Additive capable of improving electrostatic effect for spraying fluorocarbon paint

An electrostatic effect and additive technology, applied in the direction of conductive coatings, etc., can solve the problems of uneven distribution of metal particles, poor spray gun atomization rate, poor conductivity, etc., to achieve increased adsorption rate and paint rate, strong atomization rate, The effect of increasing the conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

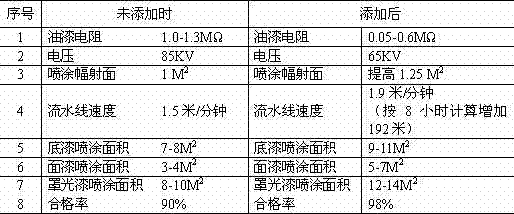

[0018] Embodiment 1 Get formula di-butanone 18%, diethylene glycol butyl ether 15%, methyl isobutyl ketone 2%, butyl acetate 4%, the additive prepared by methylcyclohexane main solution 61%, the workpiece Or the base material passes through the conventional fluorocarbon spraying pretreatment process: degreasing and decontamination, water washing, alkali washing (degreasing), water washing, pickling, water washing, chromization, water washing, and pure water washing. Then add this additive to the fluorocarbon paint, and the added amount is controlled to the same viscosity as other additives. It will be dripped in the measuring cup of ZARNNO0.2 in 18 seconds, sprayed as three coats, the thickness of the primer is 10 μm, and the thickness of the top coat is 10 μm. is 20 μm, and the thickness of the varnish is 10 μm. When spraying, the fan-shaped atomization pressure of the spray gun is 1kg / mpa, and the electrostatic voltage is 60KV. The spraying process is as follows: primer, top...

Embodiment 2

[0019] Example 2 Di-butanone 20%, diethylene glycol butyl ether 11%, methyl isobutyl ketone 4%, butyl acetate 5%, n-hexane main solution 60% additives prepared, the rest are the same as in Example 1 . The effect is also very good, and its technical parameters are basically the same as the above table.

Embodiment 3

[0020] Embodiment 3 Di-butanone 15%, diethylene glycol butyl ether 20%, methyl isobutyl ketone 3%, butyl acetate 6%, the additive that n-pentane main solution 56% is mixed with, all the other and embodiment 1 same. The effect is also very good, and its technical parameters are the same as the above table.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com