Multilayer laminating machine

A laminating machine and laminating technology, applied in the direction of removing smoke and dust, chemical instruments and methods, cleaning methods and utensils, etc. problems, to ensure cleanliness, improve cleanliness, and ensure the effect of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

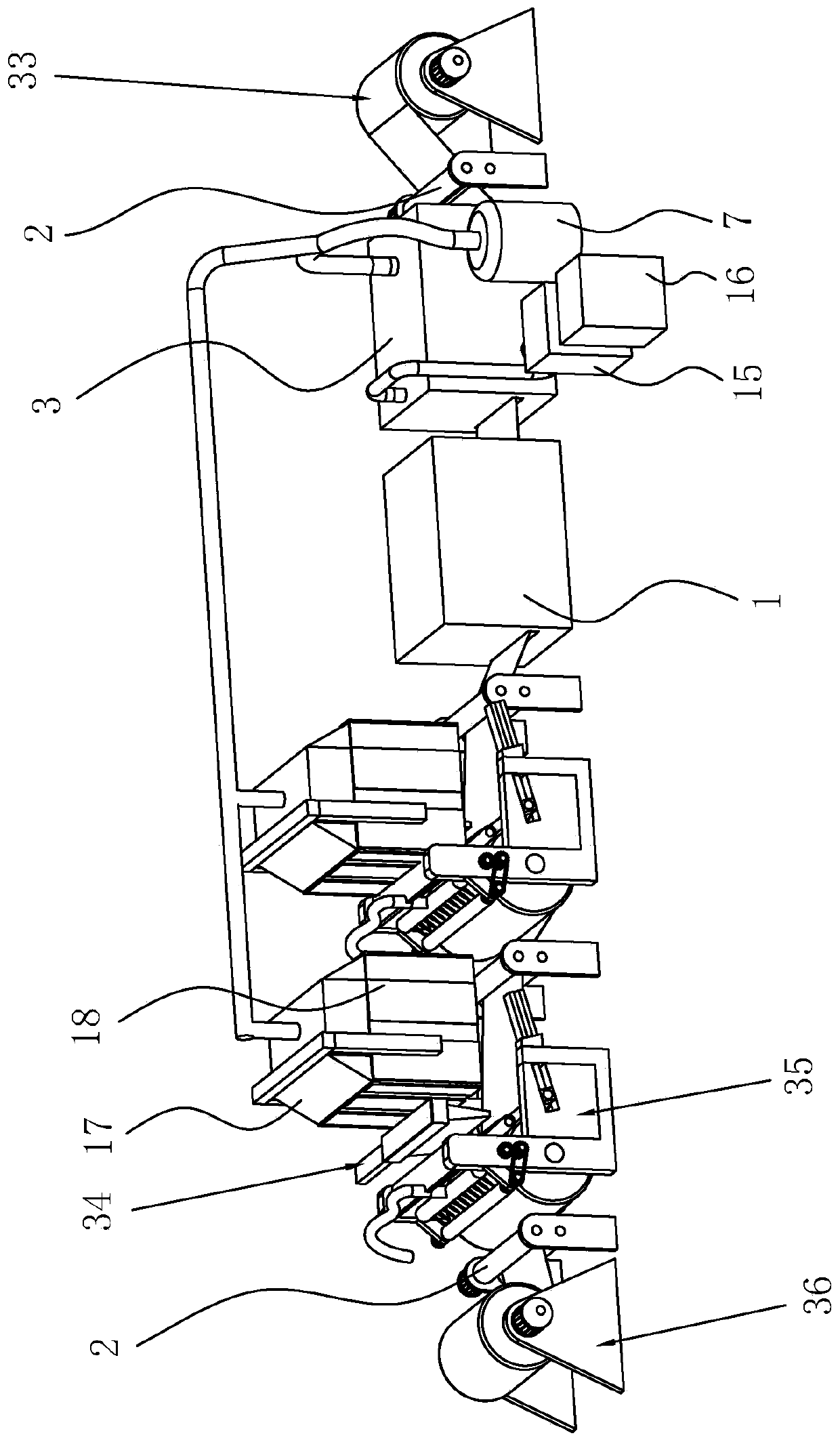

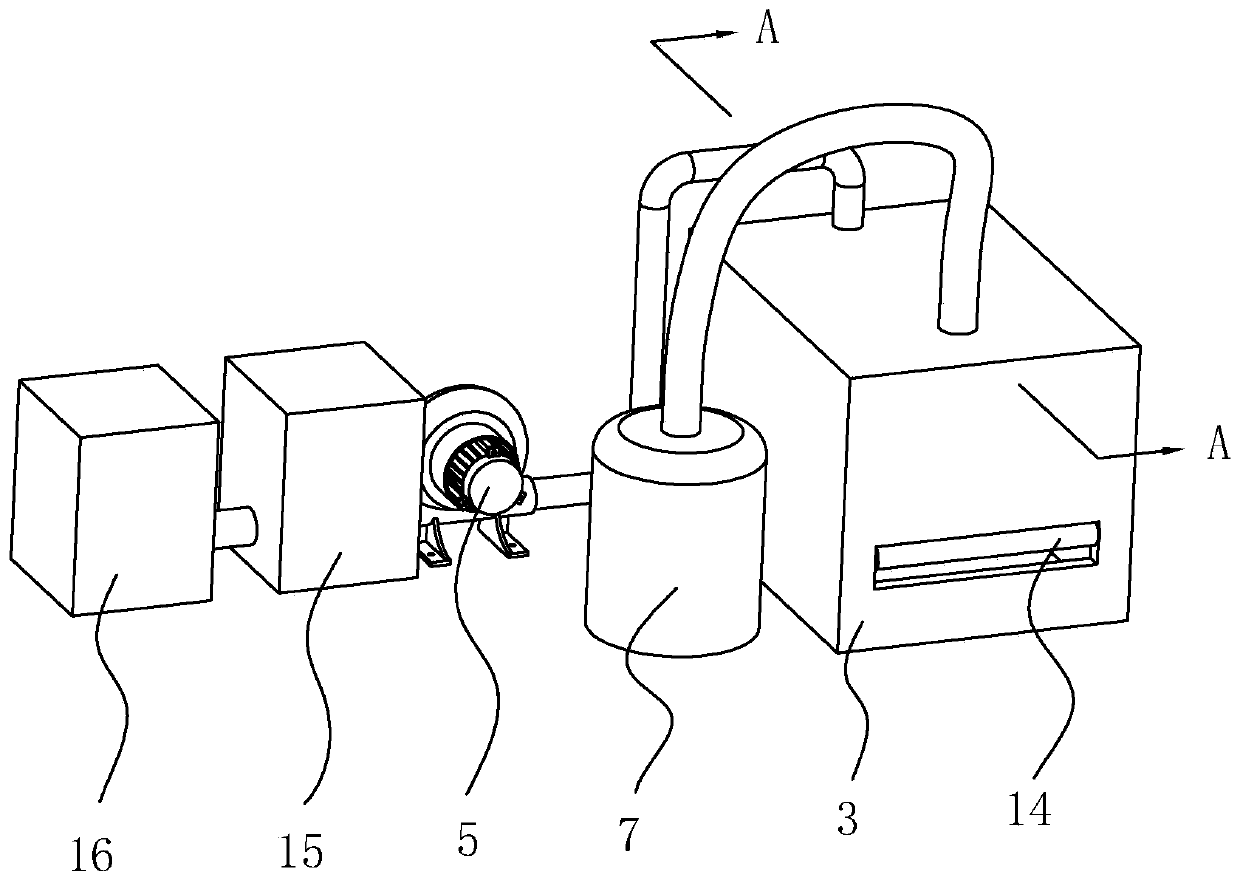

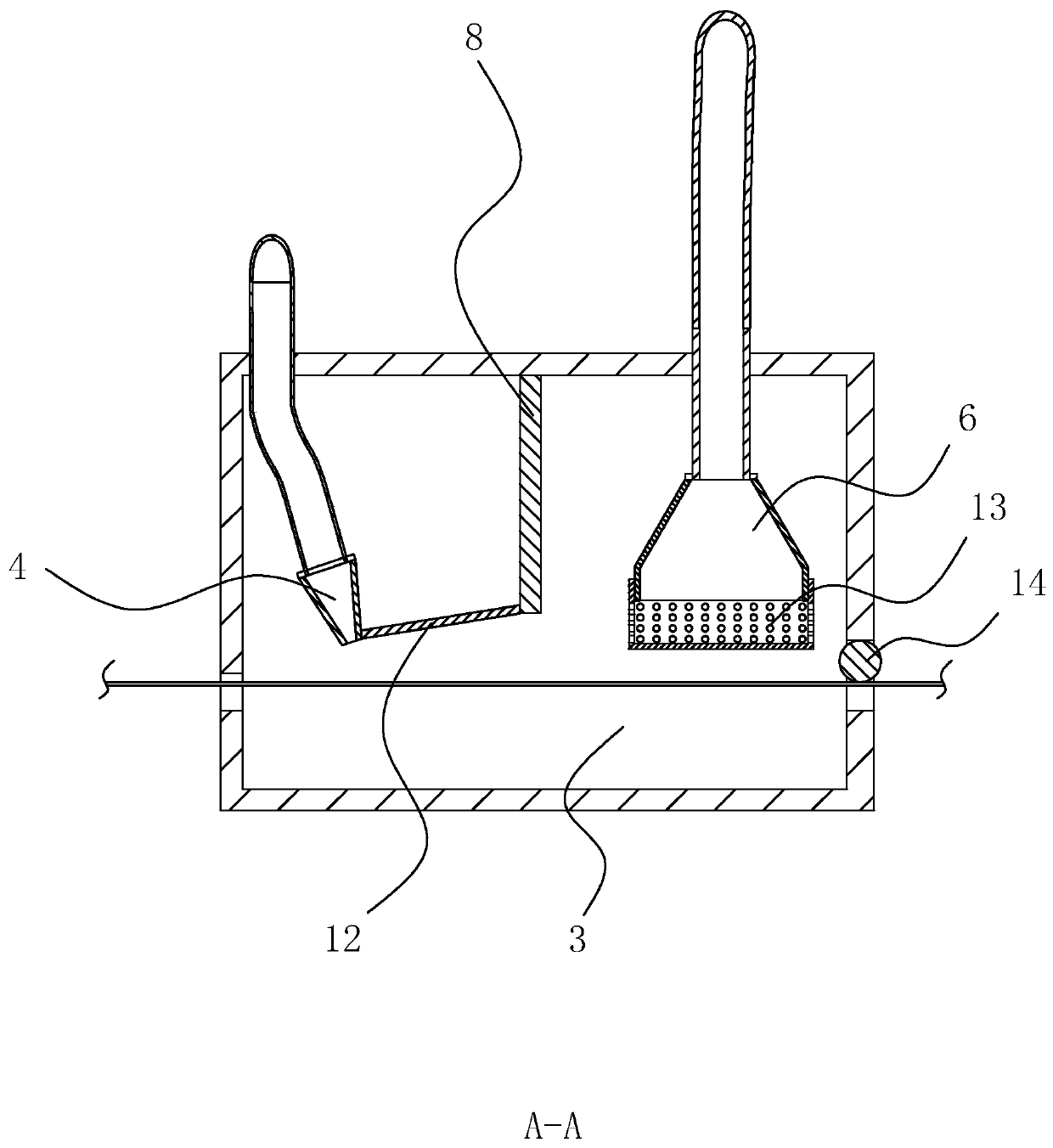

[0040] refer to figure 1 , is a kind of multi-layer coating compound machine disclosed by the present invention, comprising unwinding device 33, corona machine 1, coating extruding device 34, calendering device 35 and winding device 36 arranged in sequence, unwinding device 33, calendering Both the device 35 and the winding device 36 are provided with guide rollers 2 for conducting substrates, and a plurality of guide rollers 2 rotate synchronously through a chain transmission, wherein one guide roller 2 is driven by a motor, and the unwinding device 33 and the winding device 36 all comprise support and the cylinder that is rotatably connected on the support, and coating extruding device 34 comprises extruder and grinding head, and its specific structure is referring to the description of paragraph [0042] and [0047] in the Chinese patent that patent publicati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com