Electroplating automatic line exhaust mechanism

An automatic line and fan technology, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of not being able to ensure that all exhaust gas is sucked into the wind hood, polluting the workshop environment, and increasing the amount of exhaust gas, so as to save training costs, facilitate operation, and reduce The effect of active power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: To compare the parameters of this structure and the conventional exhaust fan mechanism, the experimental conditions are set as follows.

[0063] 1. Surface area of ventilation test tank: 1.5*0.8m

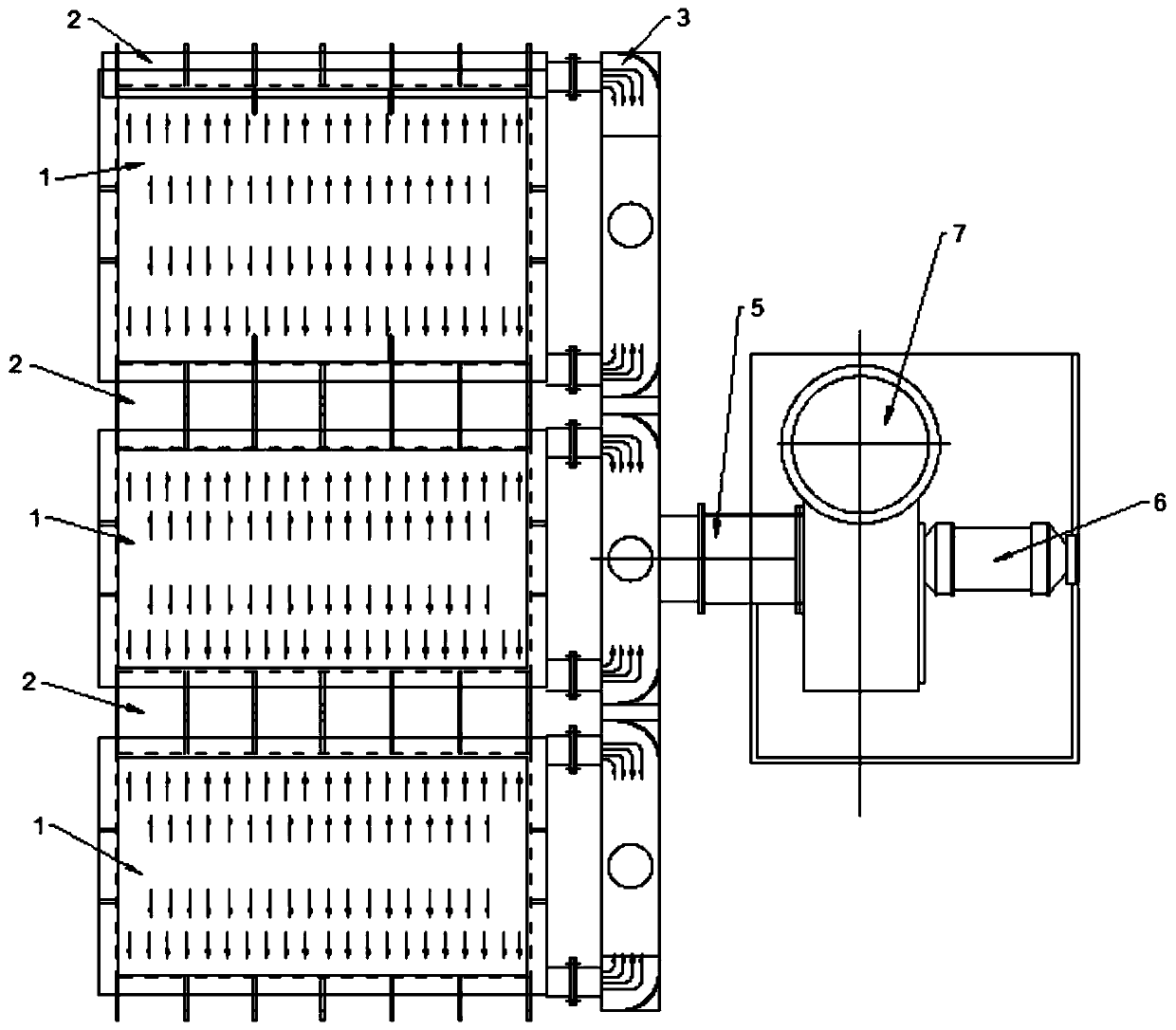

[0064] 2. Air cover 22 on both sides of the groove: traditional slit type air cover 22 and exhaust fan 6 of this structure

[0065] 3. Fan 6: exhaust air volume 2456m3 / h, wind pressure 1100Pa

[0066] 4. Chimney 7 outlet: the diameter is 315mm.

[0067] 5. Test bath: 75-85 degrees hot water

[0068] The following table is a comparison table of the suction parameters of the traditional slit-type windshield 22 and the exhaust fan 6 mechanism of the present structure.

[0069]

[0070] As can be seen from the table above, the traditional air cover 22 and fan 6 are in the high-speed operation state of 50HZ for a long time, and there is still a lot of steam and exhaust gas overflowing from the liquid surface of the solution tank 1, resulting in a humid workin...

Embodiment 2

[0071] Embodiment 2: The driving assembly 21 can be a driving cylinder and a connecting rod structure. On the premise that the space permits, it can directly drive the flap 24 to move through the driving cylinder to realize the rotation of the flap 24, and then realize the opening and closing of the flap 24 Action, if the space is limited, the drive cylinder can realize the action of the turnover plate 24 through the connection structure.

Embodiment 3

[0072] Embodiment 3: The driving assembly 21 can be a rack and pinion structure, and a gear is arranged coaxially on the turning shaft of the turning plate 24, and a rack is arranged to mesh with the gear, and the rack moves up and down under the action of the cylinder or the motor screw to drive the gear Rotate, realized the rotation of turning plate 24.

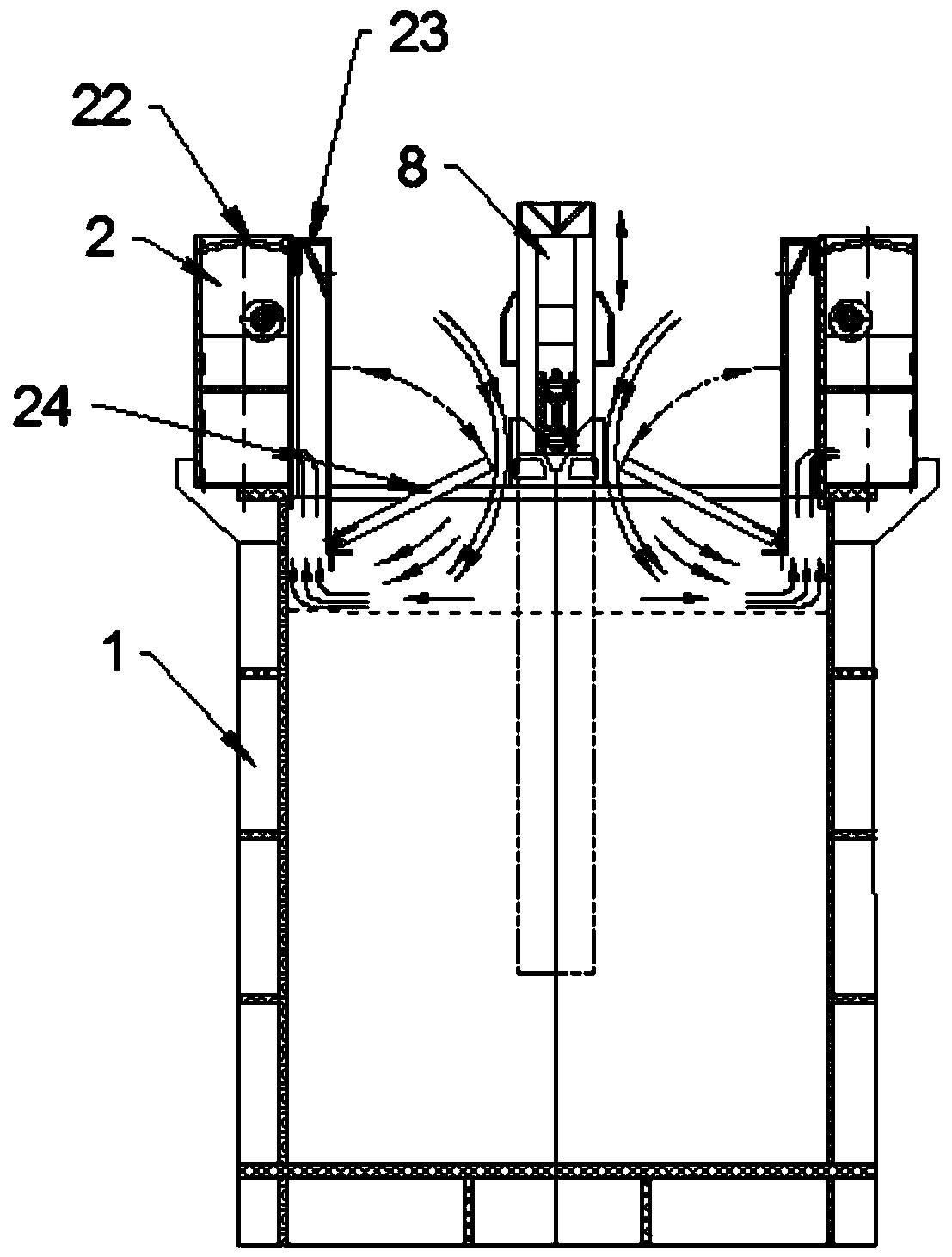

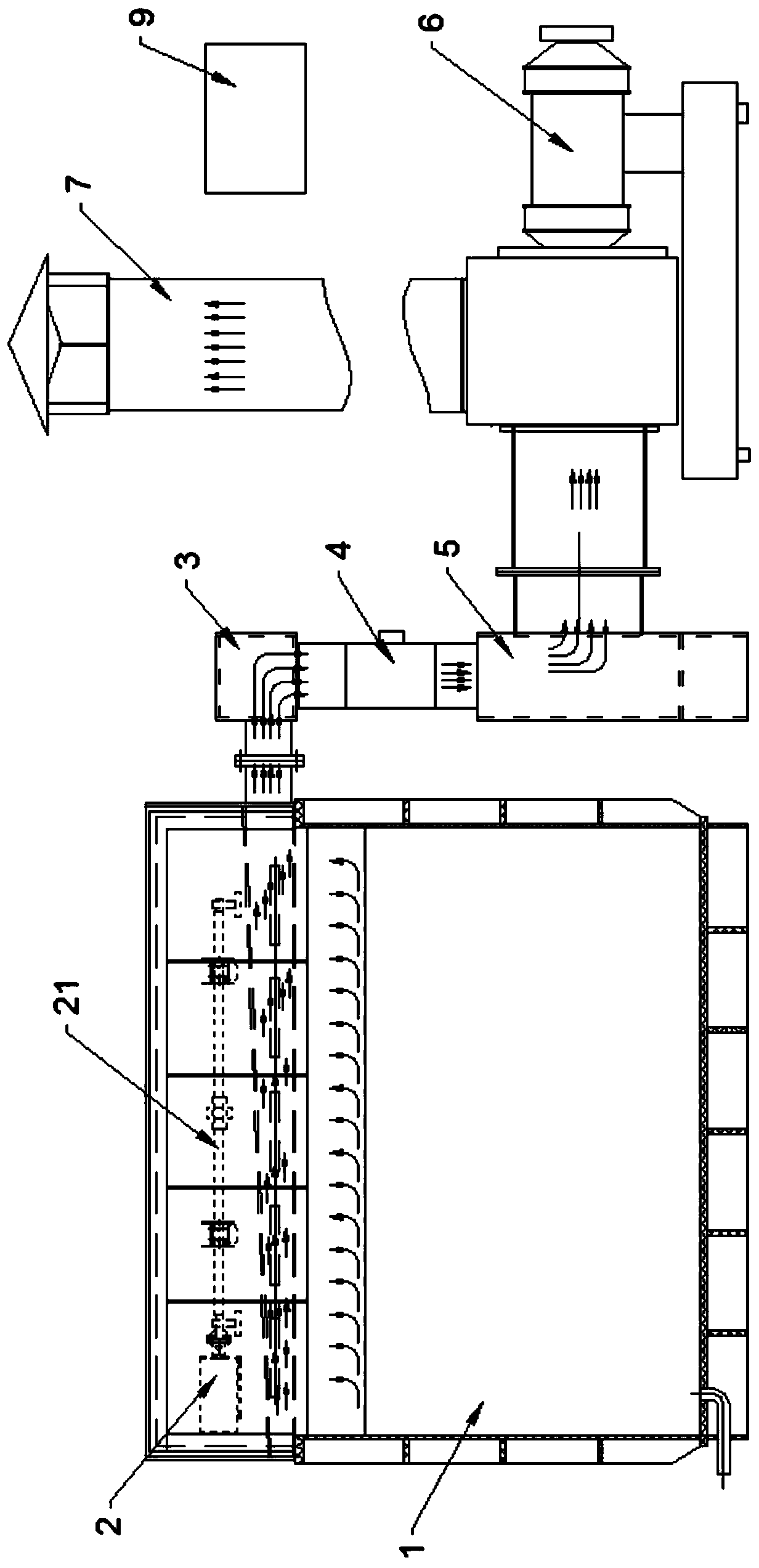

[0073] In the actual work process, such as Figure 1 ~ Figure 3 As shown, the direction of the arrow is a schematic diagram of the flow direction of the gas. The exhaust assembly 2 is arranged on both sides of the upper end of the solution tank 1 of the automatic production line. The drive assembly 21 is placed in the wind cover 22, and the drive motor 211 drives the drive wheel 213 through the drive shaft 212. Rotate, the drive shaft 212 wheel drives the flap 24 to turn over through the drive belt 214, realizing the opening action of the exhaust assembly 2, and the reverse movement can realize the closing action of the exh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com