Dry polishing of intraocular lenses

An intraocular lens, polishing medium technology, applied in the direction of intraocular lens, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of inappropriate manufacturing process, impracticality and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

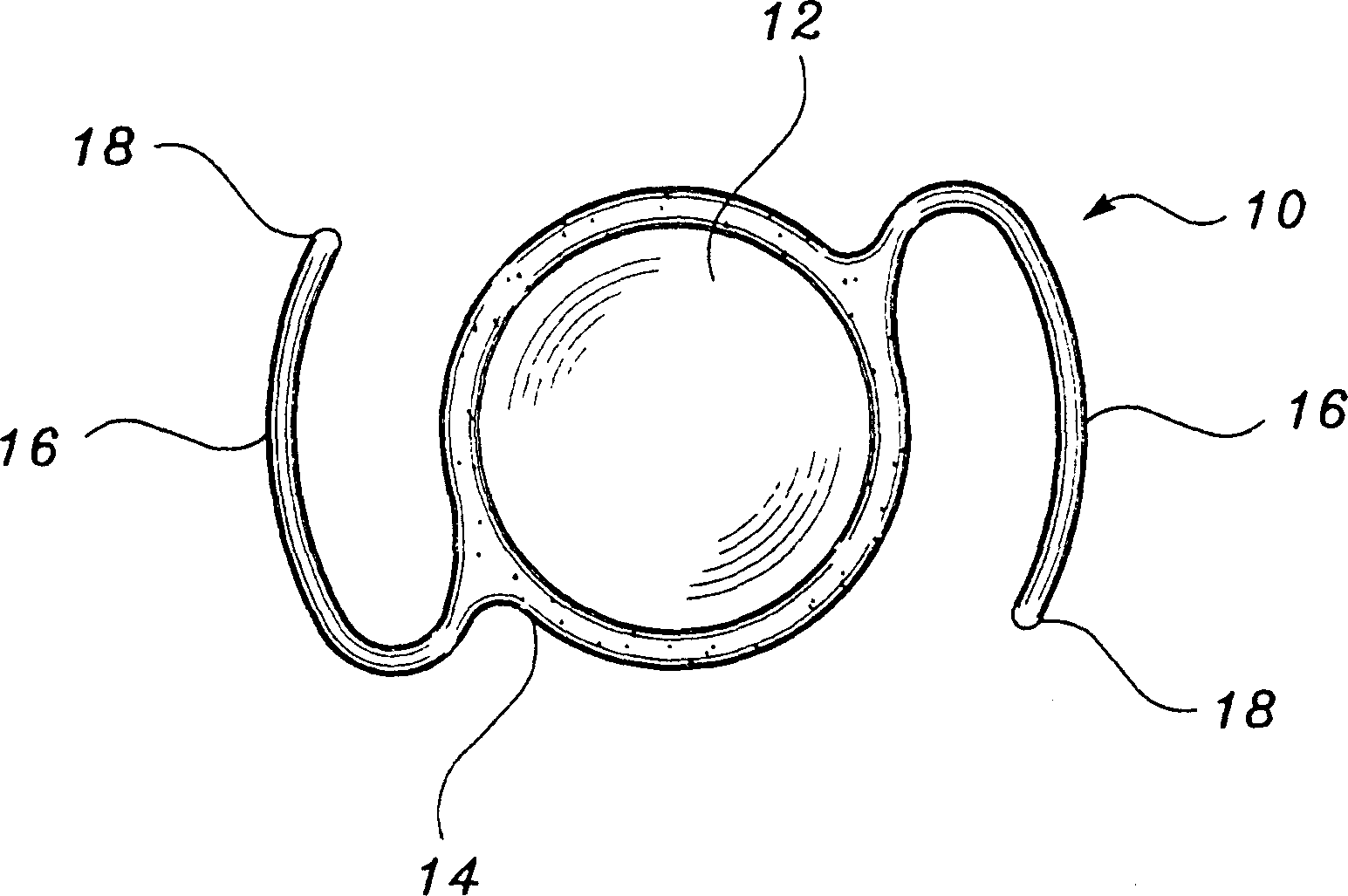

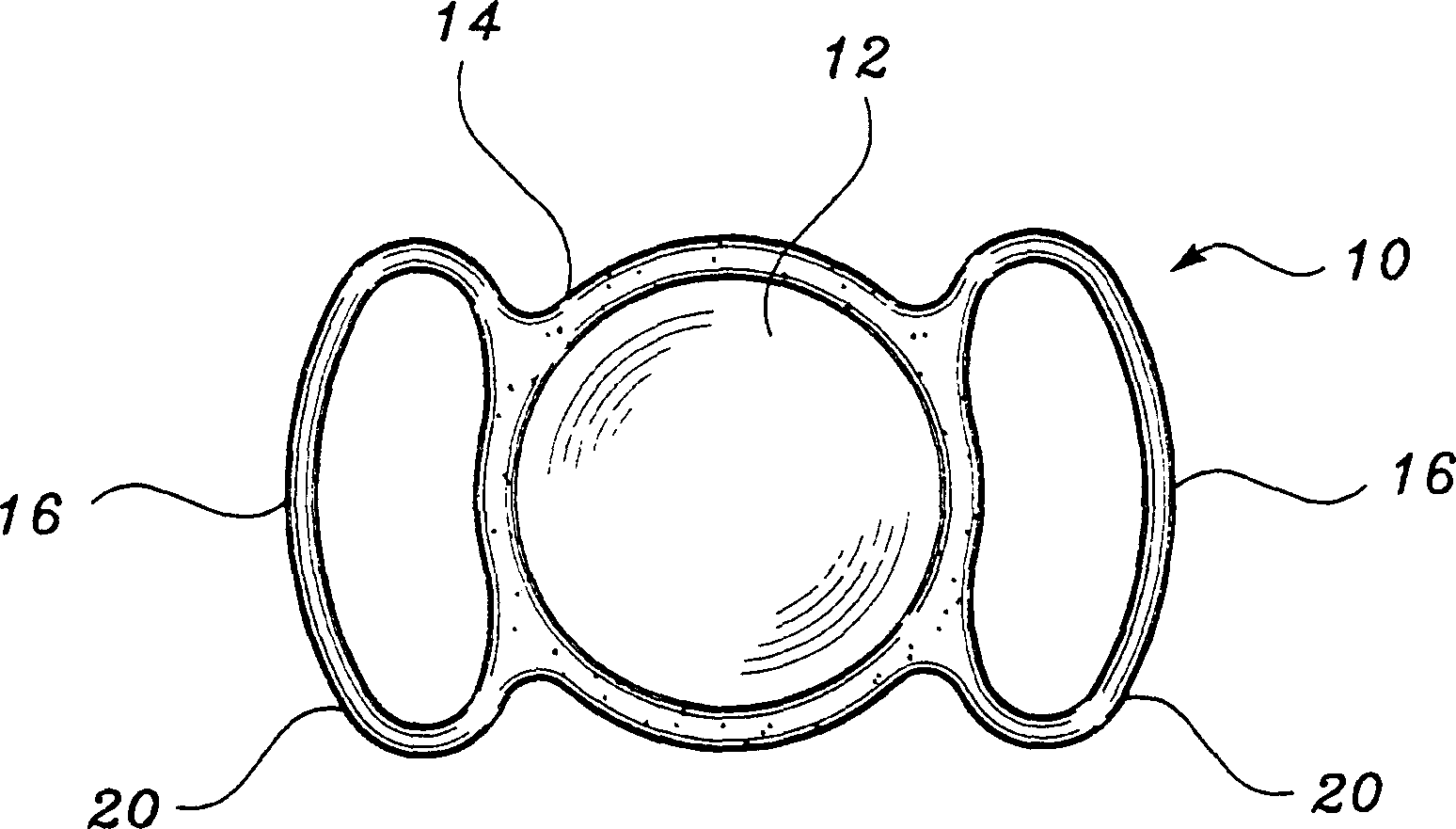

[0034] Example 1: Dry polishing of silicone intraocular lenses and intraocular lenses under the trademark "Hydroview"

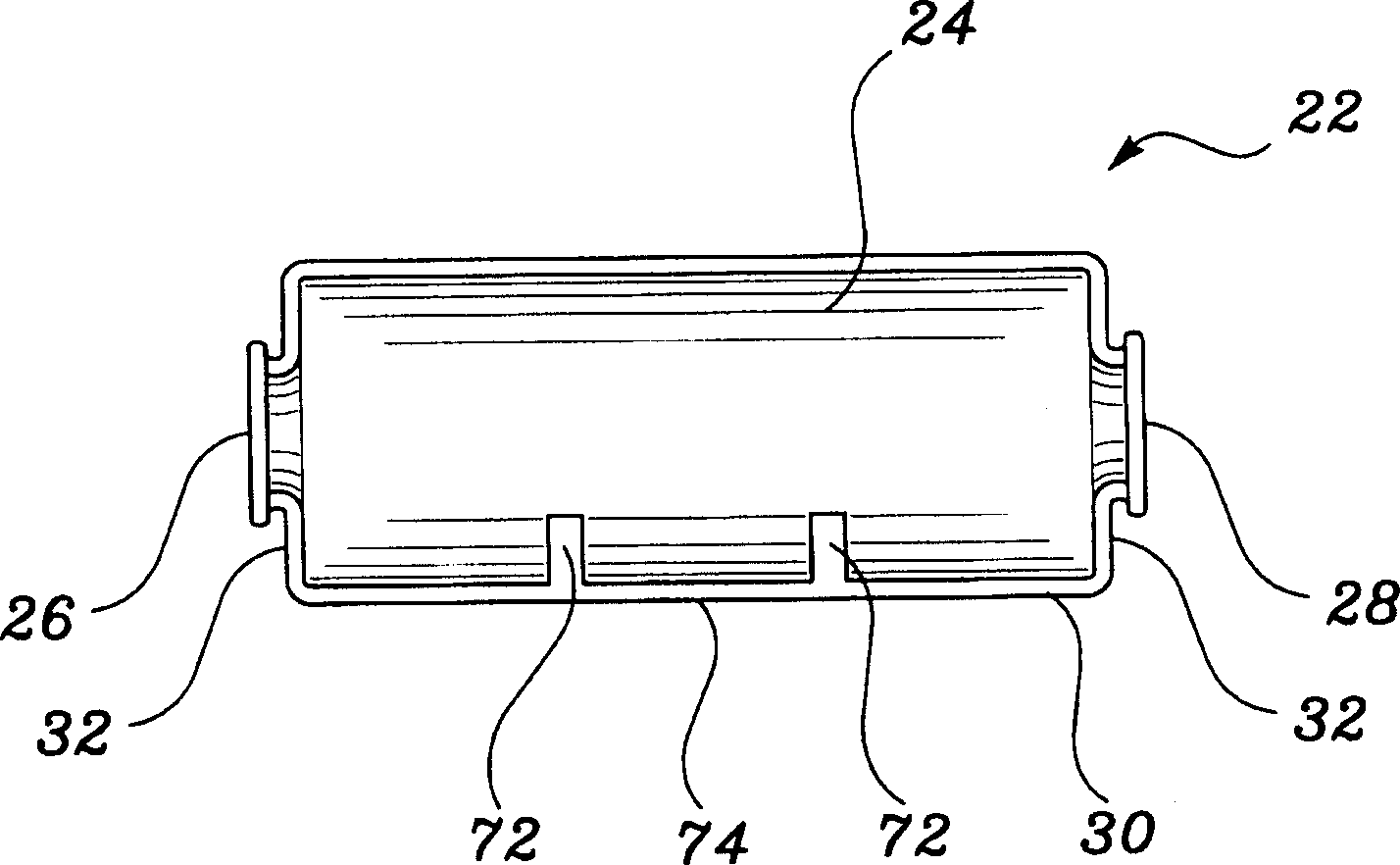

[0035] According to the present invention, ten silicone intraocular lenses and ten Hydroview intraocular lenses were dry polished. Hydroview lenses are double combination lenses that have a hydrogel part and a plexiglass cemented part. Two glass polishing chambers were utilized which were tubular in shape with an internal diameter of 2 inches and a length of 6 inches. One open end of one of the polishing chambers is covered with a plastic cover, and the polishing chamber is loaded with an intraocular lens container filled with 10 intraocular lenses and about 20 grams of glass beads, the diameter of which is 0.4 mm or less. Then, the opening of the second polishing chamber is removably sealed with a cover. Once the polishing chamber is tightly covered, place the polishing chamber horizontally on a motor-driven drum or arm. The rotational speed of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com