Viscous and granular anfo (ammonium nitrate and fuel oil) explosive and preparation method thereof

An ammonium explosive, granular technology, applied in the direction of explosives, etc., can solve the problems of large dust and explosion, combustion danger, frequent production safety accidents of emulsion explosives, incompatibility with on-site mixed explosive sensitivity, etc., to achieve no detonator sensitivity, Excellent water resistance and detonation sensitivity, easy to use in mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

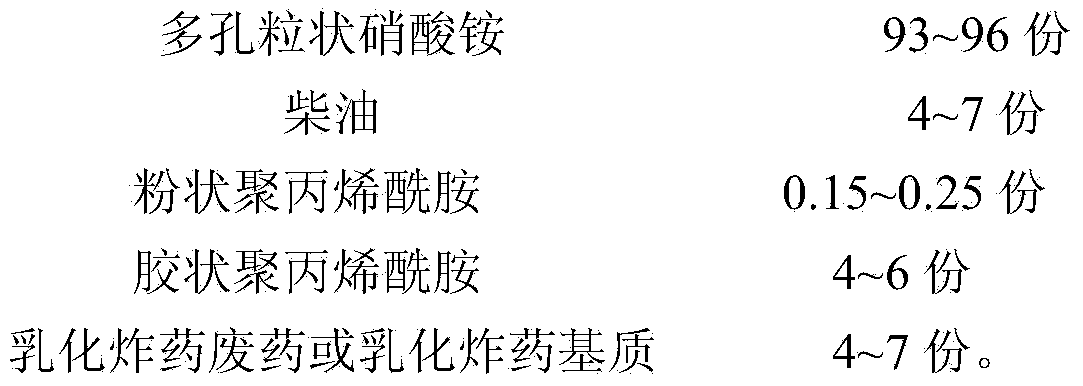

[0030] A viscous granular ammonium oil explosive, the raw material components are as follows:

[0031]

[0032] The preparation method is as follows:

[0033] (1) Drop into the porous granular ammonium nitrate in the coulter mixer, start the oil pump immediately and gradually inject diesel oil, and mix evenly;

[0034] (2) Add powdered polyacrylamide and emulsified explosive waste to the coulter mixer, and continue to stir for 3 minutes;

[0035] (3) Add colloidal polyacrylamide into the coulter mixer, continue to stir for 3 minutes, then stop stirring; open the discharge port of the coulter mixer, pack, and obtain.

Embodiment 2

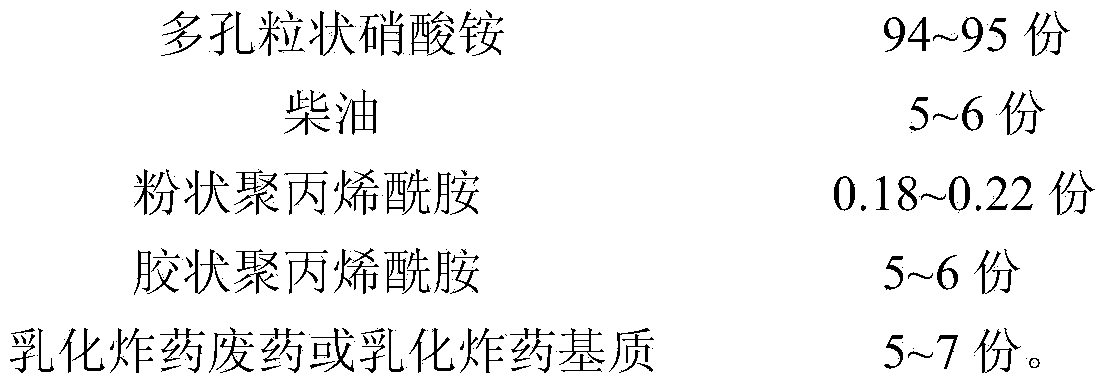

[0037] A viscous granular ammonium oil explosive, the raw material components are as follows:

[0038]

[0039] The preparation method is the same as in Example 1.

Embodiment 3

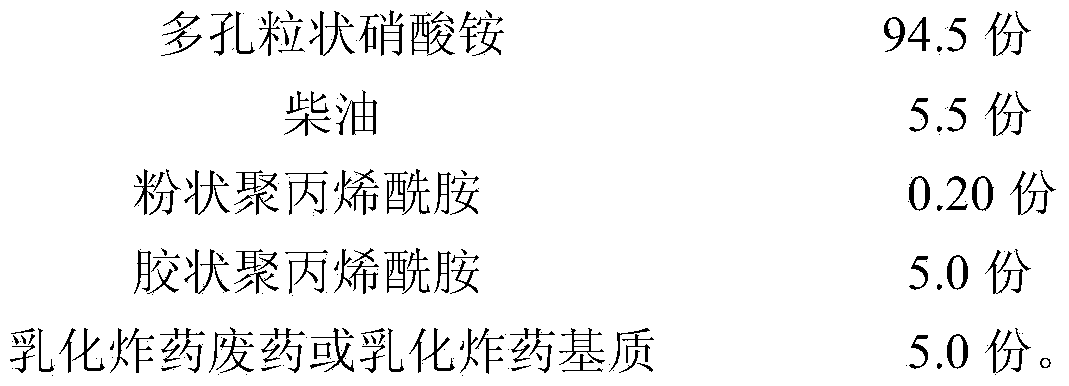

[0041] A viscous granular ammonium oil explosive, the raw material components are as follows:

[0042]

[0043] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com