Preparation method of homogenized boron nitride coating

A boron nitride and homogenization technology, which is applied in coating, metal material coating process, gaseous chemical plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

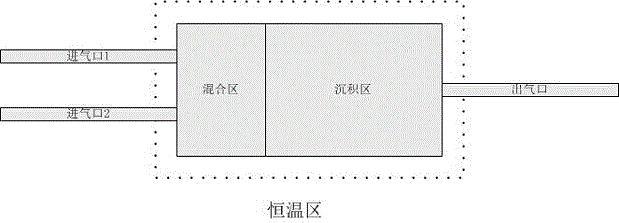

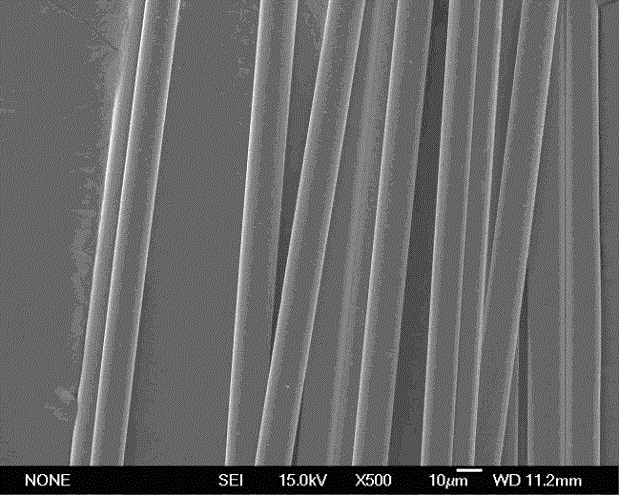

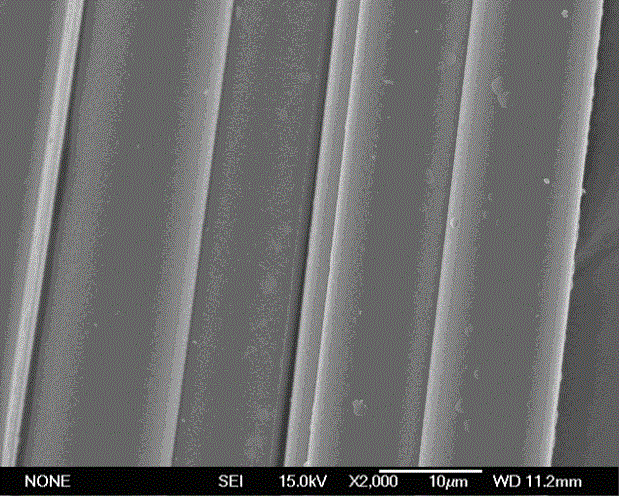

[0018] The first step: install the furnace, place the silicon carbide fiber in the deposition area, the mixing chamber and the reaction chamber are in the constant temperature area of the furnace tube at the same time, and check the air tightness of the system by vacuuming.

[0019] Step 2: Evacuate and heat up, introduce high-purity nitrogen, vacuumize, and cycle like this five times to remove residual air in the system, and heat up according to the set program.

[0020] Step 3: Intake air, heat up to the set deposition temperature of 800°C, maintain the system pressure at 20mbar, feed ammonia gas 60ml / min from inlet 1, and feed high-purity nitrogen 100mlmin and boron trichloride 20ml into inlet 2 / min.

[0021] The fourth step: mixed deposition, the gas enters the constant temperature zone, first mixed in the mixing chamber, and then enters the deposition zone to deposit boron nitride on the surface of the silicon carbide fiber for 2 hours.

[0022] The fifth step: heat t...

Embodiment 2

[0025] The first step: install the furnace, place the cleaned graphite plate in the deposition area, the mixing chamber and the reaction chamber are in the constant temperature area of the furnace tube at the same time, and check the air tightness of the system by vacuuming.

[0026] Step 2: Evacuate and heat up, introduce high-purity nitrogen, vacuumize, and cycle like this five times to remove residual air in the system, and heat up according to the set program.

[0027] Step 3: Intake air, heat up to the set deposition temperature of 1300°C, maintain the system pressure at 20mbar, feed ammonia gas 60ml / min from inlet 1, and feed high-purity nitrogen 100mlmin and boron trichloride 20ml into inlet 2 / min.

[0028] The fourth step: mixed deposition, the gas enters the constant temperature zone, first mixed in the mixing chamber, and then enters the deposition zone to deposit boron nitride on the surface of the graphite plate for 5 hours.

[0029] The fifth step: heat treatm...

Embodiment 3

[0031] The first step: install the furnace, place the needle-punched carbon felt in the deposition area, the mixing chamber and the reaction chamber are in the constant temperature area of the furnace tube at the same time, and check the air tightness of the system by vacuuming.

[0032] Step 2: Evacuate and heat up, introduce high-purity nitrogen, vacuumize, and cycle like this five times to remove residual air in the system, and heat up according to the set program.

[0033] Step 3: Intake air, heat up to the set deposition temperature of 750°C, maintain the system pressure at 20mbar, feed ammonia 60ml / min and hydrogen 100ml / min from inlet 1, and feed high-purity nitrogen 100ml / min and Boron trifluoride 20ml / min.

[0034] The fourth step: mixed deposition, the gas enters the constant temperature zone, first mixed in the mixing chamber, and then enters the deposition zone to deposit boron nitride on the surface of the needle felt for 0.5h.

[0035] The fifth step: heat tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com