High-temperature oxidation resistant coating on niobium alloy surface and preparation method of high-temperature oxidation resistant coating

A high-temperature anti-oxidation and niobium alloy technology, which is applied to the high-temperature anti-oxidation coating on the surface of niobium alloy and the field of high-temperature anti-oxidation protection. , to achieve the effect of improving strength and toughness, improving thermal cycle life, improving oxidation resistance and high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the preparation of the coating

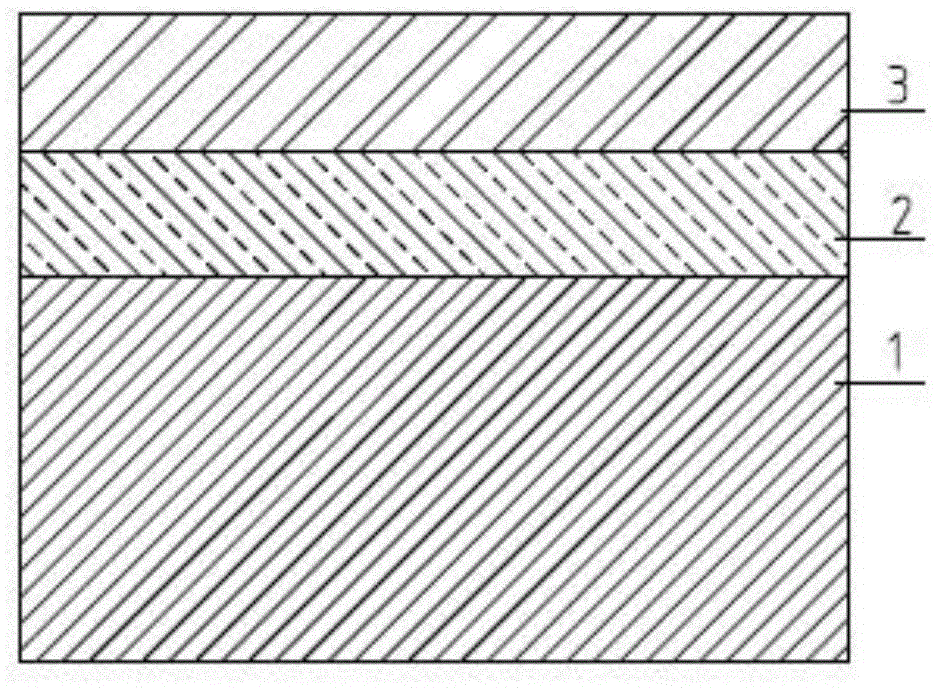

[0037]The niobium alloy surface high temperature anti-oxidation coating of the present invention prepares the bottom Mo 1-x W x (Si 1-y-z al y B z ) 2 Coating, and surface layer Mo 1-x W x (Si 1-y-z al y B z ) 2 -(10-20)%wtHfSi 2 Coating, where:

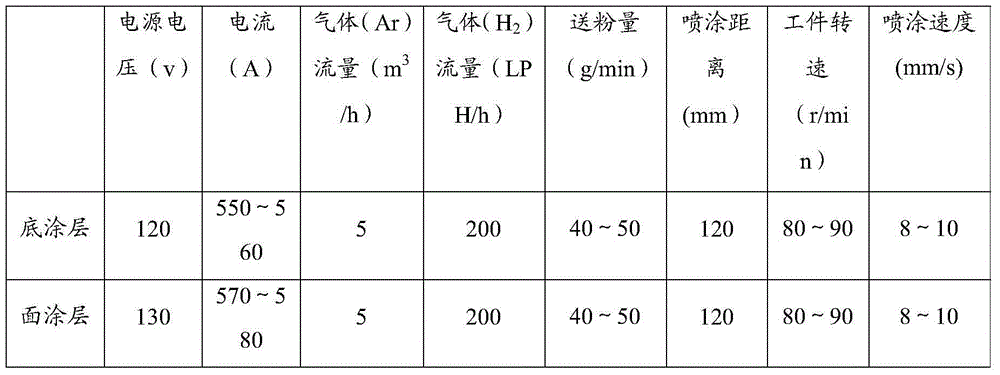

[0038] 1) Bottom Mo 1-x W x (Si 1-y-z al y B z ) 2 The coating is prepared by high-energy plasma spraying process. Mo required 1-x W x (Si 1-y-z al y B z ) 2 The spray powder material is prepared by self-propagating process. Preparation of Mo by self-propagating process 1-x W x (Si 1-y-z al y B z ) 2 Coating powder material method is as follows: Mo powder (Mo content 99.99%, powder particle size 1 ~ 3μm), W powder (W content 99.99%, powder particle size 1 ~ 3μm), Si powder (Si content 99.99%, powder particle size 1 ~ 3μm), Al powder (Al content 99.9%, powder particle size 1-3μm), B powder (B content 99.9%, powder particle size 1-3μm) according to Mo 1-x W x ...

Embodiment

[0048] The present invention provides embodiment 1-5, and the chemical composition of each embodiment is as shown in table 3, adopts following process to prepare:

[0049] 1. Powder preparation

[0050] Mo 1-x W x (Si 1-y-z al y B z ) 2 The chemical composition of the powder materials is shown in Table 3.

[0051] Table 3 Mo 1-x W x (Si 1-y-z al y B z ) 2 Chemical composition of powder materials and corresponding mole percentages

[0052]

[0053] Prepare Mo powder, W powder, Si powder, Al powder, and B powder according to the molar percentages shown in Table 1, and add appropriate amount of alcohol and ZrO 2 Grinding balls, the mass ratio of balls to materials is 3:1, put them into a ball mill tank, and use a high-energy ball mill to mill for 16 hours to fully mix the powder. After the grinding balls are taken out, the powder material is dried and compacted at low temperature to ensure that the compacted density is greater than 40%, and then placed in a self-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com