Preparation method of PANI/FE3O4/MWCNTs-paraffin composite material

A technology of composite materials and paraffin wax, which is applied in the field of preparation of PANI/Fe3O4/MWCNTs-paraffin wax composite materials, can solve the problems of low mass fraction, poor adhesion performance, unevenness, etc., and achieve uniform surface, good dielectric properties, and coating uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention provides a preparation method of PANI / Fe3O4 / MWCNTs-paraffin wax composite material. In order to make the purpose, technical scheme and effect of the present invention clearer and clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

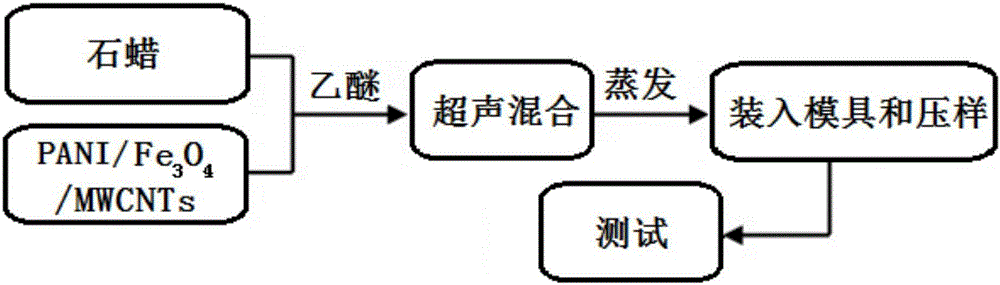

[0018] like figure 1 As shown, in the examples, this example includes the functionalization of MWCNTs, the preparation of PANI / Fe3O4 / MWCNTs heterostructures and the preparation of PANI / Fe3O4 / MWCNTs-paraffin composites.

[0019] Among them, the functionalization process of MWCNTs is as follows:

[0020] Although carbon nanotubes have excellent physical and chemical properties, due to the strong van der Waals force between carbon nanotubes, they are prone to agglomeration, which seriously affe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com