Internally ventilated brake disk

A technology of brake discs and brake linings, applied in the direction of brake discs, brake types, brake components, etc., can solve problems such as lining wear and noise, improve stability, avoid dirt, and improve mechanical stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

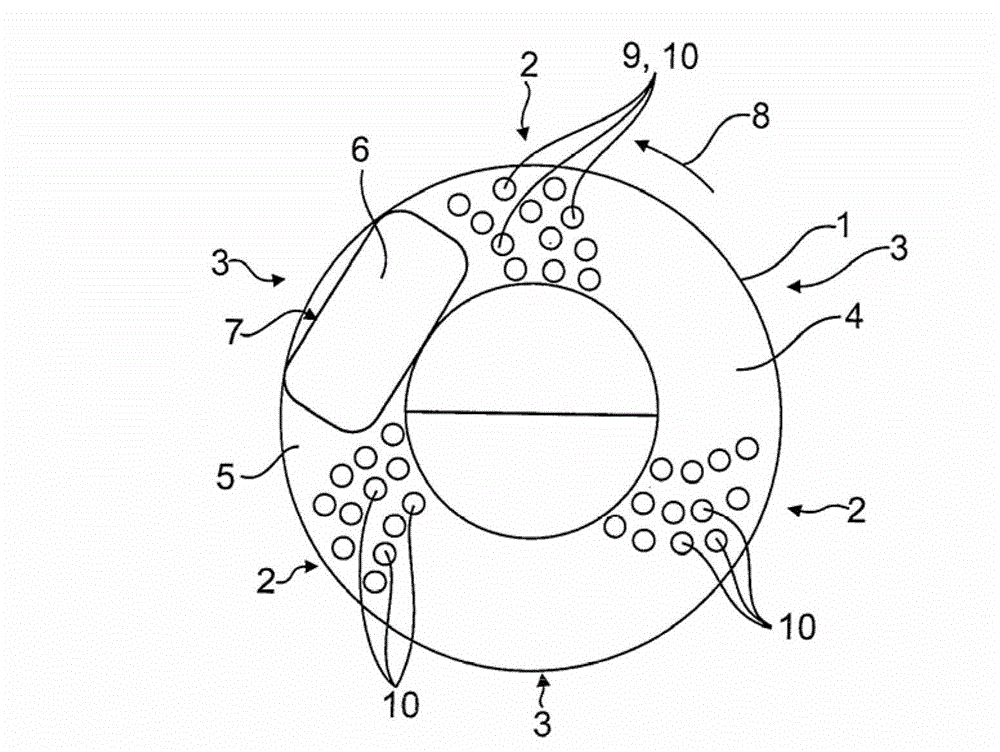

[0024] figure 1 A simplified diagram showing an internally ventilated brake disc 1 with a friction ring 4 divided into perforated segments 2 and unperforated segments 3 , through which brake linings 6 pass during braking The bottom surface / foot surface 7 , which is not visible here, bears against the visible friction surface 5 of the friction ring. On the non-visible rear friction ring of the brake disc 1 lies the opposite brake lining, also not visible here. The bottom surface 7 lies almost completely inside the unperforated segment 3 , so that maximum braking force can be achieved. If the brake disc is rotated further in the direction of rotation 8 , the holes 9 of the segment 2 passing under the brake lining 6 sweep over the bottom area 7 of the brake lining 6 . For the sake of simplicity, only a few of said holes are designated with reference numeral 9 . The remaining perforated segments 2 have corresponding holes, which can be through-holes 10 .

[0025] The holes pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com