the sensitizer configuration room for standby;

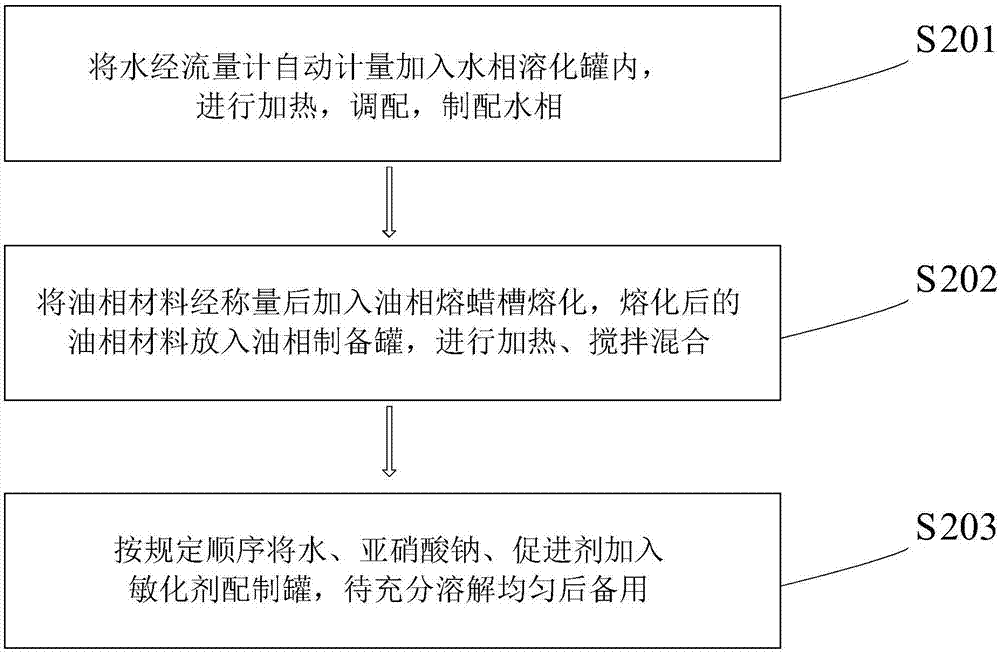

[0037] S102: Start preparing the water, oil phase and sensitizer, and prepare equipment for configuring the water phase, oil phase and sensitizer, wherein the method for configuring the water, oil phase and sensitizer includes the following steps:

[0038] S201: Water phase preparation, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com