Vacuum multi sphere ion film coating machine intelligent integrated controller

A multi-arc ion, coating machine technology, applied in the direction of computer control, general control system, control/adjustment system, etc., can solve the problems of coarse film structure, deterioration of performance, decrease of deposition rate, etc., to achieve process stability and reduce labor. Strength, effect of ensuring coating quality and equipment safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

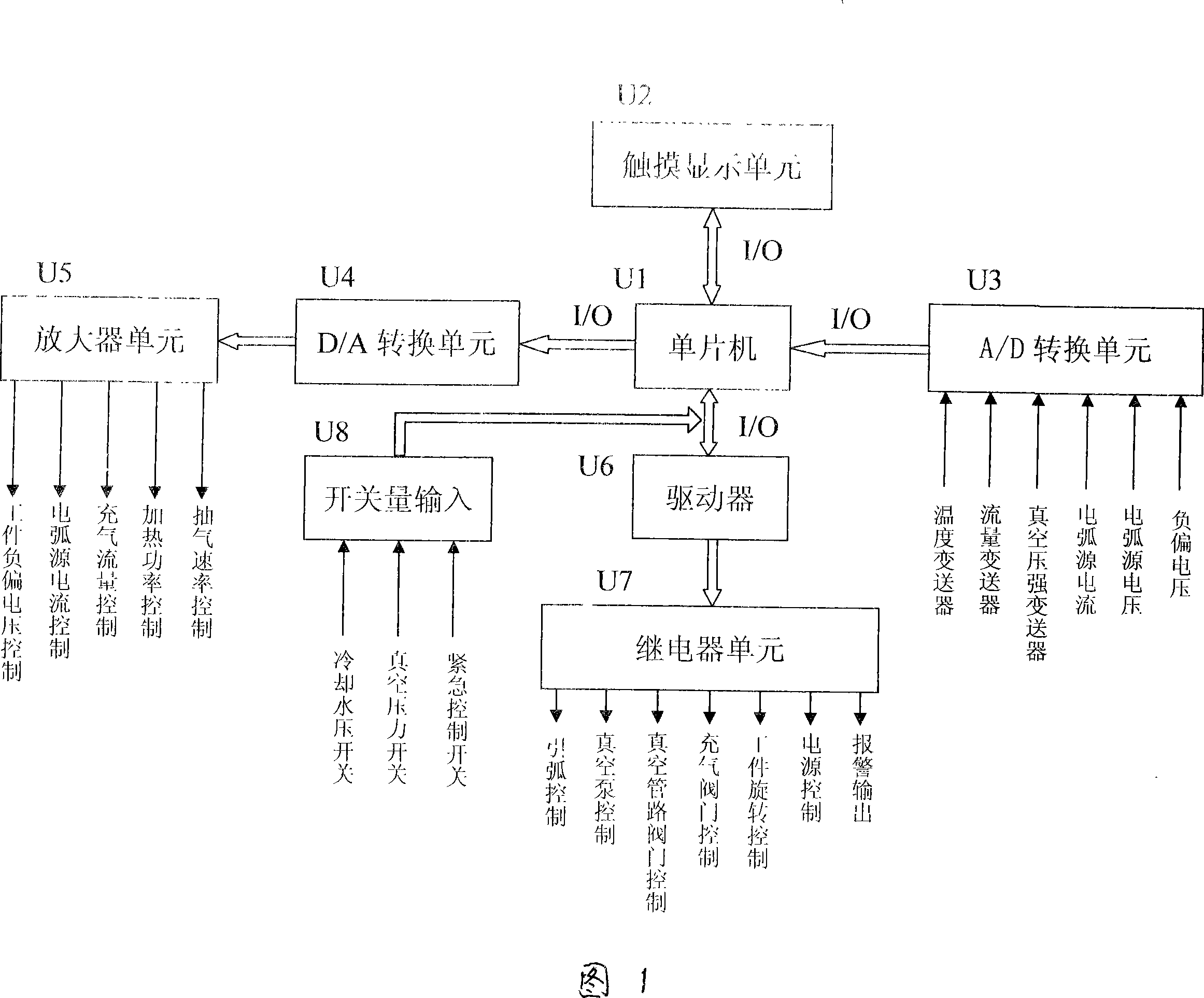

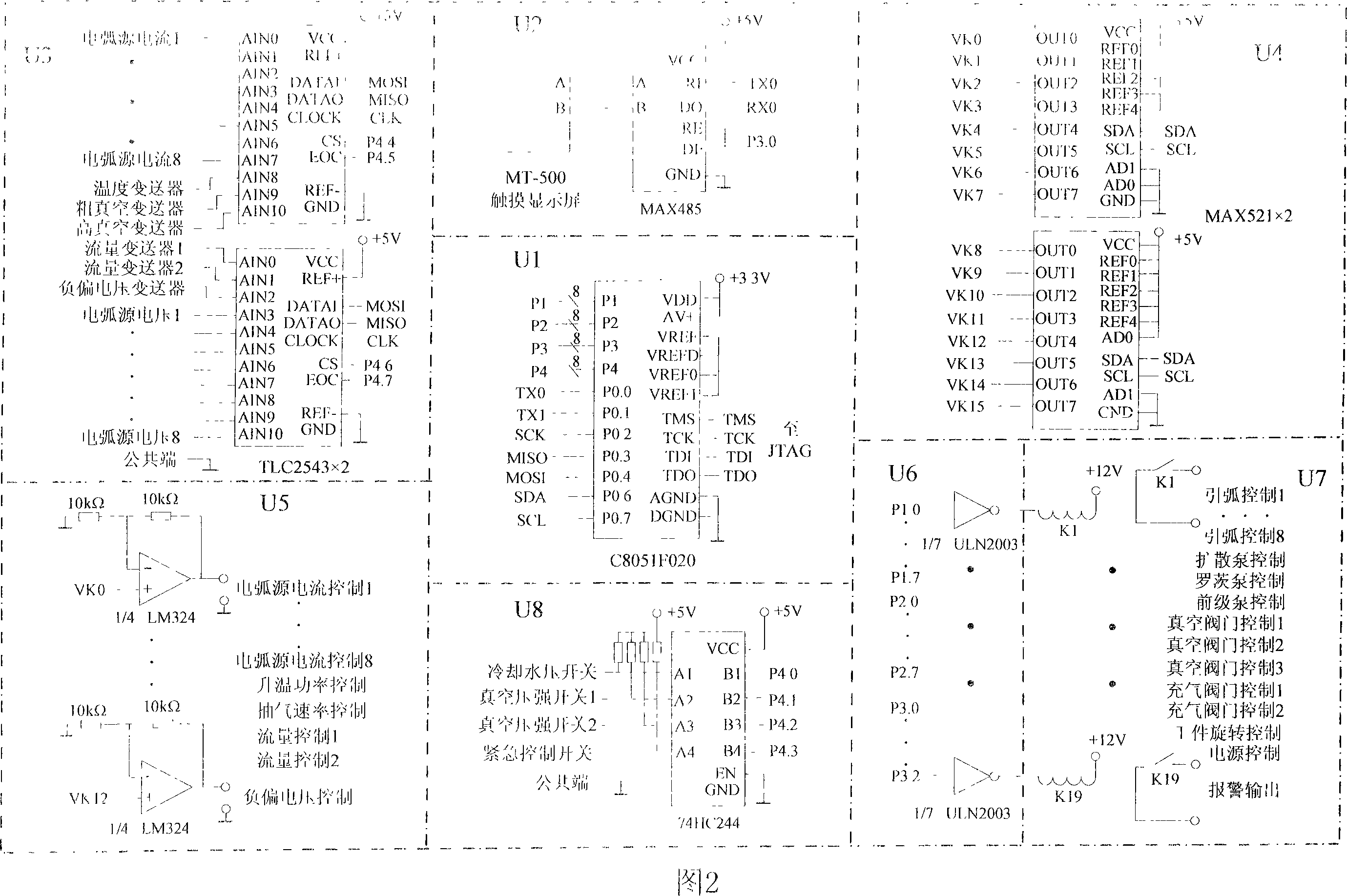

[0013] In the schematic diagram of the typical embodiment shown in Figure 2, the single-chip microcomputer U1 selects the C8051F020 mixed-signal microcontroller with a high-speed 8051 microcontroller as the core, and integrates 64KB of ISP Flash ROM and 4352 bytes of SRAM on the chip, with On-chip JTAG debugging, on-chip programmable oscillator, on-chip power-on reset function, 64-bit I / O ports, one I 2 C interface, one SPI interface and two UART serial interfaces; the touch display unit U2 uses MT500 touch screen, and the touch screen communicates with the microcontroller U1 through the RS-485 bus; the A / D conversion unit U3 consists of two 12-bit resolution, multi-analog There are 22 analog input channels in total. DATAI, DATAO, and CLOCK of TLC2543 are connected in parallel to the SPI serial port of single-chip U1, and each CS and EOC signal are respectively connected to the I / O port of single-chip U1. After connecting, the 4~20mA current signal sent by different transmitte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com