Positive electrode material and preparation method thereof, lithium ion battery

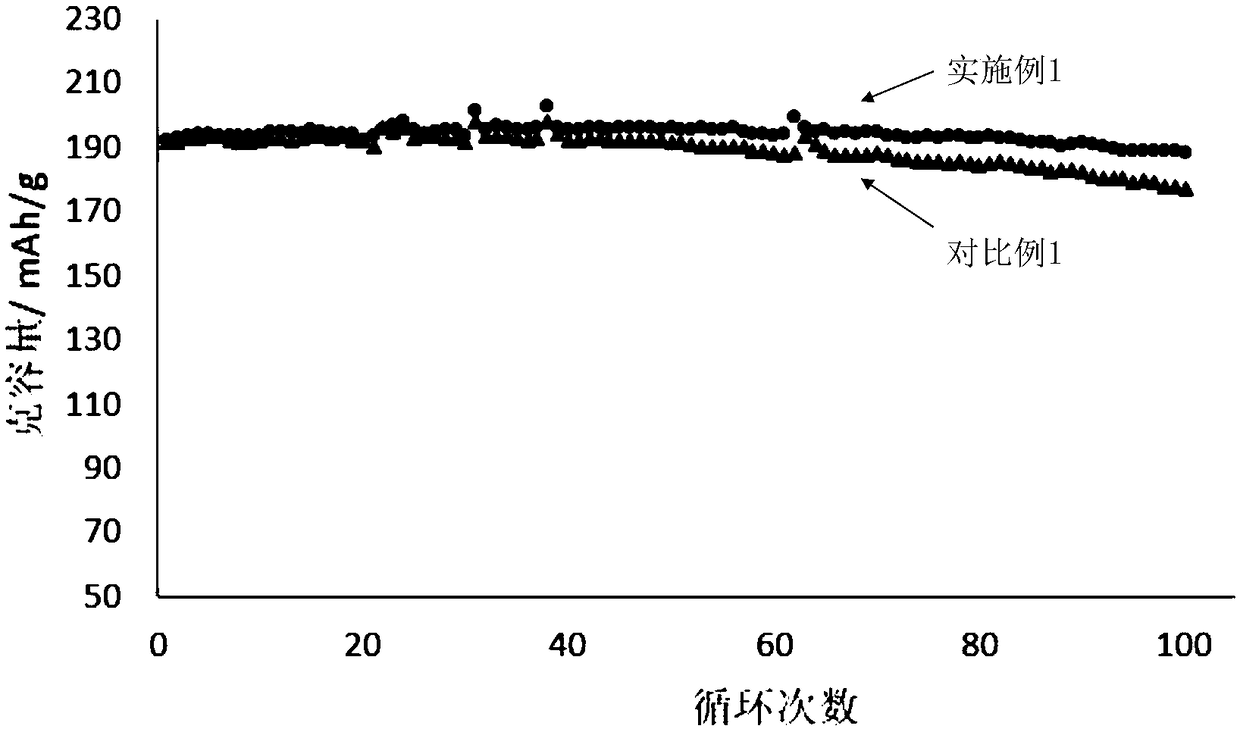

A powder material and coating technology, which is applied in the fields of lithium ion batteries, positive electrode materials and preparation methods, can solve the problems of difficult uniform coating on the surface, agglomeration of high nickel materials, and poor control of material particle size, etc., and is convenient for scale. Effects of production, low cost, excellent cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Weigh 10g of 811NCM powder material, put it into a mixed solution of 1000mL ethanol and deionized water (1:1 volume ratio) and stir for 30min to form solution A; the concentration of 811NCM solution is 2mg / mL ;

[0033] 2. Weigh 0.32g of Bi(NO 3 ) 3 ·5H2 O, dissolved in 500mL deionized water to form solution B; where 811NCM and Bi(NO 3 ) 3 ·5H 2 The molar ratio of O is 200:1, Bi(NO 3 ) 3 ·5H 2 The concentration of O aqueous solution is 0.64mg / mL;

[0034] 3. Add solution A dropwise to solution B, stir and mix for 1 hour to form solution C;

[0035] 4. Measure 500mL (NH 4 )H 2 PO 4 Aqueous solution (concentration is 0.2mg / mL), in stirring process, drips into solution C drop by drop, obtains mixed solution D; Wherein (NH 4 )H 2 PO 4 with Bi(NO 3 ) 3 ·5H 2 The mol ratio of O is 1:1; Wherein, rate of addition is 5mL / min;

[0036] 5. Heat the mixed solution D in a water bath while stirring, the temperature is 80°C, the stirring time is 2 hours, and the s...

Embodiment 2

[0039] 1. Put the 811NCM powder material into the mixed solution of ethanol and deionized water (1:1 volume ratio) for ultrasonic dispersion for 1 hour to form solution A; the concentration of 811NCM solution is 10mg / mL;

[0040] 2. Weigh Bi(NO 3 ) 3 ·5H 2 O, dissolved in deionized water to form solution B; where 811NCM and Bi(NO 3 ) 3 ·5H 2 The molar ratio of O is 300:1, Bi(NO 3 ) 3 ·5H 2 The concentration of O aqueous solution is 0.2 mg / mL;

[0041] 3. Add solution A dropwise to solution B, stir and mix for 20 minutes to form solution C;

[0042] 4. (NH 4 )H 2 PO 4 Aqueous solution (concentration is 0.047mg / mL), in stirring process, drips into solution C drop by drop, obtains mixed solution D; Wherein (NH 4 )H 2 PO 4 with Bi(NO 3 ) 3 ·5H 2 The mol ratio of O is 1:1; Wherein, rate of addition is 0.2mL / min;

[0043] 5. Heat the mixed solution D in a water bath while stirring, the temperature is 65°C, the stirring time is 4h, and the stirring speed is 200r / min...

Embodiment 3

[0046] 1. Put the powder material of 811NCM in the mixed solution of ethanol and deionized water (1:1 volume ratio) for ultrasonic dispersion for 1 hour to form solution A; the concentration of 811NCM solution is 20mg / mL;

[0047] 2. Weigh Bi(NO 3 ) 3 ·5H 2 O, dissolved in deionized water to form solution B; where 811NCM and Bi(NO 3 ) 3 ·5H 2 The molar ratio of O is 100:1, Bi(NO 3 ) 3 ·5H 2 The concentration of O aqueous solution is 2mg / mL;

[0048] 3. Add solution A dropwise to solution B, stir and mix for 1 hour to form solution C;

[0049] 4. (NH 4 )H 2 PO 4 Aqueous solution (concentration is 0.47mg / mL), in stirring process, drips into solution C drop by drop, obtains mixed solution D; Wherein (NH 4 )H 2 PO 4 with Bi(NO 3 ) 3 ·5H 2 The mol ratio of O is 1:1; Wherein, rate of addition is 10mL / min;

[0050] 5. Heat the mixed solution D in a water bath while stirring. The temperature is 90°C, the stirring time is 30min, and the stirring speed is 1000r / min. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com