Apparatus for cracking papermaking waste residues

A cracking device and papermaking waste residue technology, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of lack of ash discharge system, continuous and stable operation of production, etc., and achieve the advantages of easy manufacturing, shortening heating time, and ensuring stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

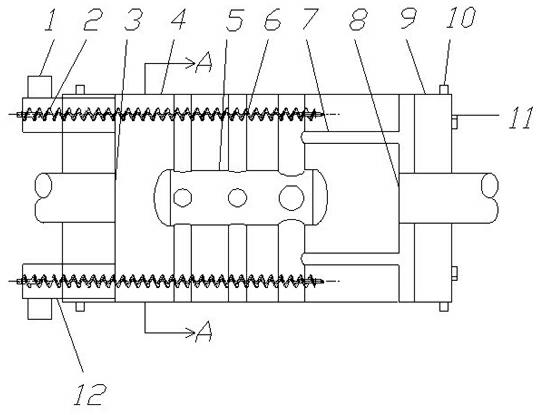

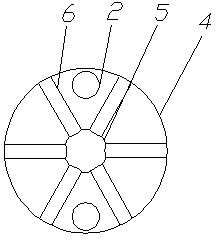

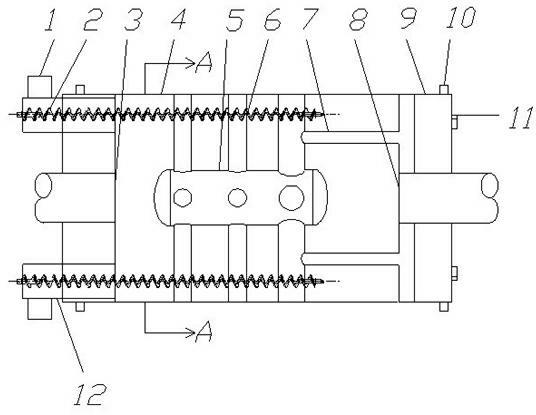

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] As shown in the figure, a papermaking waste slag pyrolysis device includes an outer cylinder 4, which is a cylindrical structure, and the center of both ends of the outer cylinder 4 is respectively provided with a feed inlet 8 and a pyrolysis gas outlet 3. The feed port 8 is connected with the feed device, and the cracked gas outlet 3 is connected with the cooling device. In order to enhance the heat insulation performance of the outer cylinder body 4 , a heat insulation layer 9 is fixedly arranged on both end surfaces of the outer cylinder body 4 , and heat insulation sand is filled in the heat insulation layer 9 . On the outside of the heat insulation layer 9, a support wheel 10 for supporting the entire outer cylinder 4 is arranged, and on the heat insulation layer 9 at one end of the feed inlet 8, the transmission gear 11 connected by the external drive devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com