Solid waste unfired ceramsite, preparation method thereof, foam concrete and light partition board

A technology of foam concrete and ceramsite, which is applied in the field of lightweight partition boards and foam concrete, can solve the problems of low strength, high pollution discharge, high energy consumption of high-temperature roasting, etc., and achieve the goal of avoiding waste, high compressive strength and low density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

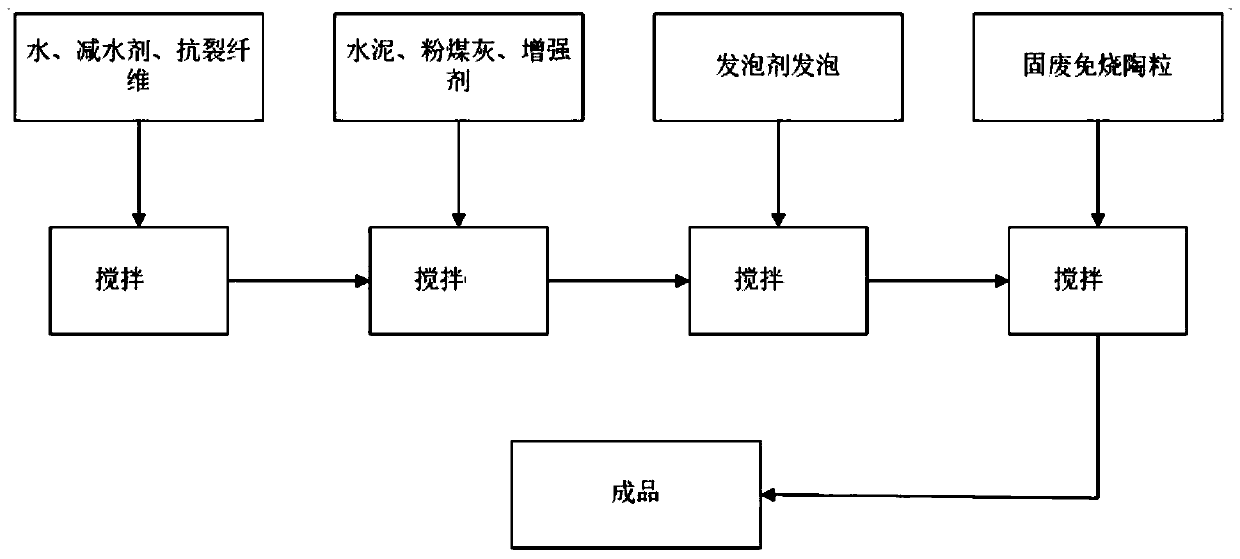

Method used

Image

Examples

preparation example Construction

[0040] The present invention also provides a preparation method of the solid waste non-fired ceramsite described in the above technical scheme, which includes the following steps:

[0041] The first mixing of steel slag powder, slag powder, cement and density regulator to obtain a solid mixture;

[0042] Perform a second mixing of the activator and part of the water to obtain the activator solution; the amount of the part of the water is 2 / 9 to 3 / 9 of the mass of the total water;

[0043] Performing a third mixing of the solid mixture and the activator solution to obtain the material to be granulated;

[0044] The remaining water is sprayed into the material to be granulated for granulation to obtain solid waste non-burning ceramsite.

[0045] In the present invention, steel slag powder, slag powder, cement and density regulator are first mixed to obtain a solid mixture. The present invention has no special requirements for the first mixing, as long as the mixing is uniform. In the em...

Embodiment 1

[0088] In terms of parts by mass, 50 parts of steel slag powder, 15 parts of slag powder, 5 parts of cement and 3 parts of HN40 soda lime borosilicate glass beads are mixed for the first time, and the stirring speed of the first mixing is 45r / min Stir for 30s at a speed of, to obtain a solid mixture, in which the bulk density of the soda lime borosilicate glass beads is 0.22g / cm 3 3 parts of water glass and 6 parts of water for the second mixing, the stirring speed of the second mixing is 35r / min, the time is 60s, to obtain the activator solution; the solid mixture and the activator solution are subjected to the third mixing, The stirring speed of the third mixing is 30r / min, the time is 60s, and the material to be granulated is obtained; during the granulation process, the remaining 18 parts of water are sprayed into the material to be granulated to obtain the granular ceramsite. Cured for 10 days in an environment of 20°C and 60% relative humidity to obtain solid waste non-sin...

Embodiment 2

[0092] In parts by mass, 55 parts of steel slag powder, 10 parts of slag powder, 5 parts of cement and 4 parts of HN40 soda-lime borosilicate glass beads are mixed for the first time, and the stirring speed of the first mixing is 45r / min , The time is 30s, and the solid mixture is obtained, in which the bulk density of soda lime borosilicate glass beads is 0.21g / cm 3 3 parts of water glass and 6 parts of water for the second mixing, the second mixing stirring speed is 35r / min, time is 60s, to obtain the activator solution; after the solid mixture and the activator solution are subjected to the third mixing , The stirring speed of the third mixing is 30r / min and the time is 60s to obtain the material to be granulated; in the granulation process, the remaining 17 parts of water are sprayed into the material to be granulated to obtain granular ceramsite, and the granular ceramsite is Cured for 12 days in an environment with a temperature of 20°C and a relative humidity of 60% to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com