High-performance Sc-Y-co-doped zirconium oxide thermal protection coating and preparing method thereof

A technology of co-doping and zirconia, applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of short thermal cycle life, low fracture toughness or thermal expansion coefficient, low thermal conductivity, etc., to achieve Low thermal conductivity, reduced thermal conductivity, good phase stability at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation method of scandium yttrium co-doped zirconia powder: ZrOCl with a purity of 99.9% 2 ·8H 2 O, Y (NO 3 ) 3 ·6H 2 O and Sc(NO 3 ) 3 ·6H 2 O as raw material, deionized water as solvent, mole percent, Sc 2 o 3 Content: 4.0~8.0mol.%; Y 2 o 3 Content: 0.5~2.0mol.% and the rest is ZrO 2 , prepared into an aqueous solution with a total concentration of three metal ions of Zr, Sc and Y of 0.4mol / L, stirred by magnetic force for 3 to 6 hours until it became clear and transparent, and then the solution was obtained, and citric acid and polyethylene glycol were added to the solution, respectively, for each The amount of citric acid added in 1 liter of solution was 100 g, and the amount of polyethylene glycol added in every liter of solution was 10 g; the sol was prepared by magnetic stirring until transparent. The sol is then spray-dried at 350°C to make spherical powder, and finally the spherical powder between 180 mesh and 500 mesh is screened to make ScYSZ ...

Embodiment 1

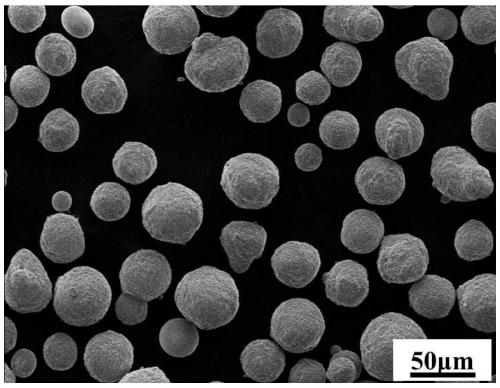

[0044] In terms of mole percentage, take 7.0mol% Sc 2 o 3 -0.5mol% Y 2 o 3 -ZrO 2 Ingredient powders are raw materials (such as figure 1 As shown), the supersonic plasma spraying technology was used to prepare the coating on the substrate preheated to 100°C. The spraying parameters were: current 450A, voltage 160V, argon flow rate 70slpm, hydrogen flow rate 15slpm, spraying distance 100mm , The amount of powder feeding is 30~40g / min, and the moving speed of the spray gun is 600mm / s.

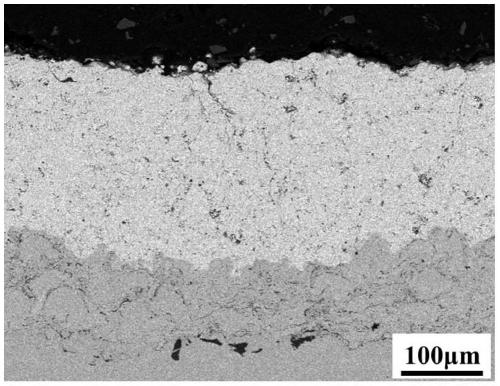

[0045] The cross-sectional morphology of the prepared thermal protection coating is as follows: figure 2 As shown, the scandium-yttrium co-doped zirconia coating has a thickness of 180-220 μm, a porosity of 9%, and a fracture toughness of 2.5 MPa m 1 / 2 .

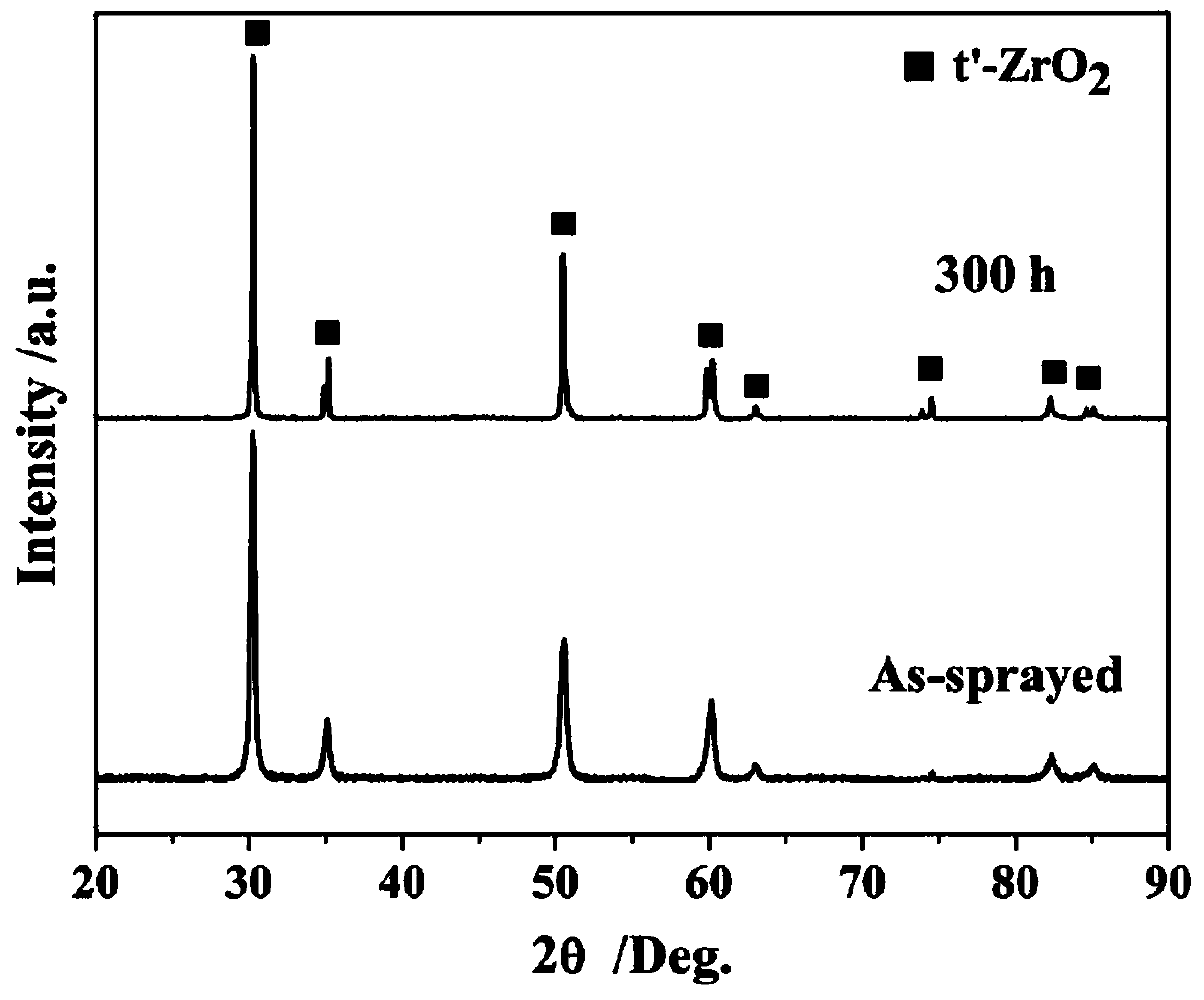

[0046] Put the matrix-free coating into a resistance furnace, and after heat treatment at 1300°C for 300 hours, the scandium-yttrium co-doped zirconia coating presents a single tetragonal phase structure (such as image 3 shown).

[0...

Embodiment 2

[0050] In terms of mole percentage, take 7.0mol% Sc 2 o 3 -0.5mol% Y 2 o 3 -ZrO 2 The component powder is used as the raw material, and the supersonic plasma spraying technology is used to prepare the coating on the substrate preheated to 200°C. The spraying parameters are: current 400A, voltage 130V, argon flow rate 65 slpm, hydrogen flow rate 12 slpm, spraying distance It is 110mm, the powder feeding amount is 30g / min, and the moving speed of the spray gun is 700mm / s.

[0051] The prepared thermal protective coating has a thickness of 100-150 μm, a porosity of 14%, and a fracture toughness of 2.2 MPa·m 1 / 2 .

[0052] The matrix-free coating was placed in a resistance furnace, and after heat treatment at 1300°C for 300 hours, the scandium-yttrium co-doped zirconia coating presented a single tetragonal phase structure.

[0053] The thermal conductivity of the coating from room temperature to 1100° C. is measured by laser flash method to be 0.8-0.95 W / m·K.

[0054] The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com