Coating improving oxidation resistance of TiAl alloy and preparing method of coating

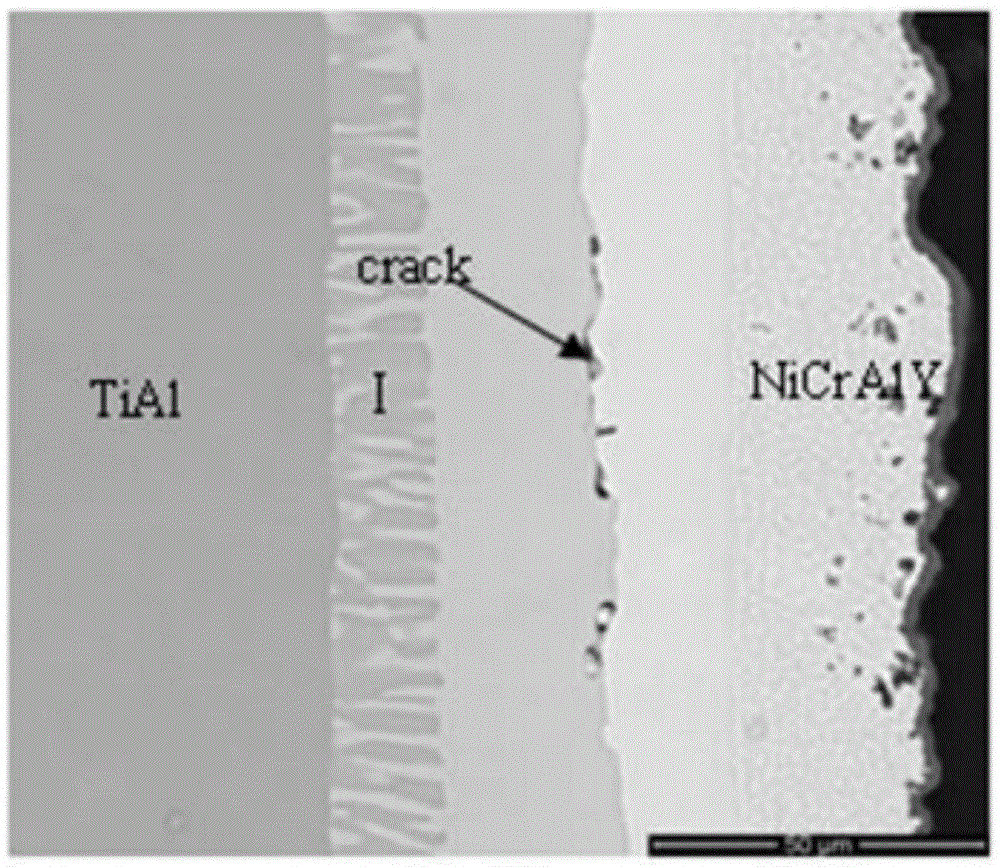

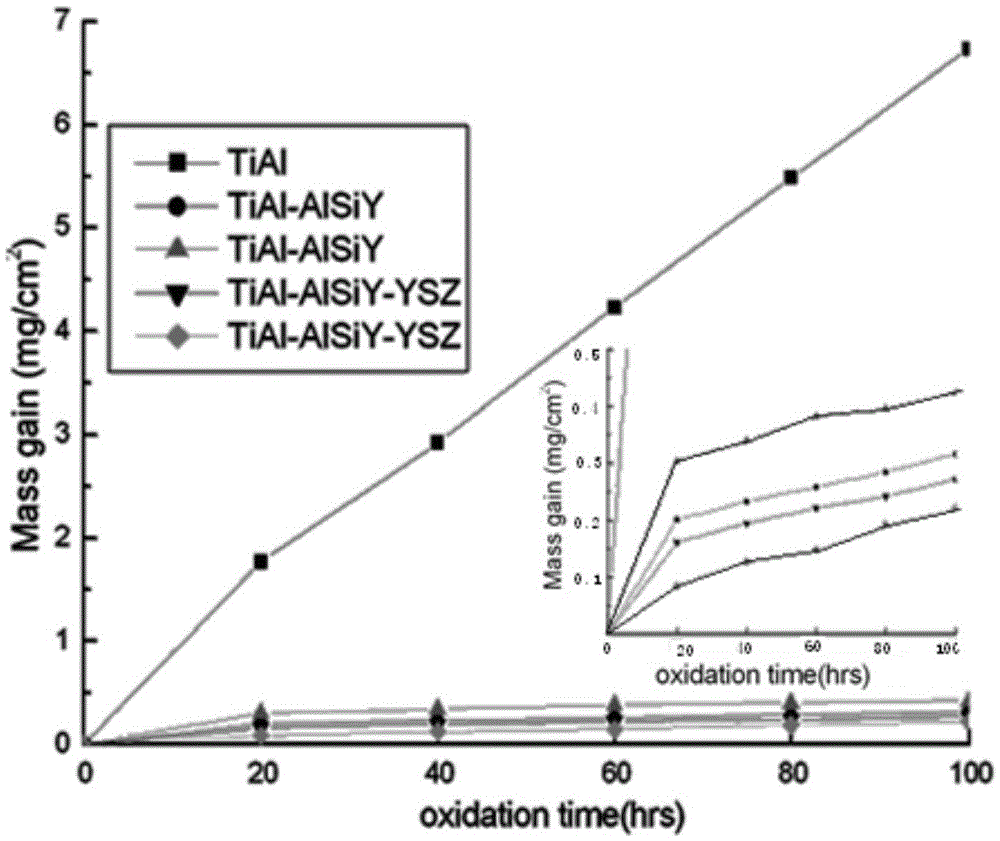

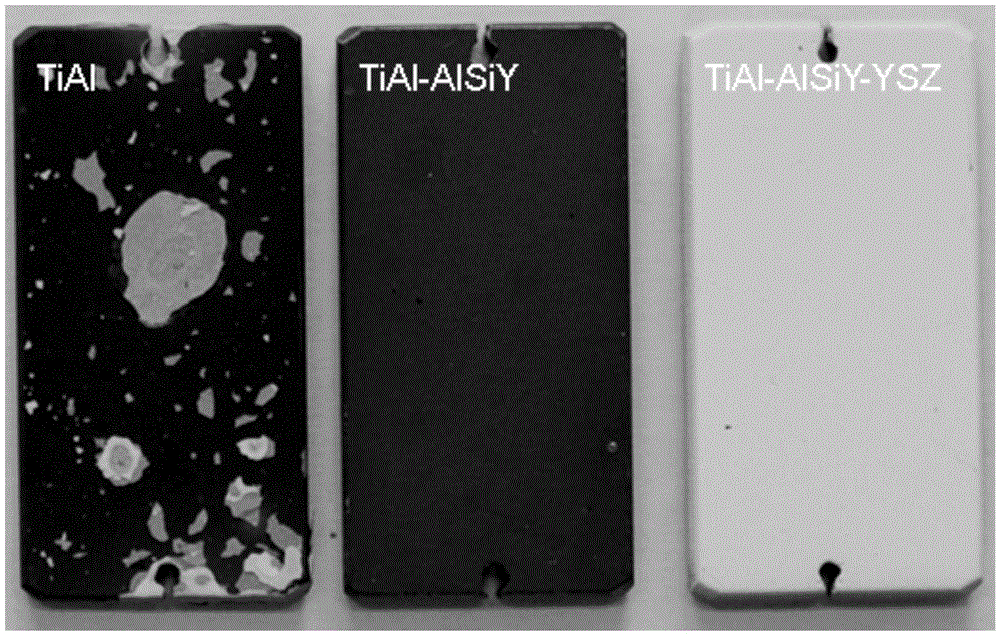

A coating and alloy technology is applied in the field of coatings and their preparation for improving the oxidation resistance of TiAl alloys, which can solve the problems affecting long-term oxidation performance and mechanical properties, poor compatibility of TiAl alloy substrates, and affecting the long-term oxidation resistance of coating systems. performance and other issues, to achieve the effect of improving the YSZ ceramic surface layer structure, improving the resistance to cold and heat cycles, and good interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Prepare an AlSiY coating of about 20 μm on the surface of the TiAl alloy sample substrate by vacuum arc plating, and then perform vacuum diffusion heat treatment at 1010-1080 °C for 2-4 hours to obtain a diffused AlSiY bottom layer with a thickness of 40-60 μm.

[0027] The AlSiY bottom layer is subjected to wet blasting treatment, ultrasonic cleaning, acetone solution immersion, and drying; the wet blasting process parameters are: white corundum sand particle size 180-280 mesh, corundum sand content 20%-35%, wind pressure 0.15MPa~0.25MPa, sand blowing distance is 180mm~350mm.

[0028] The above samples were installed on special fixtures and fastened with superalloy wires.

[0029] Install the sample into the loading chamber, turn on the mechanical pump and Roots pump, and vacuumize until the vacuum degrees of the main vacuum chamber and the loading chamber are lower than 5×10 -2 When Pa, 1Pa, open the gate valve between the two chambers, pass in Ar gas, and perform io...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com