Additive manufacturing equipment and manufacturing method for titanium alloy structural part

A technology of additive manufacturing and titanium alloy, which is applied in the field of additive manufacturing equipment and preparation of titanium alloy structural parts, can solve the problems of poor mechanical properties, high production cost of structural parts, low efficiency, etc., and achieve good product performance and low cost. Low, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

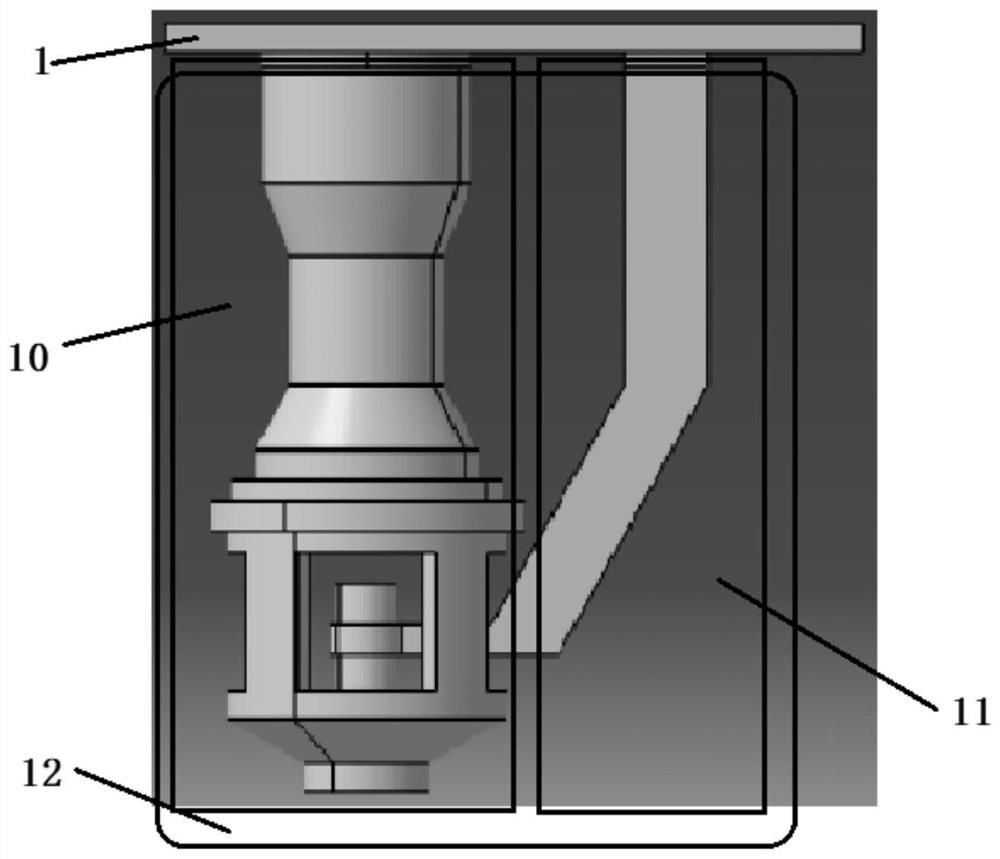

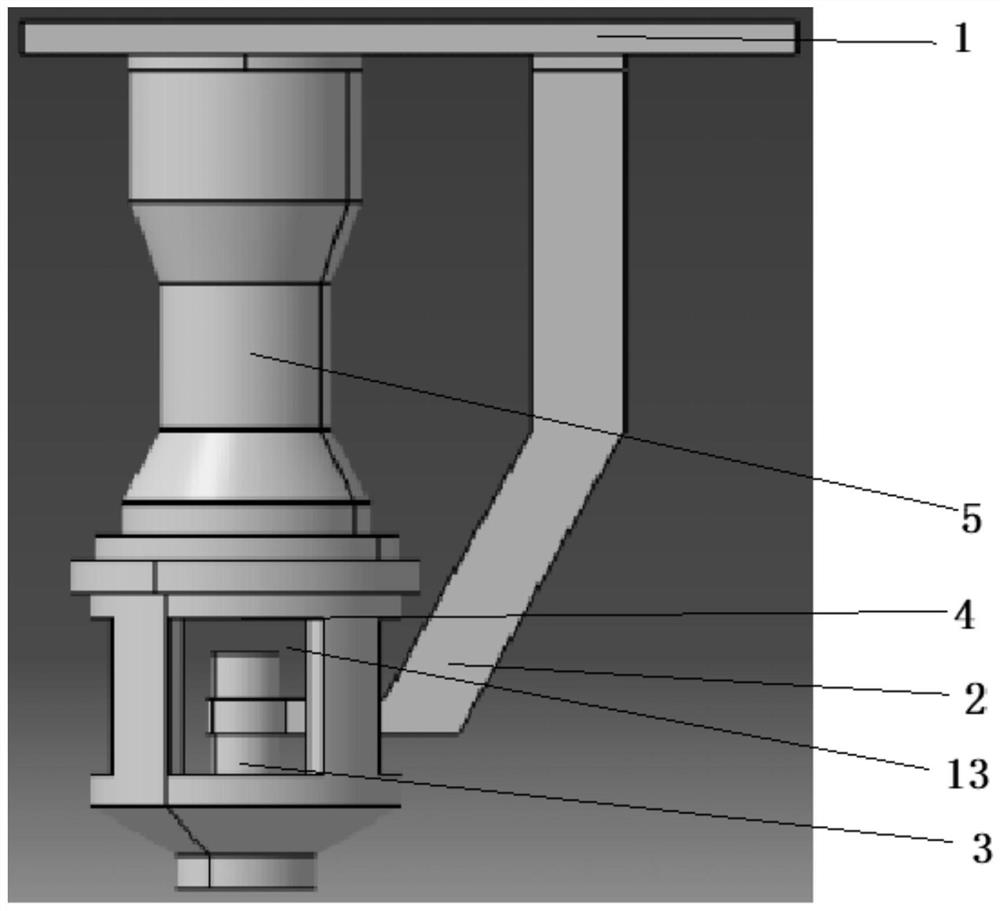

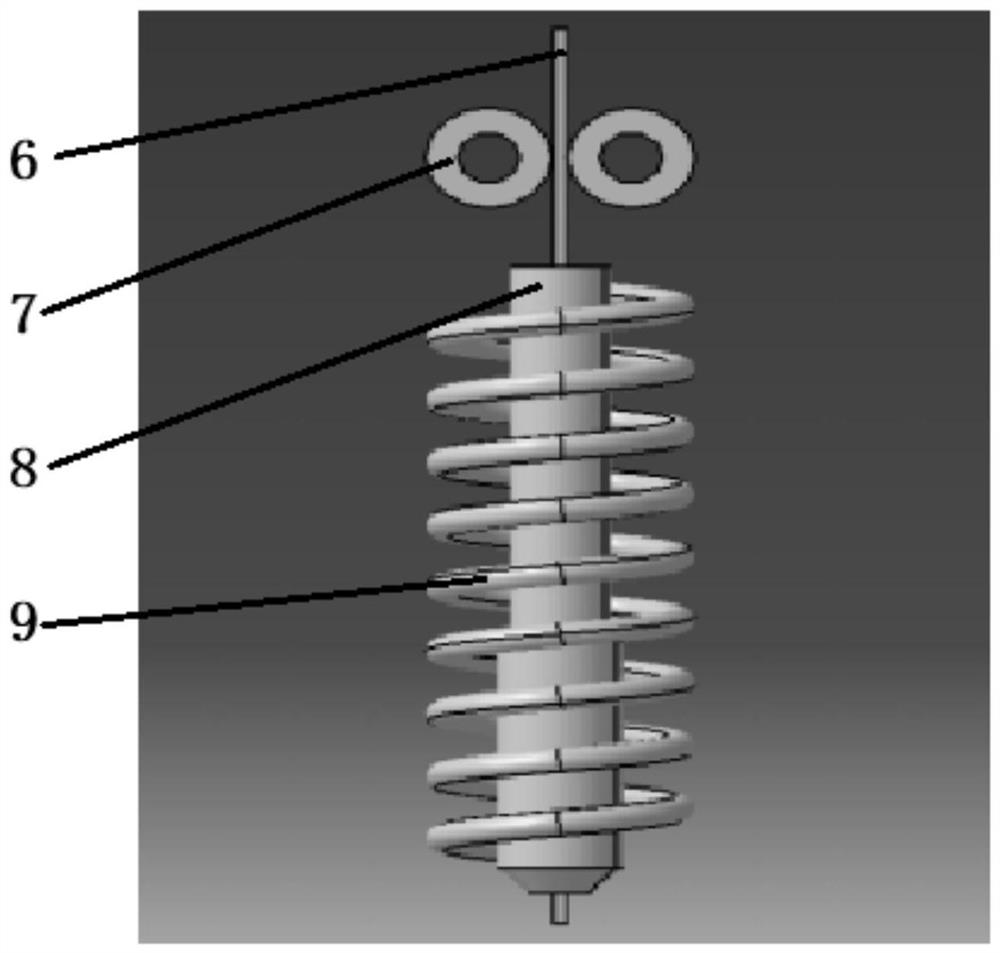

[0050] figure 1 , figure 2 It is a schematic structural diagram of an additive manufacturing equipment for a titanium alloy structural part according to an embodiment of the present invention; image 3 It is a schematic diagram of the structure of a heating wire feeding device. like figure 1 , 2 As shown, the device includes a numerical control slide rail 1 and an integrated print head 12. The integrated print head 12 includes a metal cladding part 10 and a forging part 11, and the metal cladding part 10 and the forging part 11 are respectively fixed on the numerical control slide rail superior.

[0051] The forging part 11 includes an air hammer 2 and a forging head 3 , and the forging head 3 is installed at the end of the air hammer 2 .

[0052] The metal cladding component 10 includes a heating wire feeding device 4 and a heating wire feeding device bracket 5 , and the heating wire feeding device bracket 5 is fixed on the numerical control slide rail 1 .

[0053] Hea...

Embodiment 2

[0063] On the basis of Embodiment 1, the guide sleeve 8 is made of high temperature resistant ceramic material.

[0064] The additive manufacturing method for titanium alloy structural parts applicable to the additive manufacturing equipment for titanium alloy structural parts of Example 2 includes the following steps:

[0065] 1) According to the shape of the formed parts, the parts are layered, the trajectory is designed, and the control program is formed;

[0066] 2) The additive manufacturing equipment is placed in a vacuum environment, the induction heating coil 9 is turned on, and the titanium alloy wire is heated to a cladding state of 1800° C. to 2000° C., and then the wire feed roller 7 drives the titanium alloy wire to move and cladding. onto the preform;

[0067] 3) Turn on the air hammer 2 and drive the forging head 3 to forge, deform and connect the just-coated titanium alloy material to realize the connection between the titanium alloy material and the preform; ...

Embodiment 3

[0072] On the basis of Embodiment 1, the guide sleeve 8 is made of high temperature resistant ceramic material.

[0073] The additive manufacturing method for titanium alloy structural parts applicable to the additive manufacturing equipment for titanium alloy structural parts of Example 2 includes the following steps:

[0074] 1) According to the shape of the formed parts, the parts are layered, the trajectory is designed, and the control program is formed;

[0075] 2) The additive manufacturing equipment is placed in a vacuum environment, and when the part within the boundary of the two-dimensional pattern after the part is layered is formed, the induction heating coil 9 is turned on, and the titanium alloy wire is heated to 800 ℃ ~ 1000 ℃ plastic state, and then the wire feed roller 7 drives the titanium alloy wire to move, and lays it on the preform;

[0076] 3) At the same time, the air hammer 2 drives the forging head 3 to forge, deform and connect the just-coated titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com