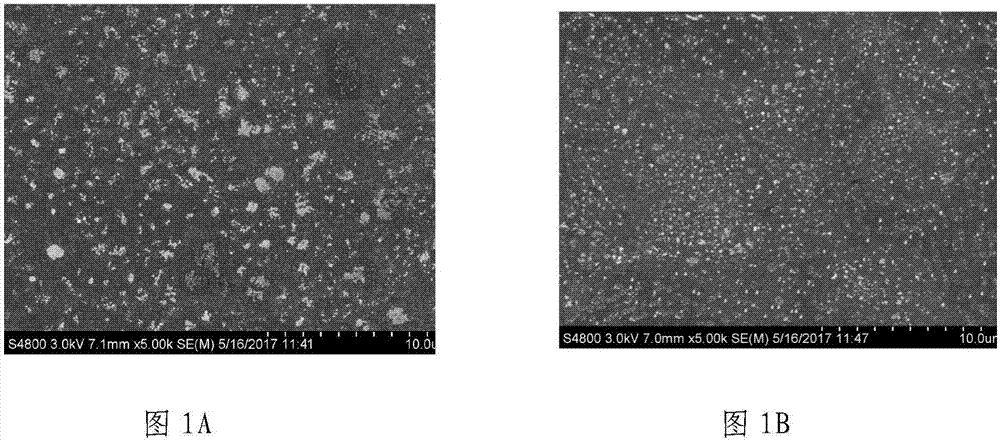

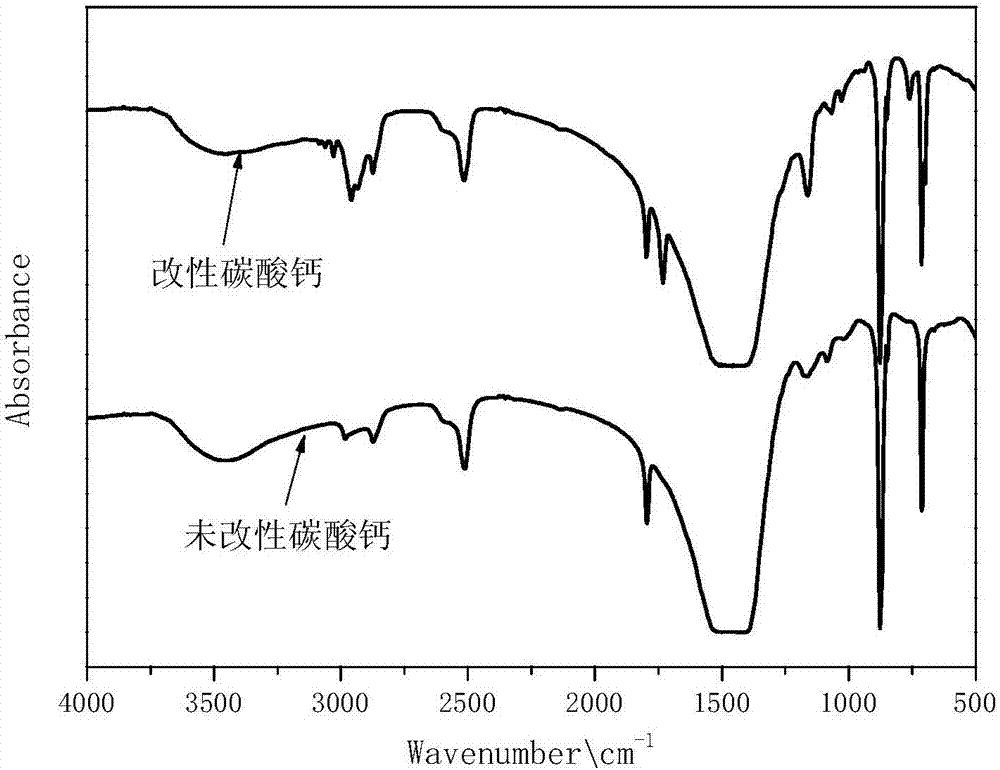

Preparation method of modified nano calcium carbonate powder for high-end waterborne coatings

A nano-calcium carbonate powder and nano-calcium carbonate technology are applied in the direction of chemical instruments and methods, coatings, fibrous fillers, etc., which can solve the complex process of in-situ polymerization, the easy loss of modifiers with water, and the amount of modifiers. Large and other problems, to achieve the effect of good dispersion and coating, short cycle, large amount of modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] The preparation method of the modified nano-calcium carbonate powder for high-end water-based paint comprises the following process steps:

[0046] A. Preparation of polymer emulsion

[0047] Prepared with the following reactants in parts by mass:

[0048] 40-50 parts of styrene; 20-30 parts of butyl acrylate; 1-2 parts of methacrylic acid; 1-2 parts of acrylamide; 1.0 parts of sodium lauryl sulfate; 1.0 parts of OP-10; 0.5 parts of potassium persulfate parts; 0.5 parts of sodium bicarbonate; 100 parts of deionized water

[0049] The reaction steps are as follows:

[0050] A1. Take 20 parts of deionized water, dissolve sodium lauryl sulfate and OP-10 in it to make an emulsifier aqueous solution; take 20 parts of deionized water, dissolve potassium persulfate and sodium bicarbonate in it to make an emulsifier solution agent aqueous solution;

[0051] A2. Place 15 parts of the emulsifier aqueous solution prepared in step A1 in a reaction flask and add 30 parts of deio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com