Protective coating for molten sediment on surface of thermal barrier coating and preparation method thereof

A technology of protective coating and thermal barrier coating, which is applied in coating, fusion spraying, metal material coating process, etc., can solve the heat insulation effect and mechanical property attenuation of the coating, increase the internal thermal stress of the coating, 8YSZ Accelerated sintering and other issues to achieve the effect of meeting protection requirements, increasing melting point, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

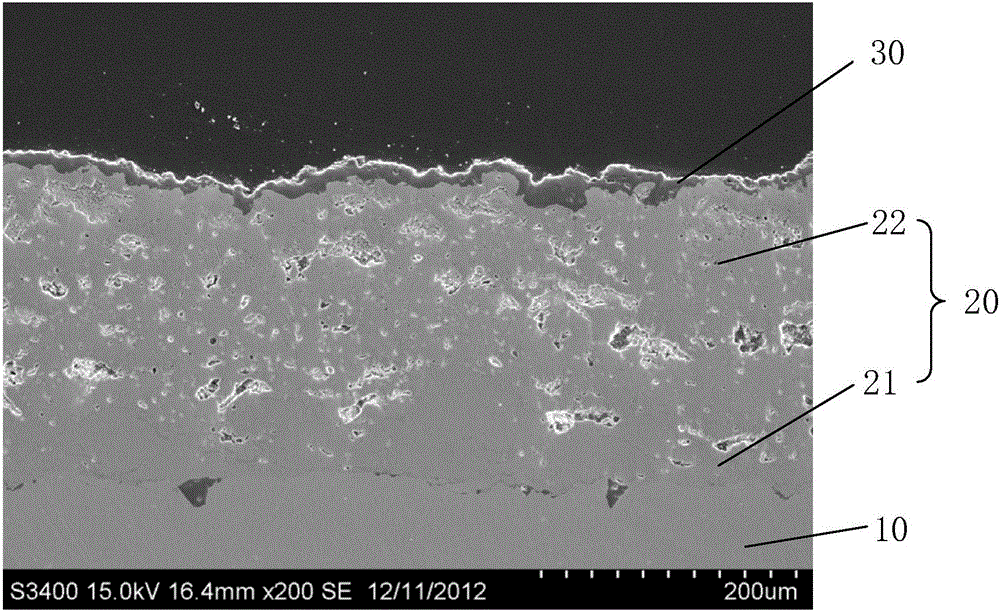

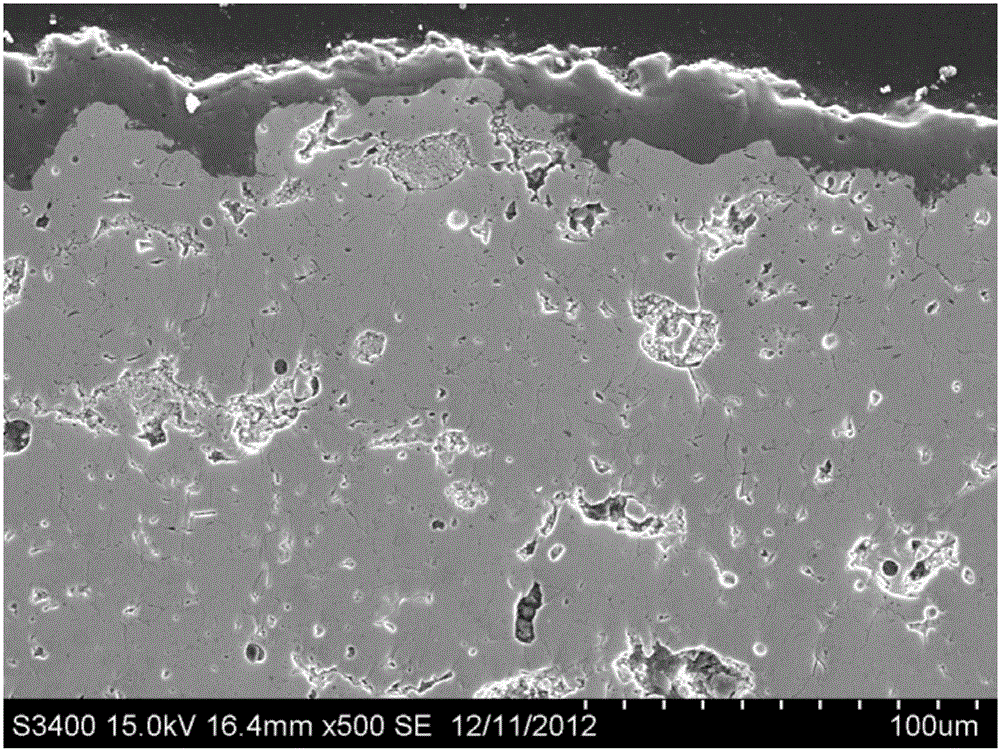

[0056] The preparation method of the fused deposit protective coating on the surface of the thermal barrier coating of the present invention, wherein the thermal barrier coating is attached to the surface of the superalloy substrate, and the thermal barrier coating includes at least one bonding layer and at least one ceramic layer, The bonding layer is coated on the surface of the superalloy substrate, the ceramic layer is coated on the surface of the bonding layer, and the ceramic layer in contact with the bonding layer is a partially stabilized zirconia material based on yttria layer, the surface of the ceramic layer is also coated with a protective coating, and the preparation of the protective coating comprises the following steps:

[0057] Step S100, alumina-based spray powder drying treatment, the alumina-based spray powder with a particle size range of 45 μm-75 μm, 15 μm-45 μm or 5 μm-25 μm is dried in an oven at a low temperature, and the alumina-based spray powder shou...

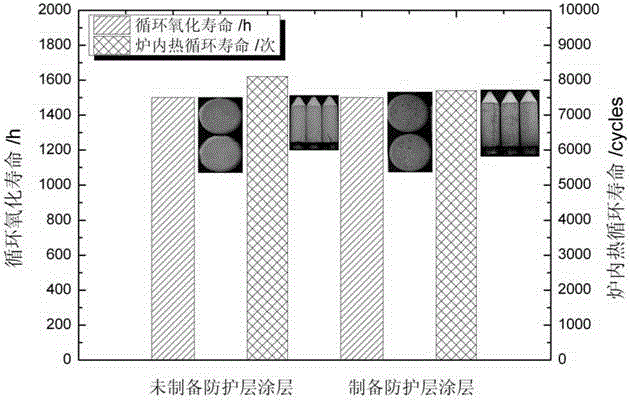

Embodiment 1

[0077] Protective coatings were prepared on conventional atmospheric plasma sprayed thermal barrier coatings.

[0078] Step S100: drying the smelted and crushed alumina-based powder with a purity of 99.5% and a particle size range of 5-25 μm in an oven at 100° C. for 2 hours, and the sprayed powder contains 5 mol% Gd 2 o 3 (gadolinium oxide);

[0079] Step S200: The workpiece of a certain type of gas turbine DZ40M alloy blade surface is supersonic flame sprayed to prepare a NiCrAlY metal bonding layer, and the conventional atmospheric plasma spray is used to prepare a nano-8YSZ thermal barrier coating into the rotary tooling, and the supersonic plasma spraying equipment is turned on, and Adjust the device parameters as follows:

[0080] Voltage: 150V;

[0081] Current: 420A;

[0082] Main gas (argon): 90L / min;

[0083] Secondary gas (hydrogen): 9L / min;

[0084] Carrier gas flow: 6.5L / min;

[0085] Powder feeding volume: 10g / min;

[0086] Spray gun swing rate: 500mm / s. ...

Embodiment 2

[0092] Protective coatings were prepared on conventional atmospheric plasma sprayed thermal barrier coatings.

[0093] Step S100: Drying the smelted and crushed alumina-based powder with a purity of 99.9% and a particle size range of 45-75 μm in an oven at 100° C. for 2 hours, and the sprayed powder contains 1.5 mol% Y 2 o 3 (gadolinium oxide);

[0094] Step S200: the surface of the K403 alloy sample with a size of φ30×3mm was prepared by supersonic flame spraying to prepare a NiCoCrAlY metal bonding layer (thickness 0.1mm), and conventional atmospheric plasma spraying was used to prepare a sample of a nanometer 8YSZ thermal barrier coating (thickness 0.3mm), And turn on the supersonic plasma spraying equipment, and adjust the equipment parameters as follows:

[0095] Voltage: 155V;

[0096] Current: 400A;

[0097] Main gas (argon): 80L / min;

[0098] Secondary gas (hydrogen): 9.5L / min;

[0099] Carrier gas flow: 7.5L / min;

[0100] Powder feeding volume: 20g / min;

[010...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com