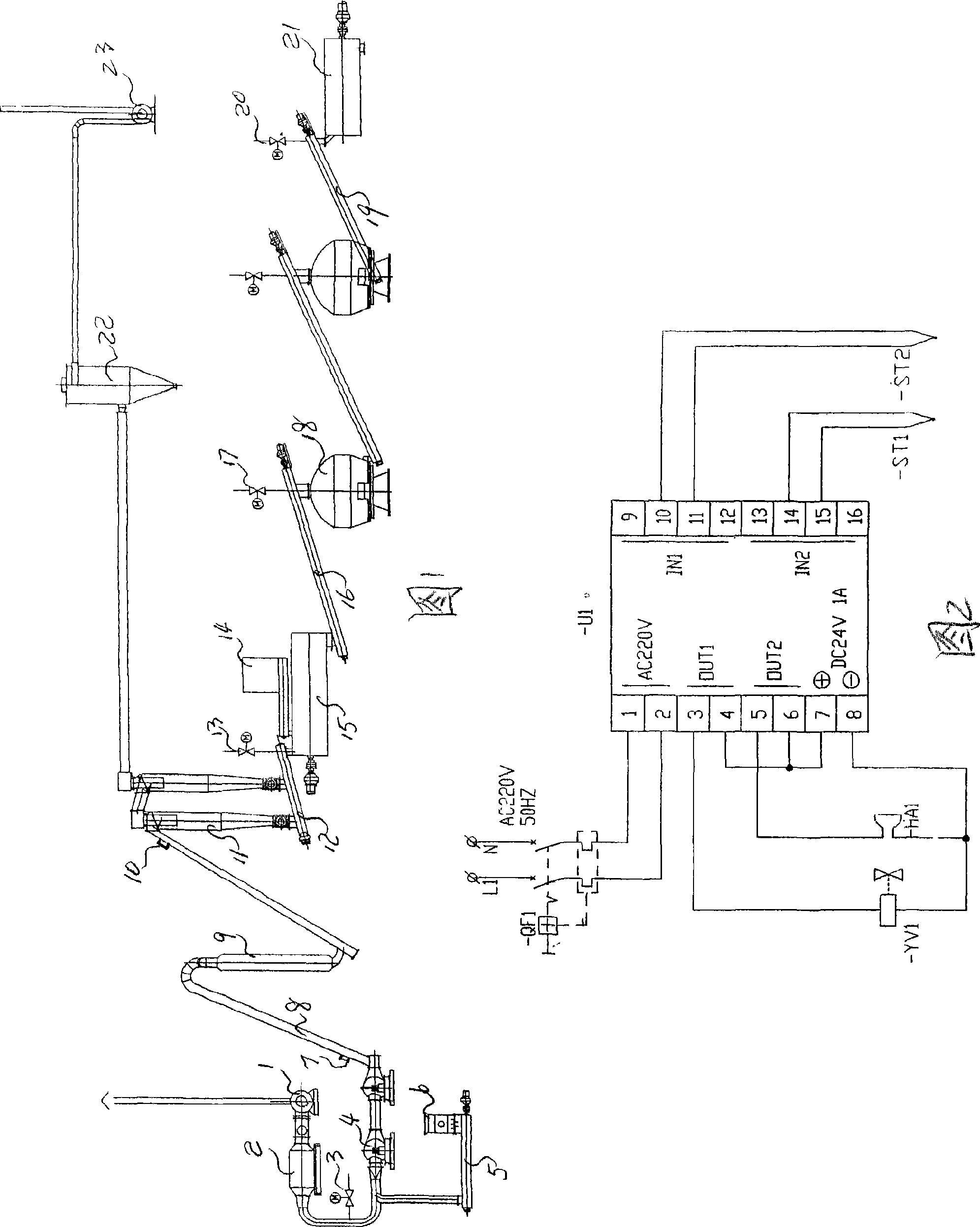

Continuous production line of modified anfo explosive

A production line and explosive technology, applied in the field of continuous production line of modified ammonium oil explosives, can solve the problems of low production efficiency, large number of employees, and poor safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

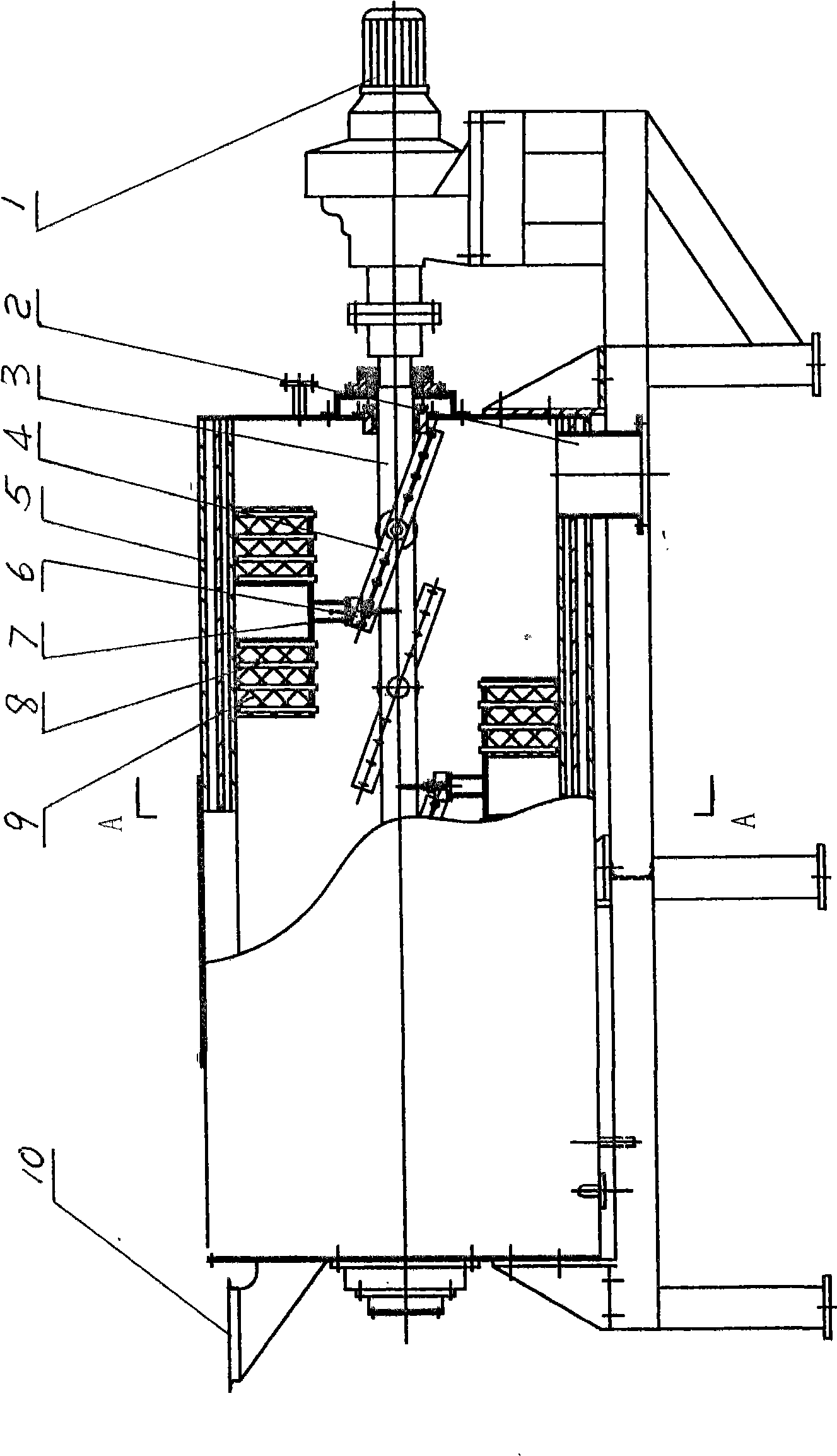

[0005] In conjunction with the above accompanying drawings, the present invention is described in detail. In order to solve the problems of discontinuous production of the existing ammonium oil explosives, many people and low efficiency, the present invention uses a pipeline screw between the rough crusher, pulverizer, mixer and medicine cooler. The conveyor is connected, and the powder is dried and conveyed by the high-temperature dry airflow, making it an uninterrupted continuous production. A heater 2 is connected in series on the pipeline between the blower 1 and the cam grinder 4. The heater is a steam heater or an electric heater. The heat energy provided by the heater should make the temperature of the air flow reach 110°C-150°C , the feeding port of the screw conveyor 5 is connected with the outlet of the crusher 6 and the outlet of the modifying agent quantitative screw feeder, and its outlet is connected with the pipeline between the heater 2 and two series-connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com