Novel heat barrier coating material

A technology of thermal barrier coating and metal bonding layer, which is applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve the problems of short coating cycle life and serious coating internal stress, and achieve The effects of small thermal gravitation, simple preparation method, and easy-to-obtain equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

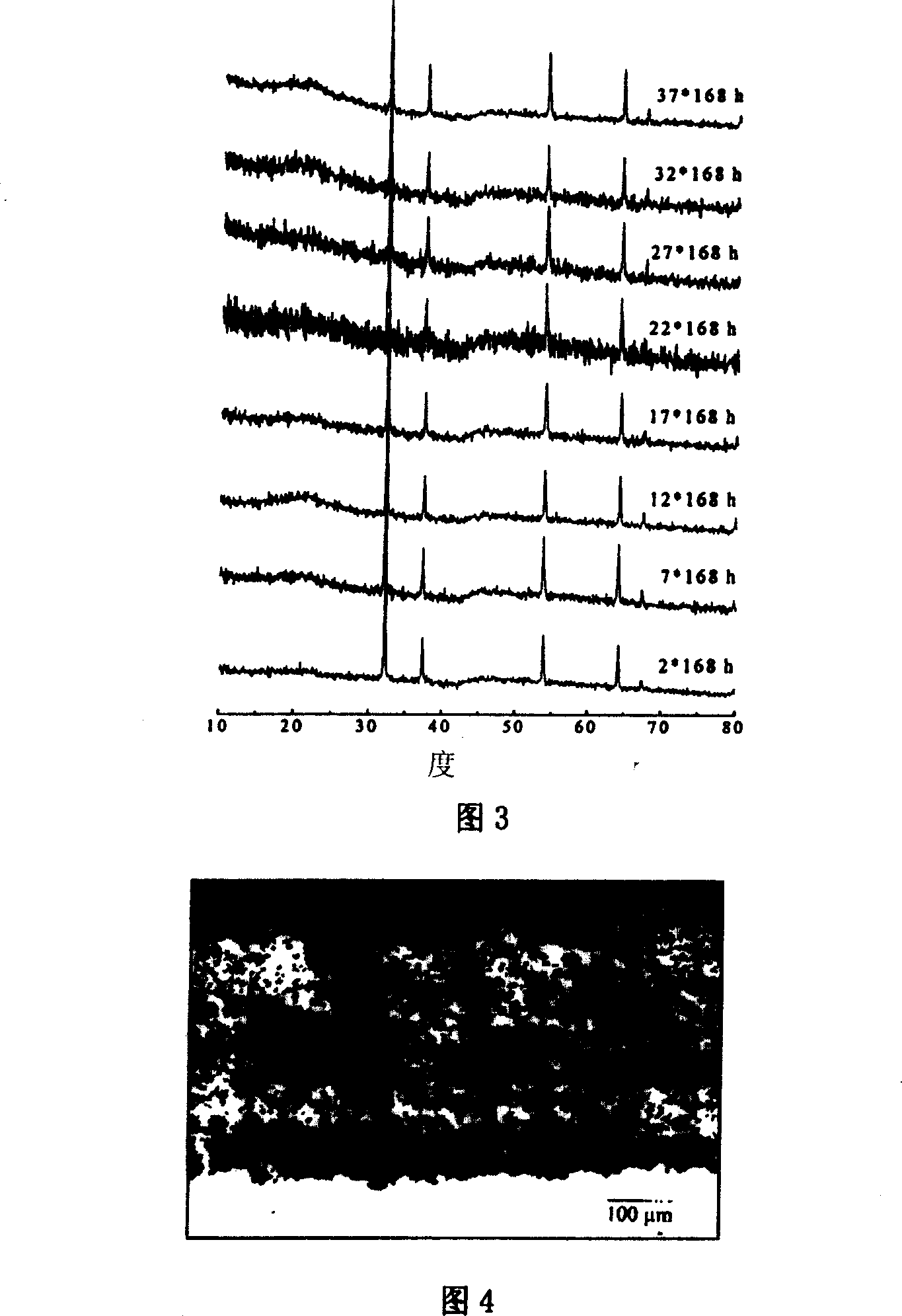

[0015] Embodiment 1: prepare powder sample Nd 2 Ce 2 o 7 (Nd 2 o 3 +2CeO 2 ), the obtained powder sample was spray-dried to make a high-fluidity powder. A NiCrAlY metal bonding layer with a thickness of about 220 μm is deposited on the surface of the nickel-based superalloy by electron beam physical vapor deposition technology, and then a layer of Nd with a thickness of about 300 μm is deposited on the surface of the bonding layer by plasma spray technology. 2 Ce 2 o 7 The ceramic surface layer and the final thermal barrier coating system are shown in Figure 4.

Embodiment 2

[0016] Embodiment 2: Preparation of powder sample Nd 2 (Zr 0.9 Ce 0.1 )2O7, the obtained powder sample was spray-dried to make a high-fluidity powder. A layer of CoCrAlY metal bonding layer with a thickness of about 250 μm is deposited on the surface of the nickel-based superalloy by electron beam physical vapor deposition technology, and then a layer of Nd with a thickness of about 250 μm is deposited on the surface of the bonding layer by plasma spray technology. 2z (Zr 0.9 Ce0.1) 2 o 7 Ceramic finish.

Embodiment 3

[0017] Embodiment 3: Preparation of powder sample Nd 2 (Zr 0.5 Ce 0.5 ) 2 o 7 , the obtained powder sample was spray-dried to make a high-fluidity powder. A layer of FeCrAlY metal bonding layer with a thickness of about 250 μm is deposited on the surface of the cobalt-based superalloy by electron beam physical vapor deposition technology, and then a layer of Nd with a thickness of about 250 μm is deposited on the surface of the bonding layer by plasma spray technology. 2z (Zr 0.9 Ce 0.1 ) 2 o 7 Ceramic finish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com