Anti-sintering long-service-life gradient column layer composite structure thermal barrier coating and preparation method thereof

A technology of thermal barrier coating and composite structure, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of coating cracking and peeling, affecting service life, increasing strain energy release rate, etc. Sharp decline, long-life co-design, reduced driving force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

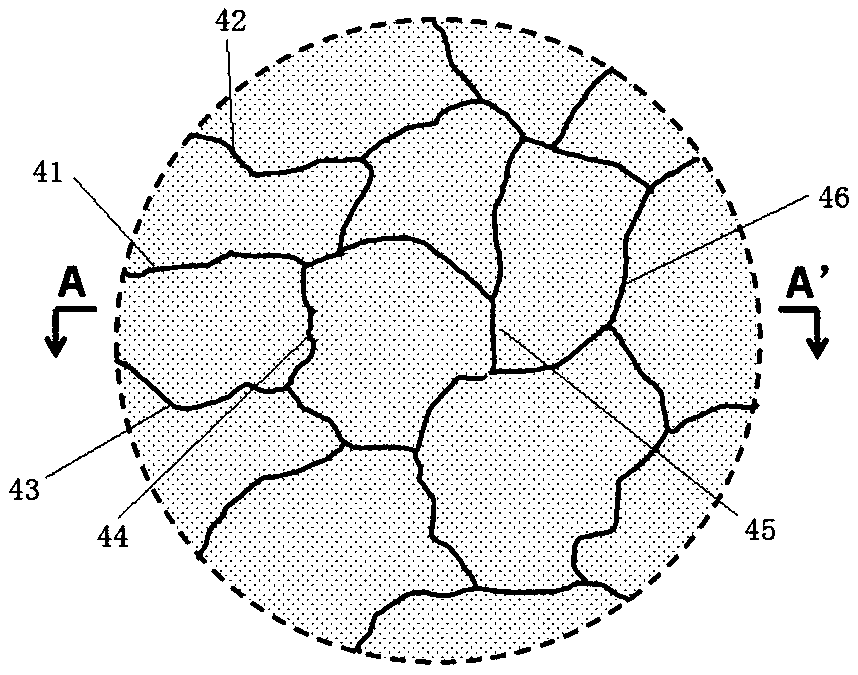

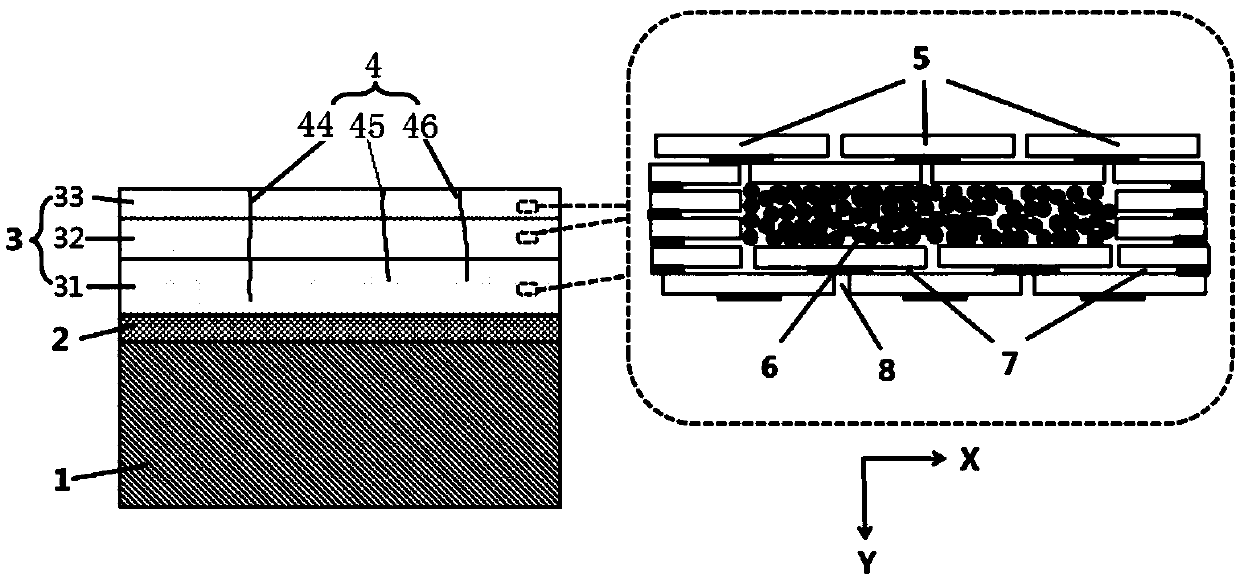

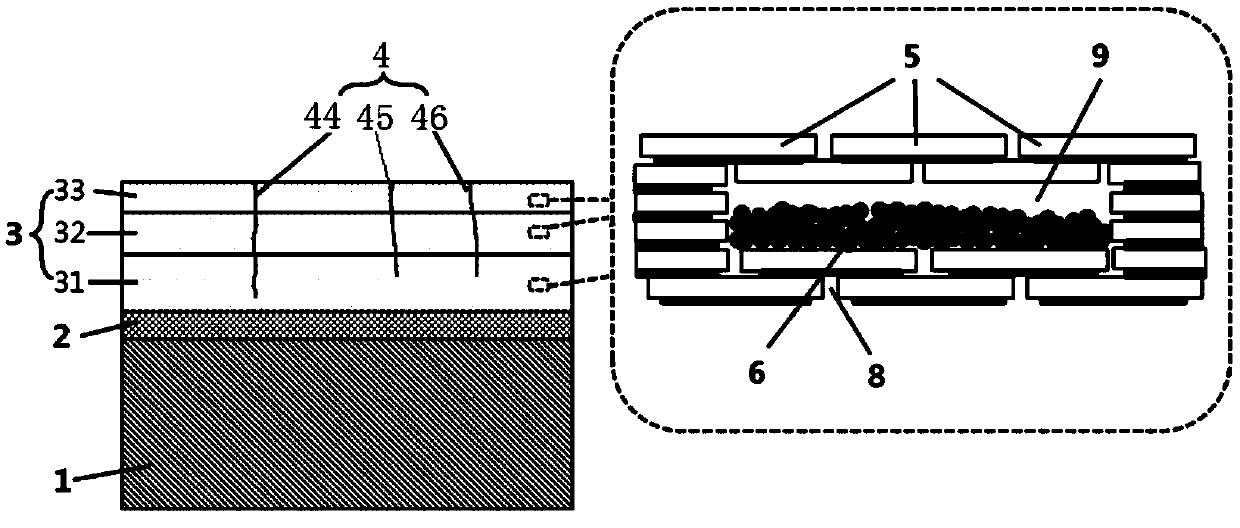

[0035] see figure 1 and figure 2 As shown, the preparation method of the present invention is described by taking the ceramic heat insulating layer 3 as an example with three sublayers.

[0036] The invention provides a method for preparing a thermal barrier coating with an anti-sintering long-life gradient column layer composite structure, which comprises the following steps:

[0037] In step 1, a metal bonding layer 2 with a thickness of 100 μm is prepared on the surface of a cylindrical superalloy substrate 1 by a low-pressure plasma spraying process. The material of the metal bonding layer 2 is spherical NiCoCrAlTaY powder with a particle size of 10 μm-40 μm.

[0038] Step 2, preparing the first sub-layer 31 of the ceramic heat-insulating layer 3 on the metal bonding layer 2 by the method of mixed spraying, which specifically includes the following steps:

[0039] Step 2.1, using yttria-stabilized zirconia smelting and crushing powder with a particle size of 20 μm to 5...

Embodiment 2

[0058] The difference between this embodiment and embodiment 1 is that in step 1, the thermal spraying method used is vacuum plasma spraying, supersonic flame spraying or cold spraying.

Embodiment 3

[0060] The difference between this embodiment and embodiment 1 is that in step 1, the thickness of the metal bonding layer 2 is 125 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com