Method for preparing nano TiO2/wollastonite compound used for papermaking

A wollastonite and composite technology, which is applied in the field of preparation of nano-TiO2/wollastonite composites for papermaking, can solve the problems of easy agglomeration and coating effect, high cost of composite particles, unsuitable for industrial application, and poor performance, and achieves weather resistance. Good performance, high output, uniform coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

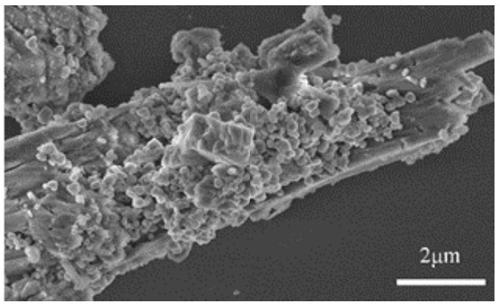

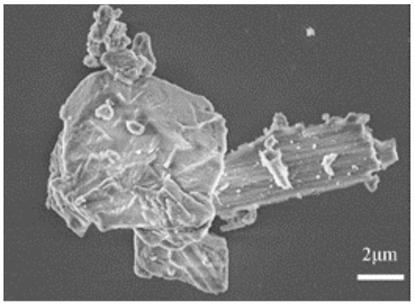

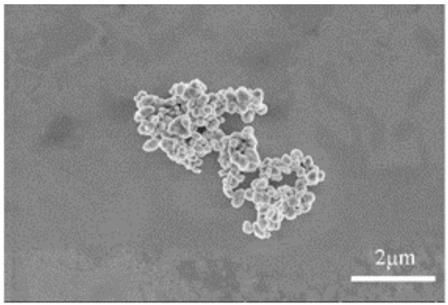

Embodiment 1

[0036] Add 30g of wollastonite to 270ml of distilled water to prepare a 10% slurry, filter through a 200-mesh screen, add 1.5g of rutile titanium dioxide, 0.01g of dispersant PEG-1000, 5g of sodium hydroxide, stir in a water bath at 50°C for 30min, and then The slurry was transferred to a quartz glass carbonization tube, and air and CO were introduced in a water bath at 50°C. 2 Mix the gas with a volume ratio of 2:1 to pH = 7 to obtain a white slurry. After vacuum filtration, place it in an oven at 80°C for 12 hours to obtain nano-TiO 2 / wollastonite composite products. The whiteness value of the obtained product was 92.2, and the yield was 88.49%. The obtained compound was used as the main filler of paper in papermaking, and the whiteness of the obtained paper was 81.3, the hiding power was 90.5, and the tearing degree was 16mN.

Embodiment 2

[0038] Add 30g of wollastonite to 270ml of distilled water to prepare a 10% slurry, filter through a 200-mesh screen, add 3g of rutile titanium dioxide, 0.01g of dispersant PEG-1000, 5g of sodium hydroxide, stir in a water bath at 50°C for 30min, and then dissolve the slurry Transfer to a quartz glass carbonization tube, and pass air and CO under the condition of a 50°C water bath 2 Mix the gas with a volume ratio of 2:1 to pH = 7 to obtain a white slurry. After vacuum filtration, place it in an oven at 80°C for 12 hours to obtain nano-TiO 2 / wollastonite composite products. The whiteness value of the obtained product was 92.8, and the yield was 90.66%. The obtained compound is used as the main filler of paper in papermaking, and the whiteness of the obtained paper is 82.1, the hiding power is 91.2, and the tearing degree is 40mN.

Embodiment 3

[0040] Add 30g of wollastonite to 270ml of distilled water to prepare a 10% slurry, filter through a 200-mesh screen, add 4.5g of rutile titanium dioxide, 0.01g of dispersant PEG-1000, 5g of sodium hydroxide, stir in a water bath at 50°C for 30min, and then The slurry was transferred to a quartz glass carbonization tube, and air and CO were introduced in a water bath at 50°C. 2 Mix the gas with a volume ratio of 2:1 to pH = 7 to obtain a white slurry. After vacuum filtration, place it in an oven at 80°C for 12 hours to obtain nano-TiO 2 / wollastonite composite products. The whiteness value of the obtained product was 93.3, and the yield was 91.85%. The obtained compound was used as the main filler of paper in papermaking, and the whiteness of the obtained paper was 86.4, the hiding power was 91.8, and the tearing degree was 48mN.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com