Elevated type on-site granular ANFO (Ammonium Nitrate Fuel Oil) explosive mixed loading automobile

A technology of on-site mixing and ammonium oil explosives, which is applied in the direction of motor vehicles, article transport vehicles, transportation and packaging, etc., can solve the problems of unsafe finished explosives, endangering the health of workers in the surrounding environment, and high prices, and achieves simple structure and convenience Mixing adjustment, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

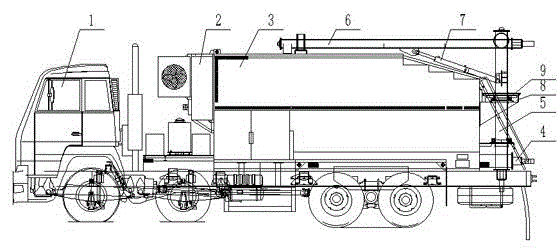

[0010] Such as figure 1 As shown, the overhead type on-site mixed granular ammonium oil explosive vehicle includes: a car body 1, a fuel device 2 and a dry material tank 3 are installed on the chassis of the vehicle body 1, and the bottom of the silo of the dry material tank 3 is arranged There is a box body screw 4, a vertical screw 5 is installed vertically on the rear frame of the car body 1, the bottom of the vertical screw 5 communicates with the box screw 4, and the top of the vertical screw 5 communicates with the top screw 6 And hinged together, the cylinder block of hydraulic cylinder 7 is hinged on the middle part fixed frame of vertical screw 5, and the piston of hydraulic cylinder 7 is hinged at the middle part of top screw 6.

[0011] The rear portion of the dry material box 3 is provided with a fixed frame 8, and the vertical screw 5 is rotatably mounted on the fixed frame 8 through a bearing 9, and the vertical screw 5 is driven to rotate by a hydraulic motor. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com