Metal plate coils centralizing apparatus

A centering device and metal plate technology, applied in the direction of winding strips, transportation and packaging, thin material processing, etc., can solve the problems of low work efficiency, high labor intensity, unmatched and other problems, and achieve intelligent integrated control, Easy to operate, accurate centering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

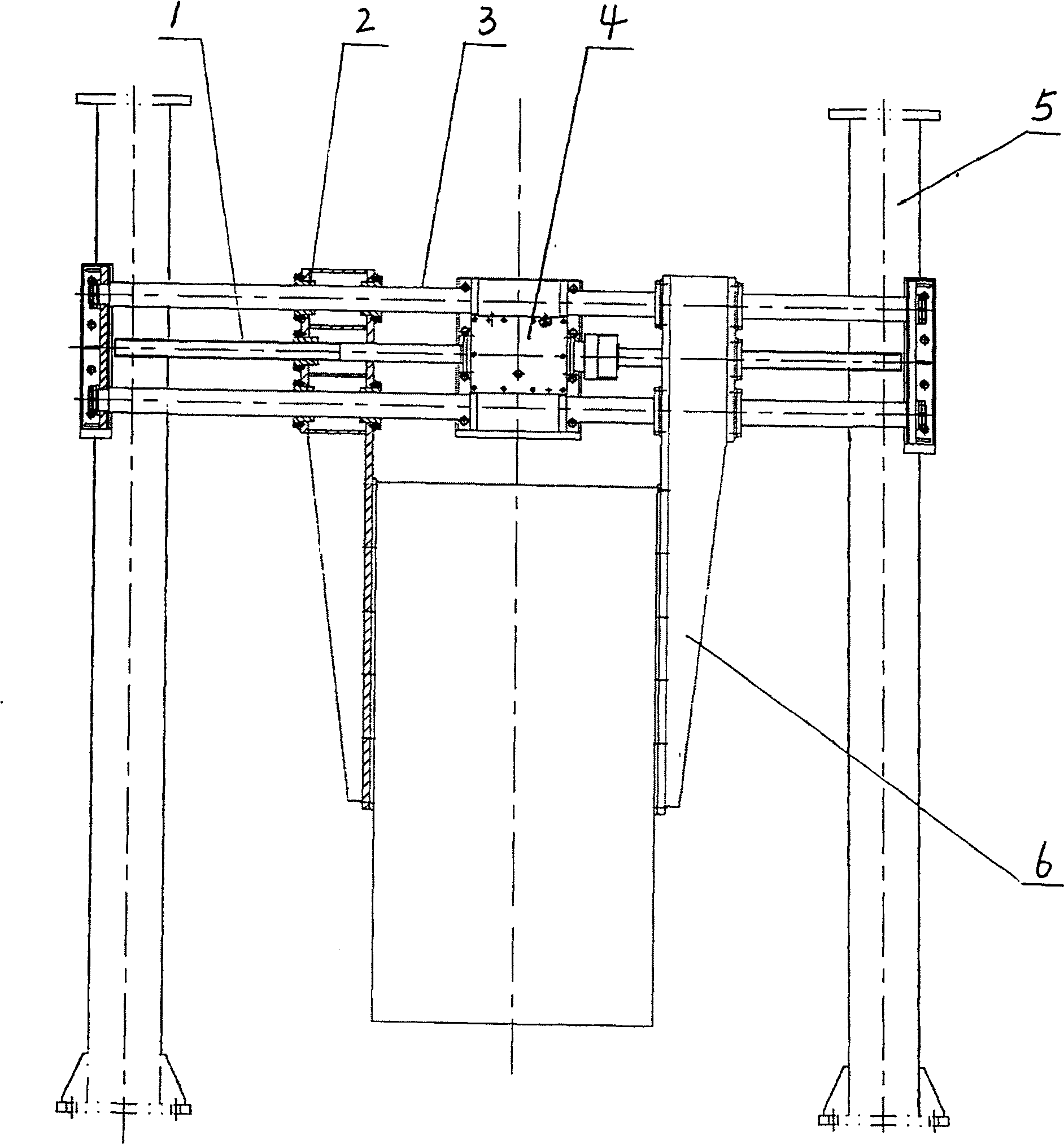

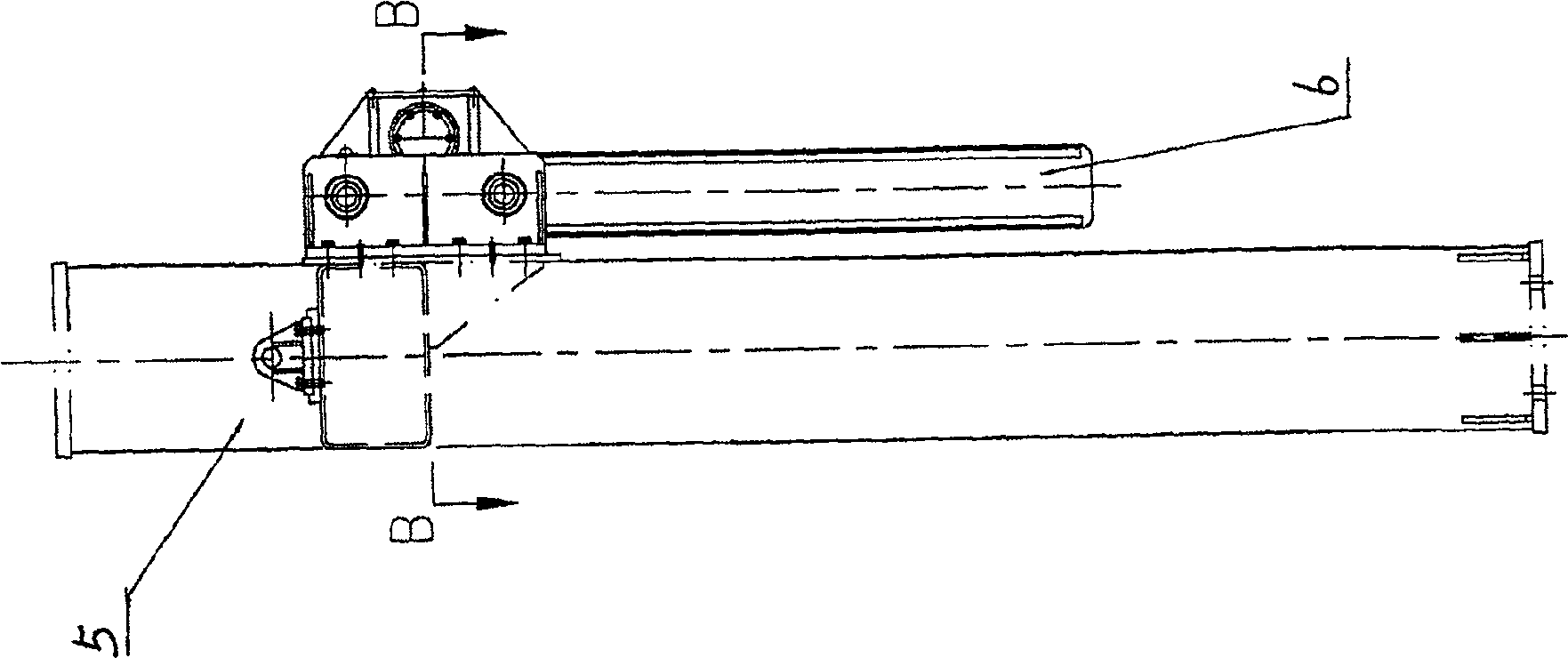

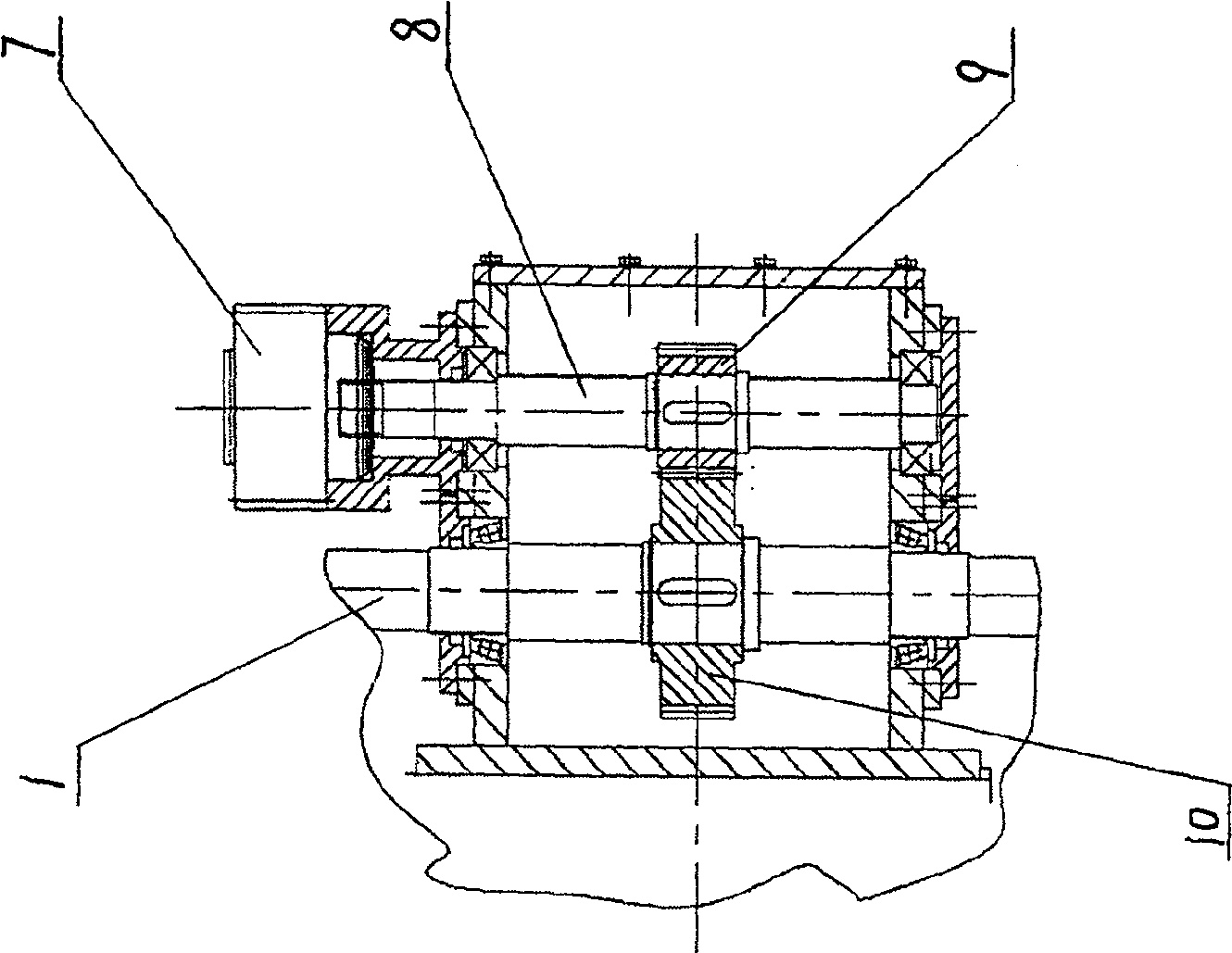

[0010] From figure 1 The structural representation of the metal sheet coil centering device of the present invention shown and figure 2 , image 3 It can be seen from the left side view and BB sectional view that the present invention is composed of frame 5, guide column 3, lead screw 1, transmission box 4, centering arm 6, etc., transmission box 4 is composed of driving gear shaft 8, driving gear 9 , lead screw gear 10 and other components.

[0011] From Figure 4 As can be seen from the schematic diagram of the layout of the metal plate coil centering device of the present invention in the production line, the frame 5 is arranged on the front part of the uncoiler 12, the upper part of the saddle 13 where the metal plate coil 14 is placed, and is connected with the foundation and the leveler. 11 (or other single machines) are rigidly connected into one. Lead screw 1 and two guide posts 3 are set on the frame 5, two centering arms 6 are installed on the guide post 3 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com