Rock Blasting Method Using Pipes Embeded In Explosive Layers Of Blast Waterhole

A technology of filling tubes and charging powder, which is applied in drilling equipment and methods, blasting, earthwork drilling and mining, etc. It can solve the problems of reducing explosive force, not being able to insert air bags, reducing rock blasting force, etc., and increasing the blasting length , prolonging the charge length and reducing the charge amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, the technical configuration of the present invention will be described in detail with reference to the accompanying drawings.

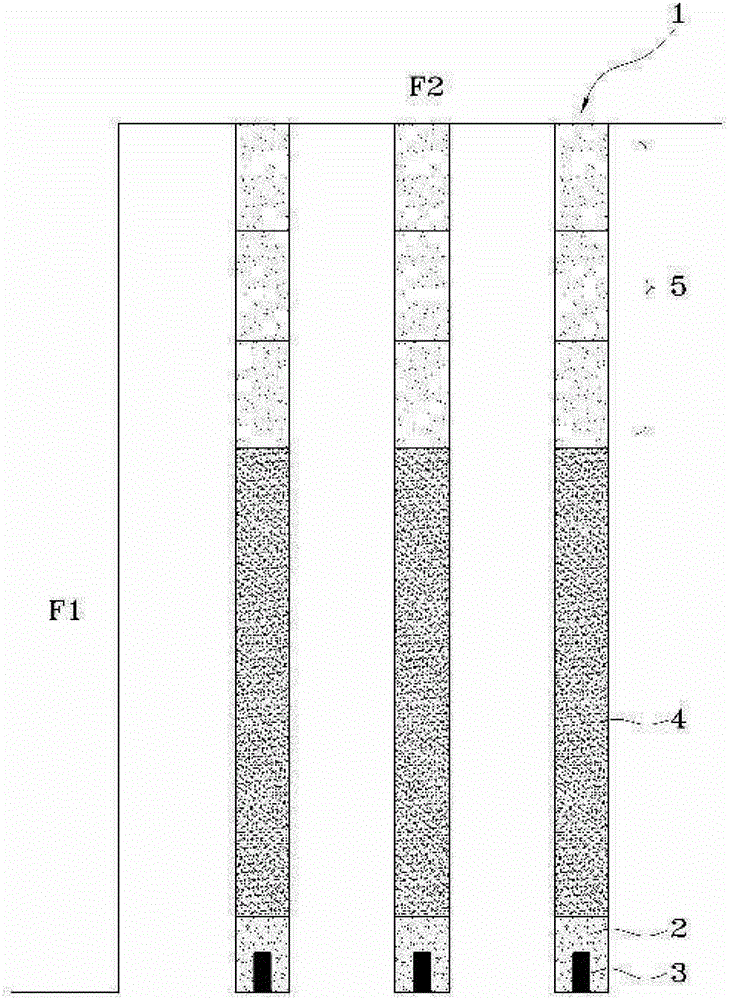

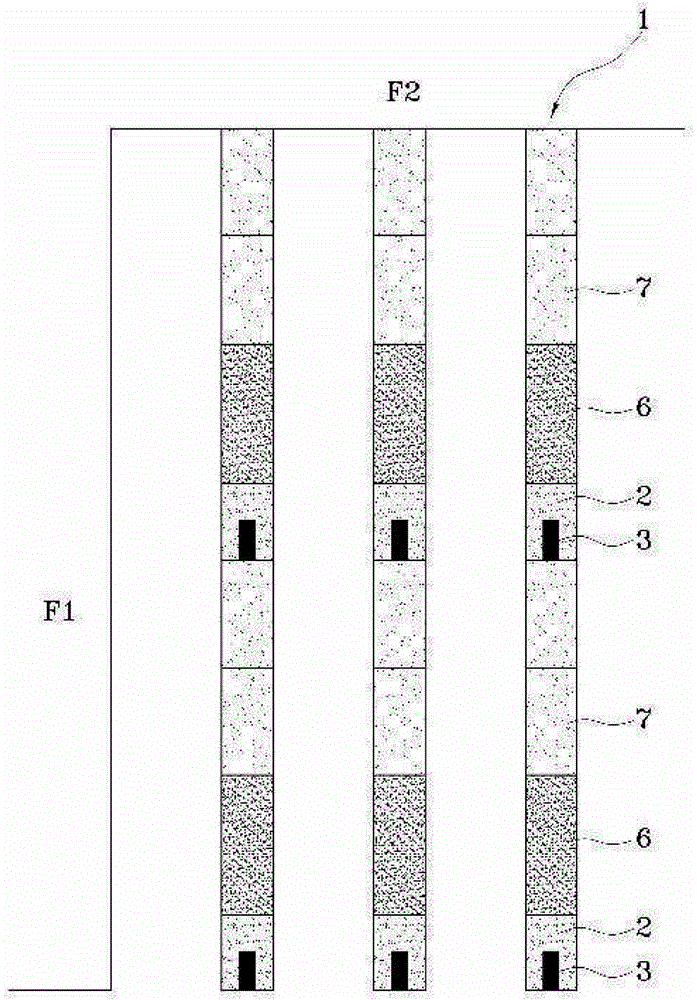

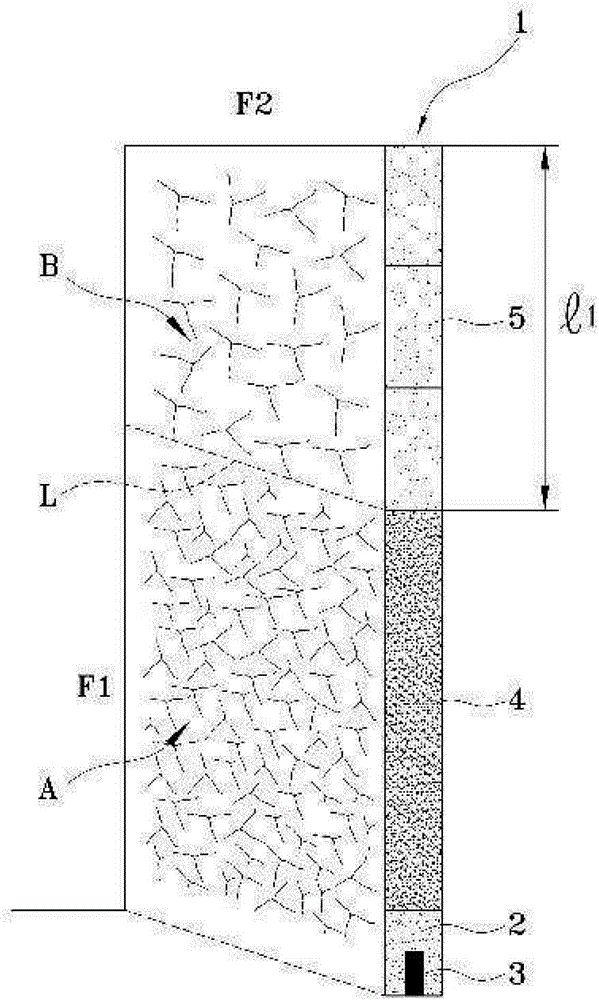

[0048] Such as Figure 3 to Figure 4 As shown, the present invention is characterized in that it includes: the steps of drilling holes according to the specified depth and regulation on the rock bed to be intercepted; respectively filling the priming powder 12, the detonator 13 and the explosive into the drilling holes, and at least After one or more filling pipes whose diameter is smaller than that of the drill hole and which have a pipe layer of a specified size inside are inserted into the hole, the outer side of the filling pipe inserted in the hole is wrapped with explosives. In order to ensure that the filling pipe is buried in the The step of loading the filling pipe body and explosives into the charge hole 11 in sequence in the inside of the charge layer 14; the filling step of filling the upper side of the explosive in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com