Patents

Literature

77results about How to "Guaranteed suction effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Automatic slurry filling device for concrete crack defect with high adhesion strength

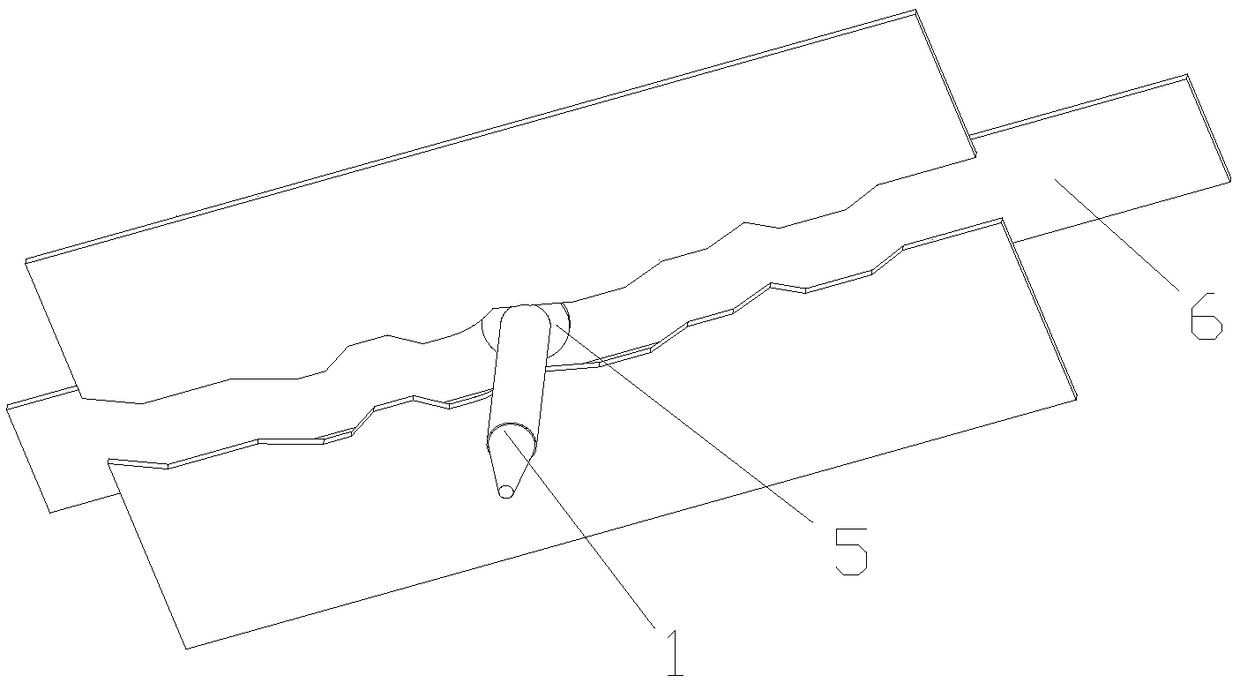

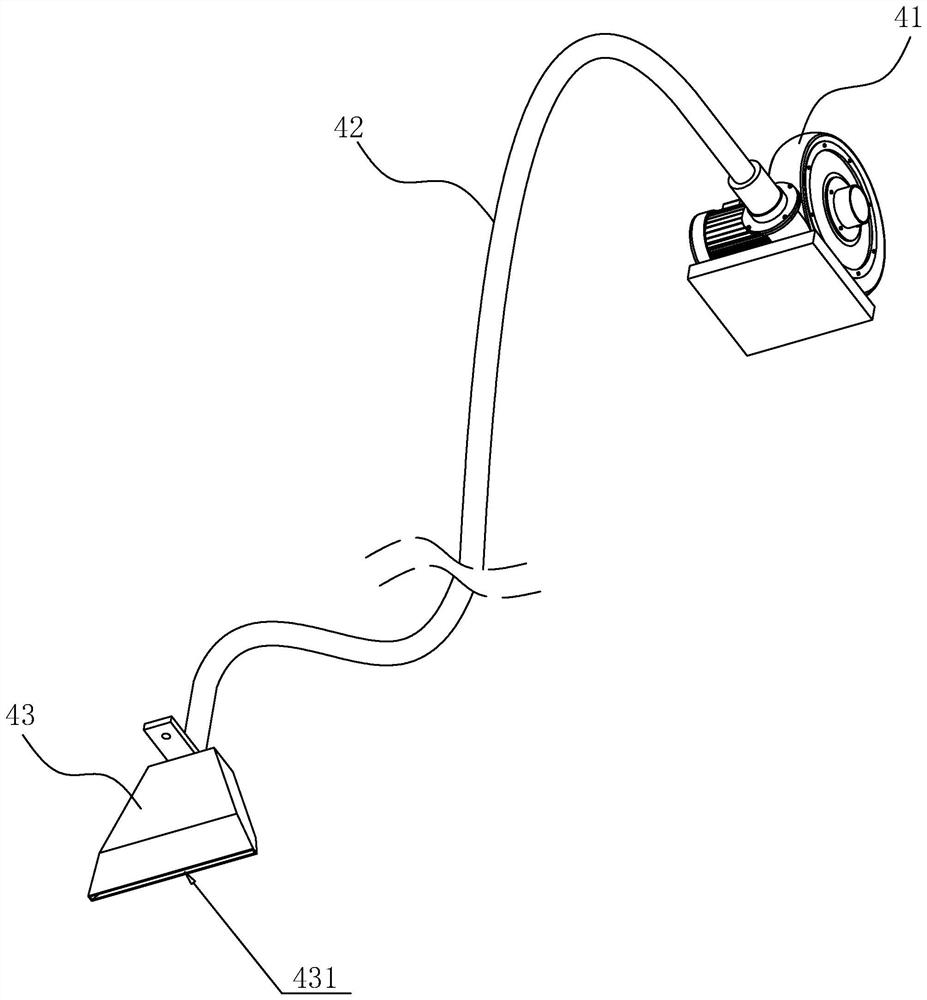

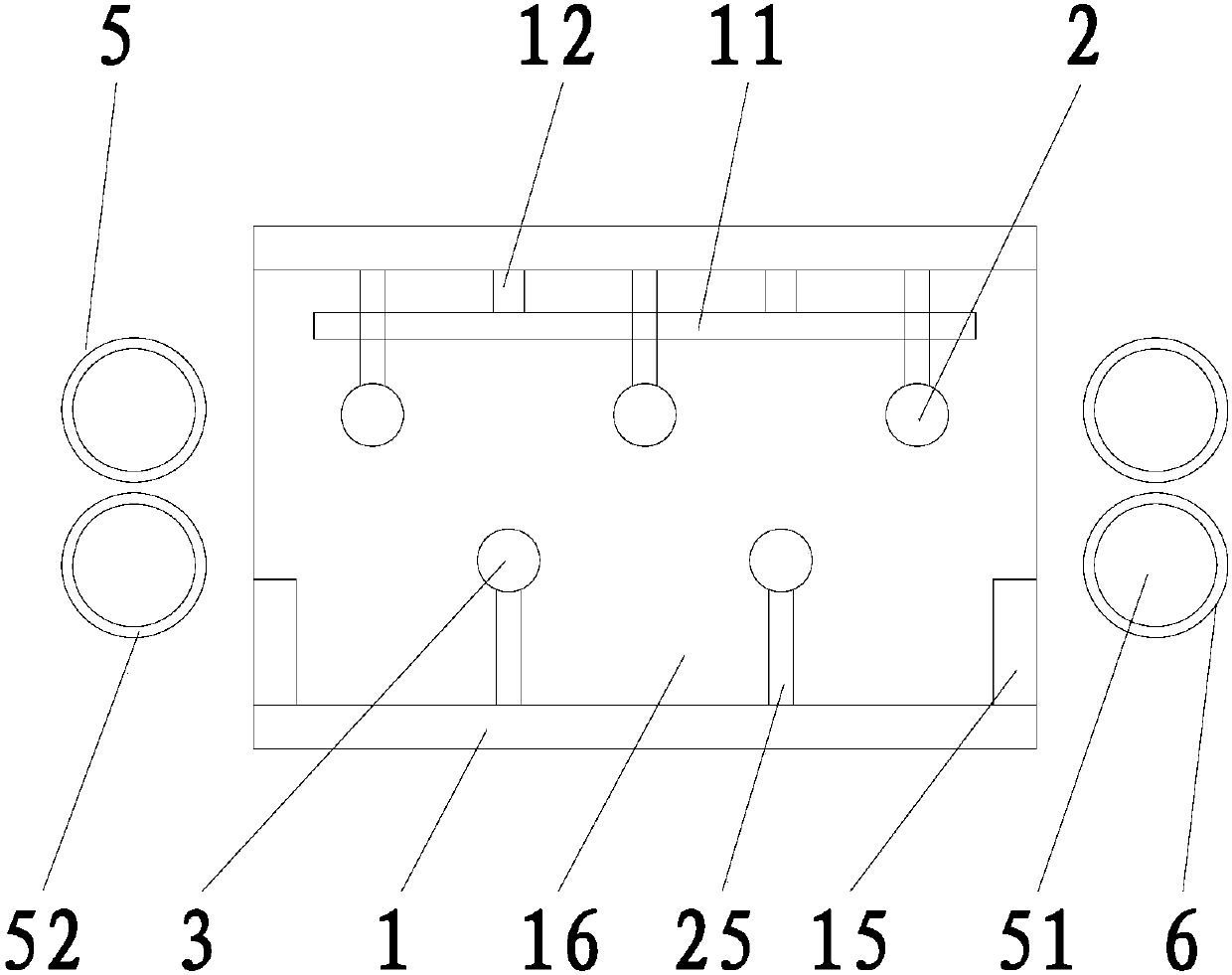

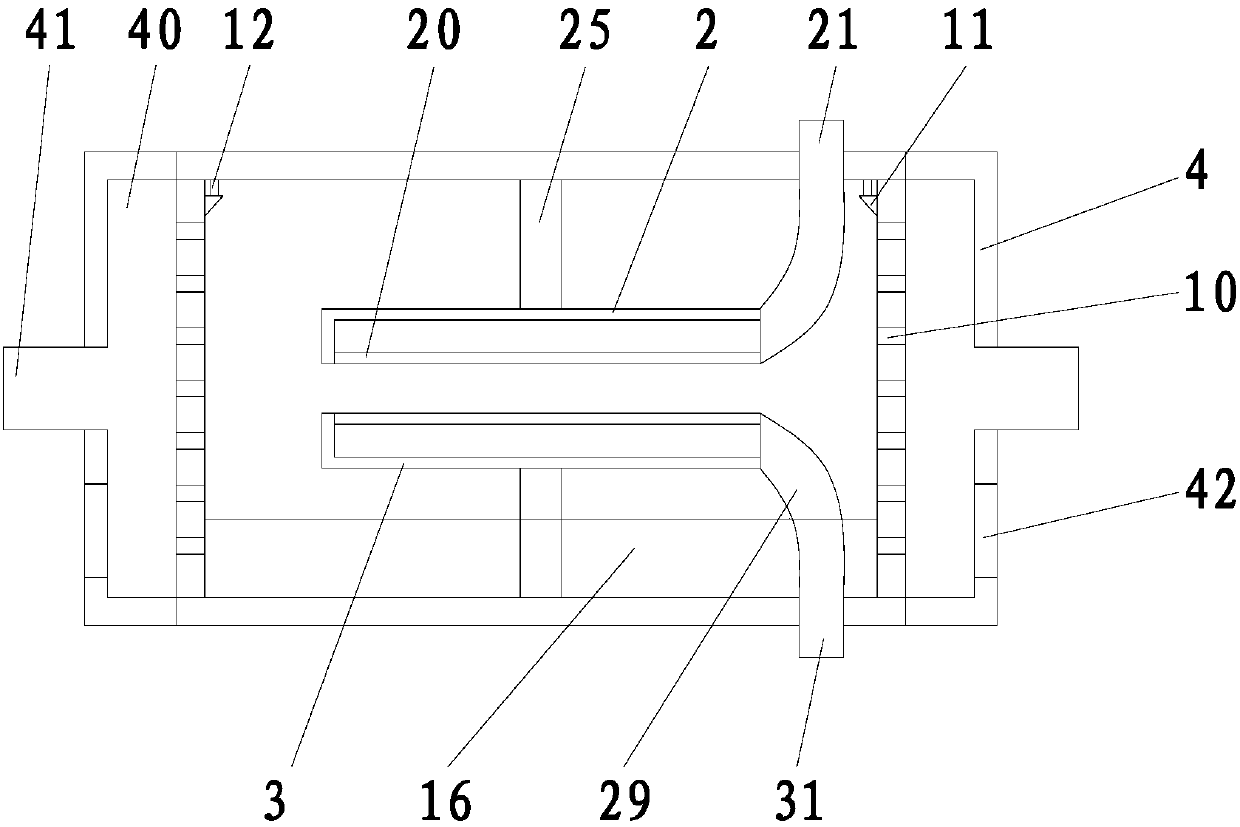

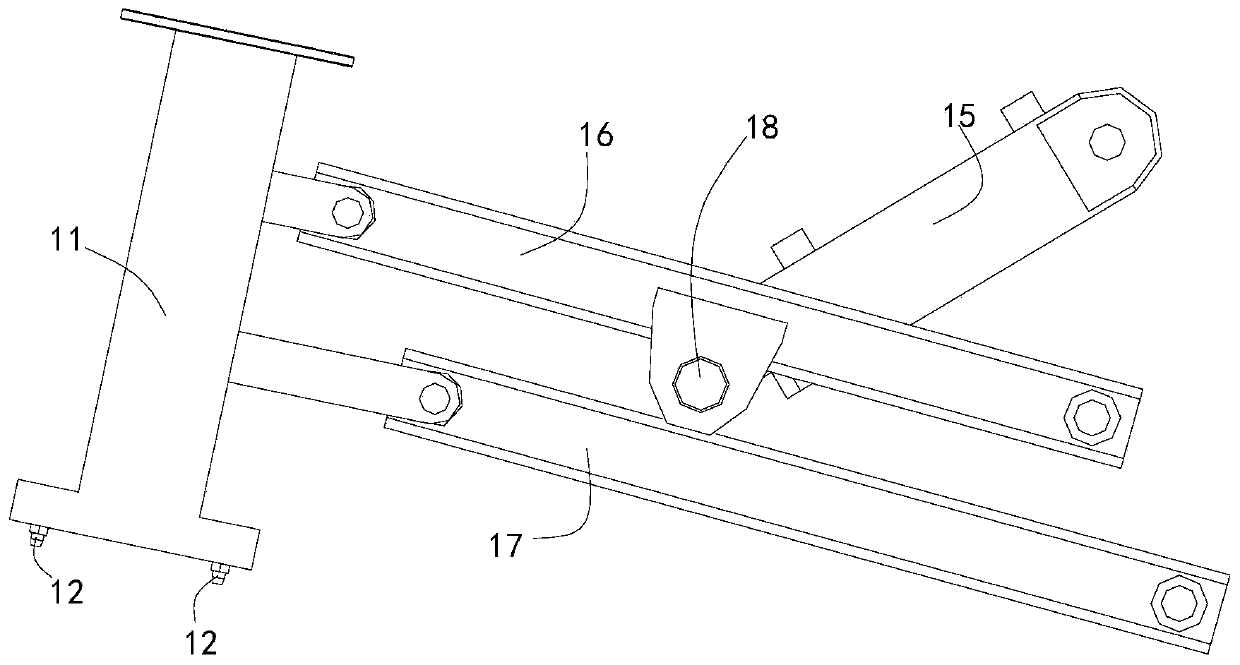

The invention discloses an automatic slurry filling device for a concrete crack defect with high adhesion strength, which comprises a slurry filling pipe, wherein the concrete slurry is injected intothe concrete crack through the slurry filling pipe; and also comprises a machine frame, an electric sliding element, an electric lifting element, a rubber sleeve, a trowel, a first supporting rod, a first sucking disc, a second supporting rod and a abutted element; the electric sliding element is in sliding fit with the machine frame, the electric lifting element is arranged on the electric sliding element, the lifting end of the electric lifting element is connected with the slurry filling pipe, and the trowel is sleeved at the periphery of the slurry filling pipe through the rubber sleeve. The first sucking disc is arranged on the end part of the first supporting rod; the connecting end of the abutted element is slidably mounted on the end part of the second supporting rod, and the abutted end of the abutted element can be contacted with the trowel. The device has the advantages that the crack can be fully filled, the slurry leakage condition is reduced, the flatness of the surface after filling the slurry is high, the slurry filling pipe can achieve sliding and grouting in the crack, and the installation stability of a bracket is high, no damage is caused on a wall body or the adhesion strength of a plate body is high.

Owner:GUANGDONG NO 2 HYDROPOWER ENGINEERING COMPANY LTD

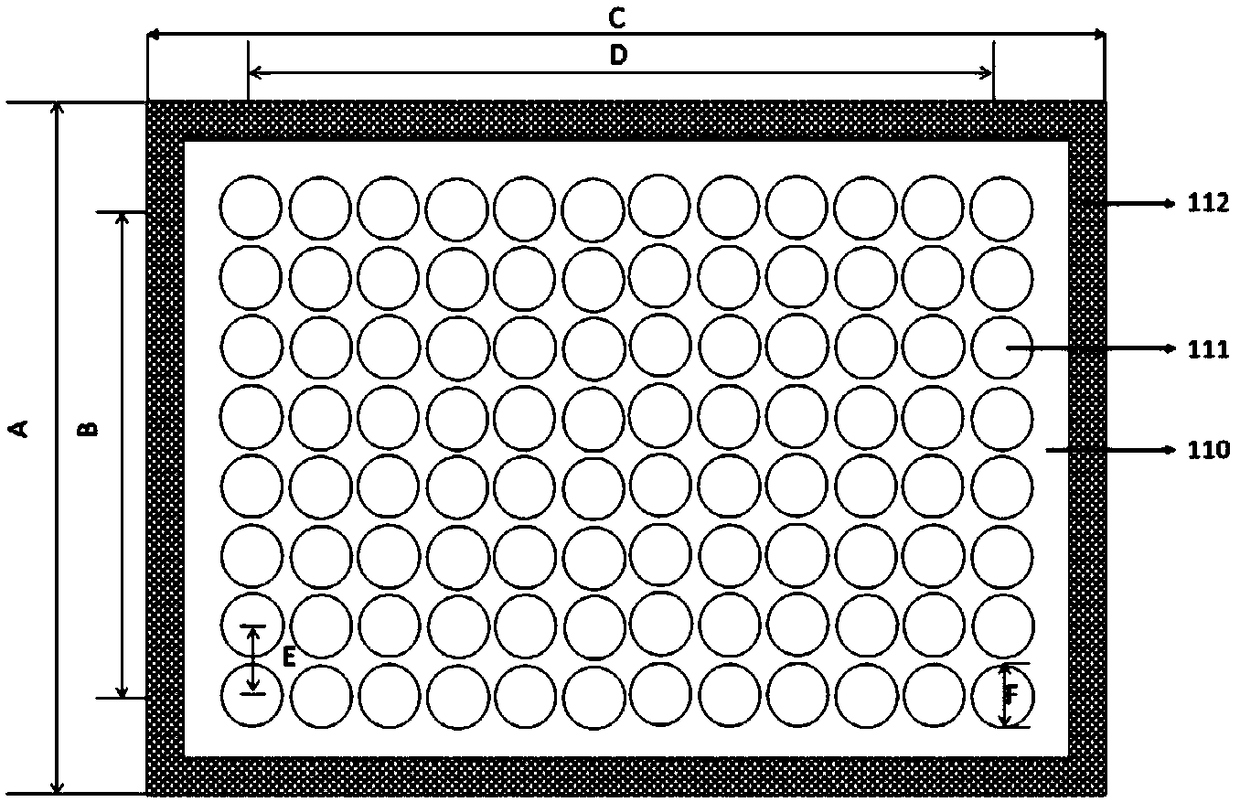

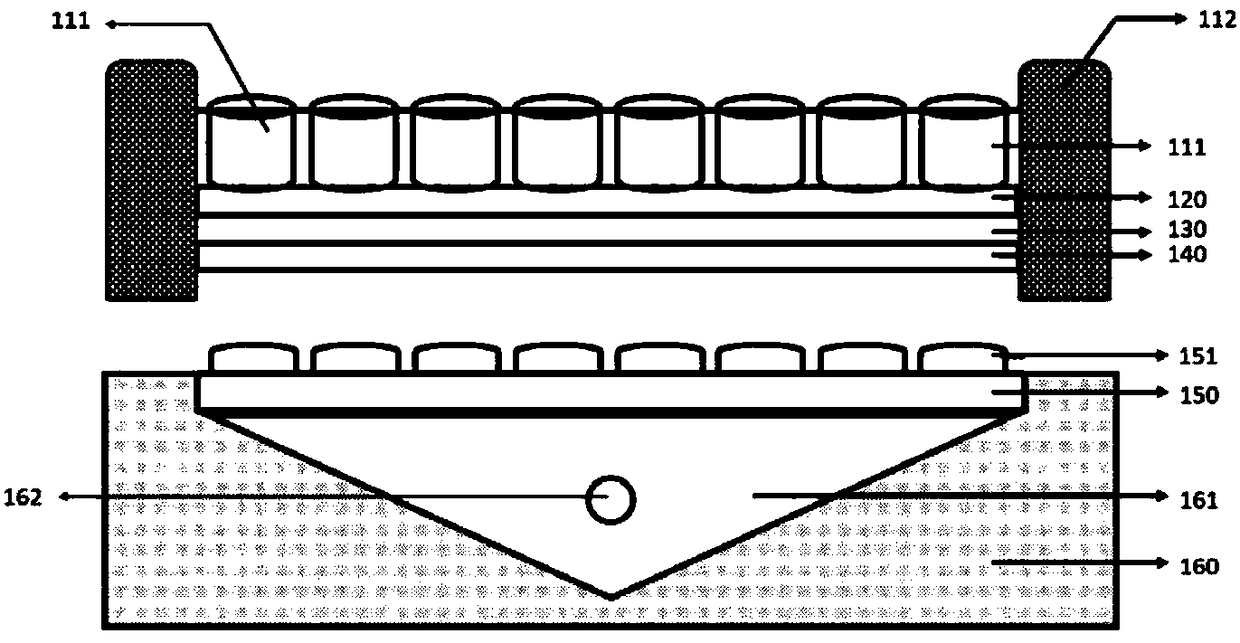

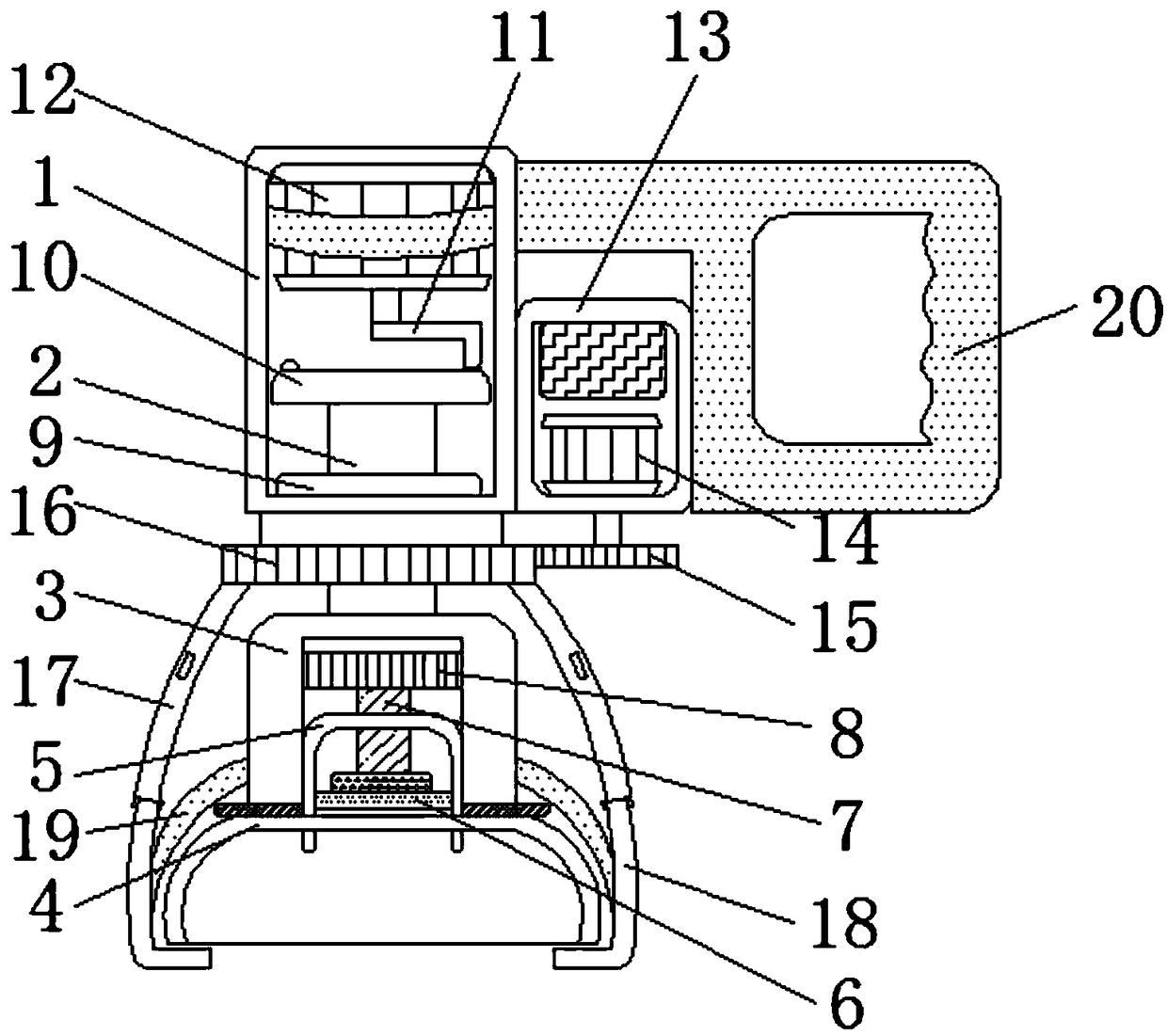

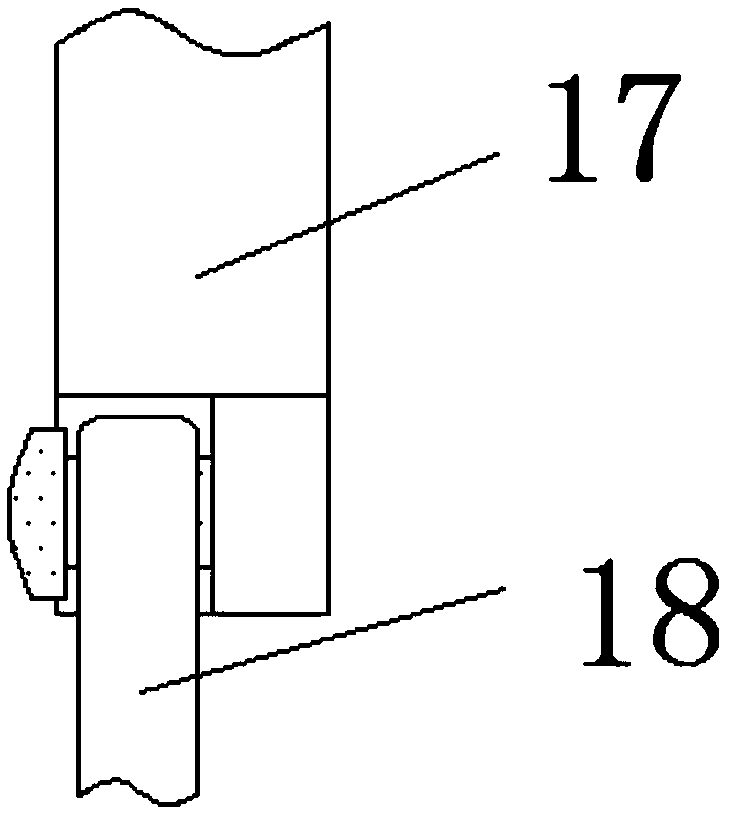

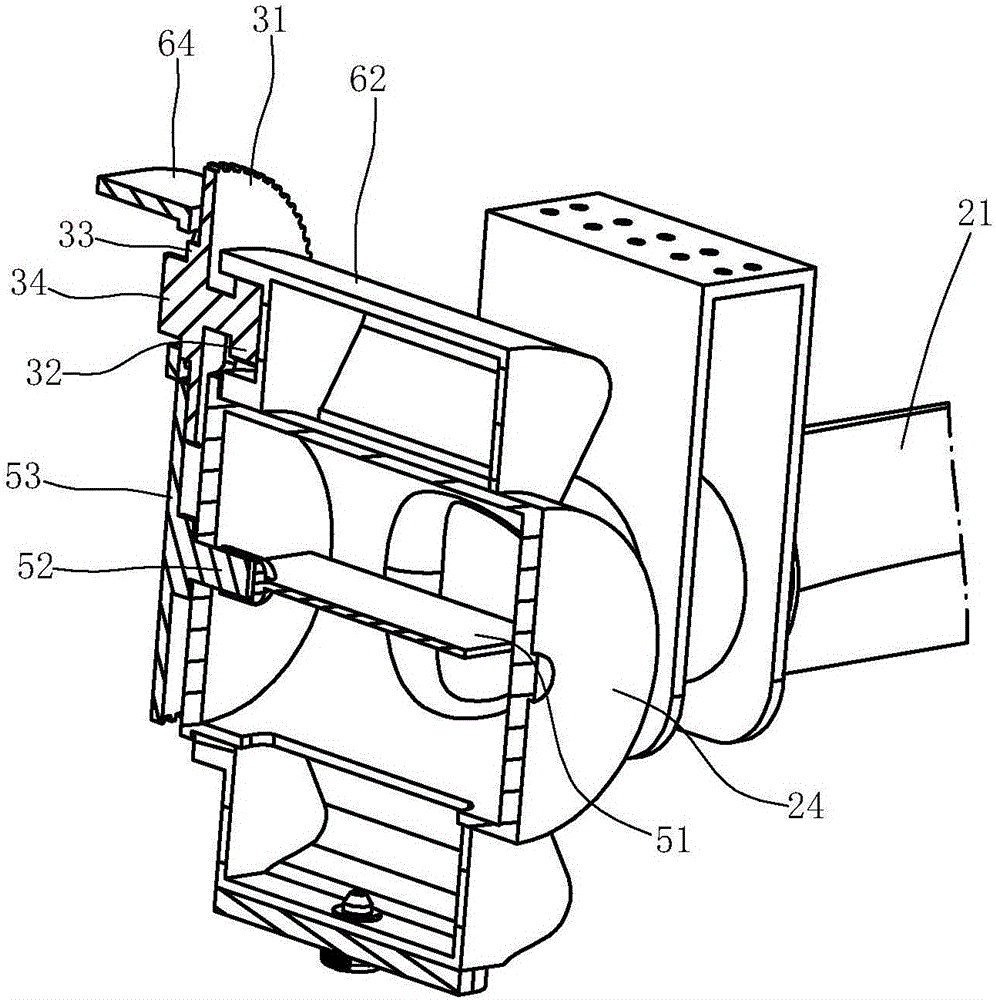

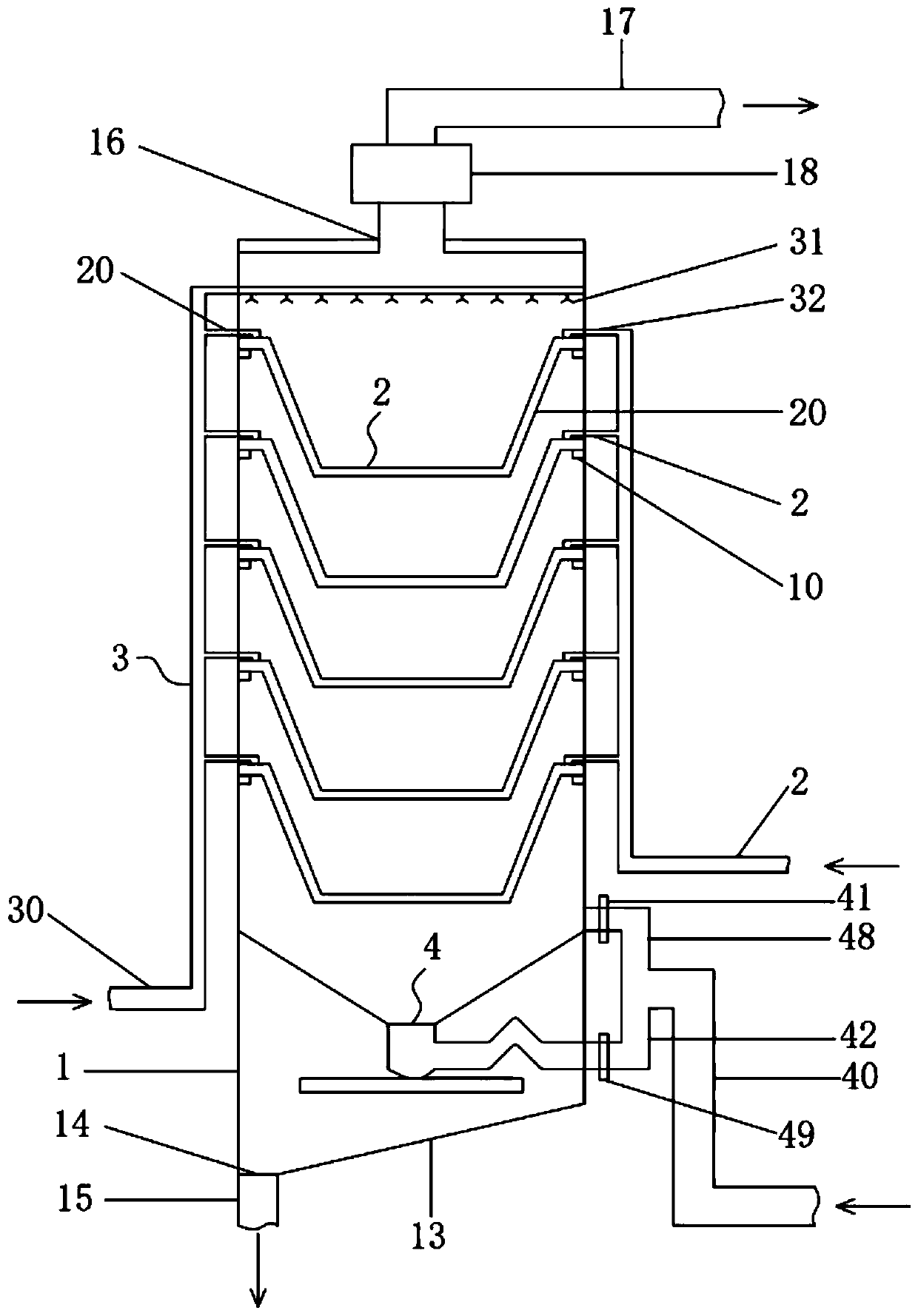

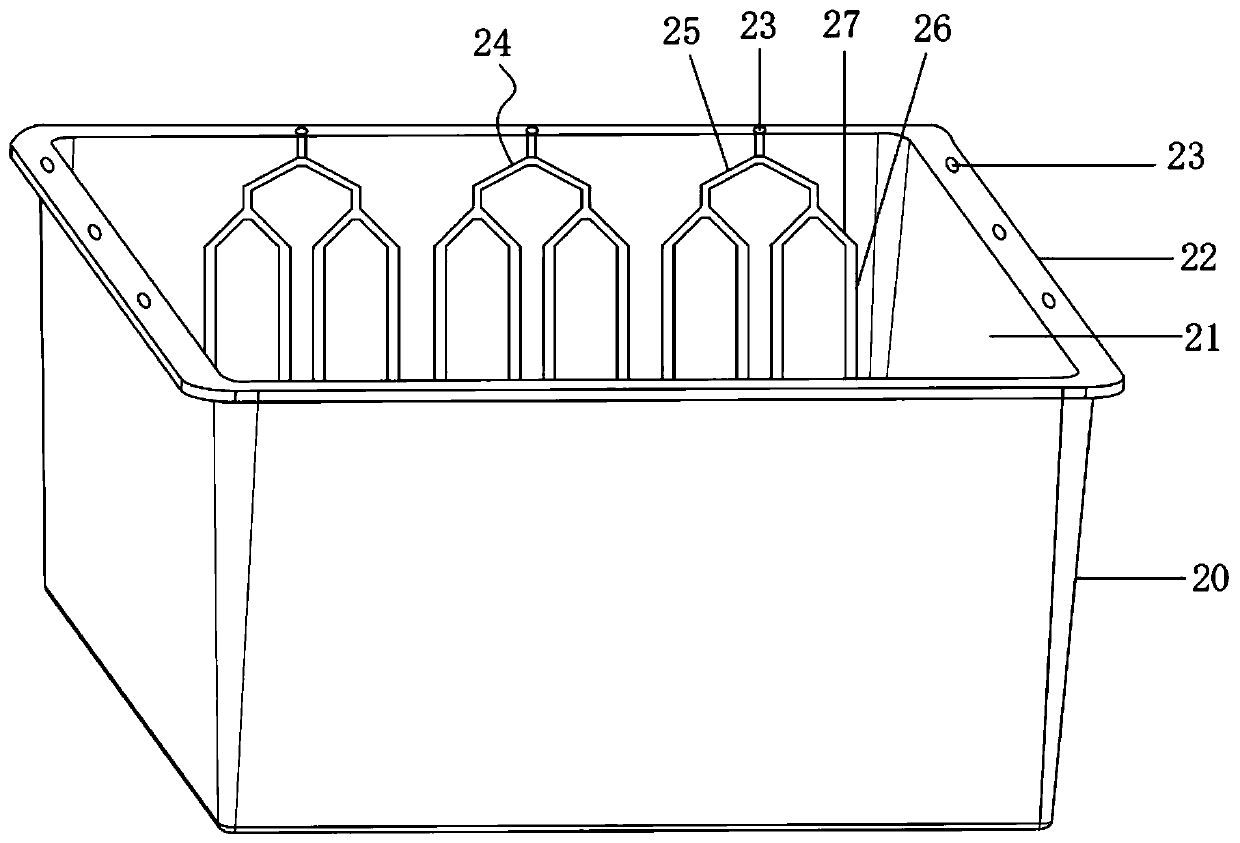

Dot blot hybridization reaction device and application thereof, and immunoblotting detection method

PendingCN109439517AEasy to operateEasy to carryBioreactor/fermenter combinationsBiological substance pretreatmentsHybridization reactionFiltration

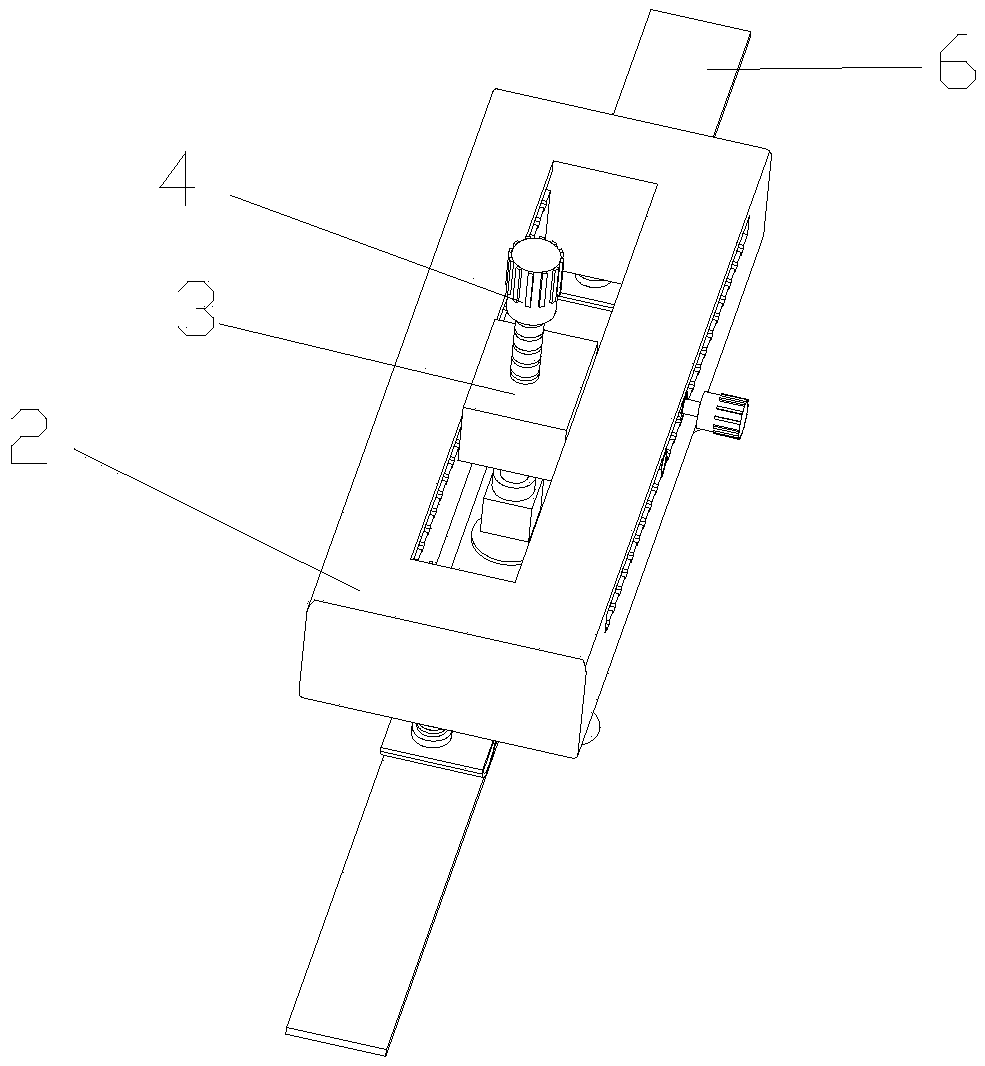

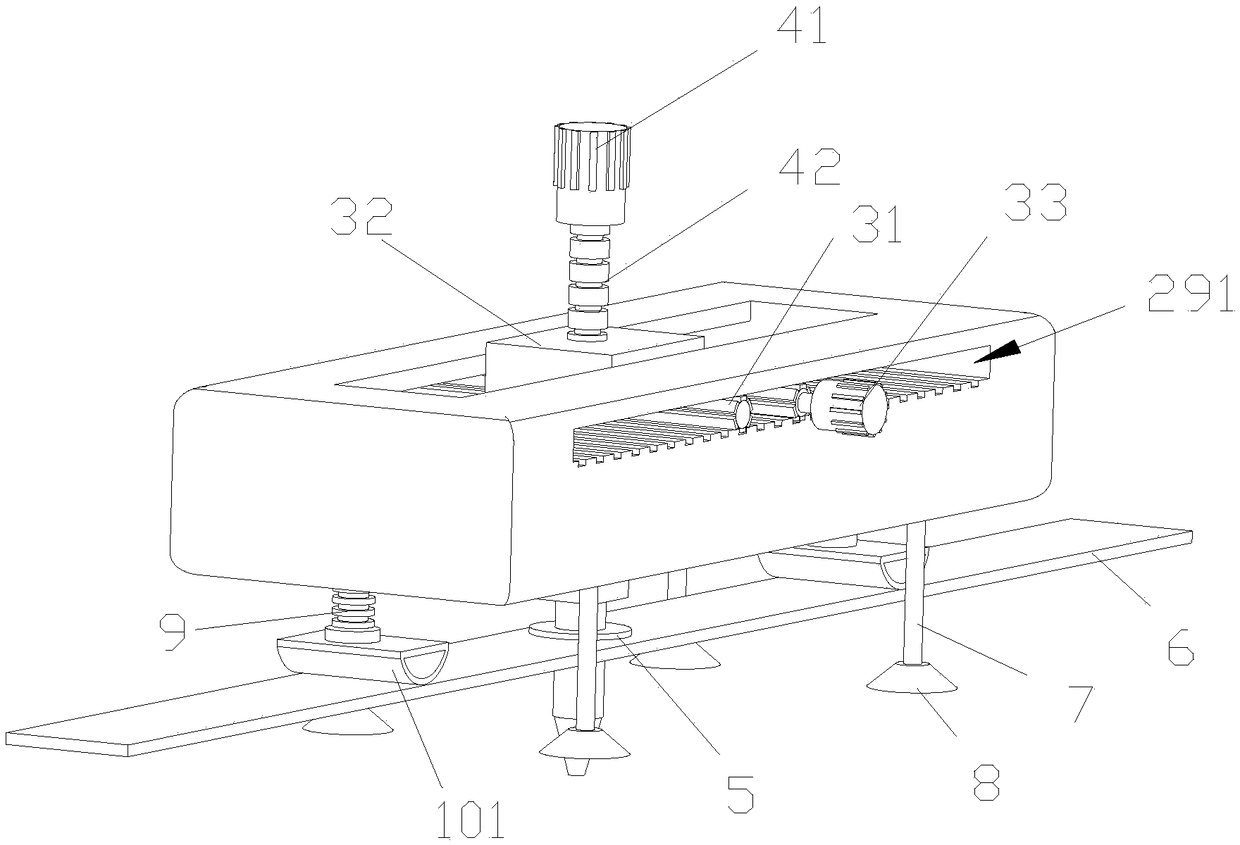

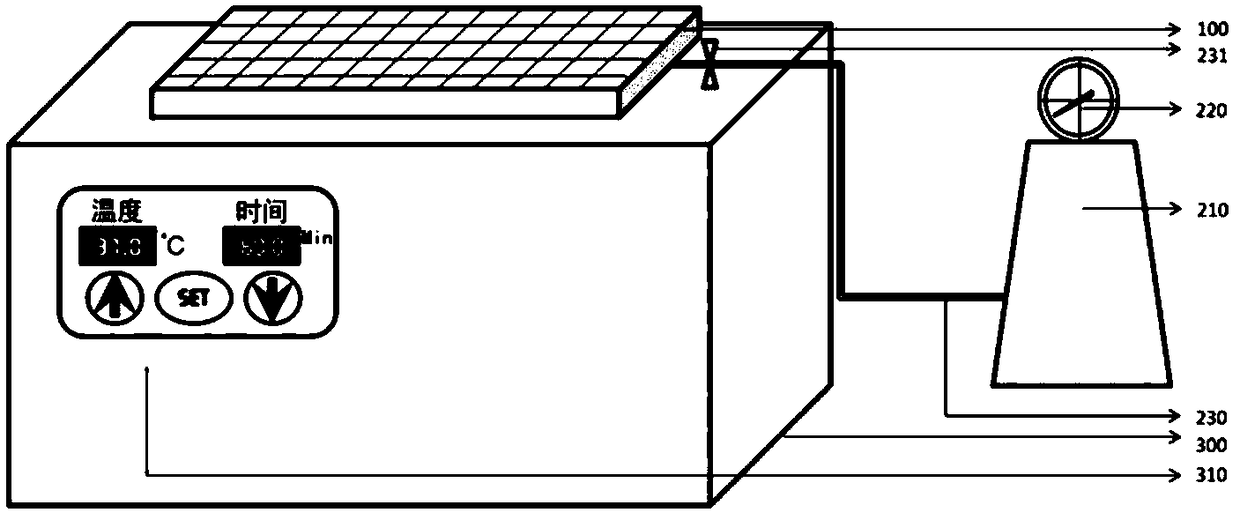

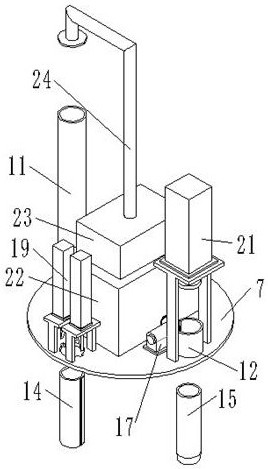

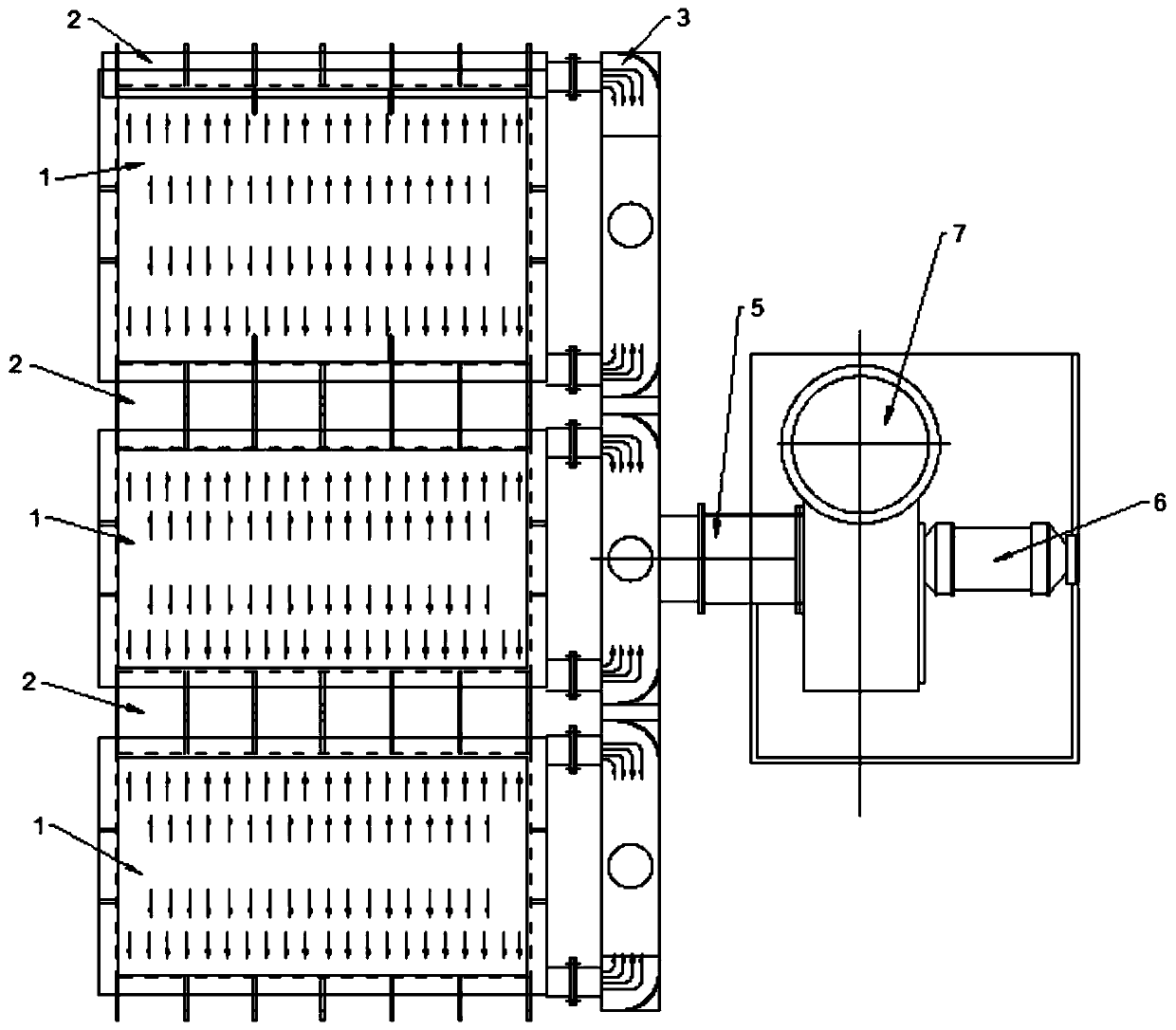

The invention provides a dot blot hybridization reaction device and application thereof, and an immunoblotting detection method and relates to the technical field of molecular hybridization experimental devices. The dot blot hybridization reaction device comprises a sampling infiltration module and a suction filtration module used for supplying a negative pressure environment for the interior of the sampling infiltration module, wherein the sampling infiltration module comprises a micropore sampling plate provided with a sample through hole, a support layer provided with an infiltration through hole corresponding to the sample through hole, and a suction filtration tank; a first actuation unit is arranged in the micropore sampling plate; a second actuation unit matched with the first actuation unit is arranged in the suction filtration tank; a closed inner chamber is formed by the matched actuation units in the manner of adsorbing and fixing; and a hybridization film layer and the support layer are successively fixed under the micropore sampling plate. The dot blot hybridization reaction device is portable, is simple in operation and can effectively prevent the problem of cross contamination of sample rooms of the dot blot hybridization reaction device.

Owner:天康生物制药有限公司

Ice block removing device in refrigerator with reciprocating vibration mode

ActiveCN109297241AChange state of motionImprove adsorption capacityLighting and heating apparatusDefrostingEngineeringRefrigerated temperature

The invention provides an ice block removing device in a refrigerator with a reciprocating vibration mode, and relates to the field of articles for daily use. The ice block removing device in the refrigerator with the reciprocating vibration mode comprises a fixed left box, a reciprocating driving rod is arranged at the bottom of the fixed left box, the bottom of the reciprocating driving rod is adhered to the top of a side control fixed cylinder, the bottom of the side control fixed cylinder is adhered to the top of a connecting sucker, and a right box and a grabbing handle are adhered to theright side of the fixed left box. The ice block removing device in the refrigerator with the reciprocating vibration mode, after the connecting sucker is adsorbed on the ice surface, a driving motoris used for controlling a poking rod to be in contact with convex particles, so that the connecting sucker can continuously vibrate in a reciprocating mode after being connected with the ice blocks, the vibration force formed by vibration is used for gradually reducing the bonding force between the ice blocks and the inner wall of the refrigerator, so that the ice blocks can be removed conveniently, no force is applied to the refrigerator without being in contact with the refrigerator, so that the traditional mode of removing ice by scraping or heating is avoided, the damage to the refrigerator is avoided, and the service life of the refrigerator is guaranteed.

Owner:邵帅

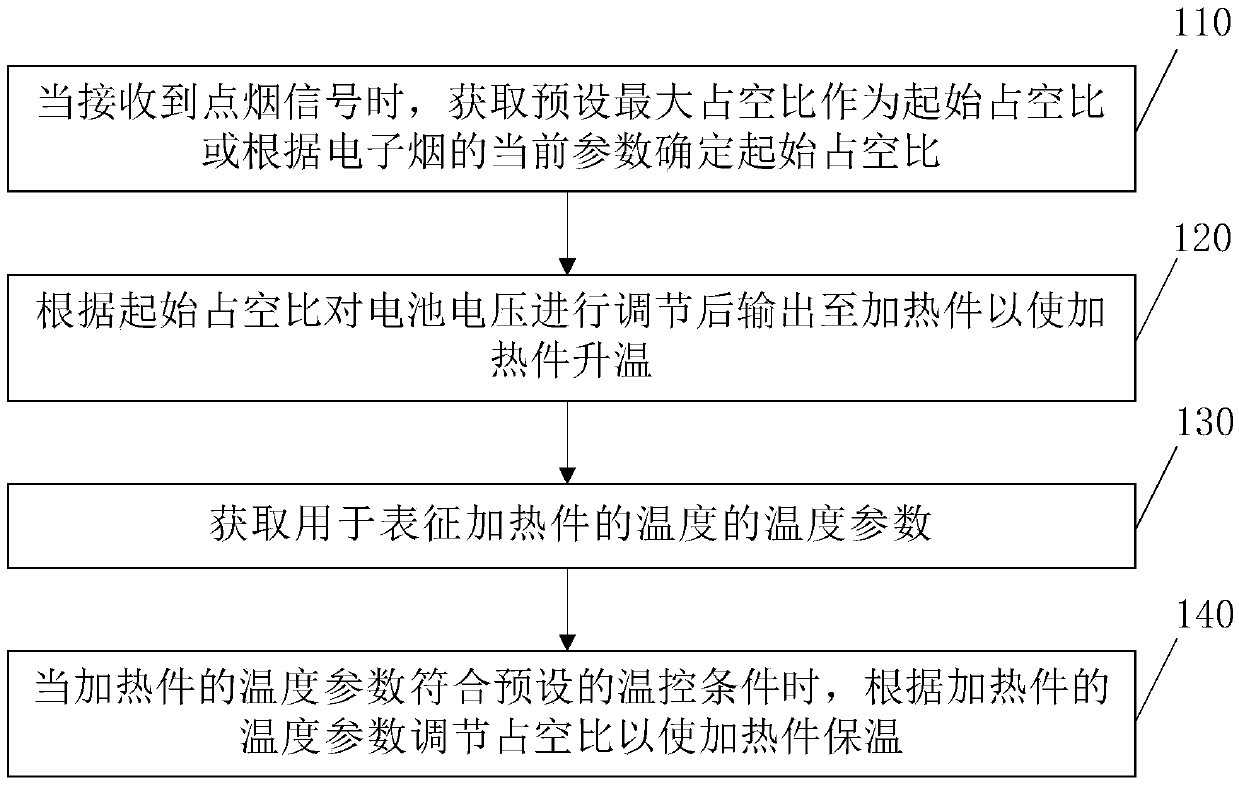

Temperature control method of electronic cigarette, electronic cigarette and computer storage medium

ActiveCN110859331ATemperature controlImprove experienceTobaccoTemperature controlProcess engineering

The invention provides a temperature control method of an electronic cigarette, the electronic cigarette and a computer storage medium. The method comprises the following steps of acquiring a preset maximum duty ratio as an initial duty ratio or determining the initial duty ratio according to the current parameters of the electronic cigarette when receiving a cigarette lighting signal; regulatinga battery voltage according to the initial duty ratio and outputting the battery voltage to a heating element to warm the heating element; acquiring a temperature parameter for representing the temperature of the heating element; and when the temperature parameter of the heating member meets the preset temperature control condition, adjusting the duty ratio according to the temperature parameter of the heating element so as to keep the temperature of the heating element. Through the method provided by the invention, the effective control of the temperature of the heating element can be realized, and the smoking effect and the smoking safety are guaranteed.

Owner:CHANGZHOU PATENT ELECTRONICS TECH CO LTD

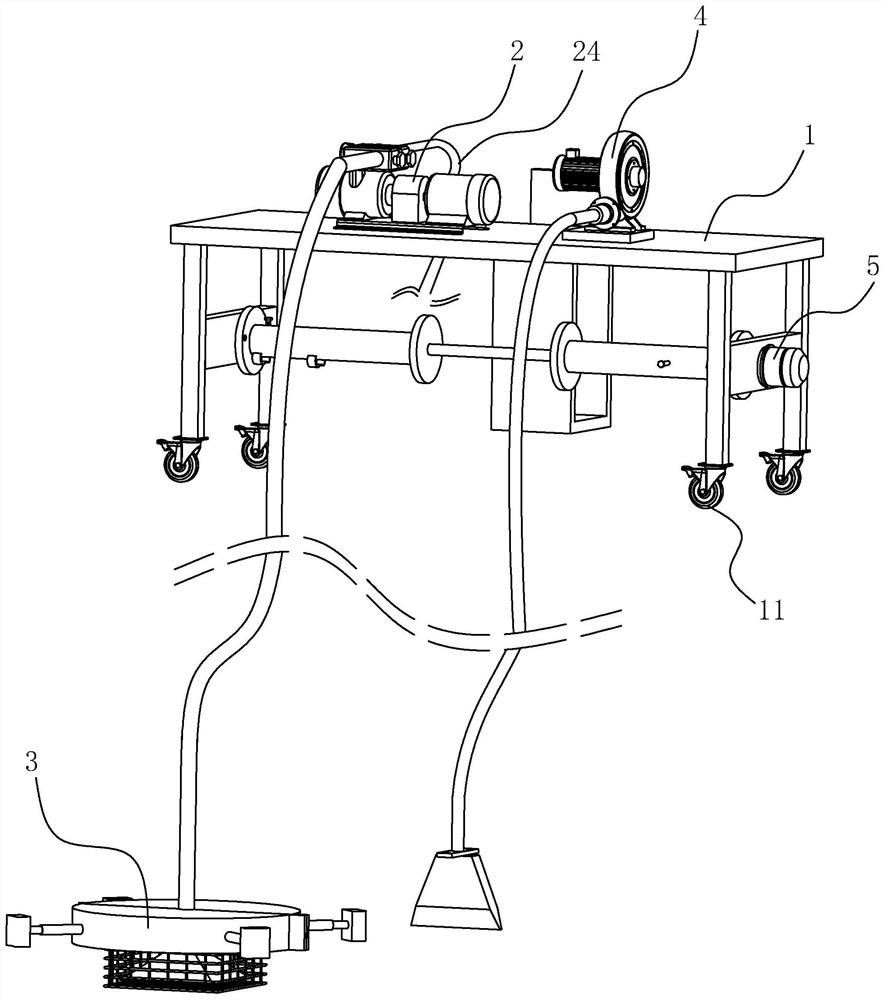

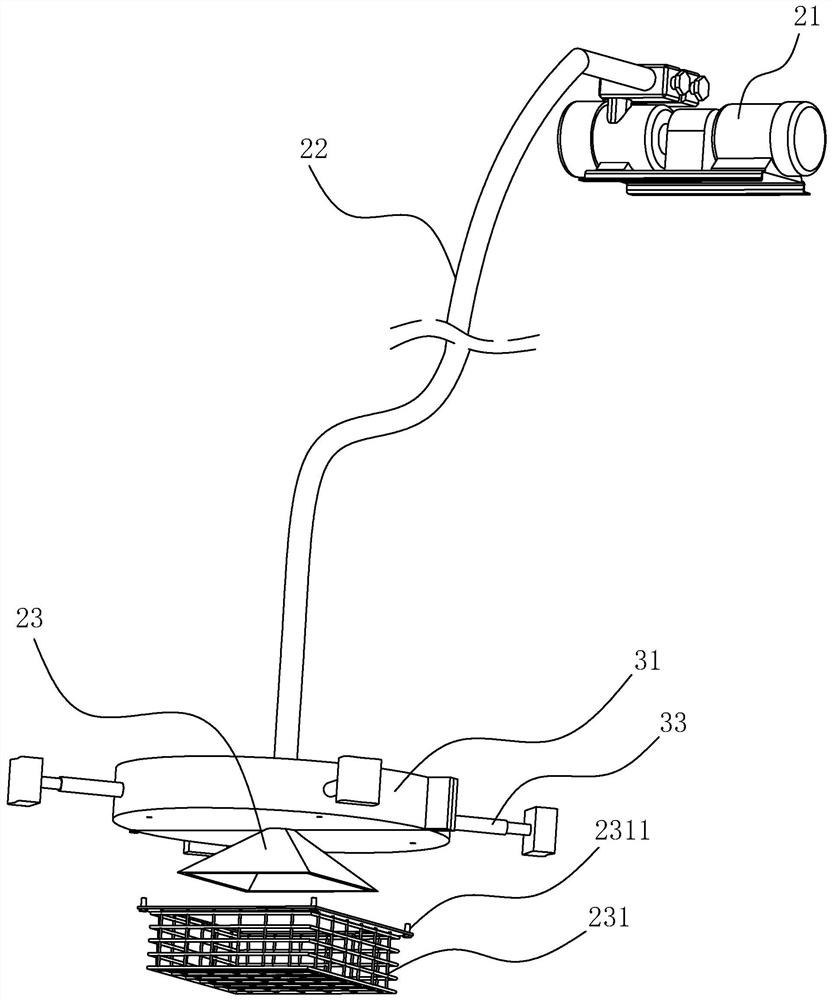

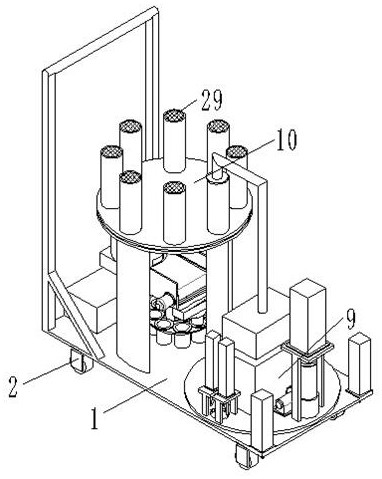

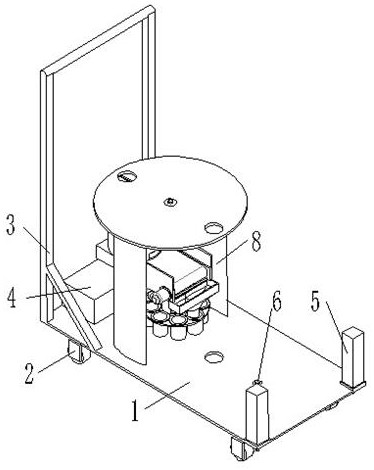

Deep foundation pit dewatering construction device and construction method

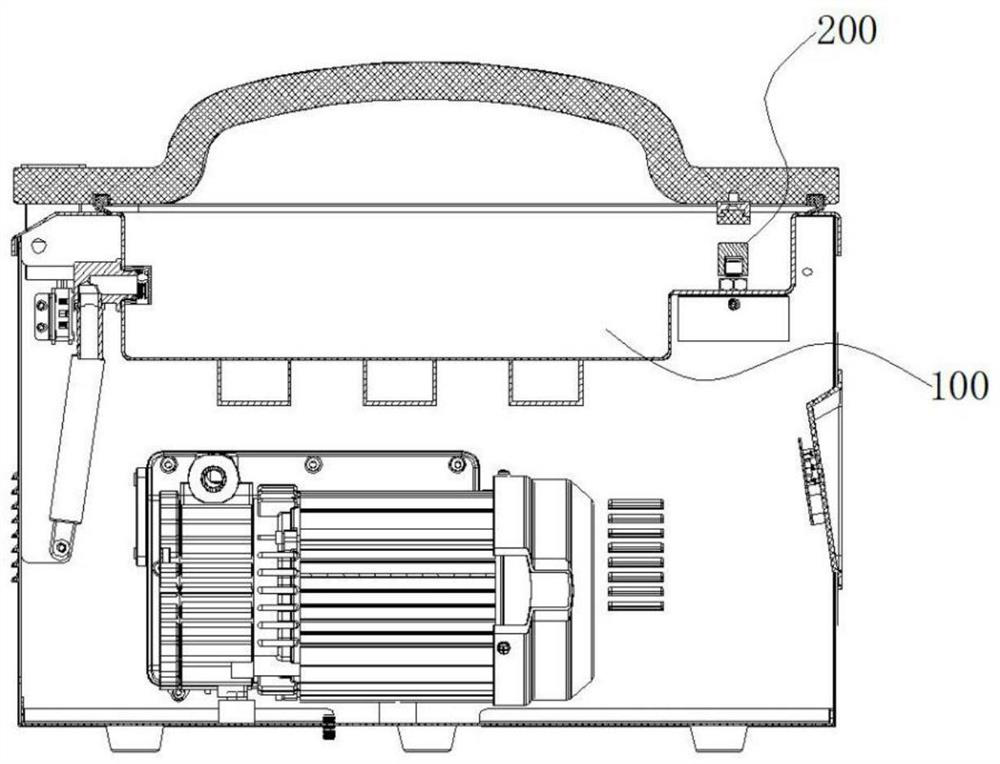

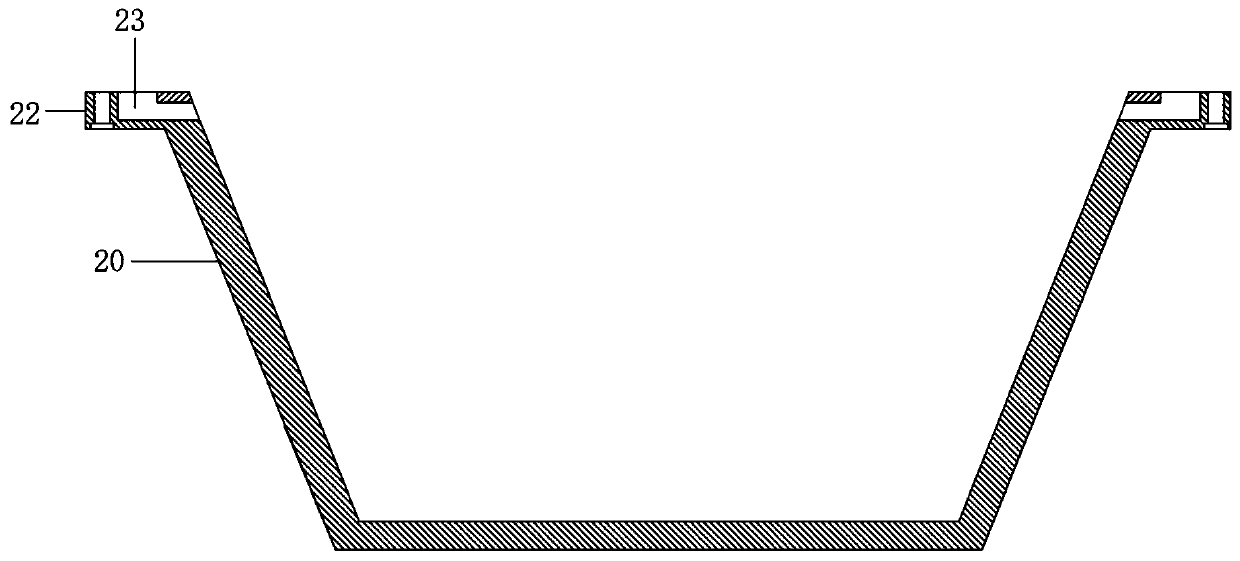

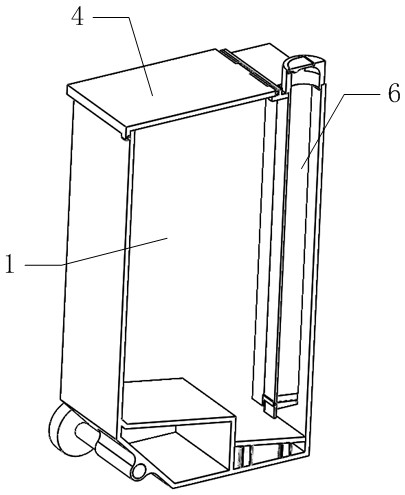

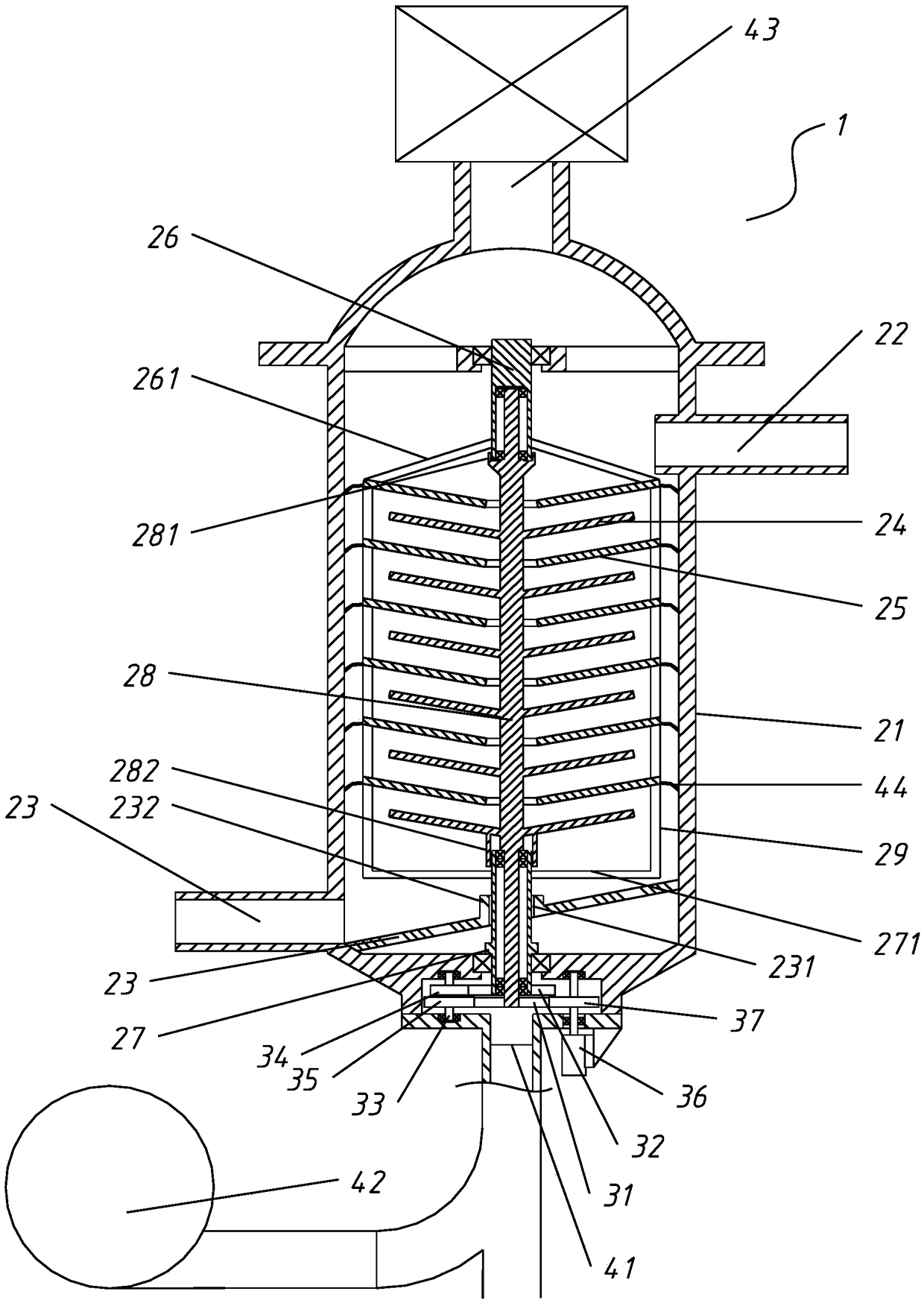

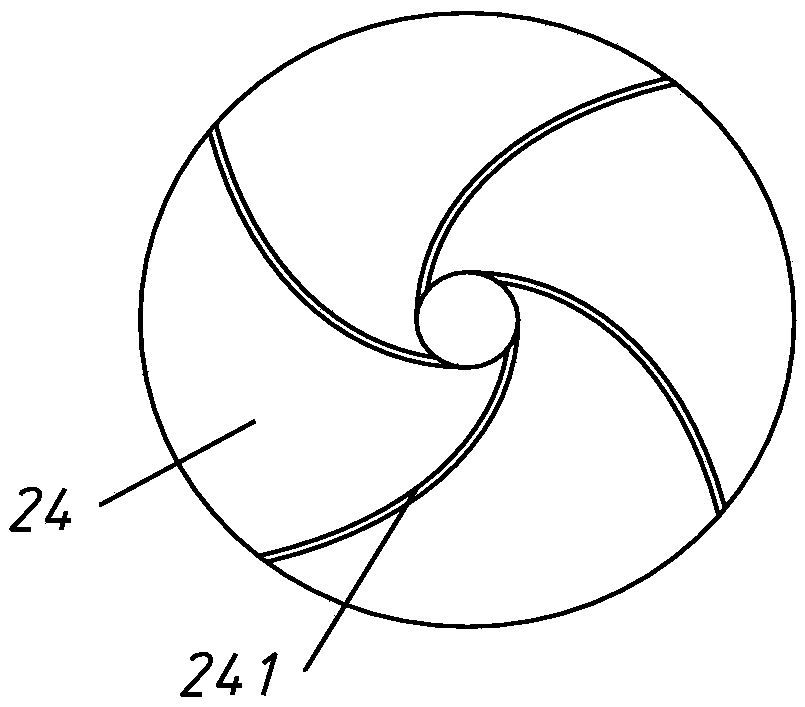

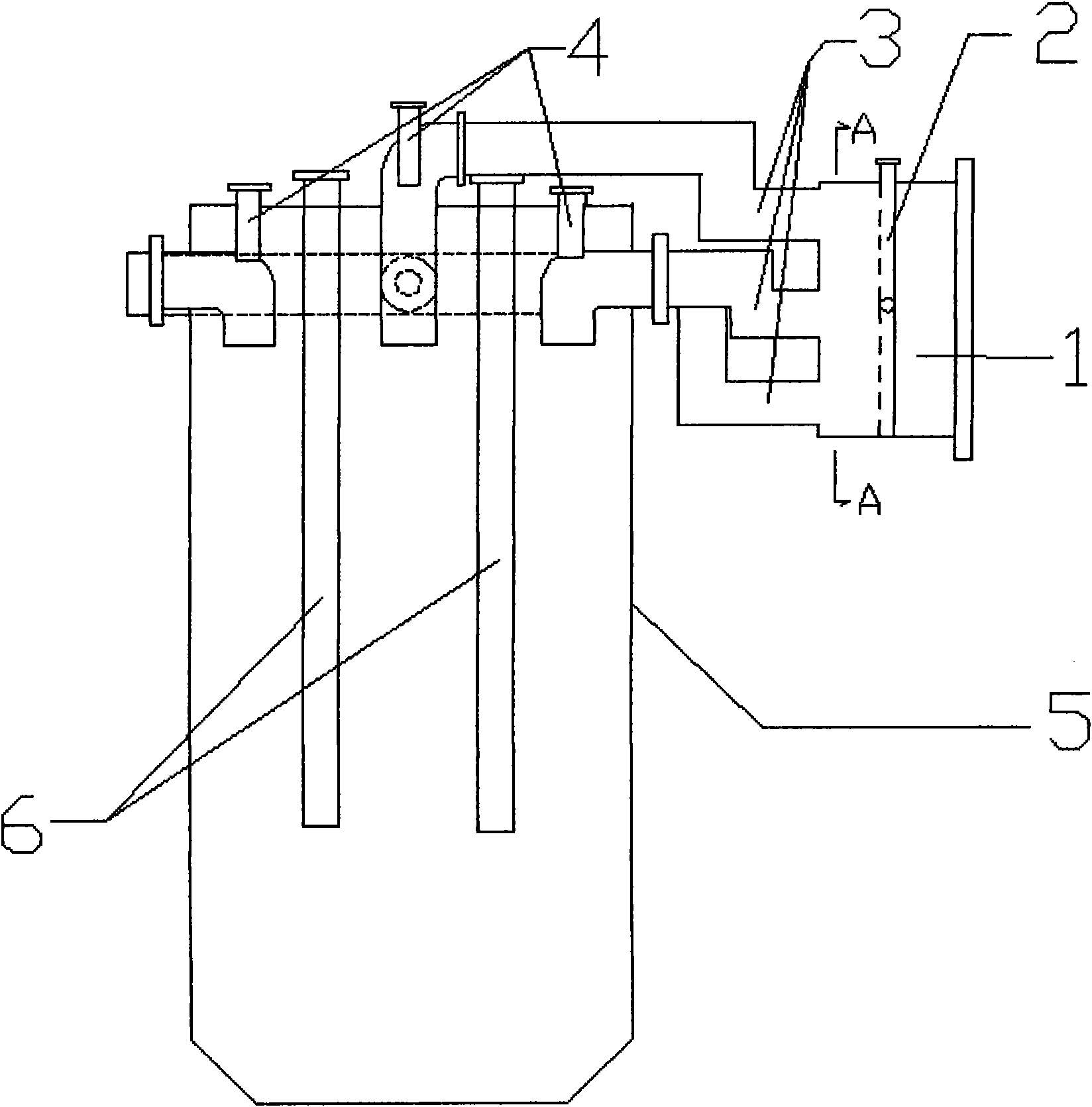

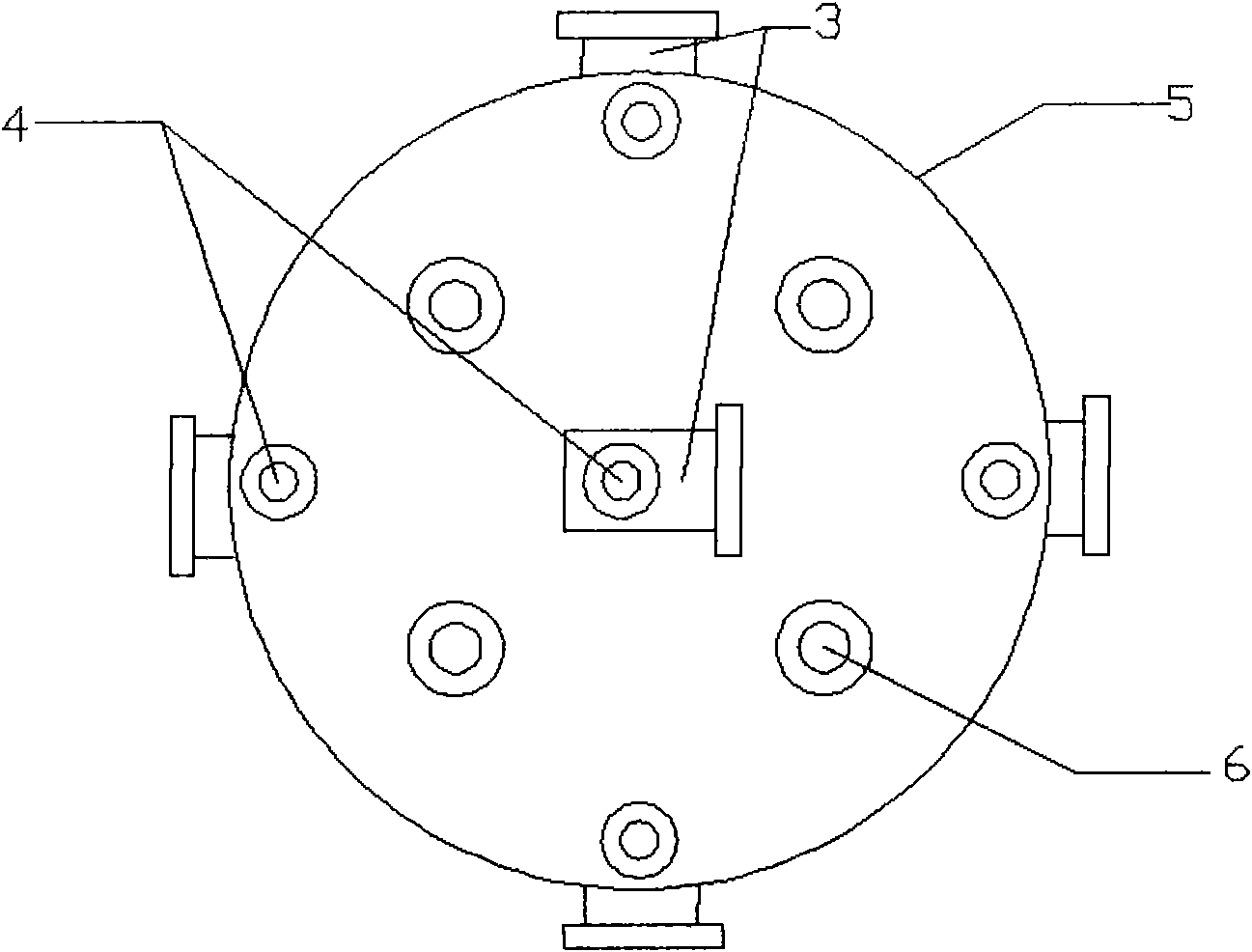

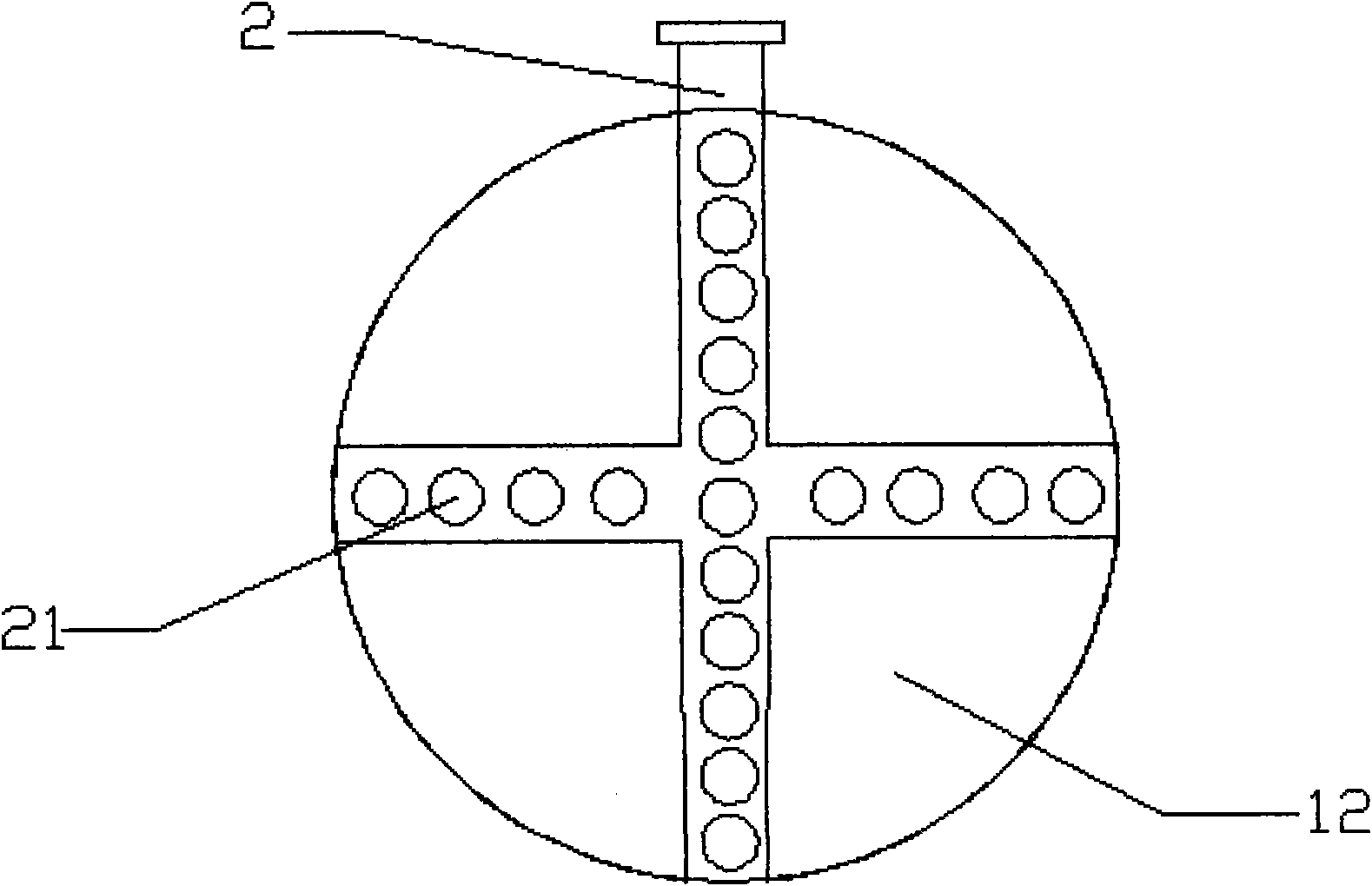

ActiveCN113774940AGuaranteed suction effectPlay a protective effectPositive displacement pump componentsFoundation engineeringPipeSlurry pump

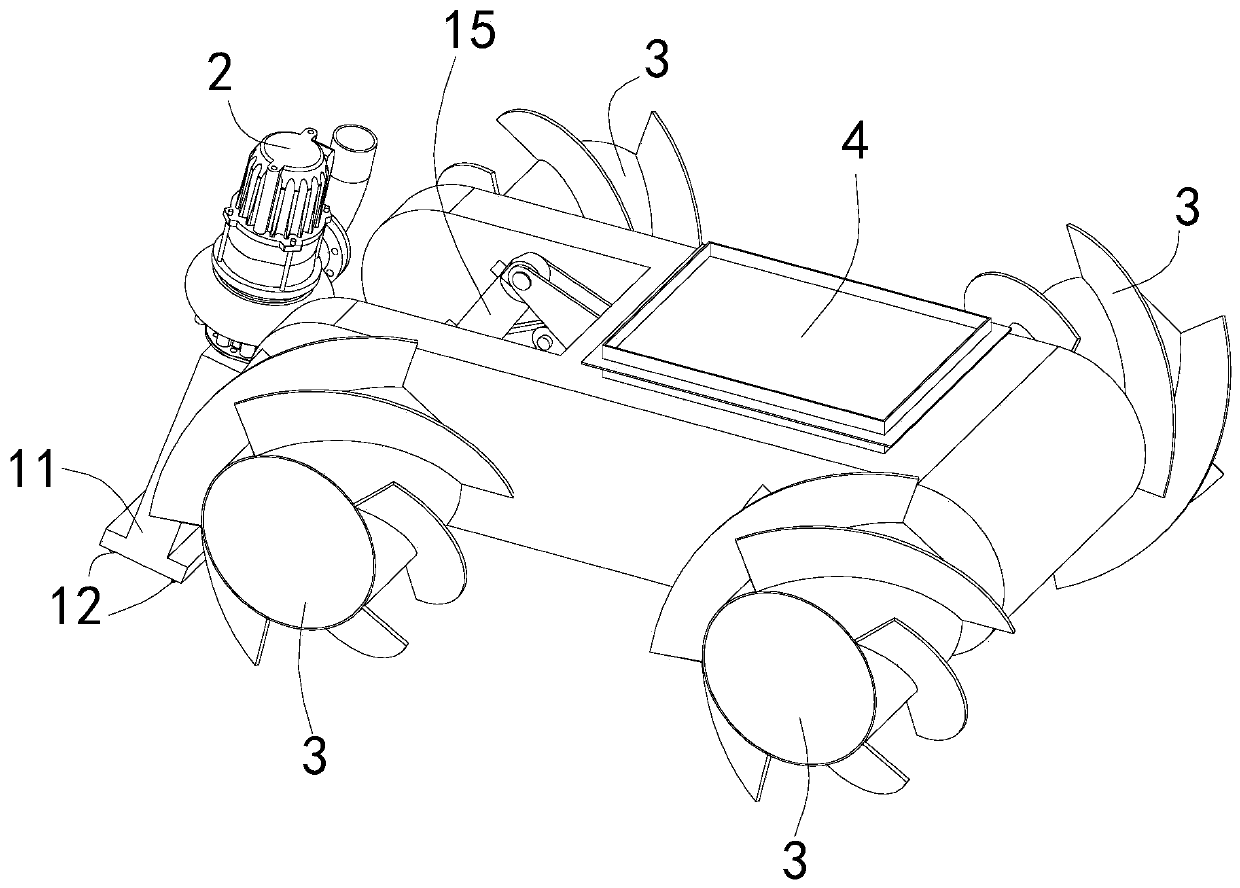

The invention relates to a deep foundation pit dewatering construction device, and belongs to the field of building construction devices. The deep foundation pit dewatering construction device comprises a cart, wherein a water pumping mechanism which is used for pumping slurry in a foundation pit is arranged on the cart, the water pumping mechanism comprises a slurry pump, a water suction pipe is arranged at the suction end of the slurry pump, a flaring suction cup is arranged at the end, away from the slurry pump, of the water suction pipe, a floating assembly which is used for preventing the flaring suction cup from sinking into the bottom of a foundation pit is arranged outside the water suction pipe and is located above the flaring suction cup, a protection frame is arranged outside the flaring suction cup, and the protection frame is located under the floating assembly and is detachably connected with the floating assembly through connecting bolts. According to the deep foundation pit dewatering construction device, the situation that the water suction pipe sinks into the bottom wall of the foundation pit to affect the slurry suction effect can be avoided to a certain extent.

Owner:浙江恒山建设有限公司

Fluff removal mechanism for artificial fur knitting machine

PendingCN108035065AEfficient suctionEfficient removalMechanical cleaningPressure cleaningWork in processEngineering

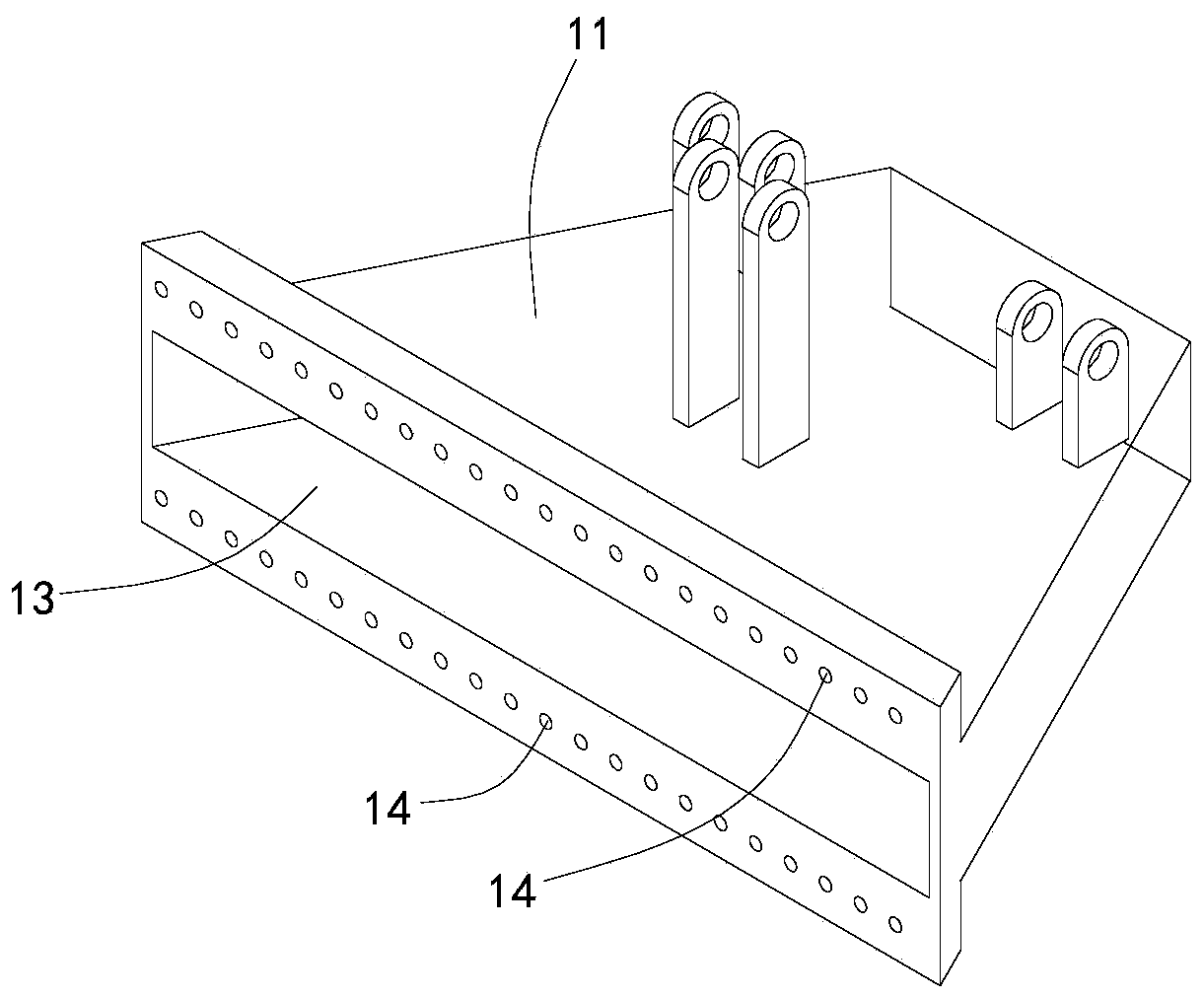

The invention discloses a fluff removal mechanism for an artificial fur knitting machine. The fluff removal mechanism comprises a feed stick group, a discharge stick group, a fluff removing box, upperbeating sticks, lower beating sticks and air suction pipes, wherein the fluff removing box is a cuboid-shaped box body, and two openings are respectively formed in the left end and the right end of the fluff removing box; the feed stick group is positioned at the left side of a fluff removing box body, and the discharge stick group is positioned at the right side of the fluff removing box body; the fluff removing box is internally provided with the plurality of upper beating sticks and lower beating sticks; the upper beating sticks are connected with the top wall of the fluff removing box bymeans of pull-push devices, and the lower beating sticks are connected with the bottom wall of the fluff removing box by means of the pull-push devices; the front side wall and the rear side wall of the fluff removing box are respectively provided with a plurality of through holes; fixed covers are respectively arranged on the front exterior and the rear exterior of the fluff removing box; each fixed cover is provided with the air suction pipe communicated with a cavity. According to the fluff removal mechanism, the upper beating sticks and the lower beating sticks are arranged in the fluff removing box, so that a semi-finished product can be effectively beaten, and fluff is further separated out.

Owner:XINCHANG KAIXIN TEXTILE

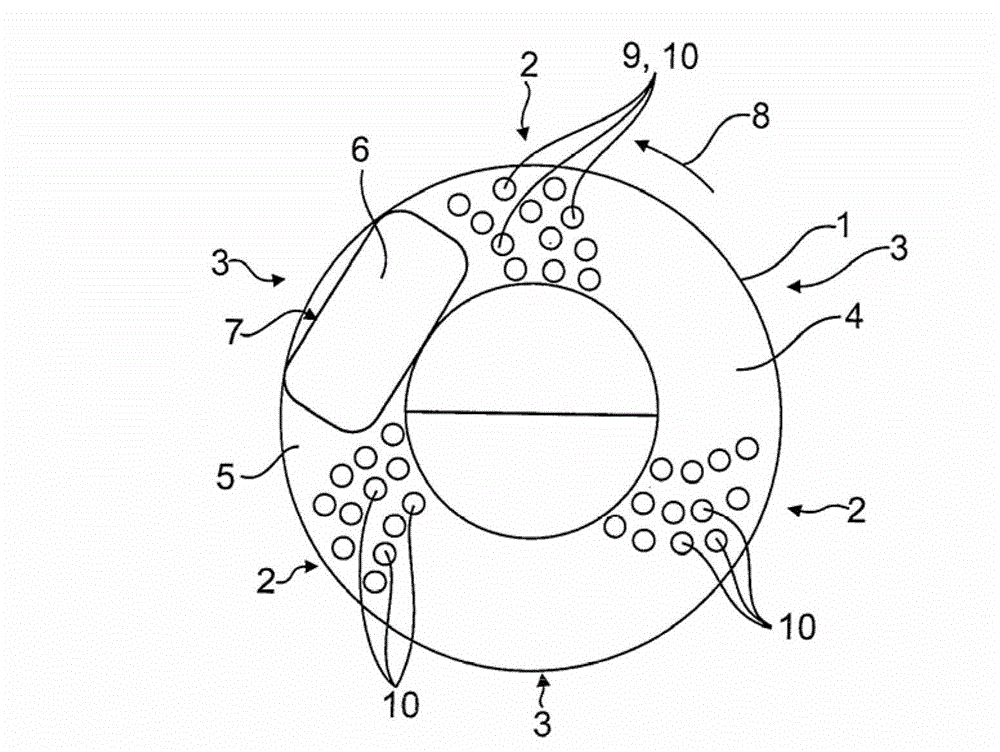

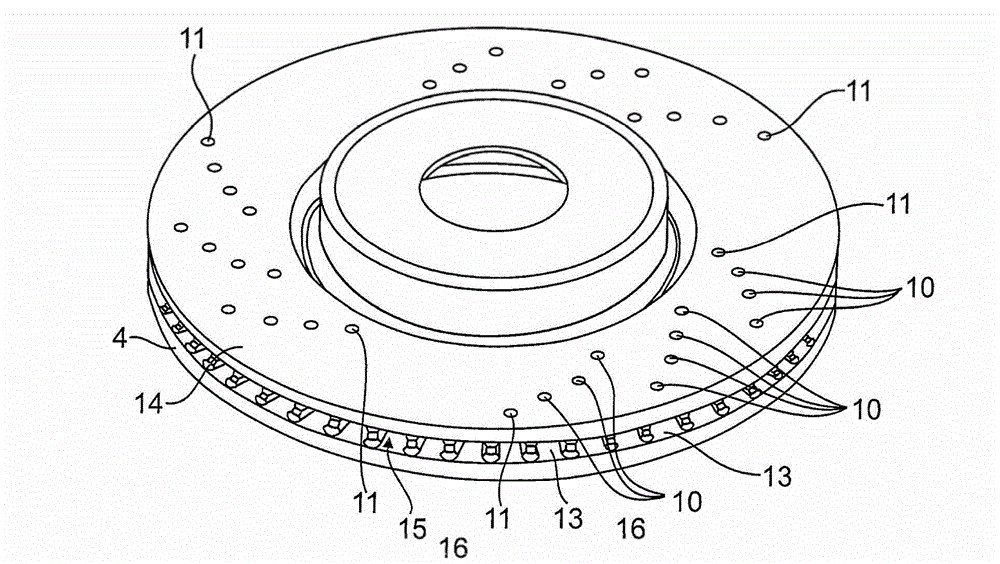

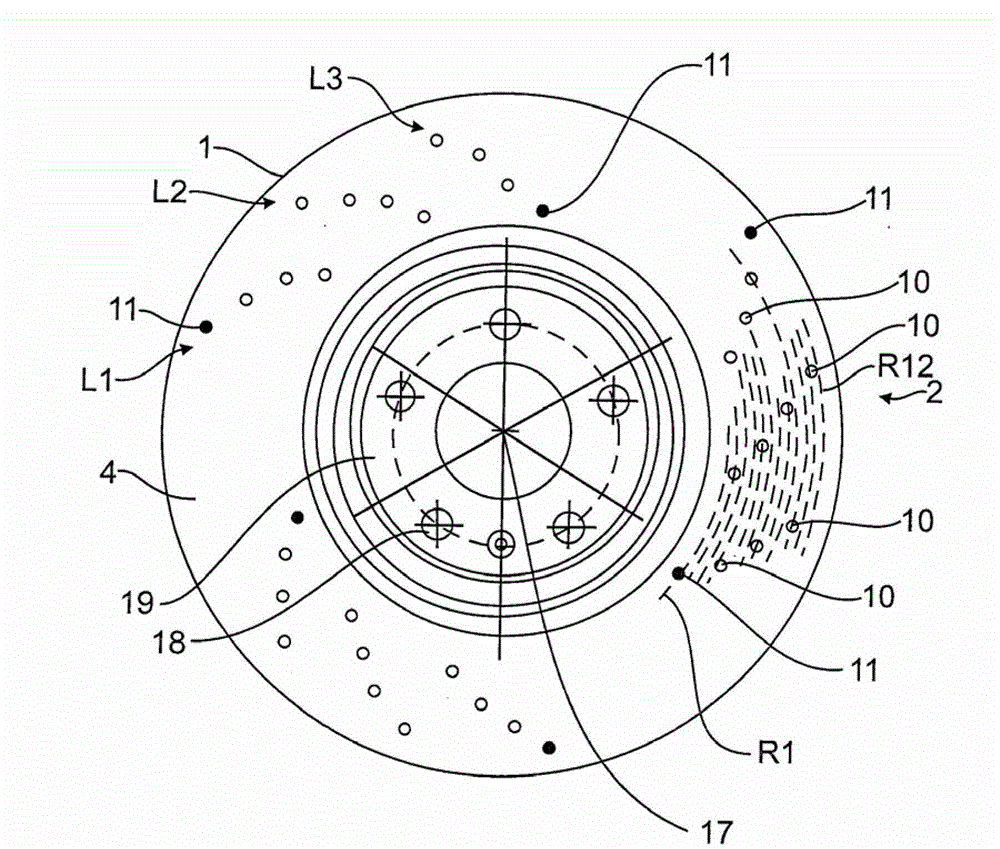

Internally ventilated brake disk

InactiveCN103062261AAvoid dirtGuaranteed suctionBraking discsFriction liningEngineeringMechanical engineering

An internally ventilated brake disk includes friction rings (4, 14) arranged on both sides. Each friction surface of the friction rings engages with a base surface (7) of a brake pad (6) during braking. Cooling channels (13) extend between the friction surfaces and leading to cooling channel openings (15) disposed on a peripheral edge of the brake disk (1). The friction rings (4, 14) comprise through holes (10) extending to the cooling channels (13) from the friction surfaces (5). The through-holes (10) in perforated fan-shaped segments of the friction rings (4, 14) are distributed in the fan-shaped surfaces. Unperforated fan-shaped segments are disposed between the perforated fan-shaped segments (2).The fan-shaped surface of each unperforated segment extends at least over half the base surface (7) of the contacting brake pad (6).

Owner:AUDI AG

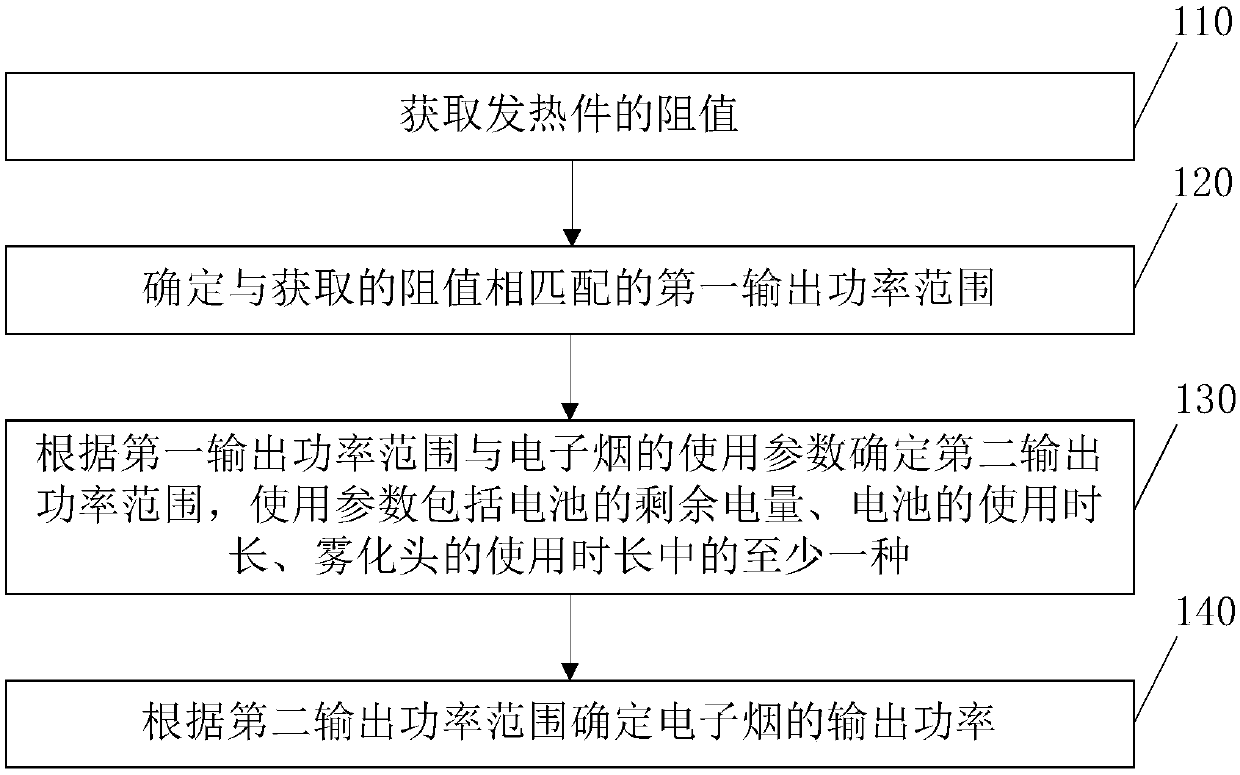

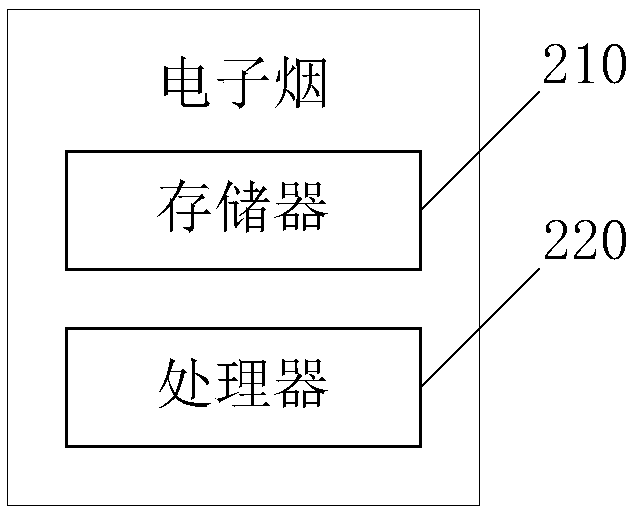

Method for determining output power of electronic cigarette, electronic cigarette and computer storage medium

ActiveCN110522079AImprove experienceGuaranteed suction effectTobacco devicesEngineeringElectronic Cigarette Use

The invention provides a method for determining the output power of an electronic cigarette, the electronic cigarette and a computer storage medium. The method comprises the steps of obtaining the resistance value of a heating element; determining a first output power range matched with the obtained resistance value; determining a second output power range according to the first output power rangeand the use parameters of the electronic cigarette, wherein the use parameters comprise at least one of the remaining capacity of a battery, the use duration of the battery and the use duration of anatomizing head; and determining the output power of the electronic cigarette according to the second output power range. According to the present invention, the output power of the electronic cigarette can be matched with the currently installed heating element and the use state of the electronic cigarette, and meanwhile the smoking effect and the smoking safety are guaranteed.

Owner:CHANGZHOU PATENT ELECTRONICS TECH CO LTD

Device and method for removing ice cubes in refrigerator by means of reciprocal vibration

InactiveCN111578602AChange state of motionImprove adsorption capacityLighting and heating apparatusDefrostingIceboxStructural engineering

The invention provides a device and method for removing ice cubes in a refrigerator by means of reciprocal vibration, and relates to field of articles of daily use. The device for removing the ice cubes in the refrigerator by means of reciprocal vibration comprises a left fixed box, wherein a reciprocating driving rod is arranged at the bottom of the left fixed box, the bottom of the reciprocatingdriving rod is bonded to the top of a side hollow fixed cylinder, the bottom of the side hollow fixed cylinder is bonded to the top of a connecting suction cup, and a right mounting box and a grabbing handle are bonded to the right side of the left fixed box. According to the device for removing the ice cubes in the refrigerator by means of reciprocal vibration, after the connecting suction cup is sucked on the ice surface, a driving motor controls a stirring rod to be in contact with protrusion particles, so that the connecting suction cup constantly makes reciprocal vibration after being connected with the ice cubes, and vibration force generated through vibration is utilized for gradually lowering the bonding force between the ice cubes and the inner wall of the refrigerator, which helps to remove large ice cubes. Meanwhile, the ice cubes are not in contact with the refrigerator and do not apply force to the refrigerator either, which avoids the damage to the refrigerator incurredby the traditional mode of ice removal through scraping or heating, and can guarantee the service life of the refrigerator.

Owner:蒋远民

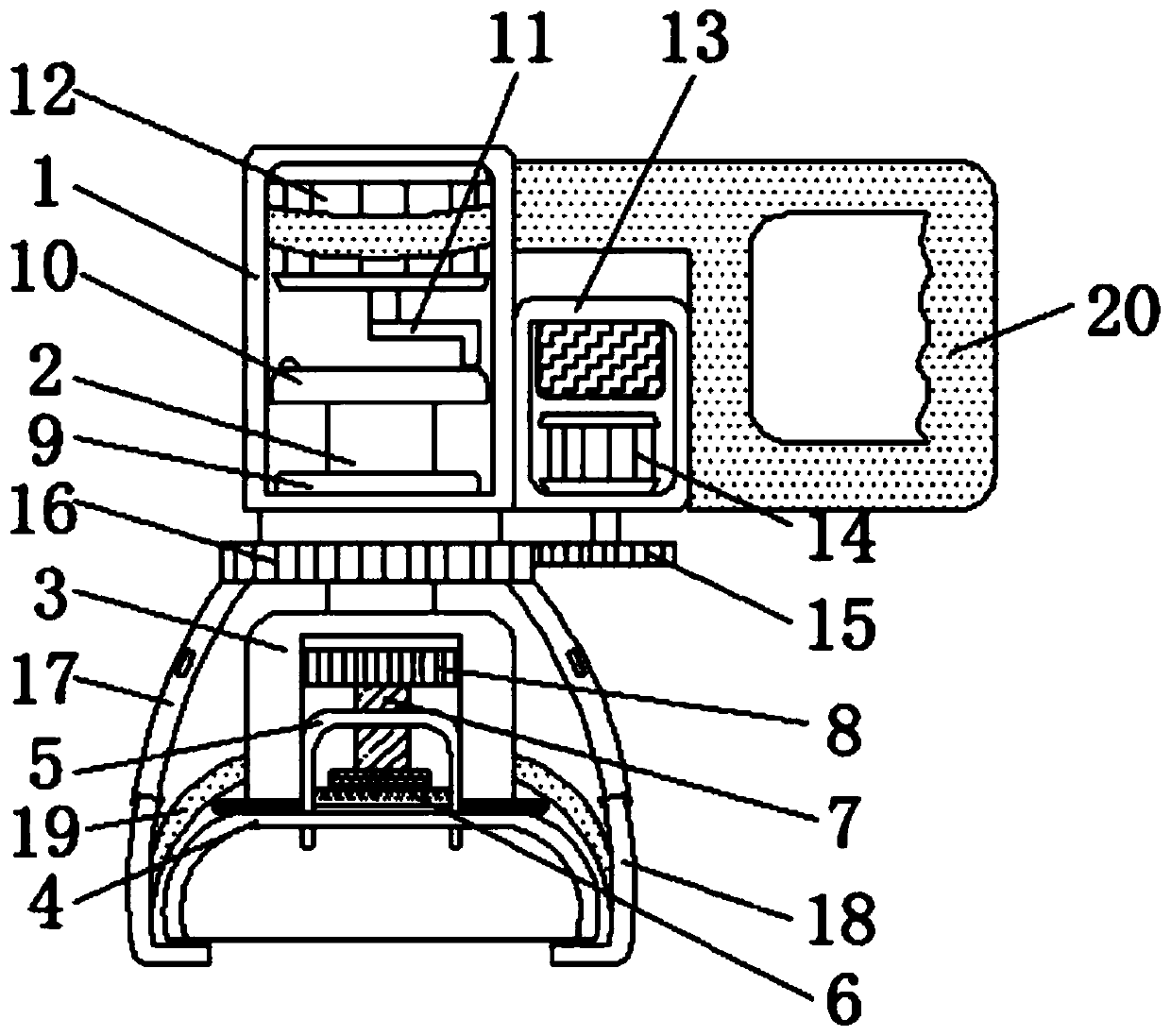

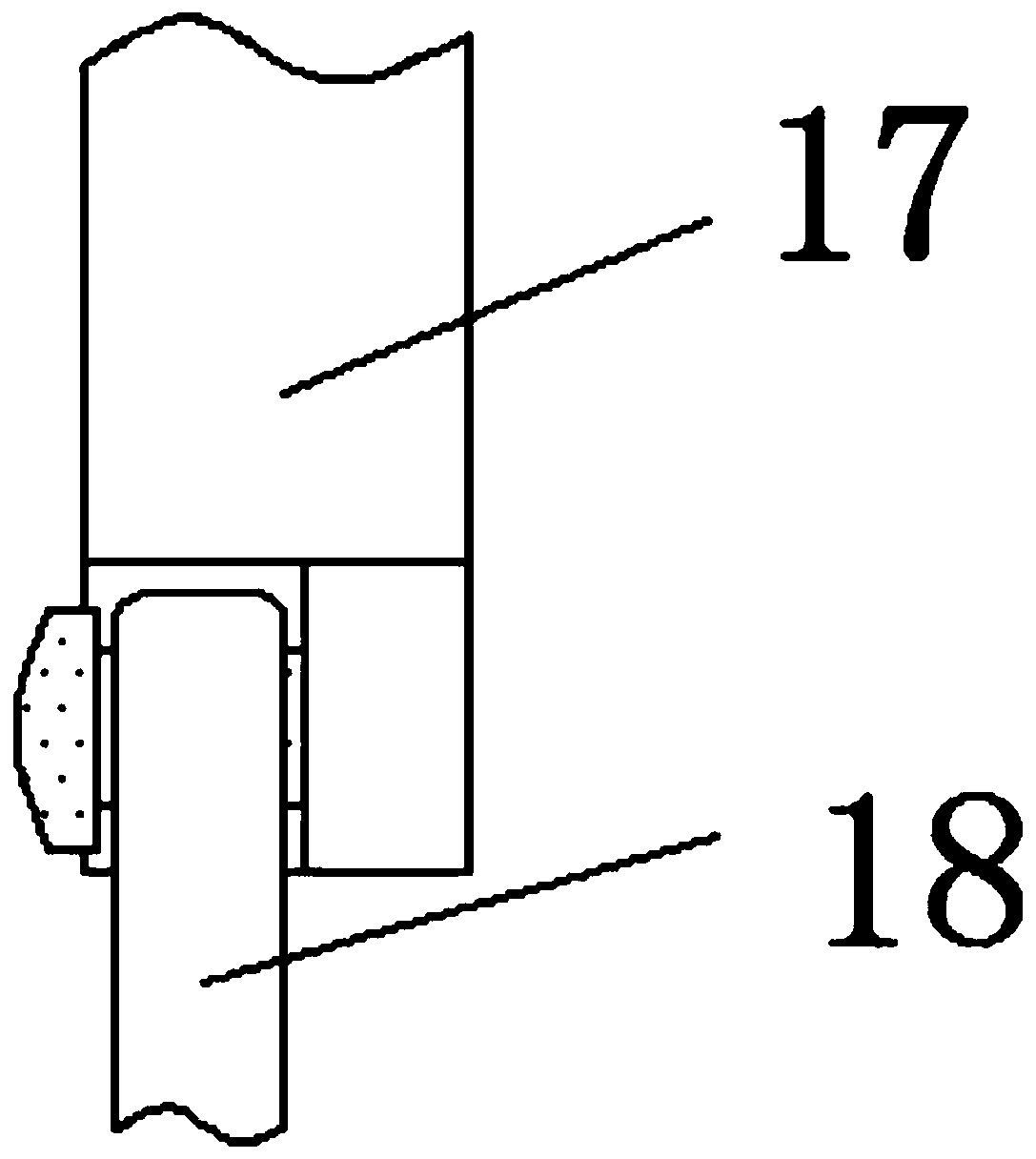

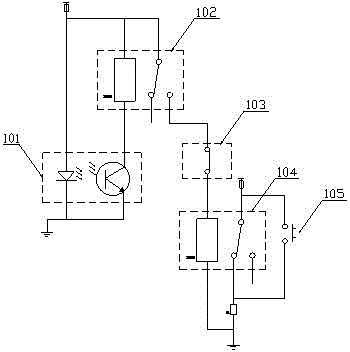

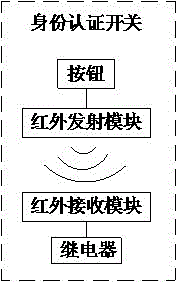

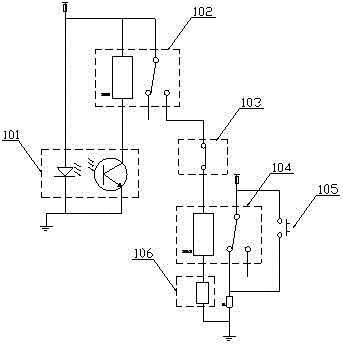

Safe anti-electric-theft electric energy meter case

InactiveCN105301309AImprove securityAvoid private lappingTime integral measurementElectromagnetic lockEngineering

The invention discloses a safe anti-electric-theft electric energy meter case which comprises a housing, a housing door and a master lock. The safe anti-electric-theft electric energy meter case further comprises an electromagnetic lock. The electromagnetic lock comprises a lock body which is arranged on the housing, and an adsorption iron plate which is used in cooperation with the lock body. The adsorption iron plate is movably arranged on the housing door through a drawing mechanism. The safe anti-electric-theft electric energy meter case is advantageous in that the electric energy meter case is provided with an identity authentication switch; when a user opens the electric energy meter case privately, an electric leakage protector is started, thereby switching off a power supply line, preventing private line connection by the user, and furthermore eliminating potential safety hazards.

Owner:STATE GRID SHANDONG ELECTRIC POWER COMPANY RIZHAOPOWER SUPPLY +1

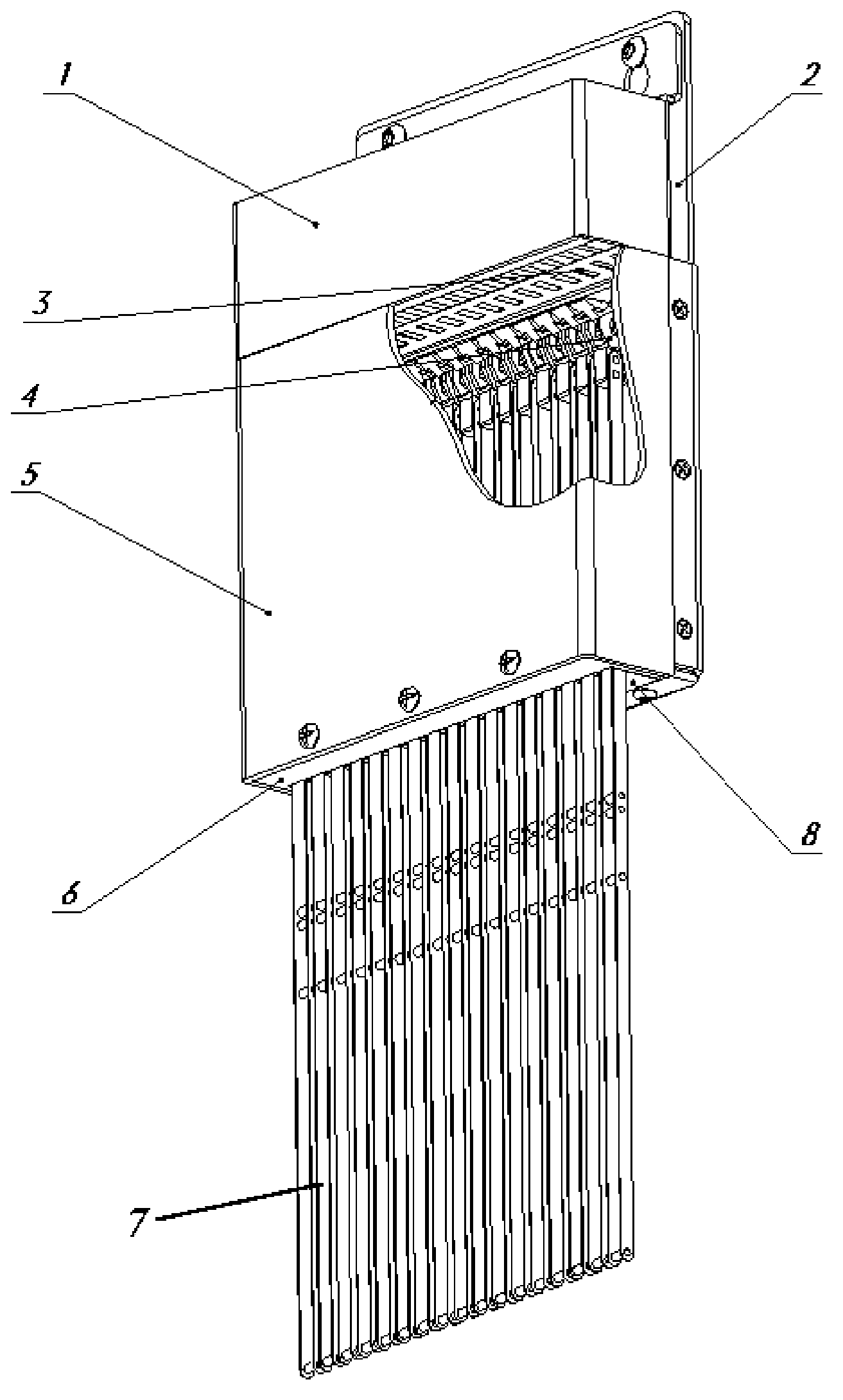

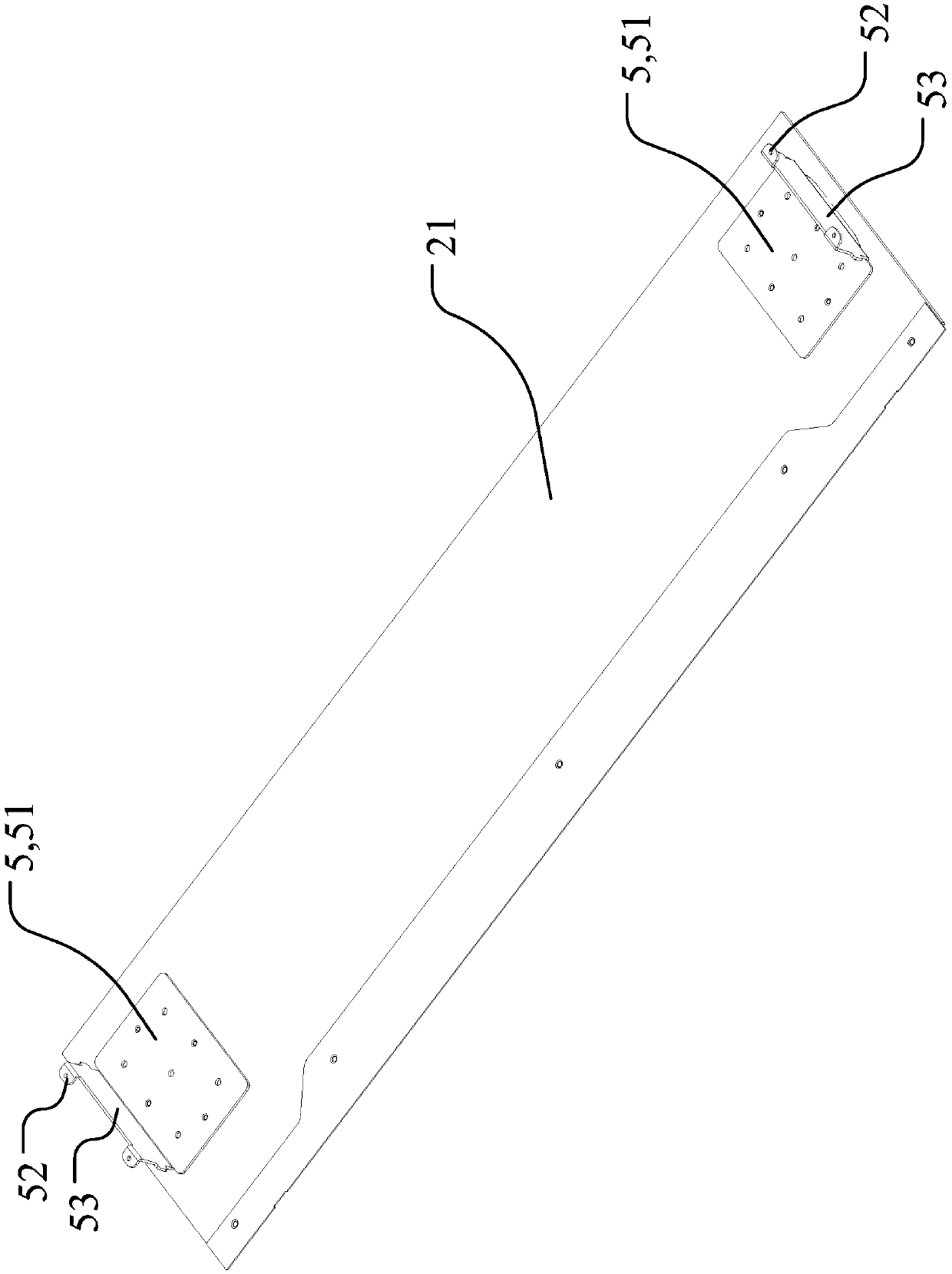

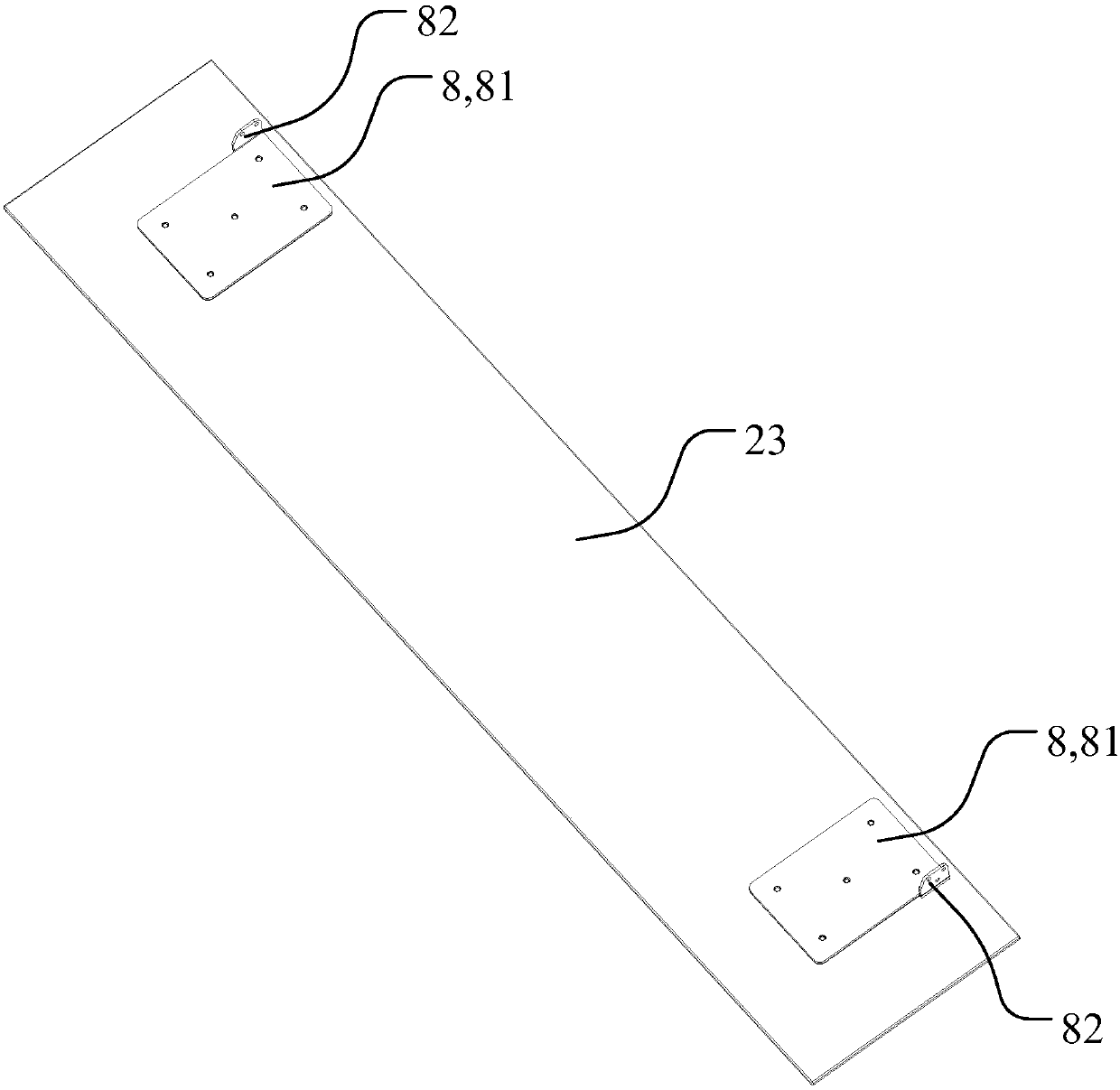

Harness component for electromagnetic heddle selection

The invention discloses a harness component for electromagnetic heddle selection, which comprises a heddle selecting electromagnetic module. The heddle selecting electromagnetic module is arranged at the upper part of a fixing plate; the heddle selecting electromagnetic module comprises an electromagnet; a heddle end part magnetic head is arranged below the electromagnet; a heddle is connected to the lower end of the heddle end part magnetic head; a heddle spacing bar is arranged at the lower part of the fixing plate; an isolated protective cover is connected on the fixing plate; the isolated protective cover encloses the suction part of the electromagnet and the heddle end part magnetic head in the heddle selecting electromagnetic module, and the isolated protective cover is made of a transparent material. According to the harness component, the isolated protective cover is arranged on the fixing plate of the electromagnetic module in the heddle in electromagnetic heddle selection, and a suction work area of the electromagnetic module and the heddle are enclosed in a sealed space, therefore, sundries such as a fiber, floss and dust in an external environment can be isolated; the suction effect is ensured, and the weaving process is ensured.

Owner:PACIFIC MECHATRONIC GRP

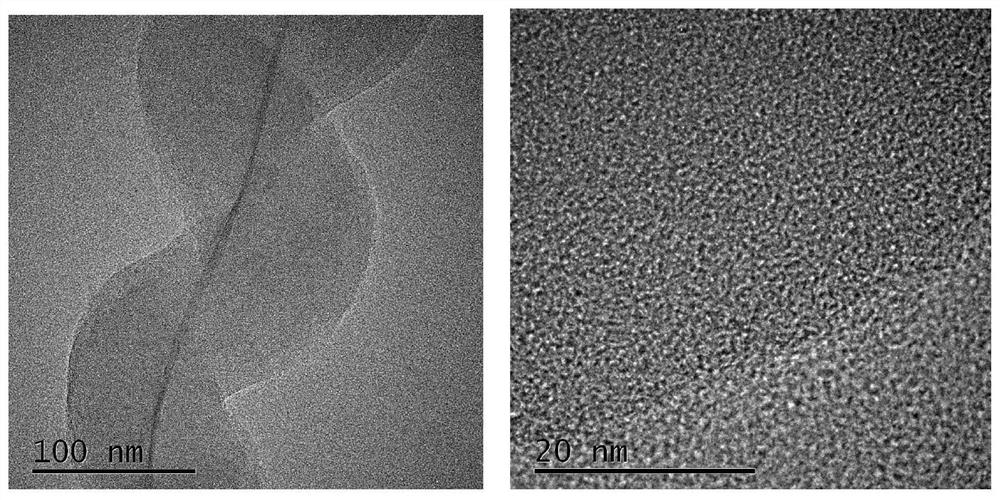

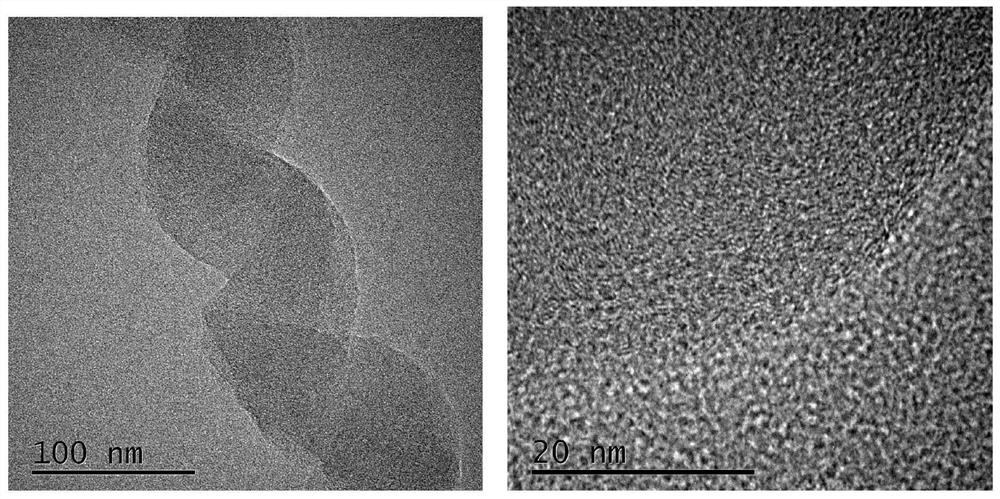

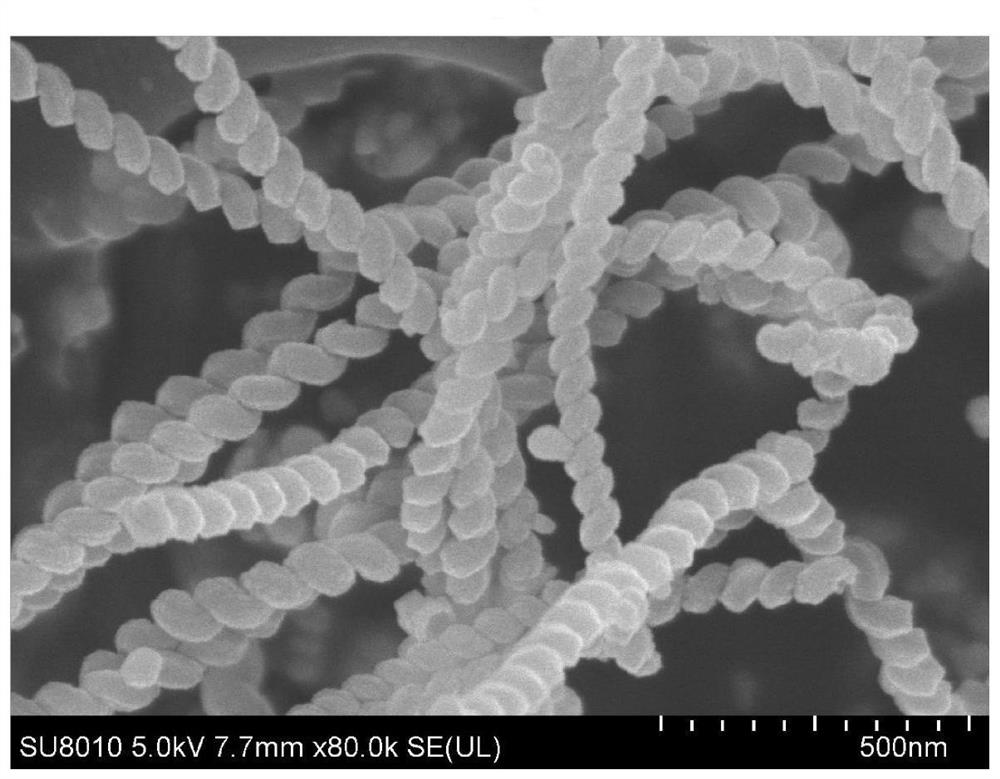

Preparation method of ferric oxide/spiral nano carbon fiber composite negative electrode material

ActiveCN112786869ALarge specific surface areaImprove stabilityMaterial nanotechnologySecondary cellsFiberCarbon fibers

The invention discloses a preparation method of a ferric oxide / spiral carbon nanofiber composite negative electrode material, which comprises the following steps: placing spiral carbon nanofibers in a vacuum environment, and carrying out heat treatment at 700-900 DEG C for 2-4 hours for later use; adding the spiral carbon nanofibers subjected to heat treatment into a mixed solution of water and ethanol, and performing ultrasonic dispersion to obtain a solution A; adding Fe(NO3)3.9H2O into the solution A, and obtaining a solution B after ultrasonic dispersion; placing the solution B in an oil bath at the temperature of 100-140 DEG C to react for 4-6 hours, and then performing suction filtration and drying to obtain a solid reactant; and putting the solid reactant into a tubular furnace, performing heating to 300-600 DEG C at a rate of 510 DEG C / min, and performing calcining for 2-4 hours to obtain the ferric oxide / spiral nano carbon fiber composite negative electrode material. The composite negative electrode material obtained by the preparation method is good in cycling stability, high in electrochemical performance, free of acidification or activation treatment steps, capable of effectively ensuring the safety of experimenters, simple in preparation process and suitable for industrial production.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

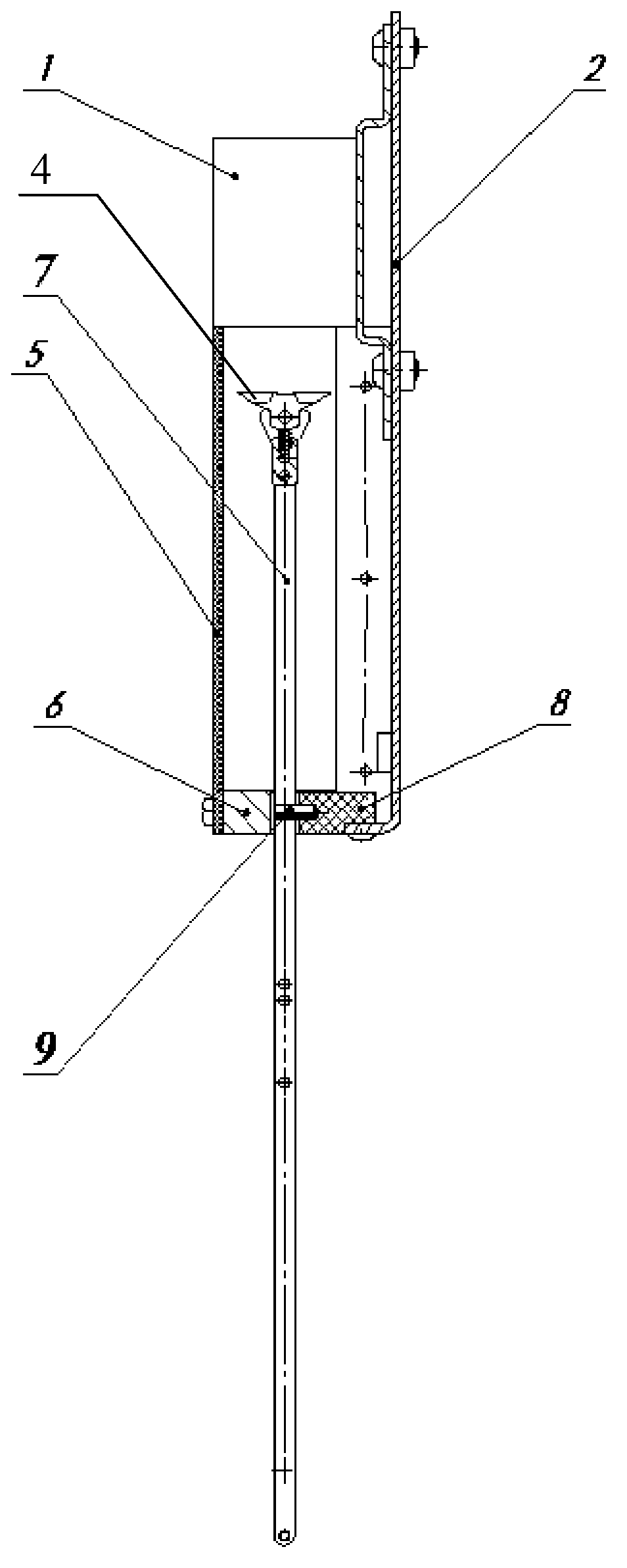

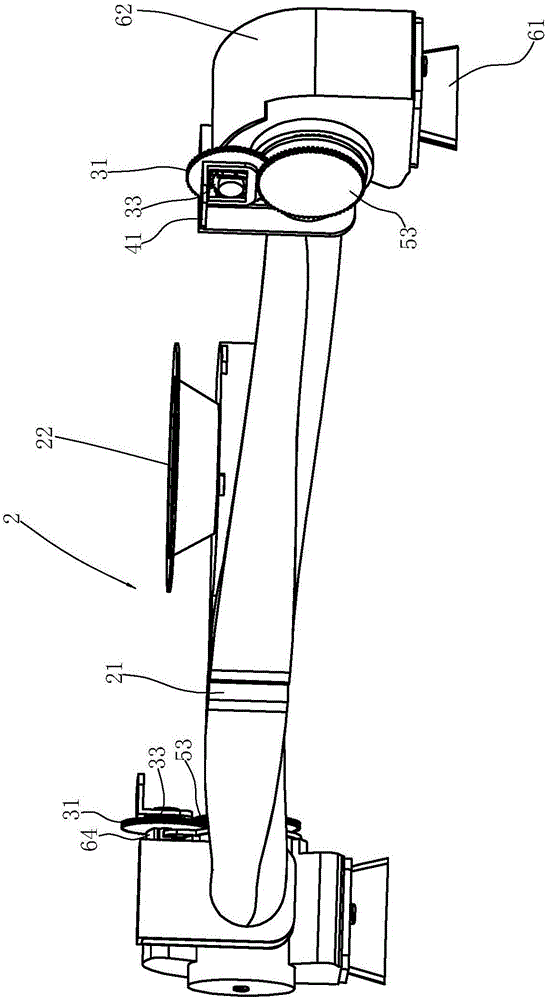

Mine hydrogeological condition detection device

ActiveCN112943232AGuaranteed collectionEfficient collectionBorehole/well accessoriesMining engineeringElectric machinery

The invention discloses a mine hydrogeological condition detection device. The mine hydrogeological condition detection device comprises a main body, universal wheels, a handle, a controller, a positioning air cylinder, a right stepping motor, a sampling disc, a supporting frame, a sampling part and a collecting part, wherein the four corners of the bottom end of the main body are each provided with a vertical universal wheel, the vertical handle is fixed to the top end of the left part of the main body, and the horizontal controller is fixed at the top end of the left part of the main body. According to the mine hydrogeological condition detection device, adjusting holes with proper sizes can be selected according to samples with different textures, so that effective collection of the samples can be guaranteed, the samples can be crushed, transported, classified and stored, and subsequent detection and analysis are greatly facilitated,; automatic drilling and breaking functions can be achieved, the sample extraction speed is greatly increased, and the sampling complexity is reduced, so that the working efficiency of geological exploration is improved, and a filter screen is used for ensuring the suction effect and preventing a suction pipe from being blocked at the same time.

Owner:山东丰源远航煤业有限公司北徐楼煤矿

Underwater desilting robot

PendingCN110565713AIncrease concentrationGuaranteed suction effectMechanical machines/dredgersVehicle frameUnderwater

The invention provides an underwater desilting robot. By arranging nozzles around a silt suction cavity, high-speed jet flow is sprayed out to cut and disturb silt, the silt concentration is greatly increased, meanwhile parallel water curtains formed by the high-speed jet flow form a sectional negative pressure area, and the suction effect of a suction cup is ensured. By arranging a link mechanismin cooperation with a wheel-drive vehicle frame, underwater operations can be quite conveniently conducted, and the height of the suction cup is adjusted according to the silt height. By arranging adriving wheel comprising a roller and a spiral rib, on one hand, walking in the silt is facilitated, and wheels are prevented from sinking in the silt; and on the other hand, the silt can be stirred and dispersed so as to be conveniently sucked.

Owner:SAFECLEEN TECH

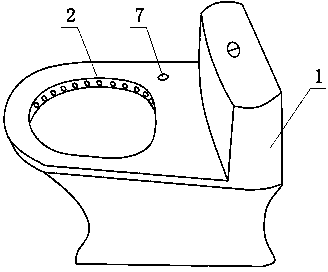

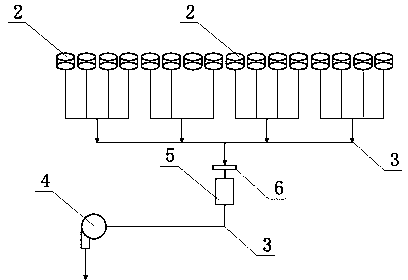

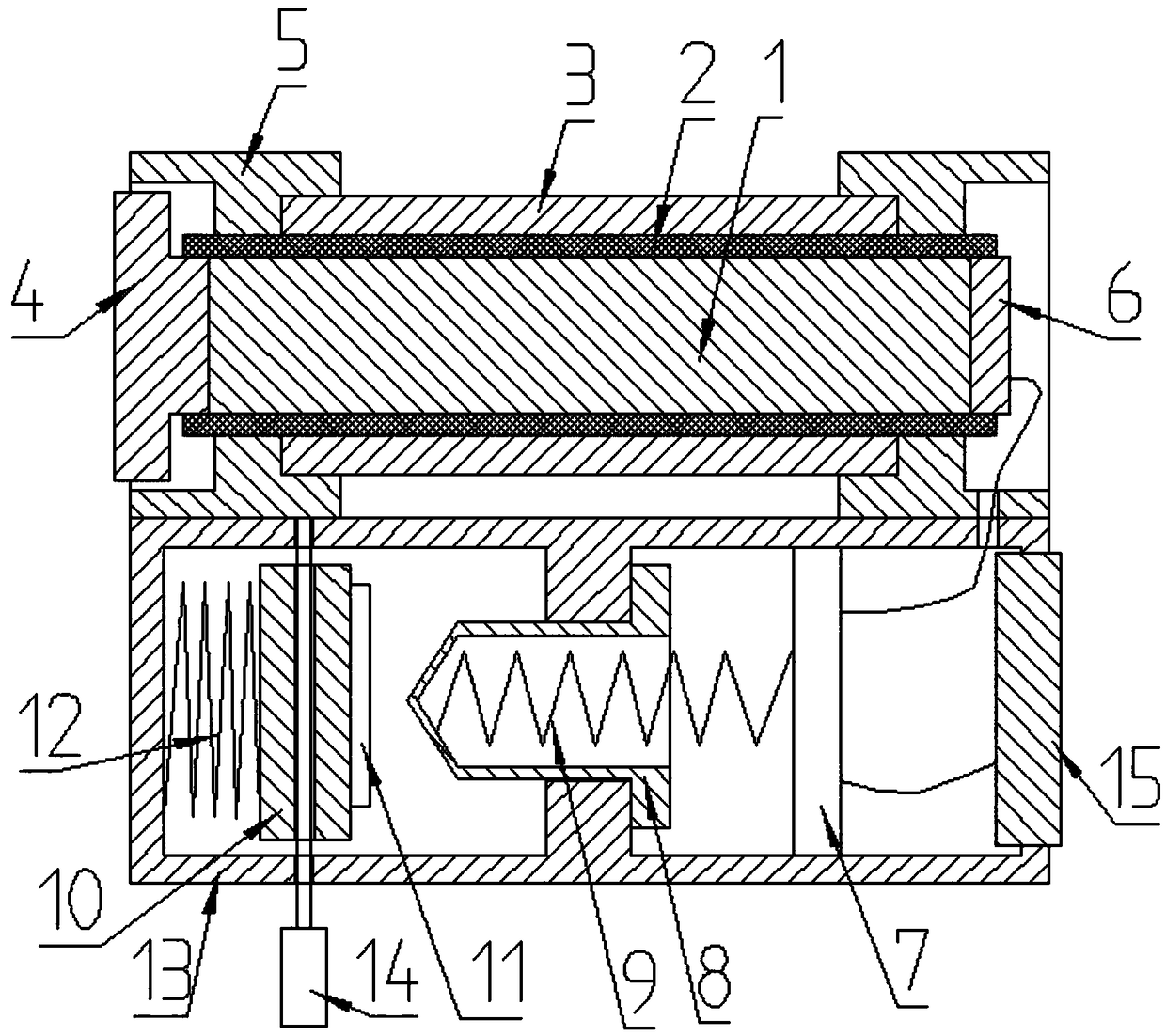

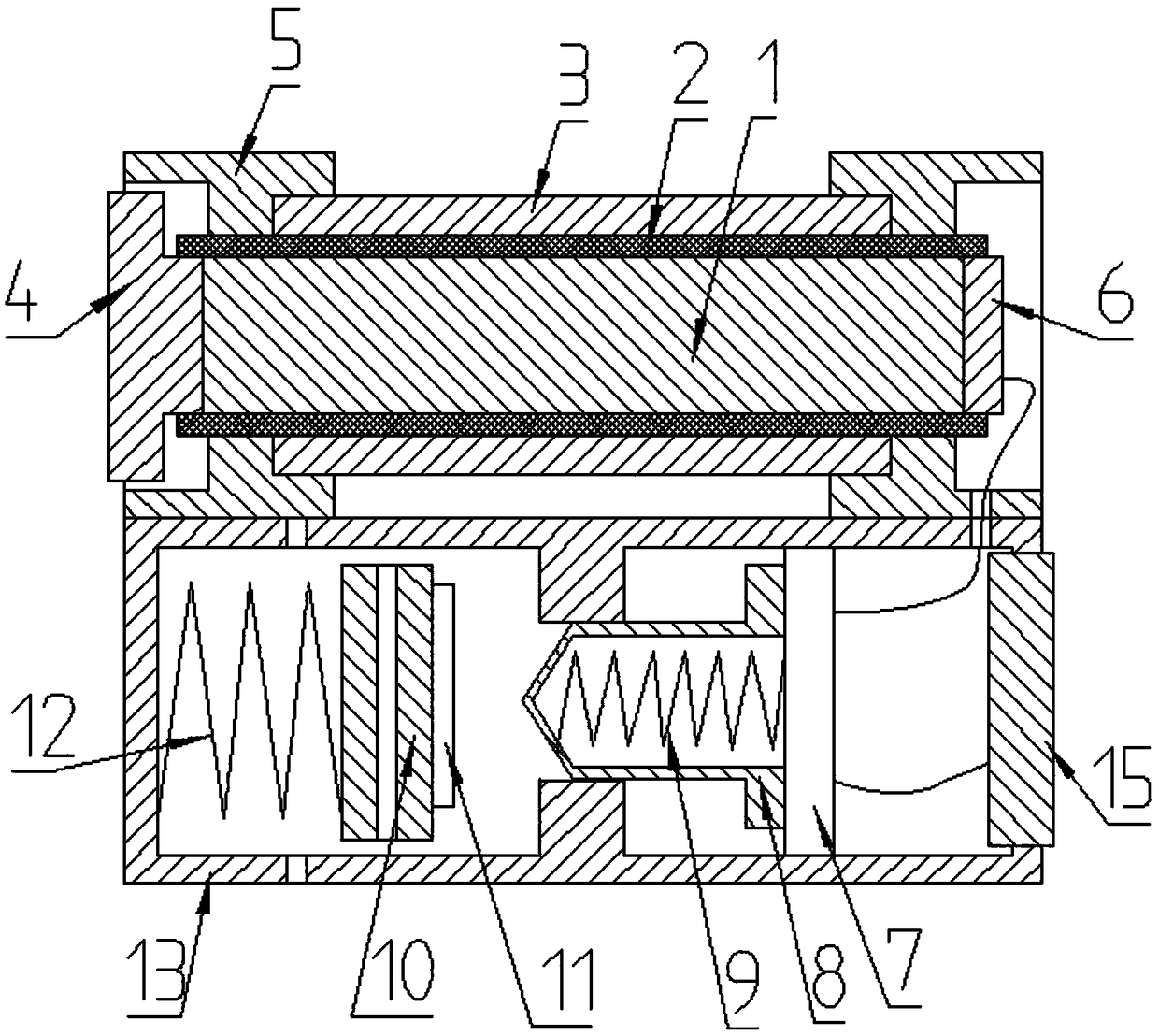

Toilet bowl

The invention discloses a bathroom utensil, particularly relates to a toilet bowl, and belongs to the technical field of bathroom utensils. The toilet bowl comprises a toilet bowl body. Air holes are formed in the upper edge of the toilet bowl body, evenly formed in the periphery of the toilet bowl body, and communicated with an air suction way, the air suction way extends out of a room, and an exhaust fan is further arranged on the air suction way. The toilet bowl is ingenious in design, simple in structure and comfortable and convenient to use, air can be actively sucked when the toilet bowl is in use, peculiar smell air generated in use of the toilet bowl can be efficiently exhausted through the manufactured micro-negative-pressure environment, and interference in the external is less.

Owner:张仕霖

High-voltage fuse

The invention discloses a high-voltage fuse. The high-voltage fuse comprises a support post, a fuse wire, a shell, a left cover plate, end caps and a right cover plate, wherein the fuse wire wraps thesupport post, the shell wraps the fuse wire, two ends of the fuse wire are respectively connected with the left cover plate and the right cover plate, the end caps are respectively arranged at two ends of the fuse wire, and the high-voltage fuse is characterized in that the material of the shell is transparent plastic or transparent glass. The material of the shell is the transparent plastic or the transparent glass, thus, the high-voltage fuse can be used for intuitively observing and determining whether the internal fuse wire is fused or not by an eye, the risk that the fused high-voltage fuse cannot be timely found out is prevented, and replacement of the high-voltage fuse is facilitated.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

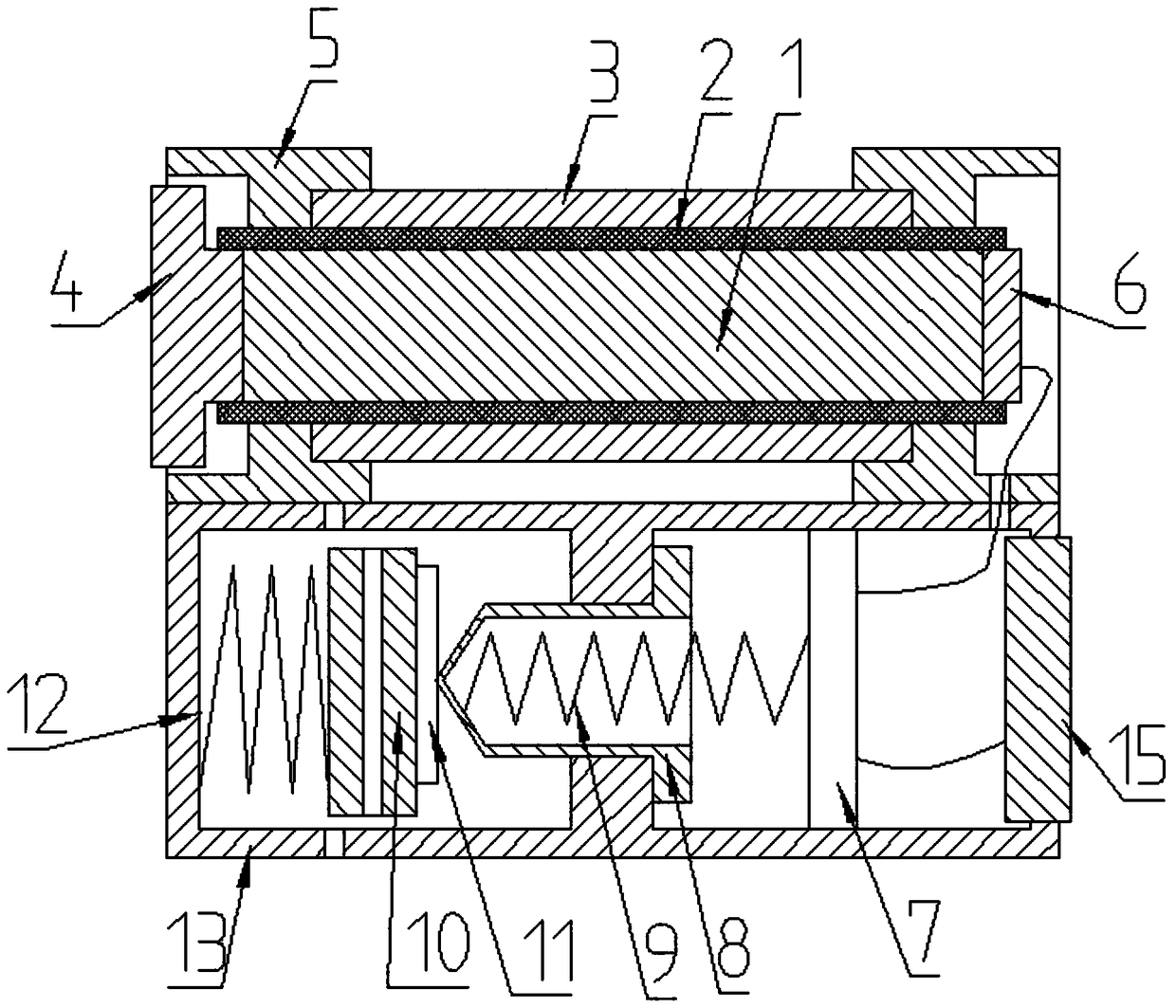

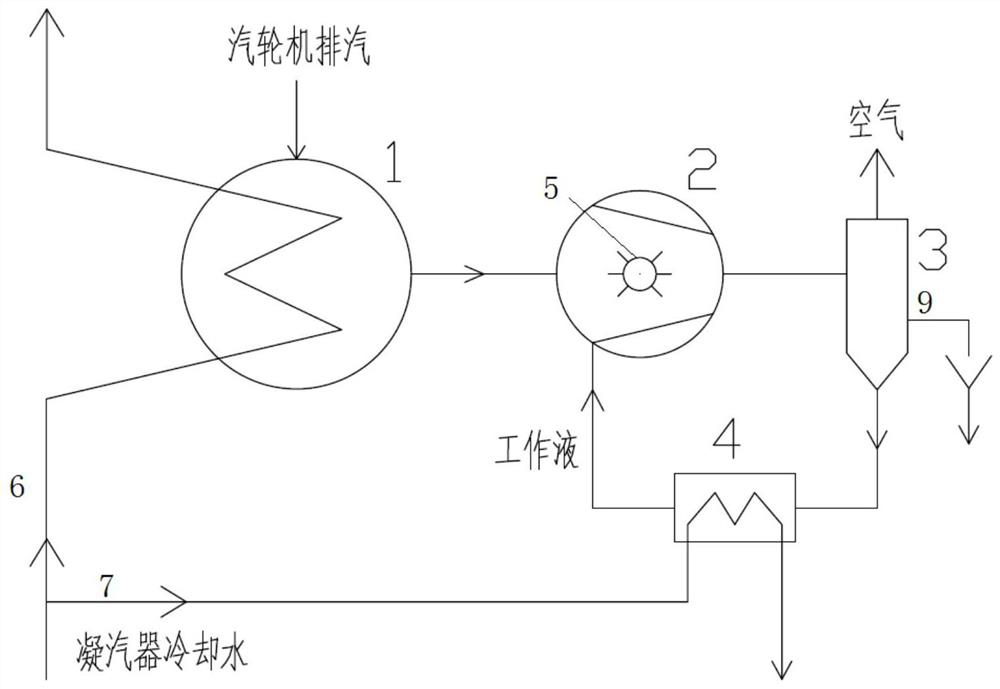

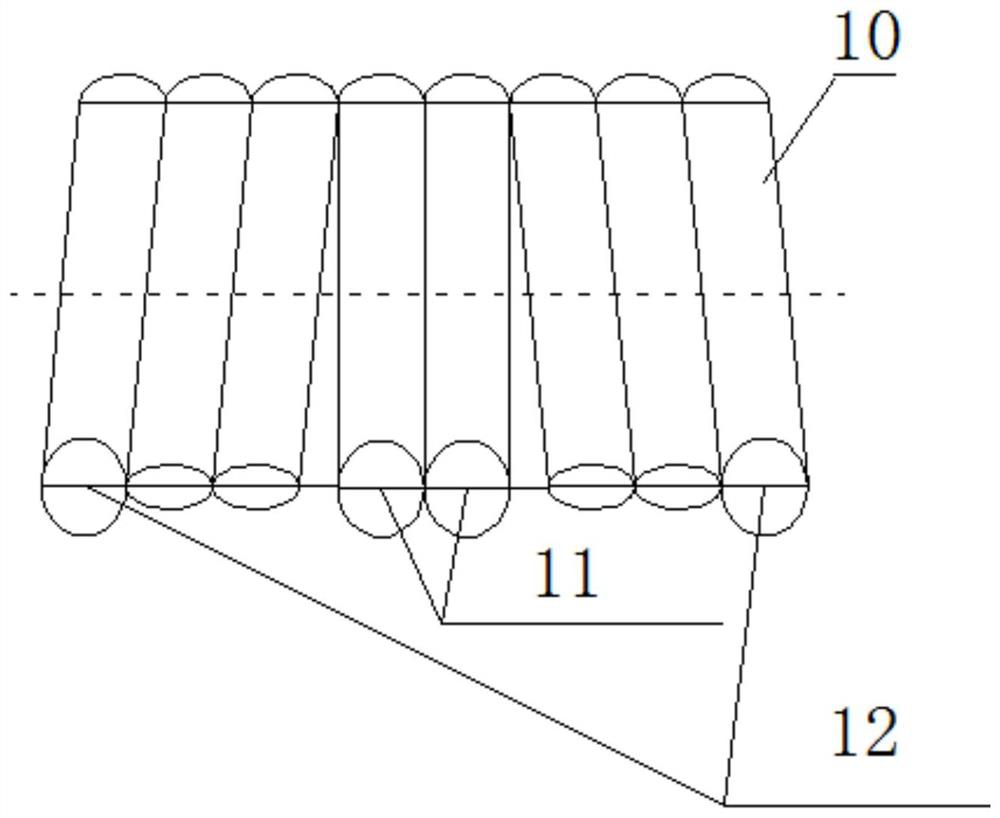

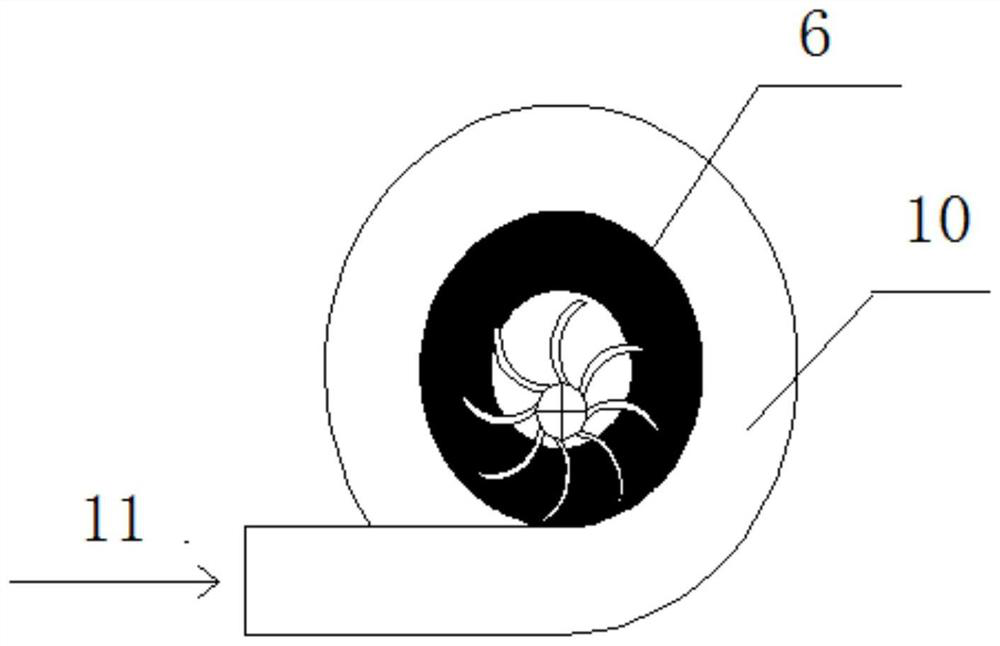

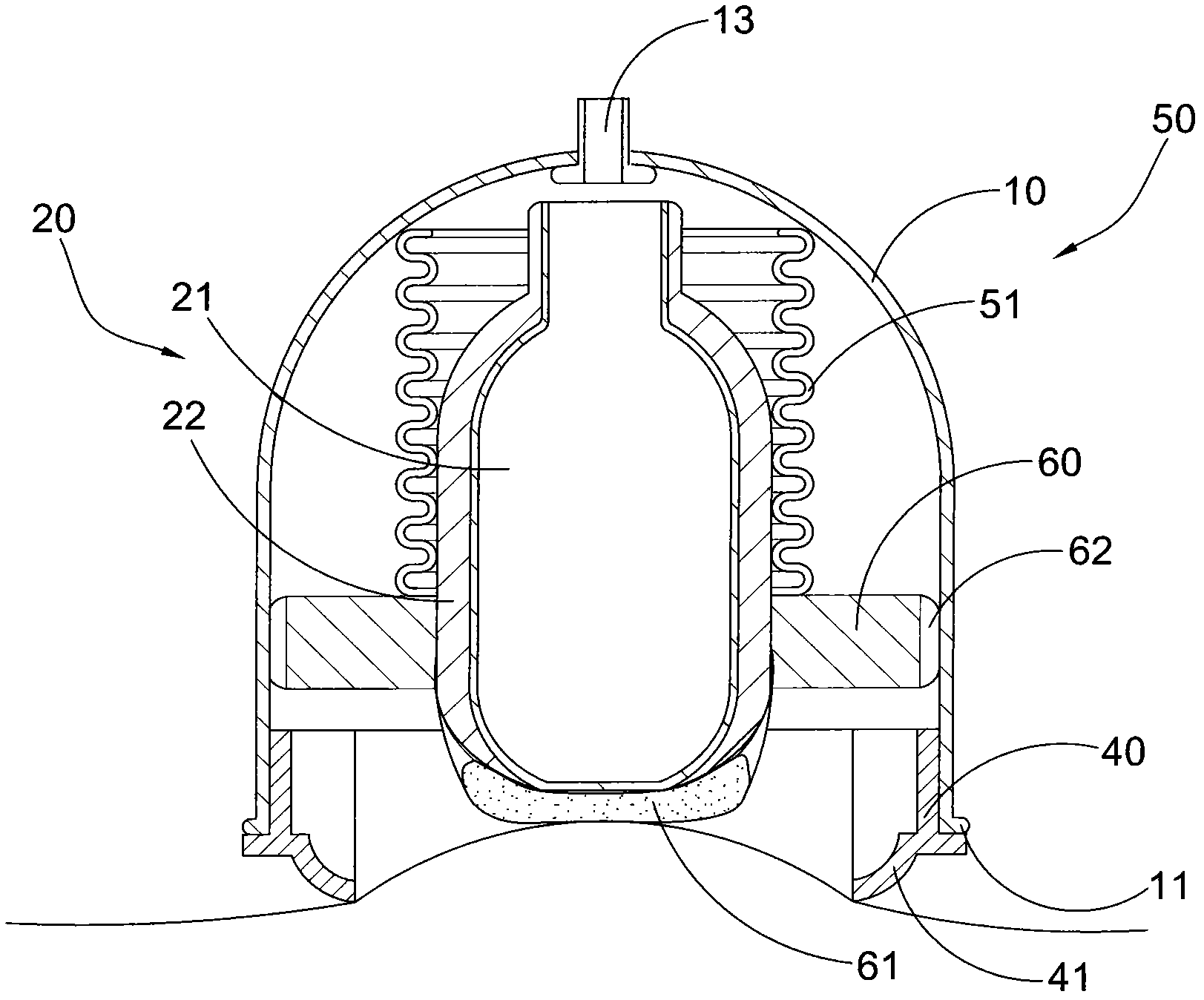

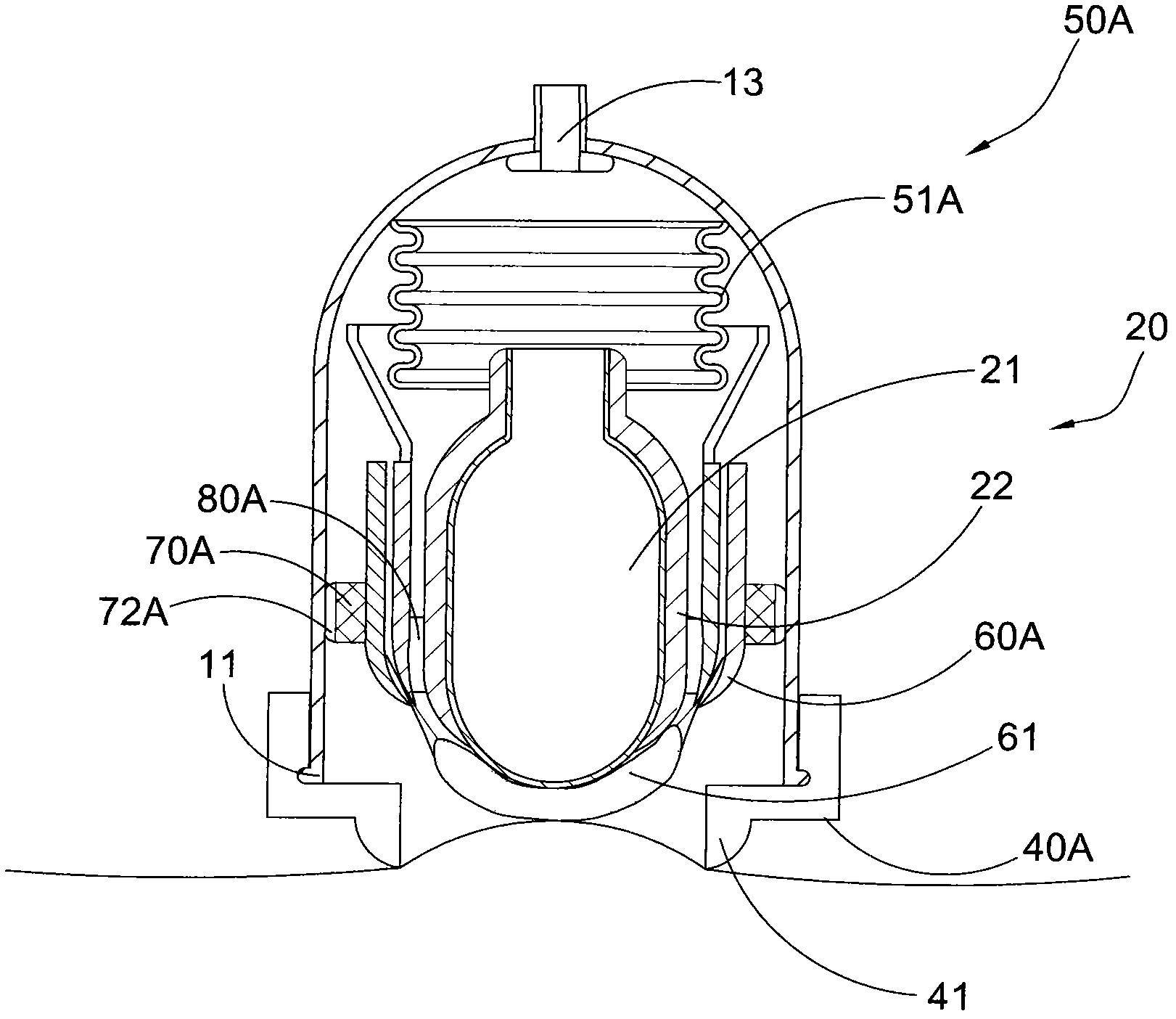

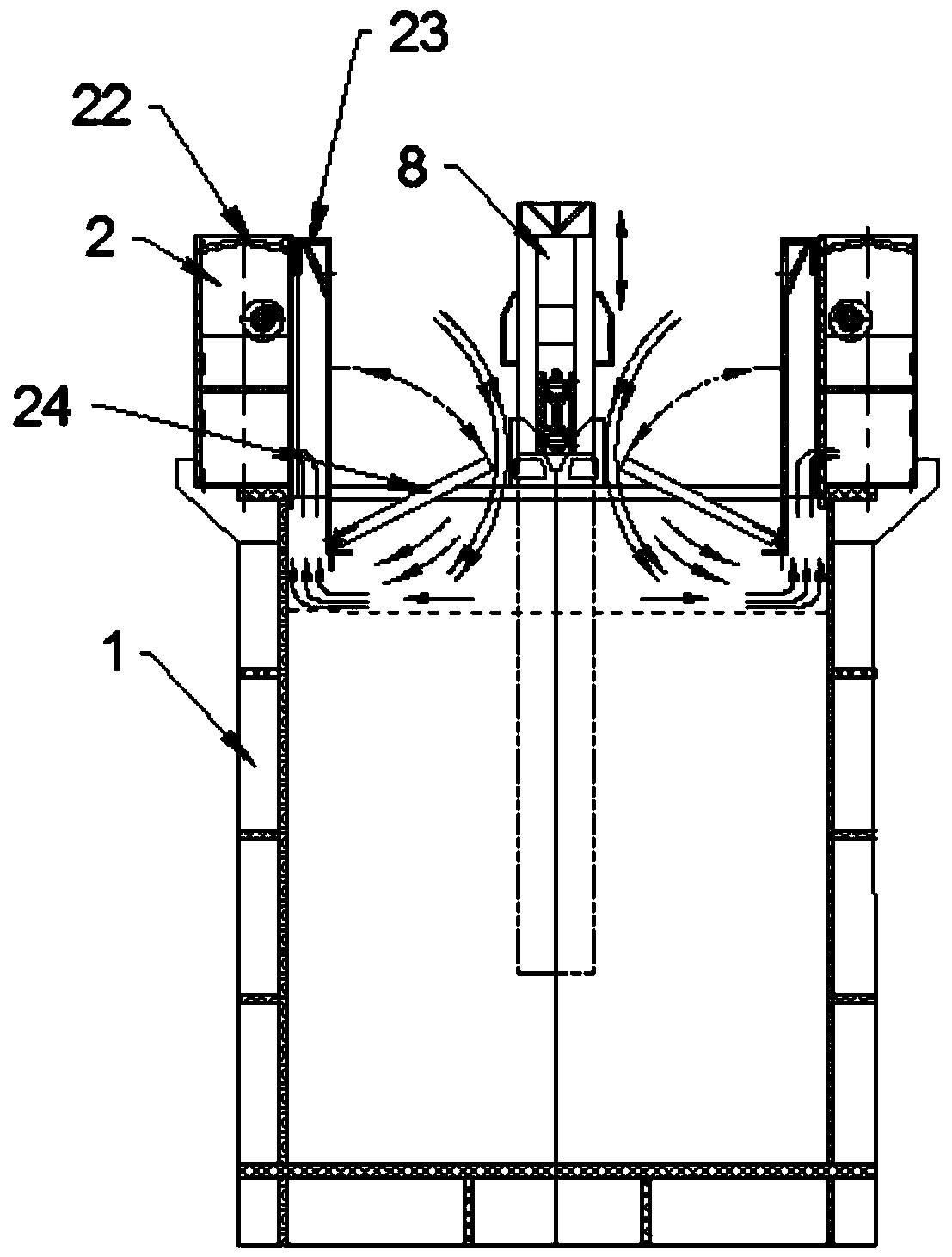

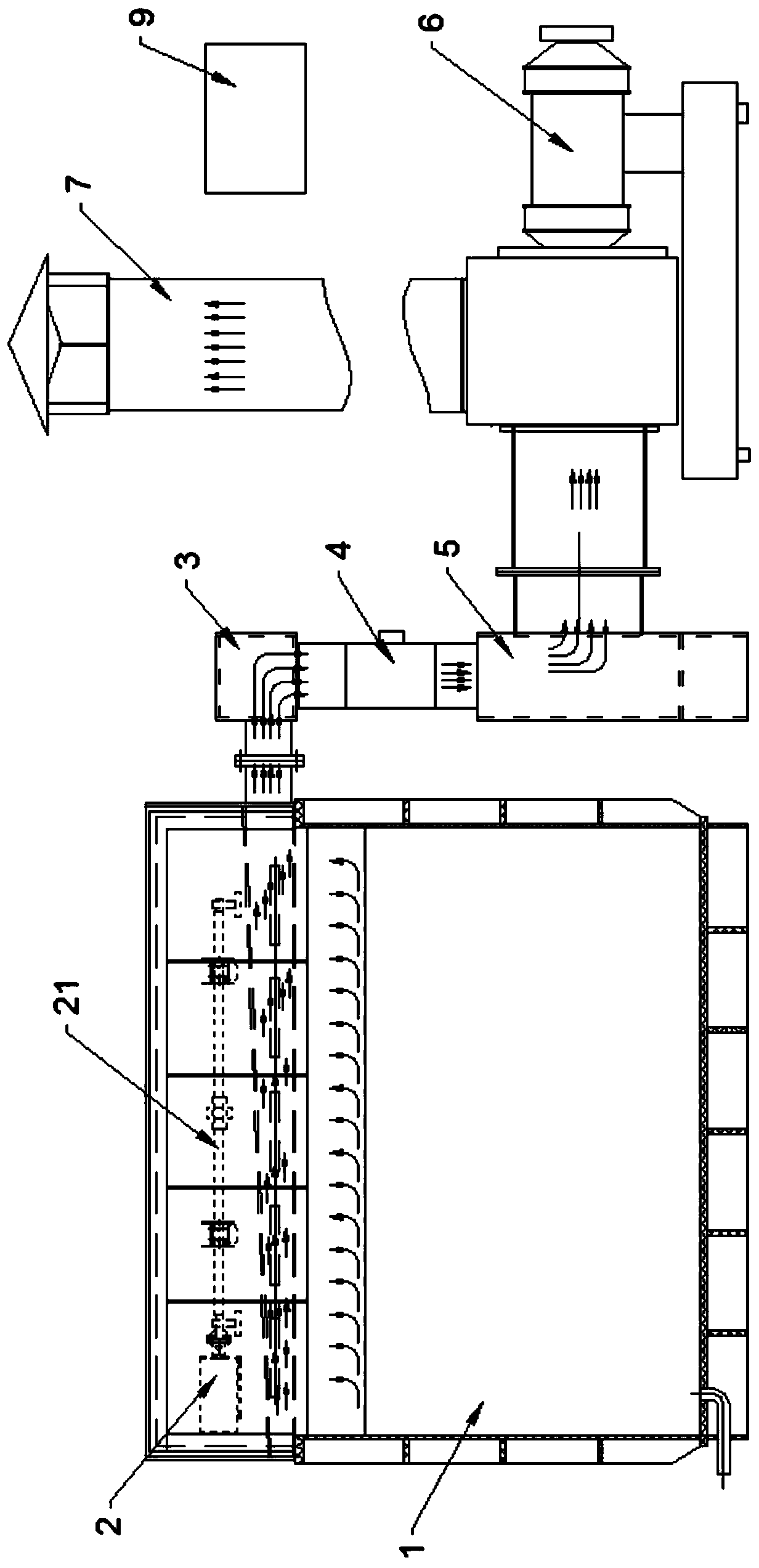

Water ring vacuum system with coil pipe condensation cylinder

PendingCN113090526AAchieve isothermal compressionGuaranteed suction effectRotary piston pumpsRotary/oscillating piston pump componentsWorking fluidEngineering

The invention discloses a water ring vacuum system with a coil pipe condensation cylinder. The water ring vacuum system is characterized in that a water ring vacuum pump cylinder is designed into a coil pipe structure for condensate water to pass through; and through transformation on an equipment body, the suction effect of a water ring vacuum pump is ensured to the greatest extent, and isothermal compression in the water ring vacuum pump is realized as far as possible. In the operation process of the water ring vacuum pump, the condensate water is introduced into the coil pipe cylinder and performs non-contact heat exchange with a water ring formed by the working fluid in the cylinder, so that the working fluid of the water ring vacuum pump is further cooled, and the cooling efficiency of the water ring vacuum pump is improved.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

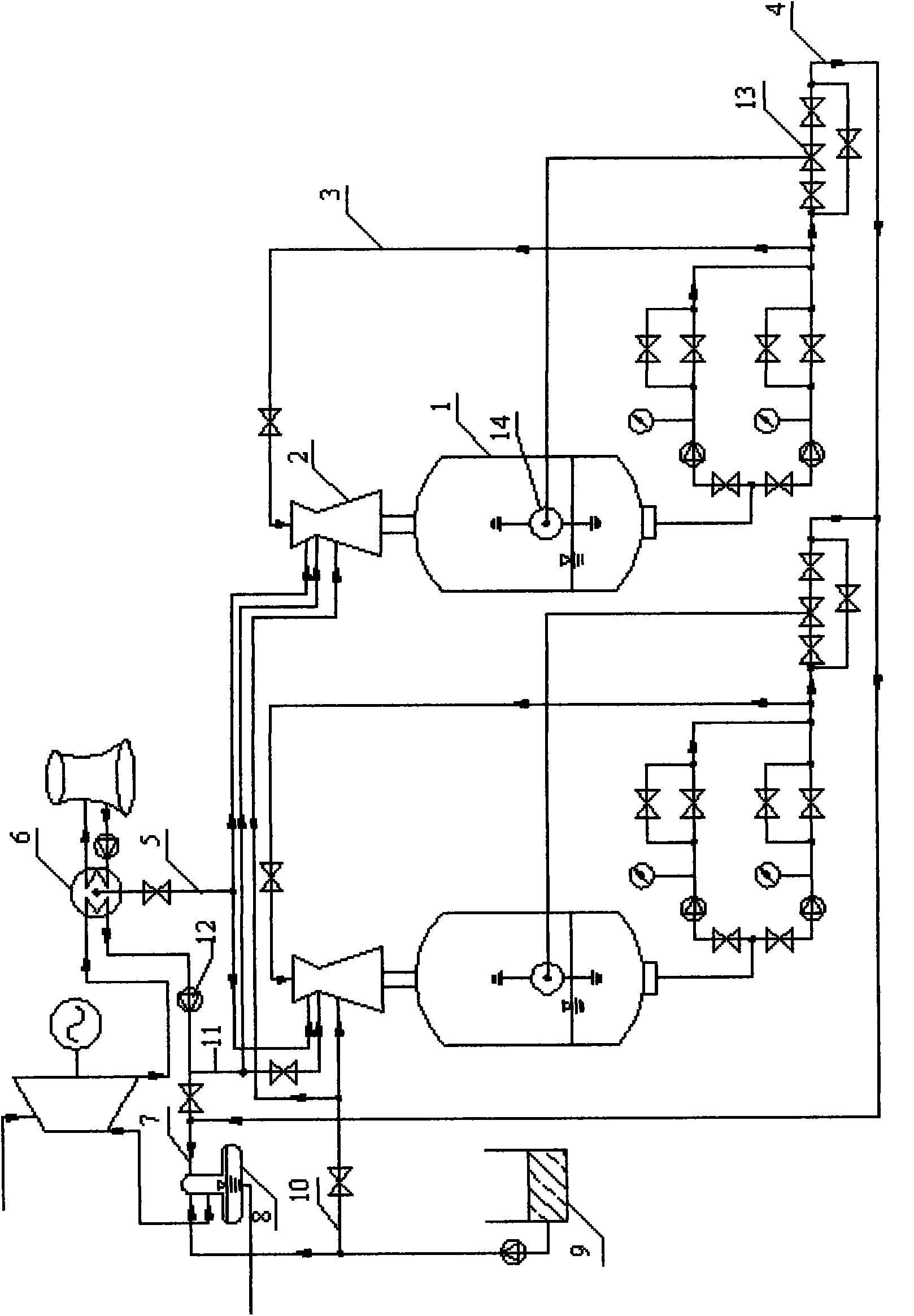

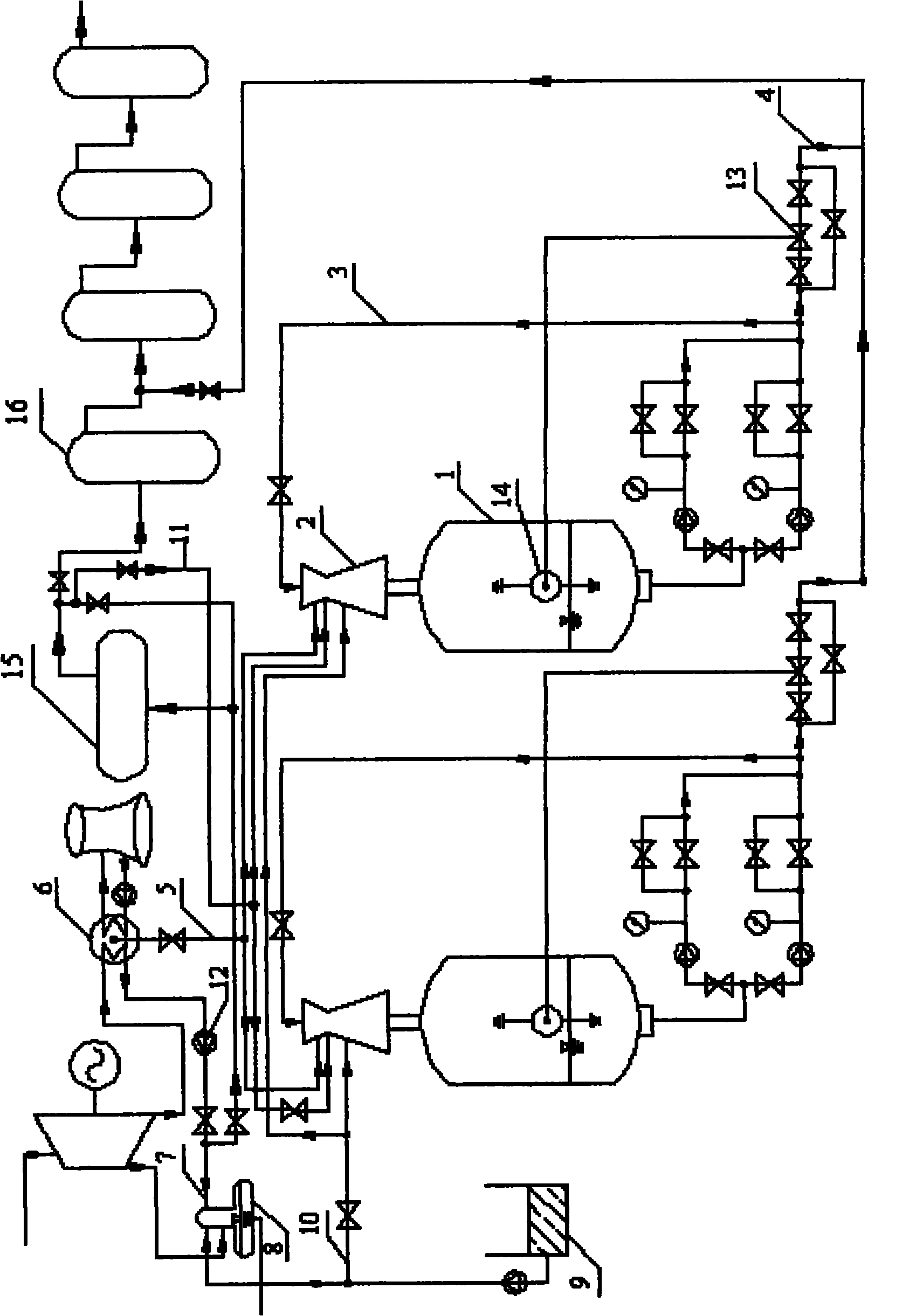

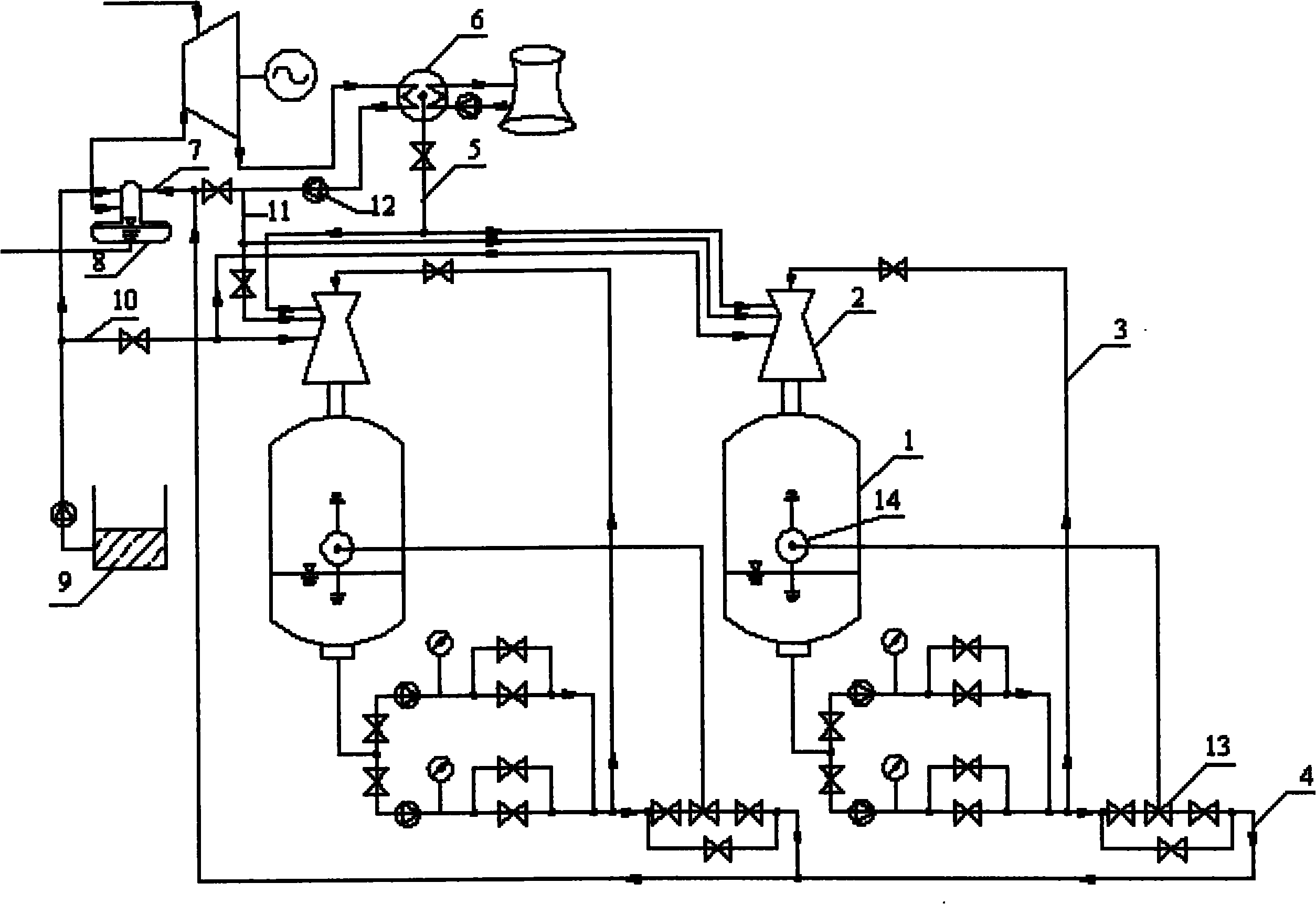

Vacuum steam heating and pressurizing recycling device for steam turbine

InactiveCN102108886AIncrease vacuumReduce condensate vacuumSteam regenerationEnergy industryCondensed waterThermal energy

The invention relates to a vacuum steam heating and pressurizing recycling device for a steam turbine, which comprises a recovery tank and a jet pump, wherein the recovery tank has a jet pipe and a drainage pipe; the jet pipe has a high-pressure pump; the jet outlet of the jet pump is connected with the inlet of the recovery tank through a pipe, the jet inlet of the jet pump is connected with the jet pipe, and the suction entrance of the of the jet pump is connected with a steam discharge pipe of a condenser through a steam inlet pipe; and the drainage pipe is connected with a deaerator. In the invention, the vacuum steam and condensed water generated after the vacuum steam passes through a condenser are sucked into the recovery tank under the suction action of the jet pump, and the condensed water is heated and pressured in the recovery tank and then delivered to the deaerator; and thus, the heat needed to be absorbed by the condensed water to be heated to a saturated temperature in the deaerator is reduced, the water resource and heat in the vacuum steam are recovered and recycled, and the aims of energy conservation and environment protection are fulfilled.

Owner:李树生

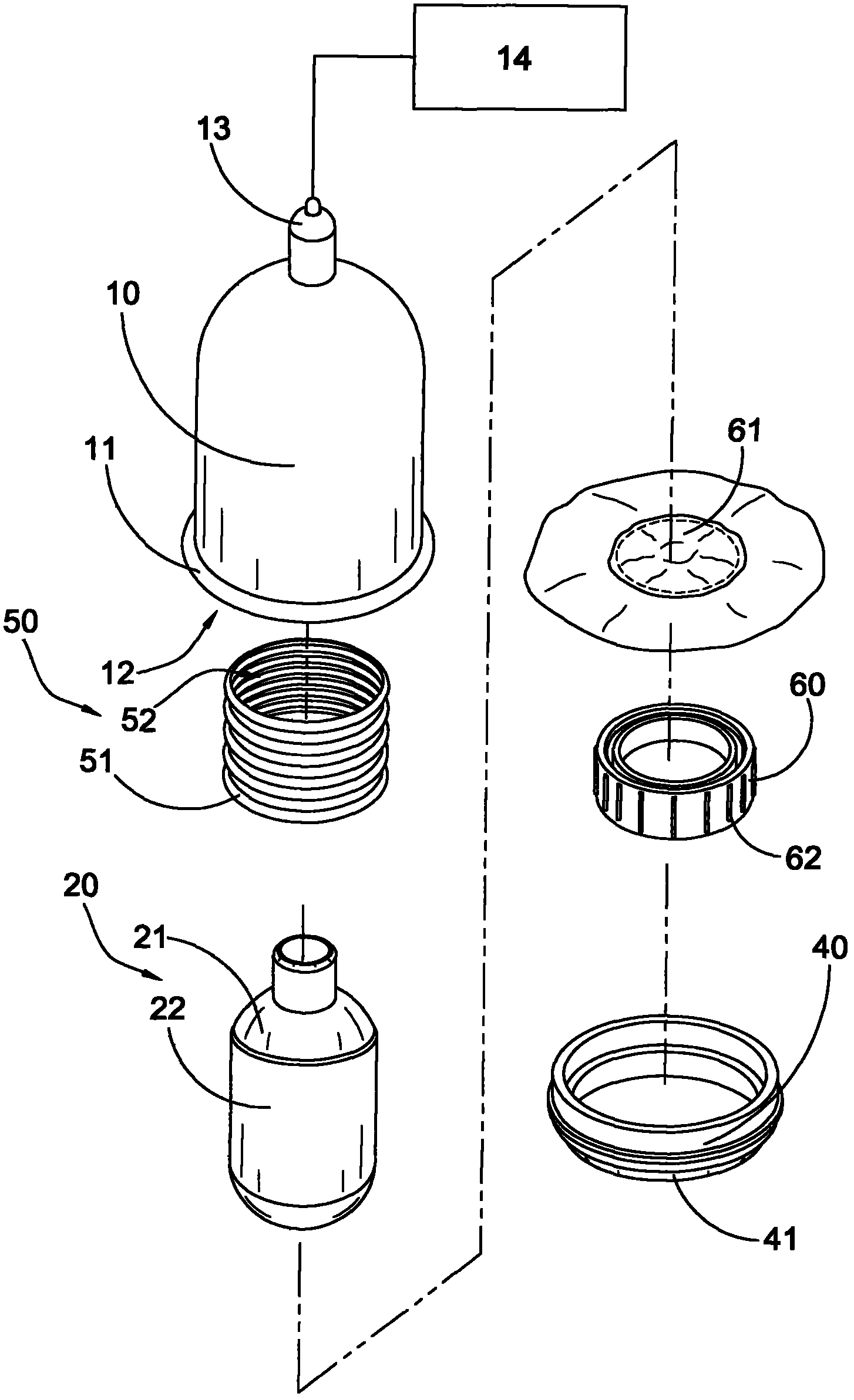

Thermal vacuum therapy and apparatus thereof

InactiveCN102989046AGuaranteed suction effectAvoid burnsDevices for heating/cooling reflex pointsPneumatic massageConductive materialsEngineering

An apparatus, for a thermal vacuum therapy by using a suction cup on a skin of a patient, includes a heating unit disposed in the suction cup. The heating unit includes a heat core made of high heat conductive material and a heat retention sleeve made of low heat conductive material, wherein the heat core is wrapped by the heat retention sleeve and is arranged in such a manner that after the heat core rapidly stores heat energy, the heat retention sleeve is adapted for keeping the heat energy at the heat core so as to enable the heat core being gradually released heat within the suction cup during cupping treatment.

Owner:刘俸玉 +1

Electroplating automatic line exhaust mechanism

The invention provides an electroplating automatic line exhaust mechanism, and belongs to the field of electroplating equipment. The electroplating automatic line exhaust mechanism comprises exhaust assemblies, single-groove air flues, main air flues and fans, wherein the exhaust assemblies, the single-groove air flues, the main air flues and the fans are arranged on the two sides of the upper ends of solution tanks; each exhaust assembly is arranged corresponding to one single-groove air flue and comprises an air cover, a door cover, an air cover air cavity and an air sucking opening; the airsucking openings communicate with the interiors of the air cavities and the interiors of the solution tanks; one ends of the air cavities communicate with the single-groove air flues which communicate with the main air flues; the fans are arranged at the ends, away from the single-groove air flues, of the main air flues; and the door covers are arranged at the ends, close to the solution tanks, of the air covers, and the height of the lower end faces of the door covers is smaller than that of the air sucking openings. The electroplating automatic line exhaust mechanism is simple in structure,good in air sucking effect, free of leakage, and capable of achieving energy saving and environmental protection.

Owner:万向新元绿柱石(天津)科技有限公司

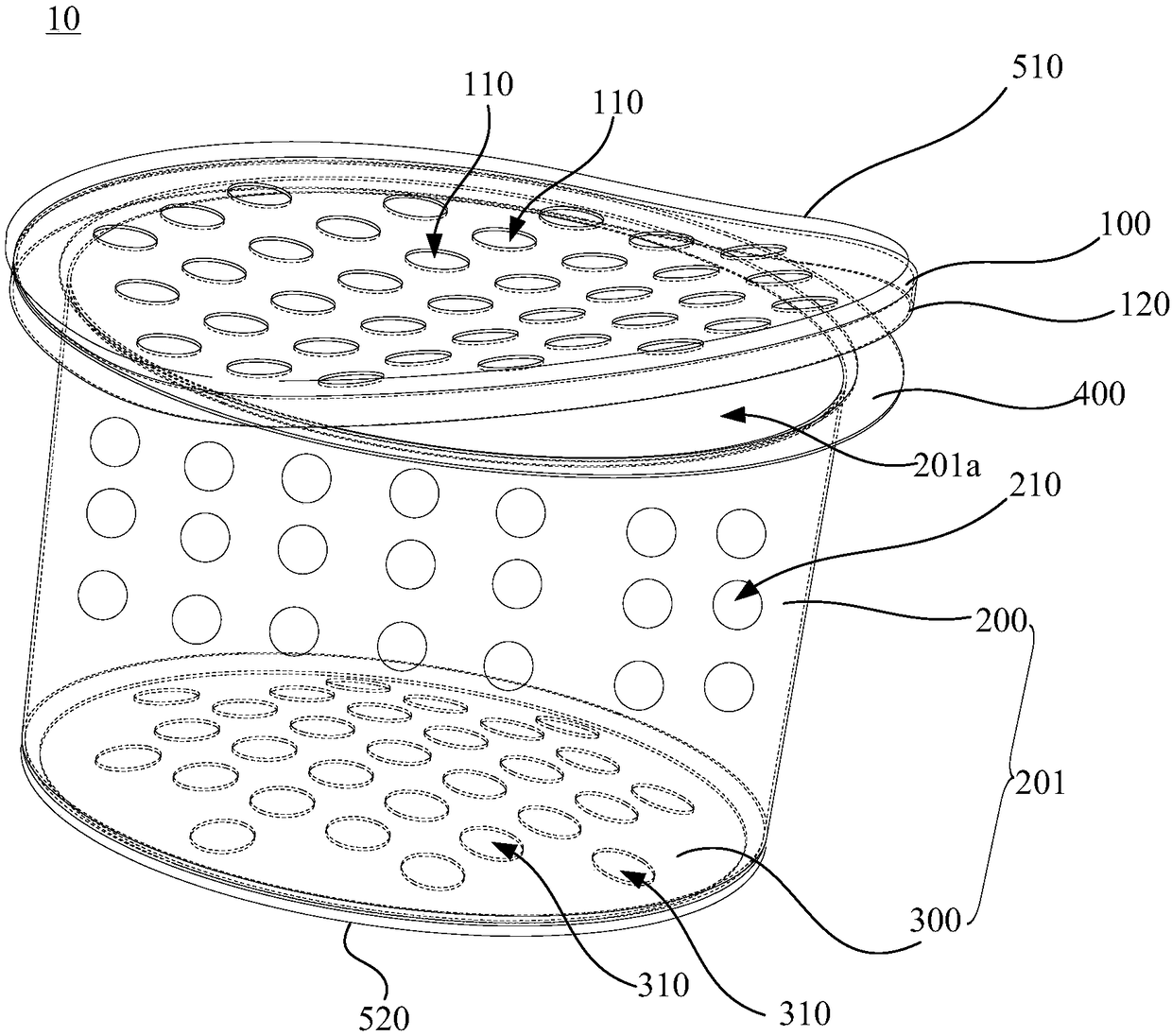

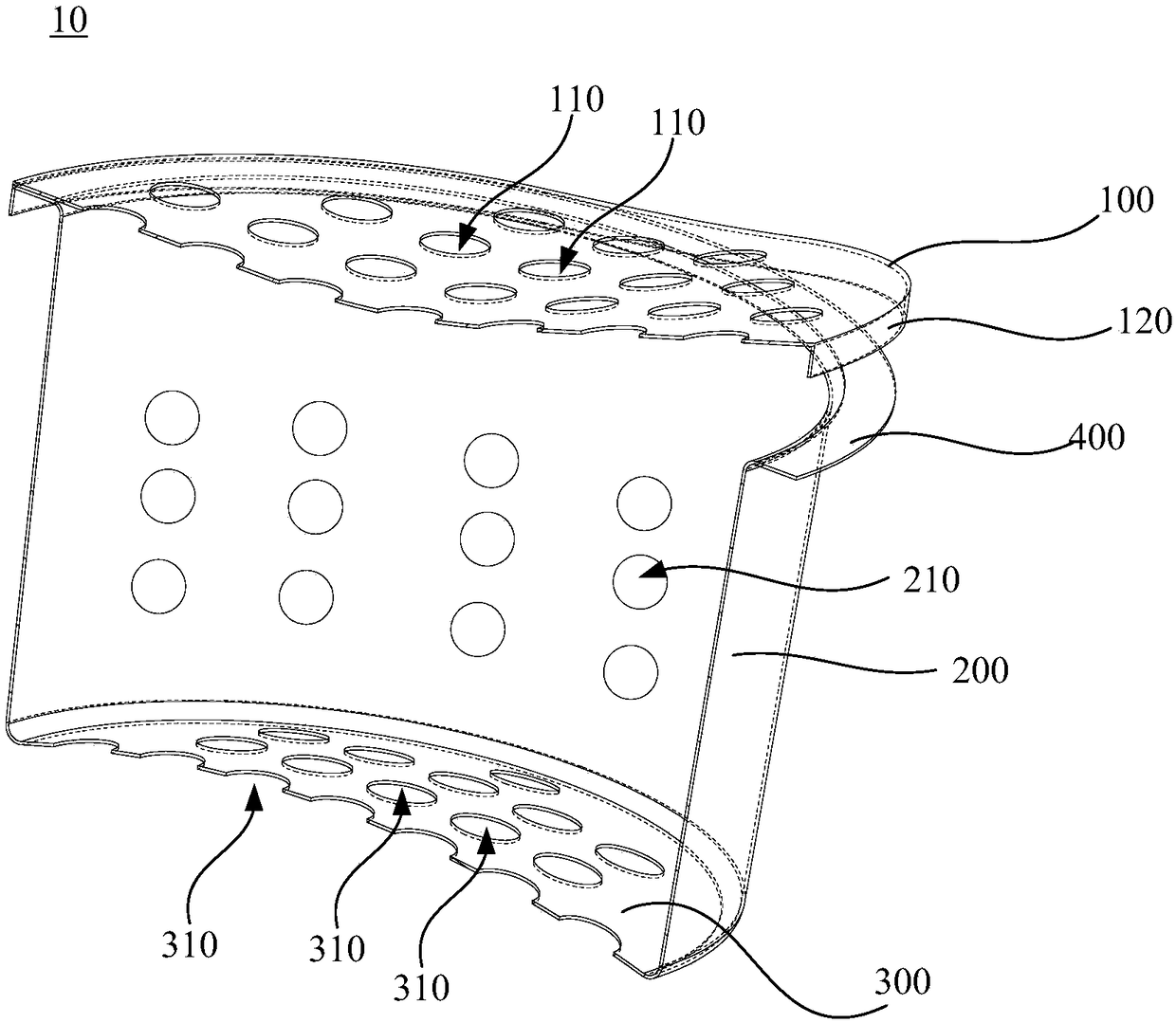

Filter screen for range hood

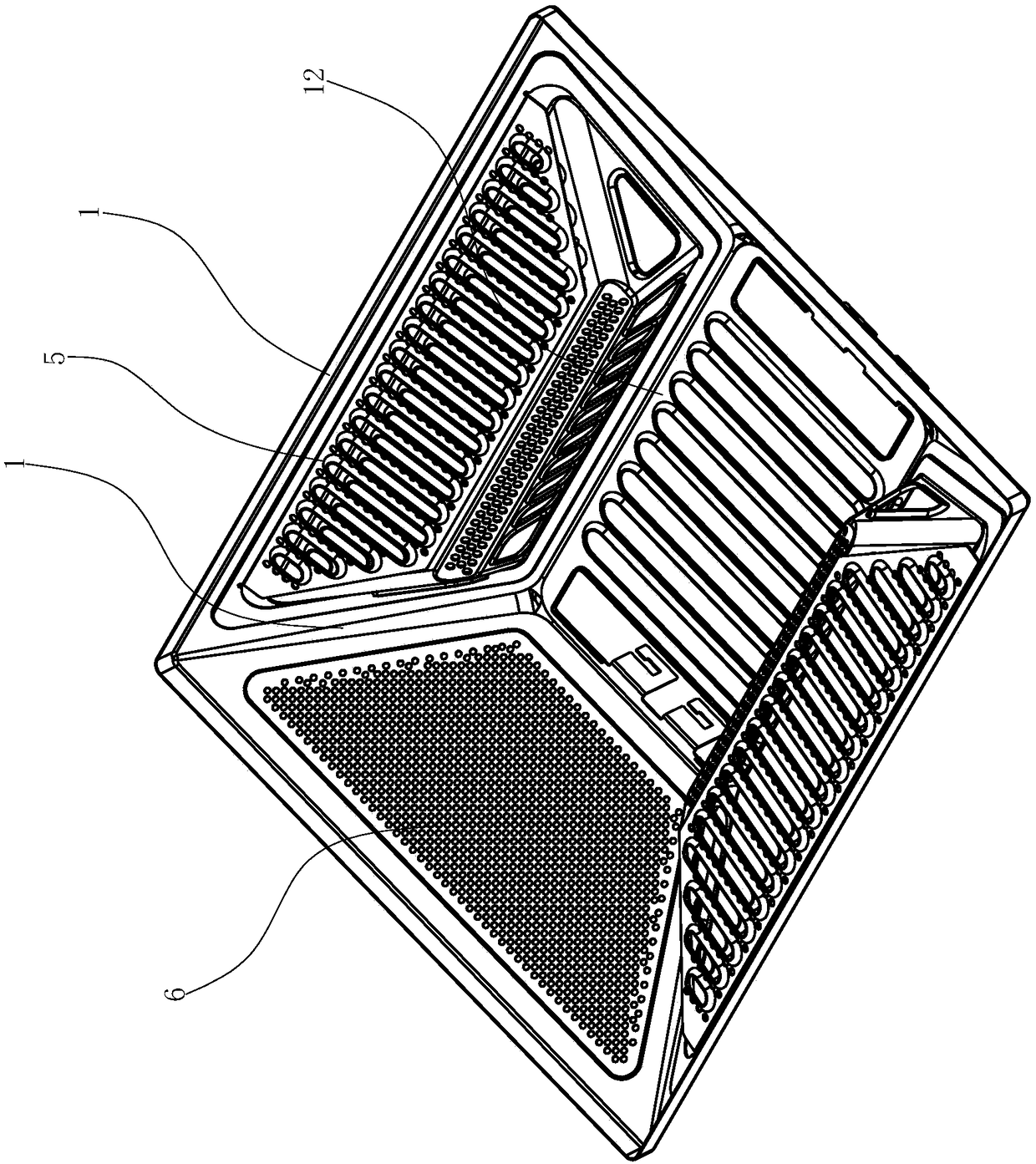

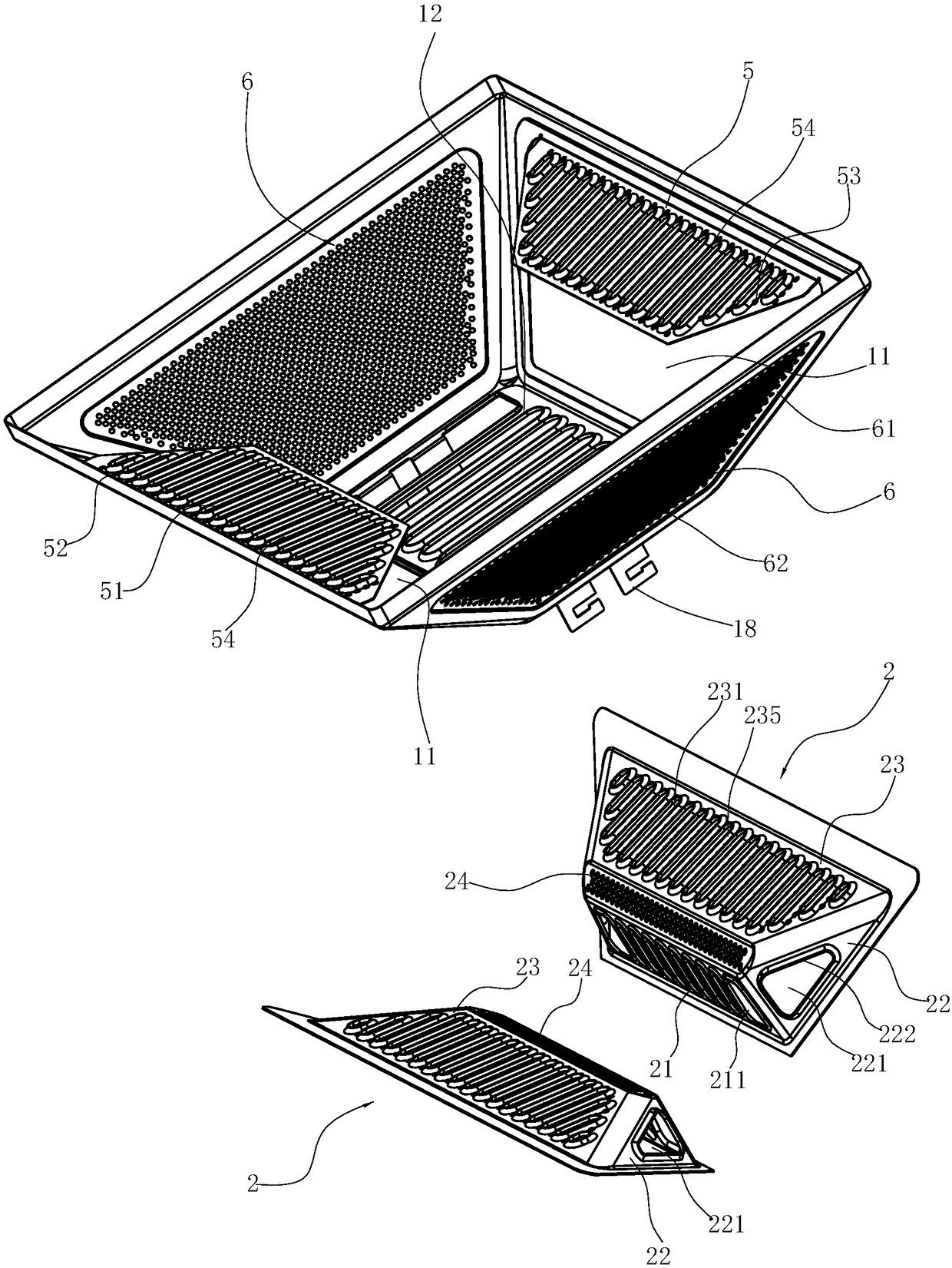

PendingCN108061320AEasy to cleanImprove oil separation effectDomestic stoves or rangesLighting and heating apparatusLarge mouthEngineering

The invention relates to a filter screen for a range hood. The filter screen comprises a bucket-shaped body with a large mouth and a small bottom, the body has a hollow-out bottom surface, and the sidewall of the body is provided with at least three first through holes for communicating the inner cavity of the body; at least one of the first through holes is detachably connected with a hollow-outfirst filter frame; elongated second air inlet holes are arranged in the first filter frame at intervals, a gap between the adjacent second gas inlet holes forms a first rib plate, and every first ribplate is a netted structure; the body is also connected with a folded filter; the folded filter is located above the first filter frame, and a gap exists between the folded filter and the first filter frame; a plurality of elongated third air inlet holes are arranged in the folded filter at intervals, a part between the adjacent third air inlet holes forms a second rib plate, and every second ribplate is a netted structure; and the second rib plates on the laminated filter are arranged corresponding to the second air inlet holes in the first filter frame, and the first rib plates are arranged corresponding to the third air inlet holes.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

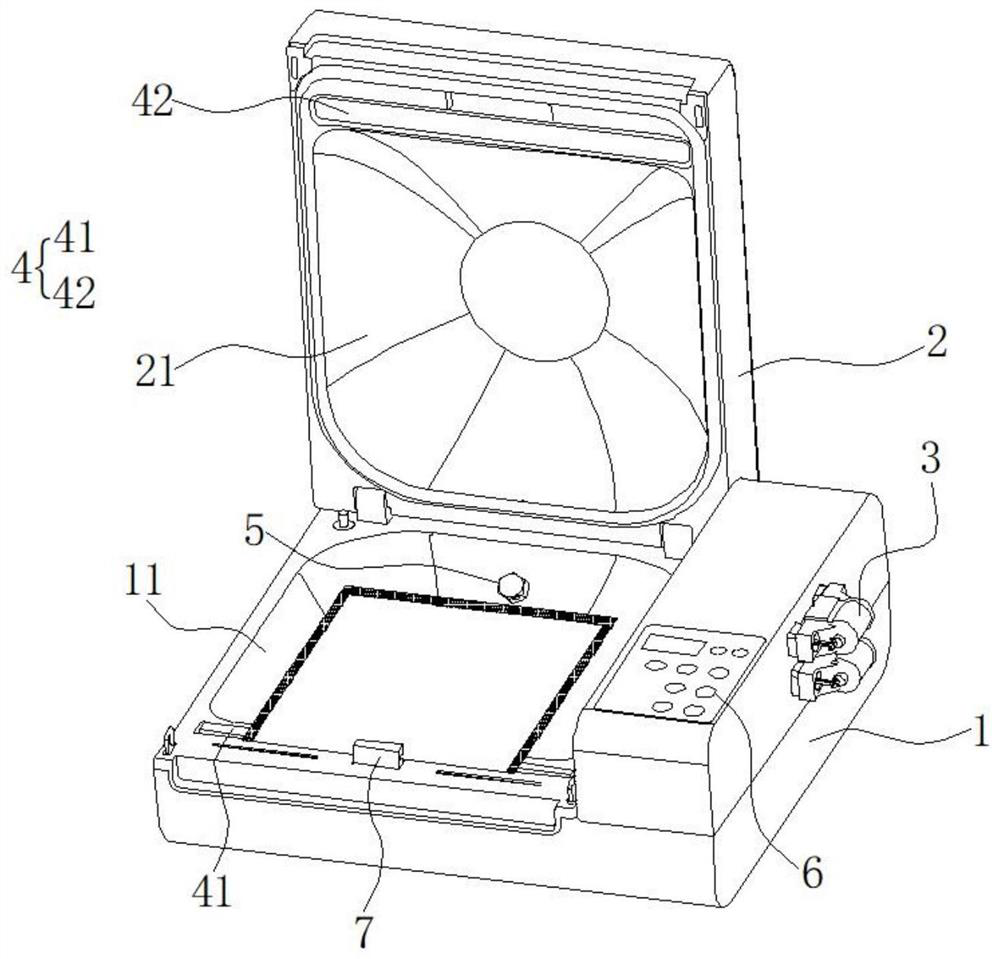

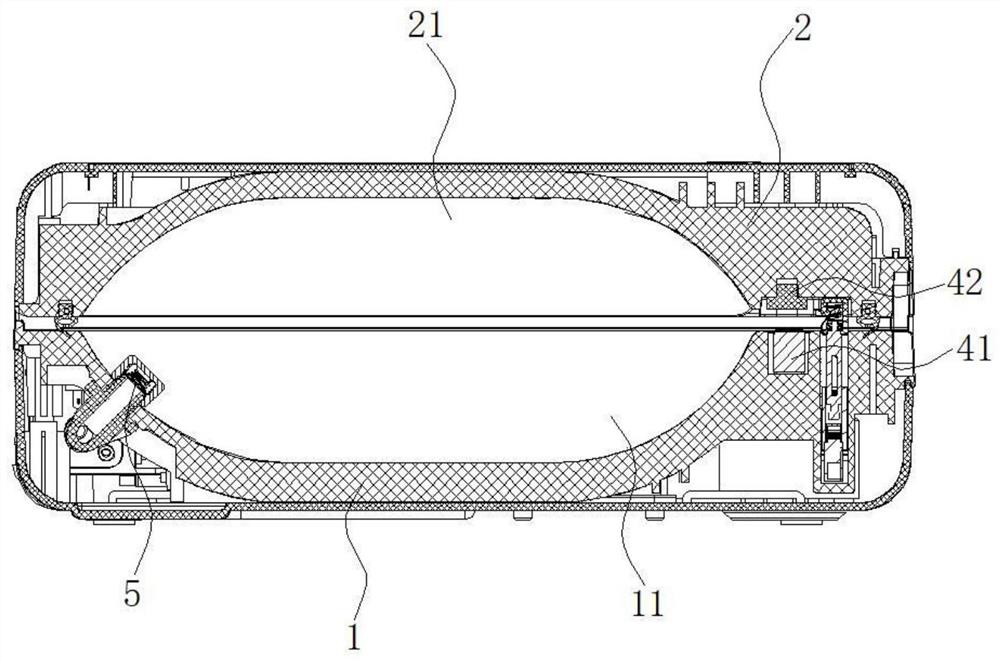

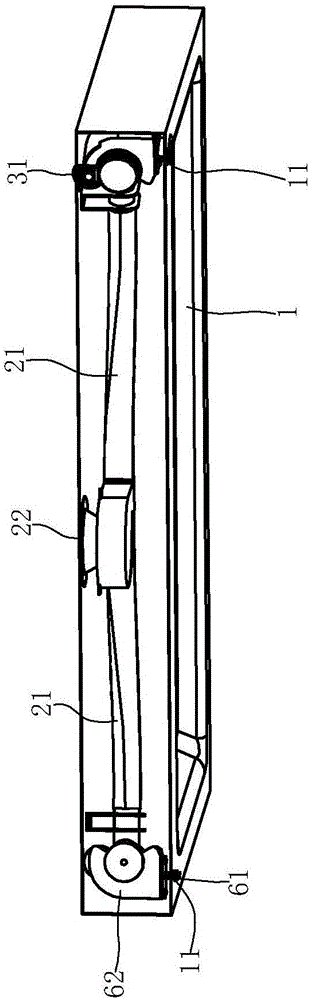

Multifunctional vacuum packaging machine

PendingCN112937987AReduce manufacturing costEasy to usePackaging under vacuum/special atmospherePackaging by pressurising/gasifyingControl systemEngineering

The invention relates to the technical field of vacuum packaging, and discloses a multifunctional vacuum packaging machine. The multifunctional vacuum packaging machine comprises a base and a top cover which are connected in a hinged mode, wherein a lower cavity is formed in the top face of the base, an upper cavity is formed in the bottom face of the top cover, a heating system, a vacuum pump set and a control system are arranged on the base, the heating system comprises a heater and a pressing strip, the heater is arranged on the base and located outside the lower cavity, the pressing strip is arranged on the top cover and located outside the upper cavity, the vacuum pump set communicates with the lower cavity through an extraction opening formed in the cavity wall of the lower cavity, and the control system is used for controlling the heater and the vacuum pump set to complete heat sealing and suction operation. According to the multifunctional vacuum packaging machine, the arrangement position of the heating system is optimized, inner pumping and outer pumping of a vacuum packaging bag can be achieved simultaneously, practicability is high, use is convenient, popularization is easy, meanwhile, the volume of a vacuum cavity is reduced, the power requirement of the vacuum pump set is lowered, and control over the manufacturing cost is facilitated.

Owner:GUANGZHOU ARGION ELECTRIC APPLIANCE CO LTD

Air-volume-adjustable range hood capable of realizing suction assistance

ActiveCN106152223AGuaranteed suction effectDomestic stoves or rangesLighting and heating apparatusAir volumeEngineering

The invention relates to an air-volume-adjustable range hood capable of realizing suction assistance. The range hood comprises an air supply device mounted in a smoke collecting hood of the range hood, wherein the air supply device comprises an air duct and a fan arranged in the air duct; the range hood is characterized in that an air outlet port of the air duct is connected with an air guiding piece; an air supply pipe with a downward outlet is connected onto the air guiding piece and communicates with the air outlet port; an adjusting mechanism for driving the air guiding piece to rotate and driving a valve plate to rotate is further arranged on the smoke collecting hood; and the valve plate is arranged between the air guiding piece and the air outlet port and is used for controlling the air outlet volume of the air supply pipe. Compared with the prior art, the range hood has the advantages that the air supply angle and the air supply volume of the air supply device can be adjusted simultaneously to be better adapted to cookware with different calibers and different air volume gears, and the suction assistance effect is further guaranteed.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Flue gas desulfurization device

ActiveCN110585881AImprove desulfurization effectFully contactedDispersed particle separationFlue gasProcess engineering

The invention discloses a flue gas desulfurization device. The flue gas desulfurization device comprises a desulfurization tower body, a wet filtering assembly, a spraying assembly and a gas distributing assembly, wherein the wet filtering assembly is arranged in the desulfurization tower body; the spraying assembly is used for supplying absorbing liquid to the desulfurization tower body; the gasdistributing assembly is used for conveying to-be-treated flue gas into the desulfurization tower body; the wet filtering assembly comprises a plurality of box filters which are arranged along the height direction of the desulfurization tower body in a stacked way; and microporous structures which are arranged densely and run through the main bodies of the box filters are arranged on the box filters and are used for flue gas to pass through. According to the flue gas desulfurization device provided by the invention, on one hand, through the box filters, complete contact of the flue gas and theabsorbing liquid can be guaranteed and the desulfurization effect of the flue gas is effectively improved; and on the other hand, spiraling gas flow is formed through the gas distributing assembly, so the desulfurization effect can be further improved and the desulfurization efficiency can be improved.

Owner:苏州仕净科技股份有限公司

Waste gas collecting method

ActiveCN109811394ACollection Method AdvantagesReduce the total amount of exhaust airCellsDirt cleaningCovering systemEngineering

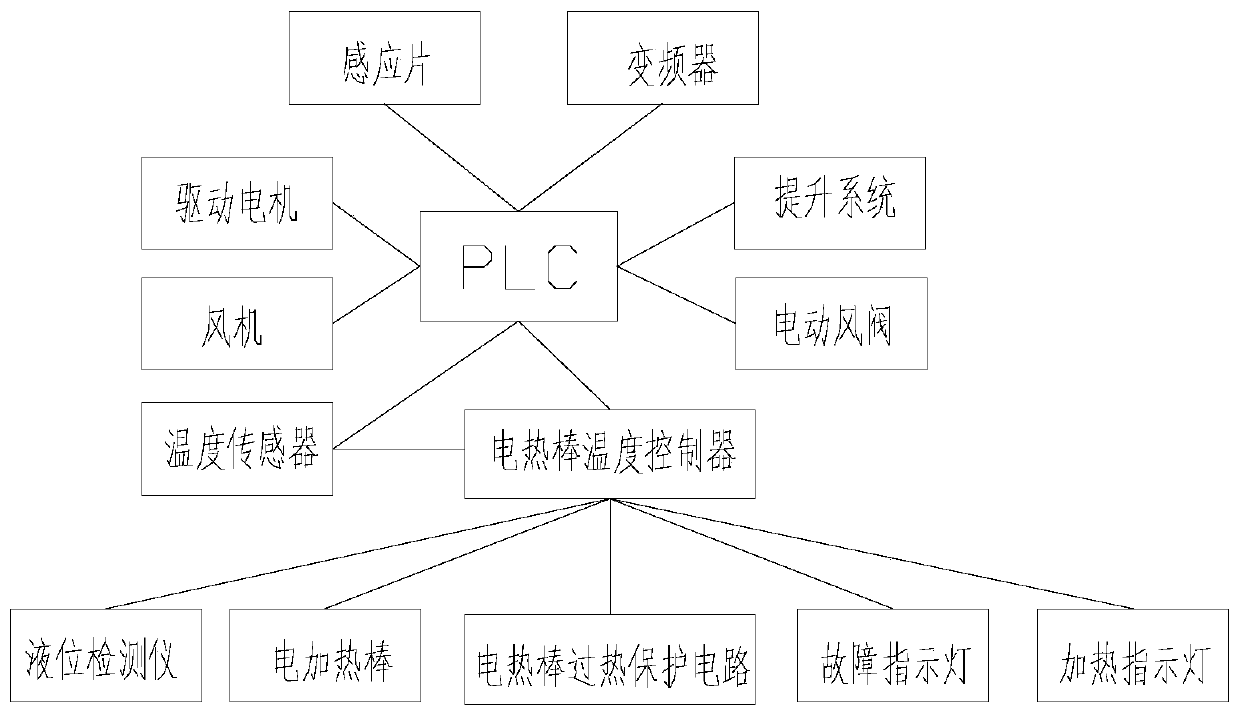

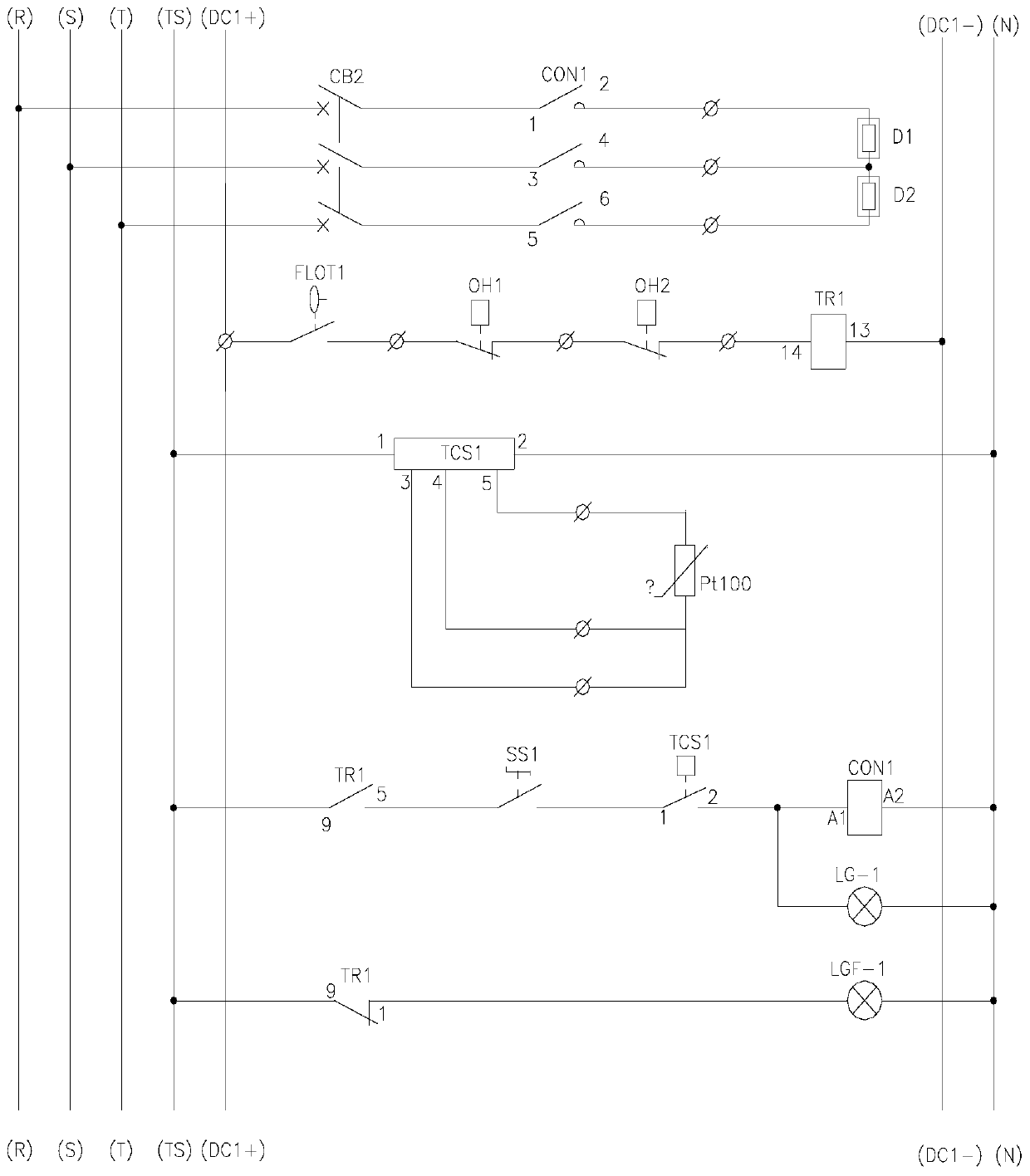

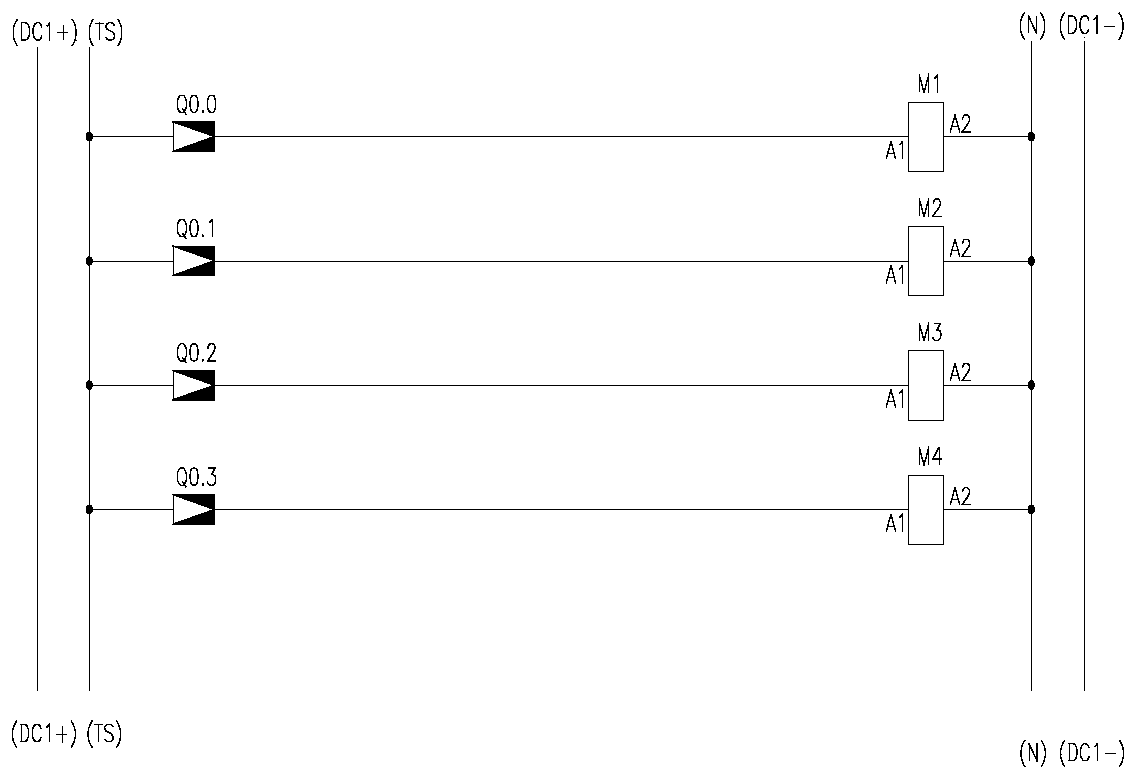

The invention provides a waste gas collecting method. An intelligent control system, a variable-frequency fan system, a ventilation system and a tank cover system are included; the intelligent controlsystem comprises a controller and a lifting system in linkage with the controller; when a tank cover of the tank cover system is required to be closed according to process parameters of a crane lifting system, the controller of the intelligent control system controls the tank cover to be closed, and meanwhile, the variable-frequency fan system is controlled to be in the low-energy-consumption state; when the tank cover of the tank cover system is required to be opened according to the process parameters of the crane lifting system, the controller of the intelligent control system controls thetank cover to be opened, meanwhile, the variable-frequency fan system is controlled to work, and waste gas inside a solution tank is discharged through the ventilation system. With the waste gas collecting method, the total waste gas discharging amount is reduced, the fan power is reduced, the method is beneficial to the health of operators, and the national energy conservation, emission reduction, clean production and environmental protection concepts are conformed.

Owner:万向新元绿柱石(天津)科技有限公司

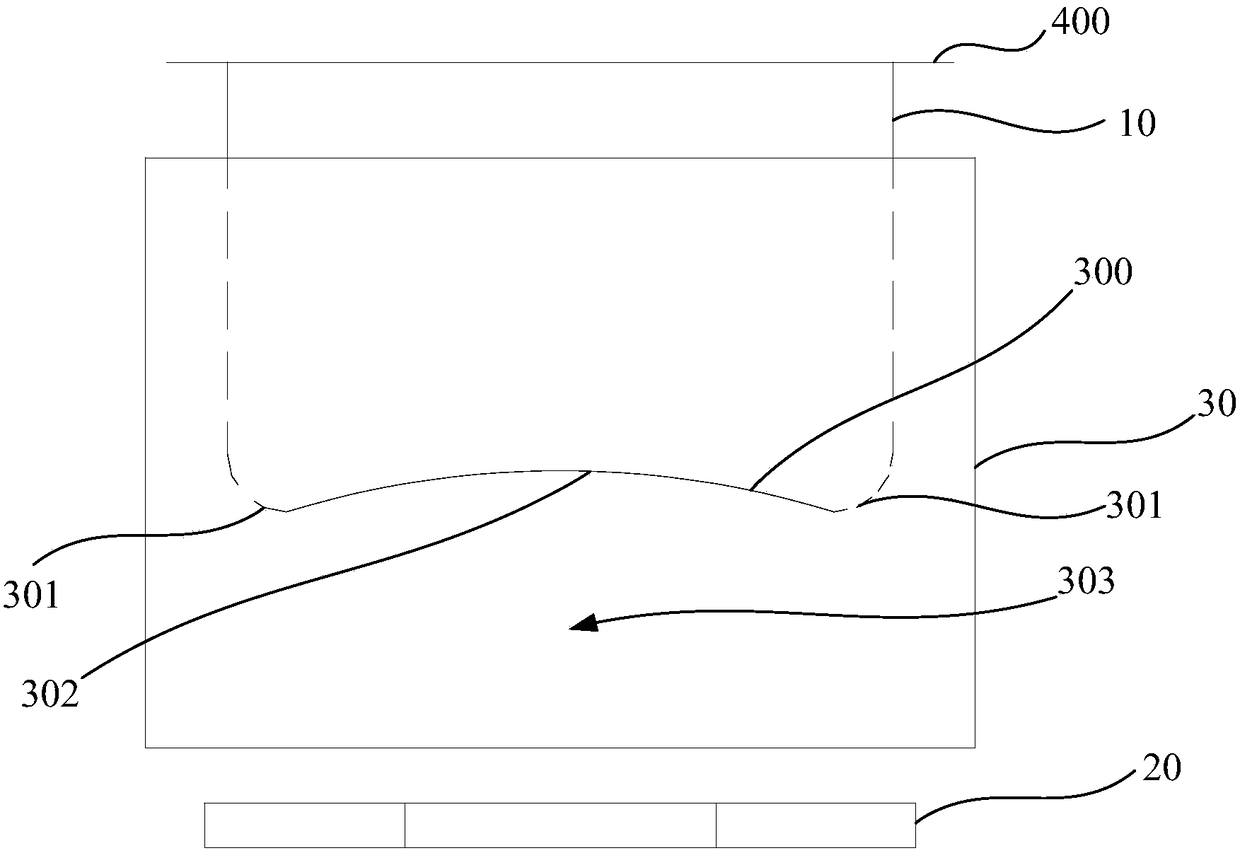

Container for shisha

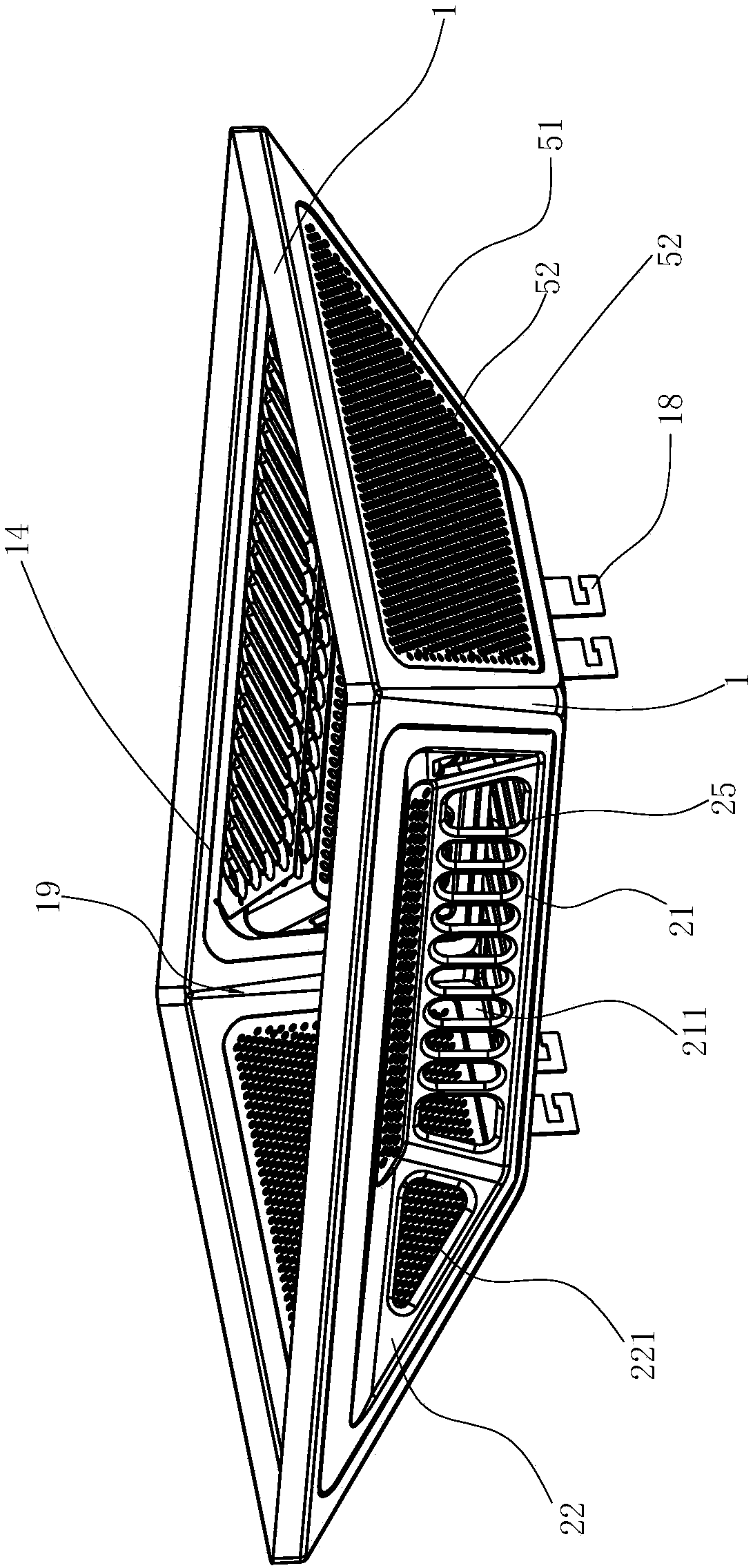

InactiveCN108201171ATemperature rises steadilyGuaranteed suction effectTobacco pipesProject areaTop cap

The invention relates to a container for shisha comprising a top cover and a box body; the top cover is provided with multiple first air vents with intervals; one end of the box body is open and the box body comprises a side wall and a bottom wall; the bottom wall is provided with second vent holes with intervals; the bottom wall is curved surface; the effective contact area of the bottom wall anda heating cup is smaller than the projected area of the curved surface on the bottom of the heating cup; an air flow channel is formed between the bottom wall and the bottom of the heating cup so that the effective contact area of the box body bottom wall and the bottom of the heating cup is limited; hot air flow enters from the heating cup and passes through the air flow channel and then entersto the box body through the second air vents, which can ensure that the temperature of the shisha in the box keeps rising steadily, so that the shisha is not heated excessively and the generation of paste smell and irritating odor is avoided, so that the suction effect and the taste can be effectively ensured.

Owner:SMISS TECH

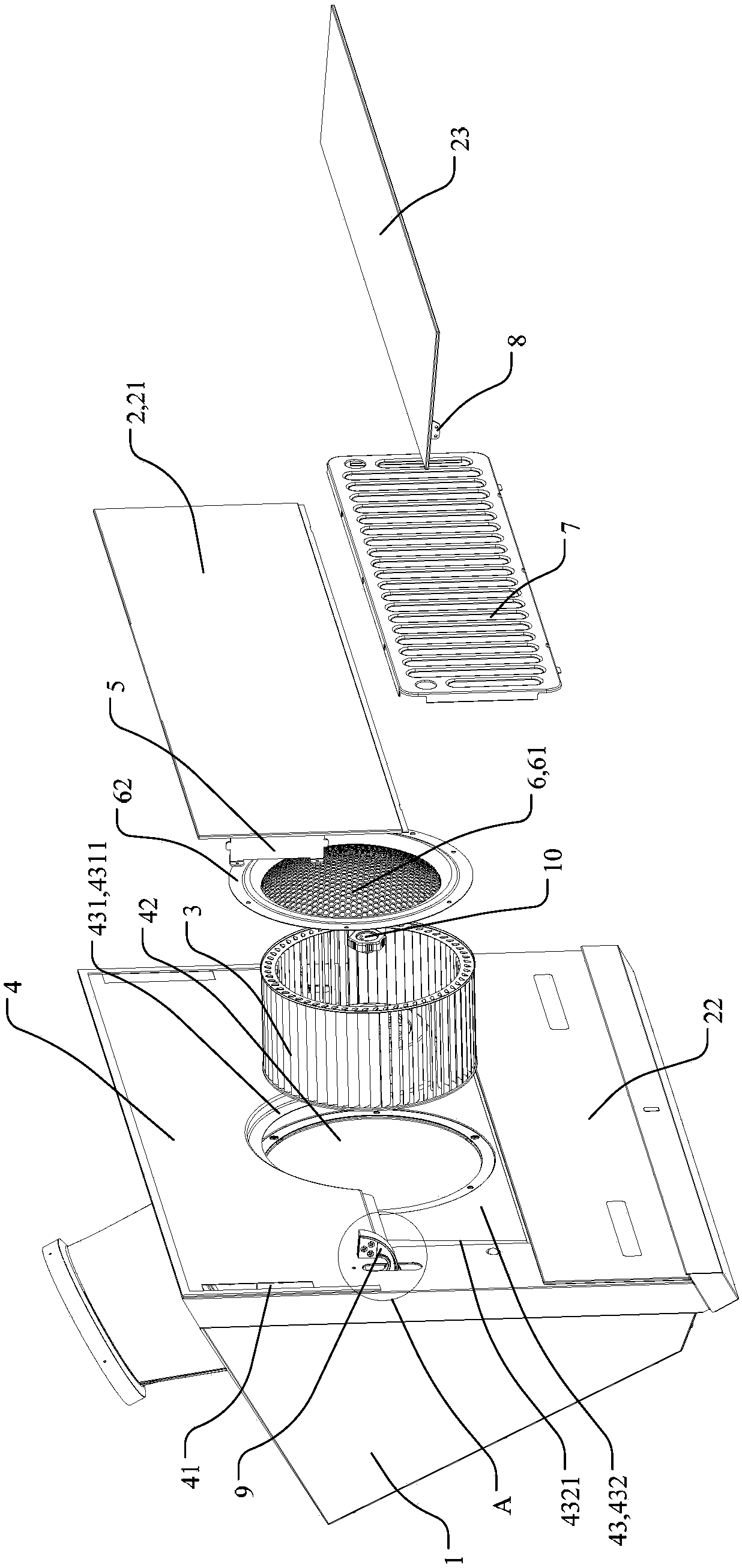

Range hood

PendingCN107830565AGuaranteed suction effectExtended service lifeDomestic stoves or rangesLighting and heating apparatusUser needsEngineering

The invention discloses a range hood. The range hood comprises a shell with an opening at one side and a smoke inlet panel assembly which is arranged on the shell. The smoke inlet panel assembly is arranged at the opening of the shell. A wind wheel is arranged in the inner cavity of the shell. The smoke inlet panel assembly is structured as follows: at least the opening of the shell can be openedin the area corresponding to the wind wheel, and the wind wheel can be taken out of the area. As the smoke inlet panel assembly of the range hood is arranged in the mode that the opening of the shellcan be opened in the area corresponding to the wind wheel, a user can conveniently take out the wind wheel from one side of the smoke inlet panel assembly only by opening the smoke inlet panel assembly when the user needs to clean the wind wheel and the inner sidewall of the spiral shell. Thereby, the user can conveniently clean the wind wheel which has been taken out and extend into the spiral shell to clean the inner sidewall of the spiral shell. Thus, suction ability of the range hood is guaranteed, and service life of the range hood is prolonged.

Owner:GREE ELECTRIC APPLIANCES INC

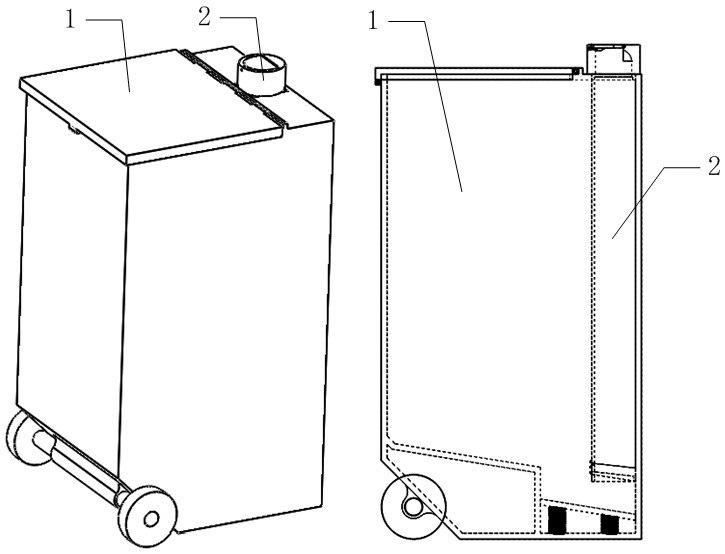

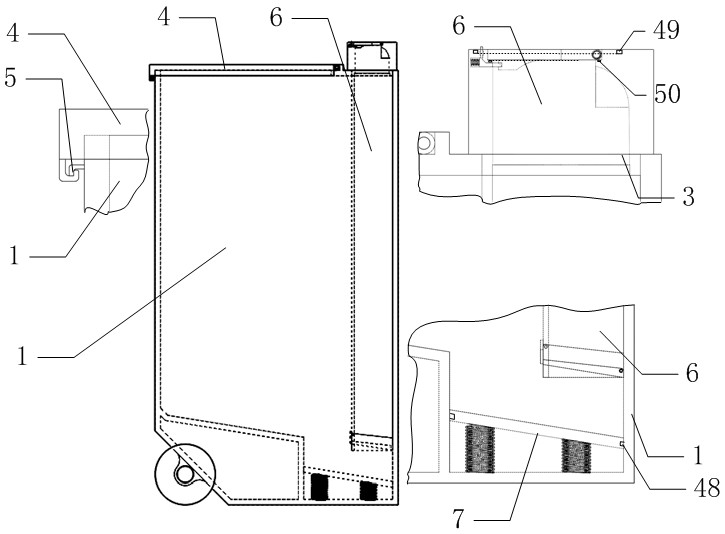

Kitchen waste recovery equipment

InactiveCN111674786AGuaranteed tightnessAvoid influenceRefuse receptaclesEnvironmental engineeringWaste recovery

The invention belongs to the technical field of waste recovery, and particularly relates to kitchen waste recovery equipment. The kitchen waste recovery equipment comprises a waste bin body, a waste cover, buckles and a traveling mechanism. According to the kitchen waste recovery equipment, when kitchen waste in a waste bin is collected, a connecting pipe is connected from a collecting vehicle, atightening sleeve is rotationally mounted on the connecting pipe, and thus during collecting, one end of the connecting pipe is aligned with the upper end of a suction channel; the connecting pipe isfixed to the upper end of the suction channel through the tightening sleeve, and the connecting pipe is tightly pressed on the suction channel through the tightening sleeve; then through a pump on thecollecting vehicle, the kitchen waste in the waste bin is sucked into a tank body of a waste vehicle through the suction channel; and airtightness in the collecting process is ensured, and liquid inthe waste and the foreign flavor of the waste are prevented from being exposed in air and then influencing the ambient environment.

Owner:钱理

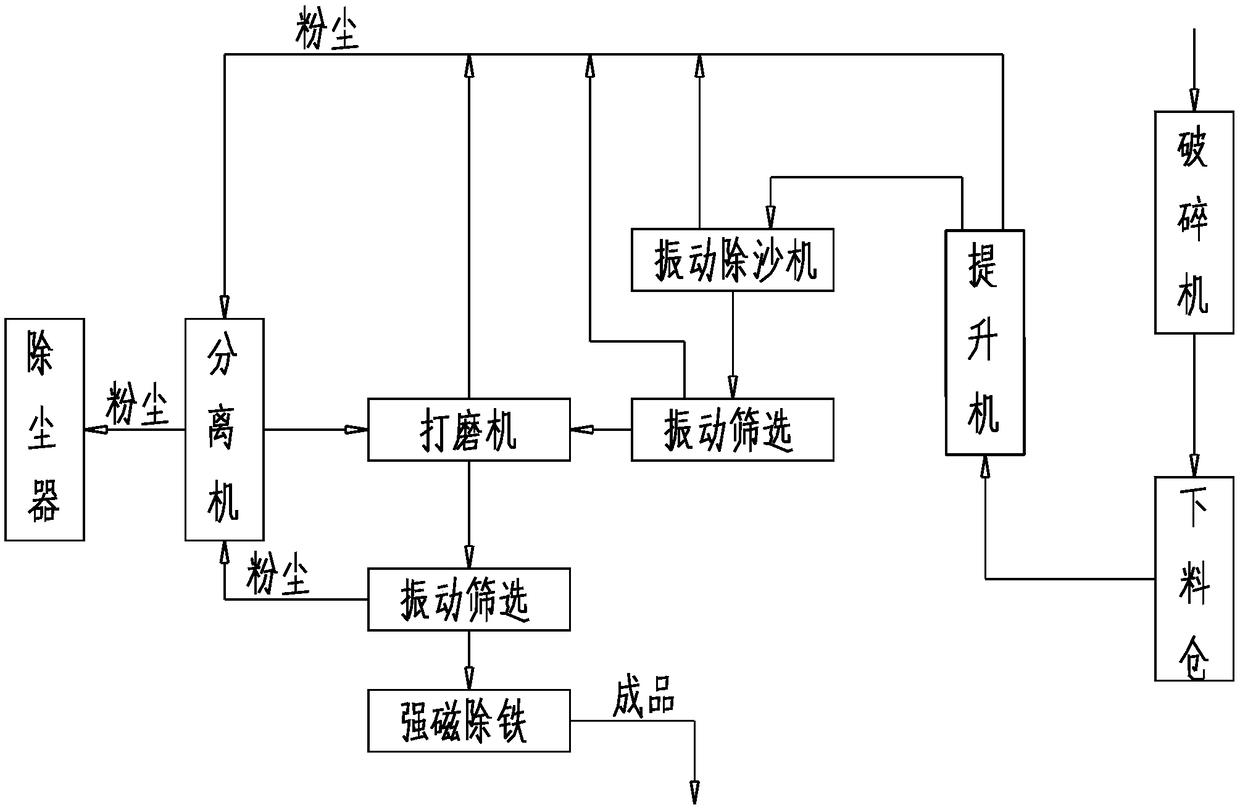

Production process for wooden water-purifying activated carbon

ActiveCN108928817AImprove product qualitySuitable for large-scale productionCarbon compoundsOther chemical processesActivated carbonMaximum diameter

The invention belongs to the technical field of production of activated carbon, and provides a production process for wooden water-purifying activated carbon. The production process comprises the following steps: crushing an activated material through a crushing machine so as to obtain a finely-crushed activated material, conveying the finely-crushed activated material to a first screening machineto sieve finely-crushed sand and activated carbon particles with a maximum diameter of less than 2 mm out of the finely-crushed activated material, conveying the activated material sieved for the first time to a second screening machine to sieve activated carbon particles with a maximum diameter of more than 10 mm out of the activated material sieved for the first time, conveying the activated material sieved for the second time to a grinding machine for grinding, conveying the ground activated material to a third screening machine to sieve the activated material with a minimum diameter of less than 2 mm out of the ground activated material, conveying the activated material sieved for the third time to an iron removing machine to remove iron so as to obtain a finished product after completion of iron removal. Thus, the production process for the wooden water-purifying activated carbon provided by the invention solves the problem of incapability of achieving good effects in the grinding stage of the activated carbon in the prior art.

Owner:承德宏伟活性炭有限公司

Multi-stage and multi-pipe efficient jet pump

InactiveCN102052355AImprove suction effectThe momentum of the medium increasesJet pumpsMachines/enginesSuction forceAerospace engineering

The invention relates to a multi-stage and multi-pipe jet pump, which comprises a pump body, a suction pipe, a first-stage jet pipe, a second-stage pipe and a third-stage pipe, wherein the outlet of the first-stage jet pipe is formed in the pump body; the outlet of the second-stage jet pipe is formed in the suction pipe; the outlet of the third-stage jet pipe is formed between the second-stage jet pipe and the pump body in the suction pipe; and the outlet direction of each jet pipe is along the medium flowing direction in a pipeline in which the jet pipes are positioned. In the invention, a multi-stage jet type is adopted to suck a sucked medium, generate the negative pressure by the jet in multiple different regions of equipment, and form a suction force of the medium flowing through the region of the medium so that the sucked medium rapidly flows through the region to form a multi-stage jet and make up the flow rate loss of the sucked medium in the pipeline or the pump body, thereby greatly enhancing the suction capability of the jet pump and the suction amount of the sucked medium and meeting the medium delivery requirements with higher efficiency.

Owner:李树生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com