Laser photoacoustic compound detection method for elements and defects and system thereof

A composite detection and laser technology, applied in the direction of optical testing flaws/defects, measuring devices, thermal excitation analysis, etc., can solve problems such as long analysis time, high detection cost, and inability to detect element distribution, so as to reduce costs and improve detection efficiency , Improve the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

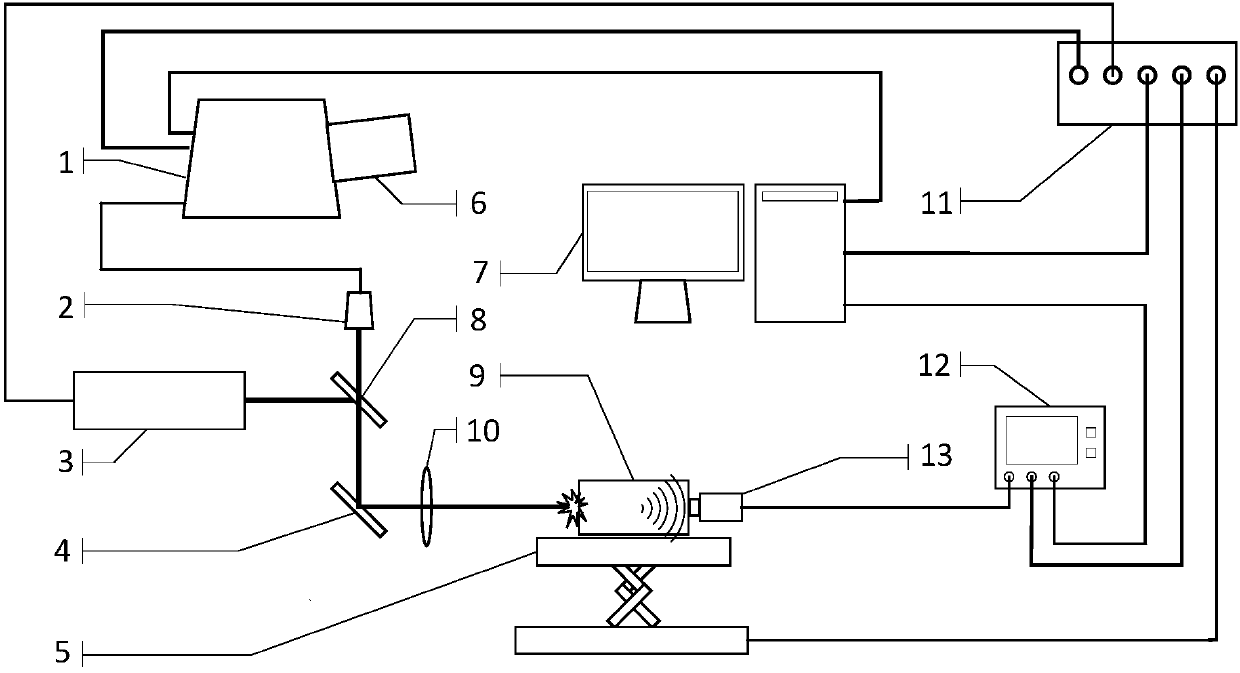

[0043] Now take the detection of steel welds as an example to illustrate the use process of the laser photoacoustic composite detection system of the present invention. The specific operation steps are as follows:

[0044] (1) The pulsed laser 3 is a Nd:YAG Q-switched laser with an emission wavelength of 532 nm, a pulse duration of 6 ns, and an adjusted pulse energy of about 40 mJ. The water immersion ultrasonic probe 13 is focused on a non-focal plane with a frequency of 20 MHz. The model of the digital delay generator 11 is DG535, and its delay resolution is 5Ps.

[0045] (2) Place the welding sample on the 3D displacement platform 5 . The scanning surface is facing the laser light outlet, adjust the position of the 3D translation platform 5 in the X-axis direction and the position of the focusing objective lens 10, so that the pulsed laser beam is focused at the defocus amount -1mm position; adjust the position of the 3D translation platform 5 on the Y-Z axis To the initi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com