Production method and device of anfo explosives

A technology for ammonium explosives and production methods, applied in explosives processing equipment, explosives, offensive equipment and other directions, can solve problems such as waste of manpower, material resources and energy, obstacles to the development of ammonium explosives, complex production equipment, etc., to achieve no dust generation, The effect of saving human resources and energy, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

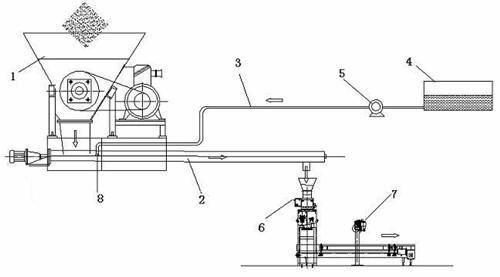

[0034] A kind of production method of ammonium oil explosive, comprises the following steps:

[0035] Step 1: Get 95 parts of the following components ammonium nitrate according to the mass fraction, and get raw materials in 5 parts of diesel oil;

[0036] Step 2, putting the ammonium nitrate into a grinder for crushing;

[0037] Step 3, putting the diesel oil into the oil phase tank and transporting it to the bottom of the grinder through the oil phase tank delivery pipe;

[0038] Step 4, mixing the diesel oil sprayed out through the nozzle of the delivery pipe of the oil phase tank and the crushed ammonium nitrate through the mixer, and transporting them to the inlet of the charging machine;

[0039] Step five, discharging, packing and sealing.

[0040] In step 2, the granularity of ammonium nitrate after crushing is 60 mesh, and the crushing machine is a double-roller crushing machine.

[0041] In step 3, the delivery amount of the diesel oil is metered by the oil phase ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com