Patents

Literature

47results about How to "Improve the bonding rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

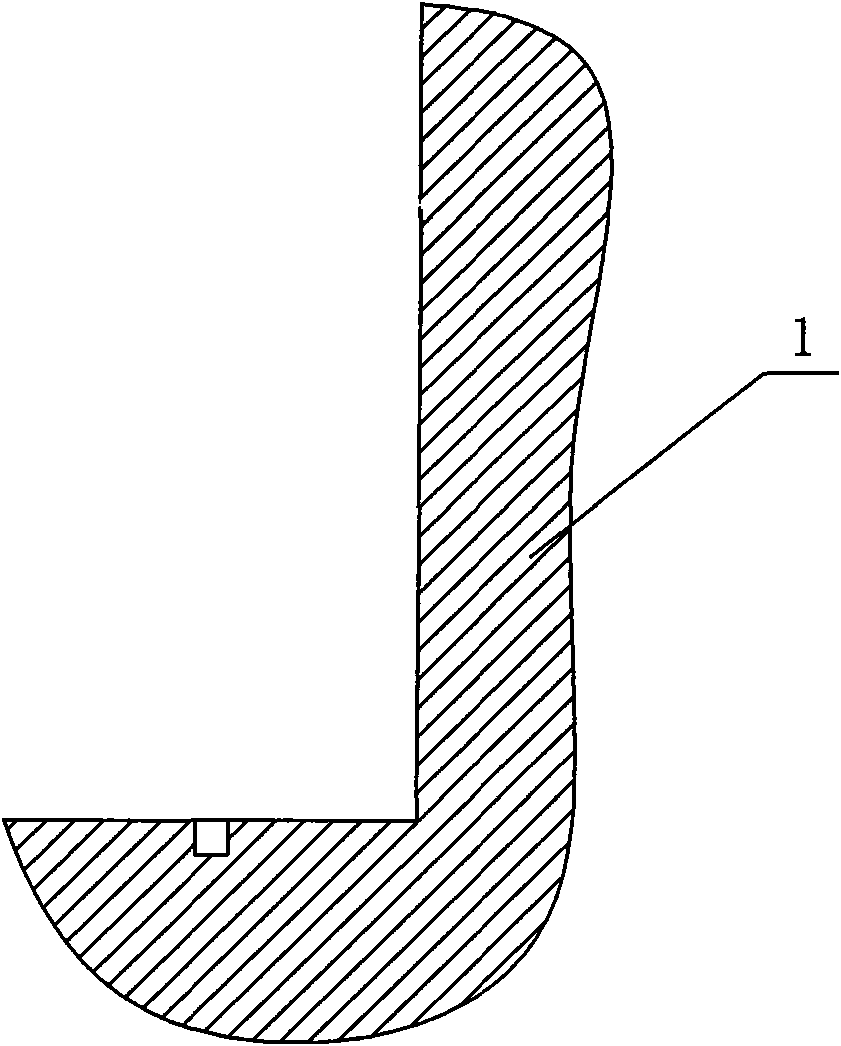

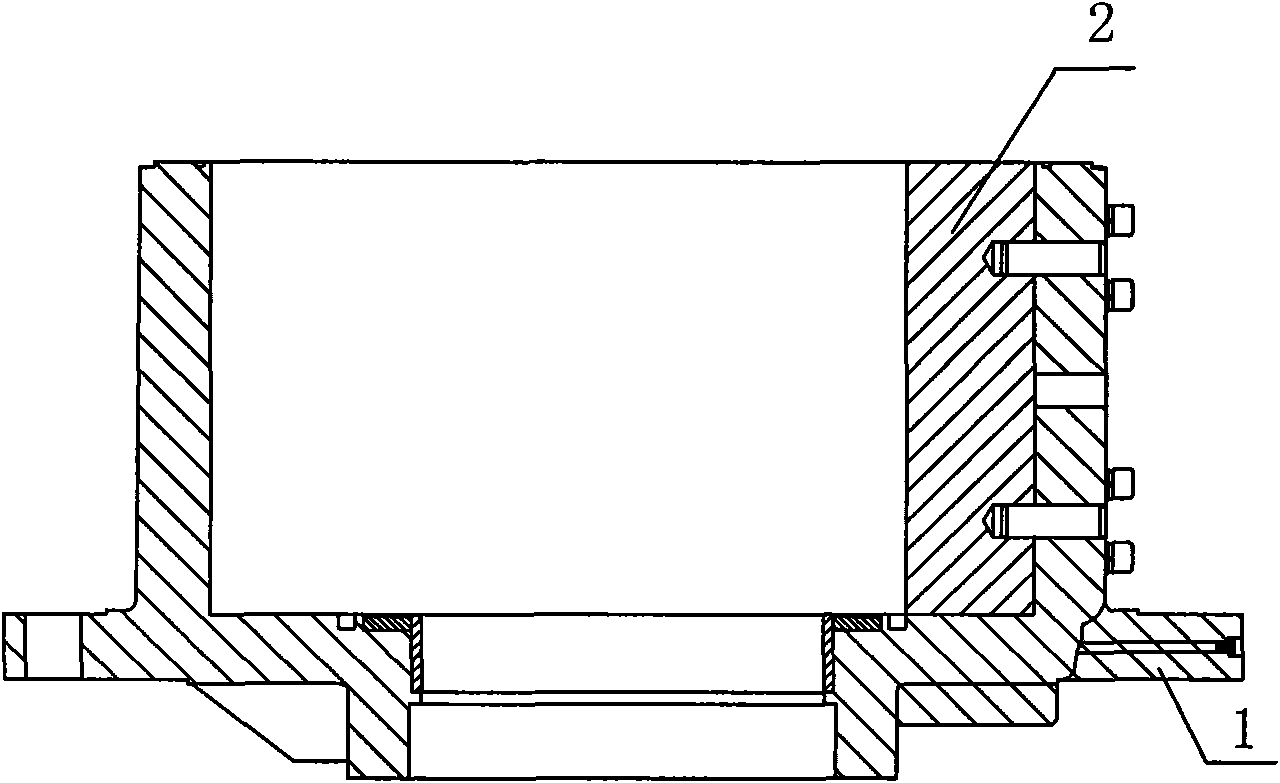

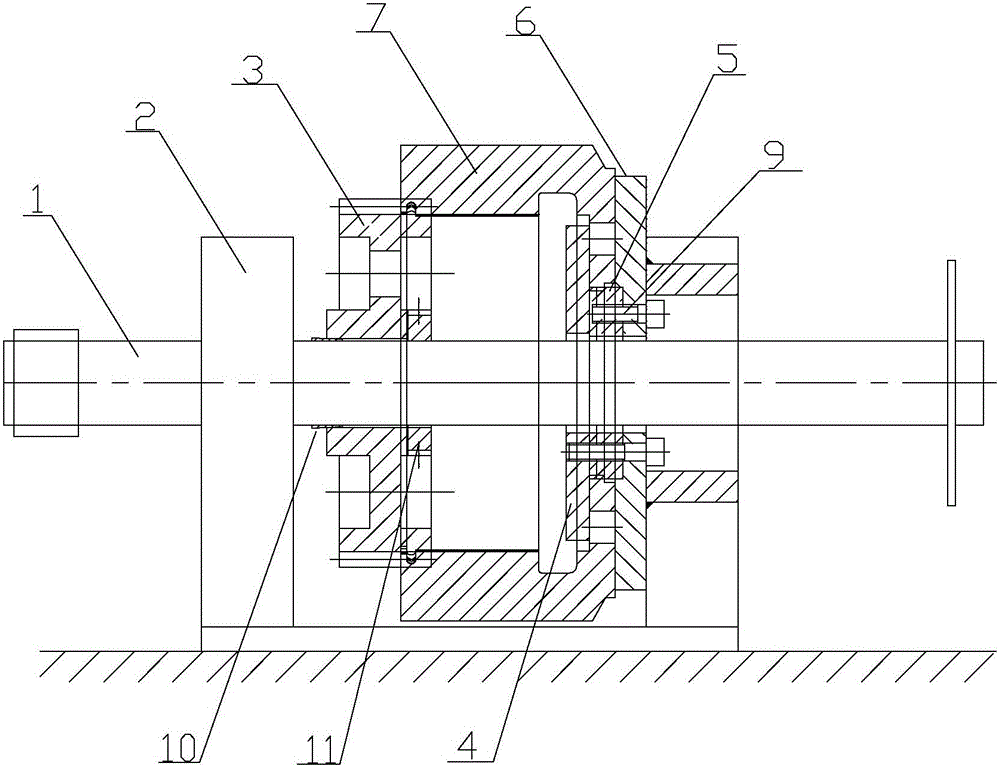

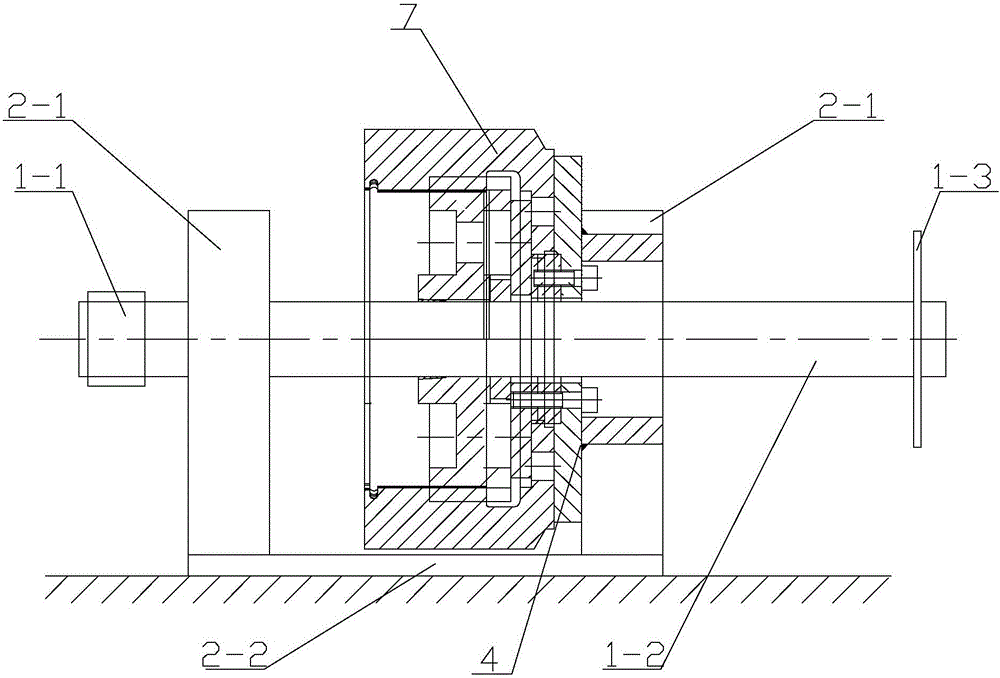

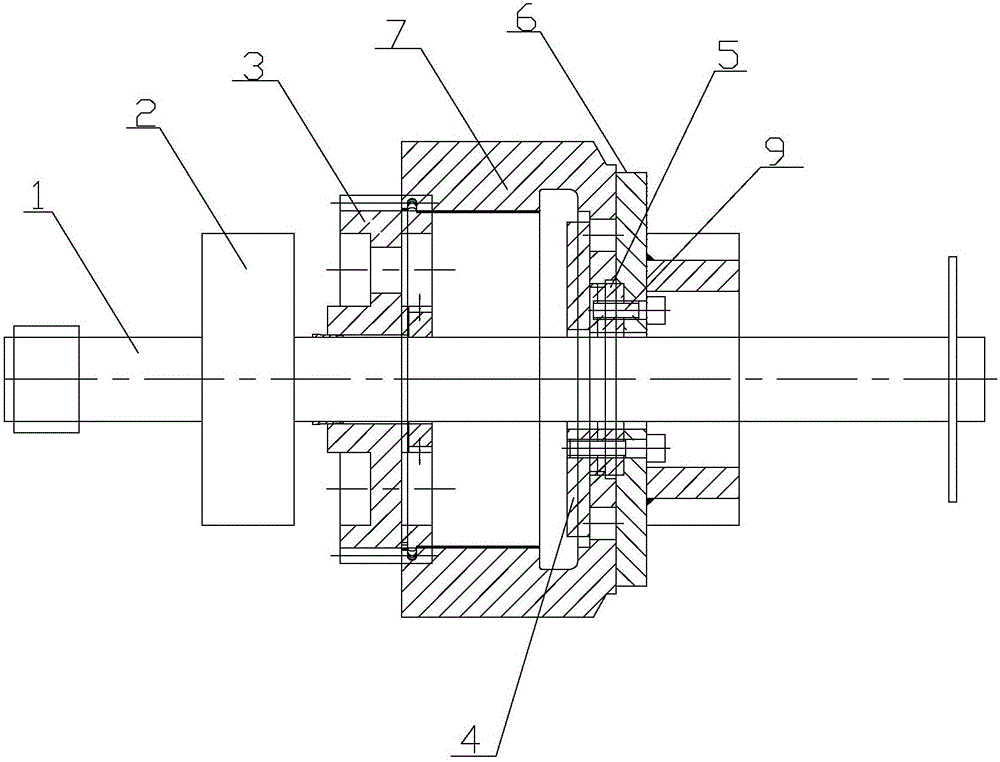

Machining technology for rotary blade type hydraulic steering gear

InactiveCN101537569AImprove consistencyReduce manufacturing costOther manufacturing equipments/toolsEngineeringCopper

The invention relates to the machining technology for a steering gear, in particular to the machining technology for a rotary blade type hydraulic steering gear, comprising a machining procedure for an inside hole of a cylinder body and a sealing surface at the lower end of the cylinder body, a machining procedure for a sealing groove on the sealing surface at the lower end of the cylinder body, a machining procedure for appearance of a stationary blade and a machining procedure for the stationary blade and a connecting hole of the cylinder body, a combination machining procedure for the cylinder body, the stationary blade and a copper sleeve, a machining procedure for an inside conical hole of a rotor and a machining procedure for an incomplete arc surface of the rotor. The machining procedures of the invention can greatly improve the machining accuracy and efficiency of each main part of the rotary blade type hydraulic steering gear, lower the production cost, as well as improve the working efficiency and the product quality.

Owner:CSSC NANJING LUZHOU MACHINE

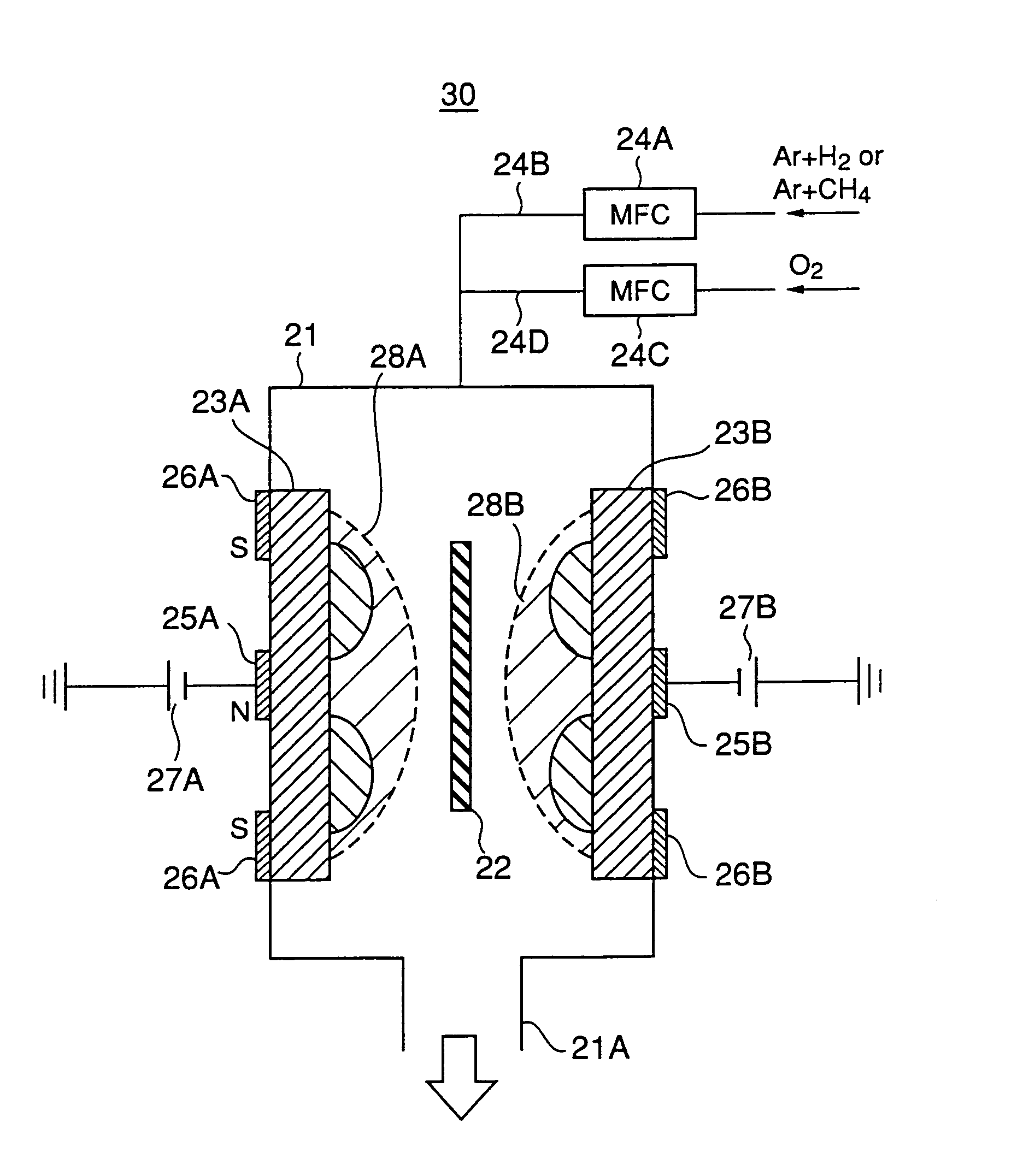

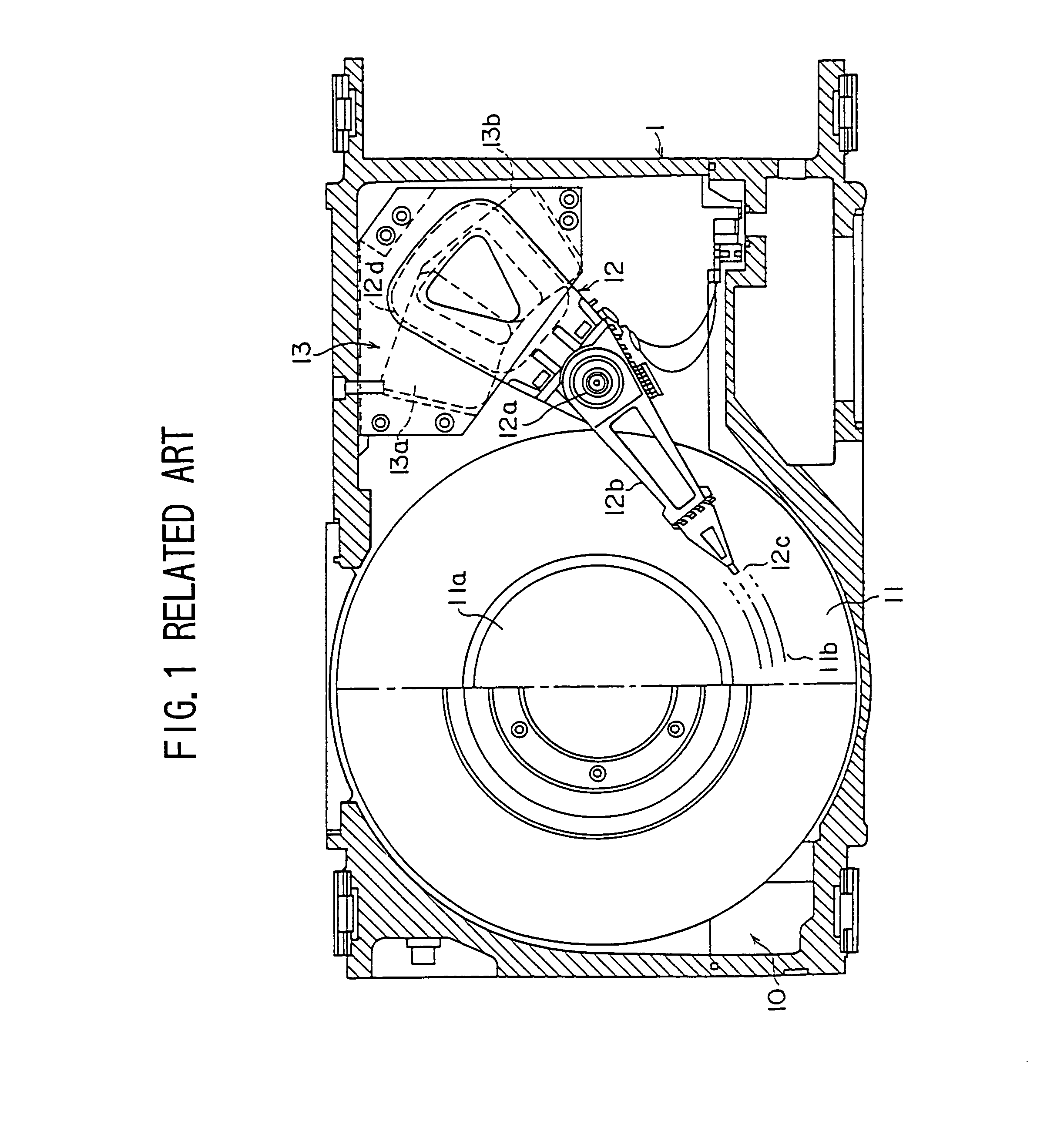

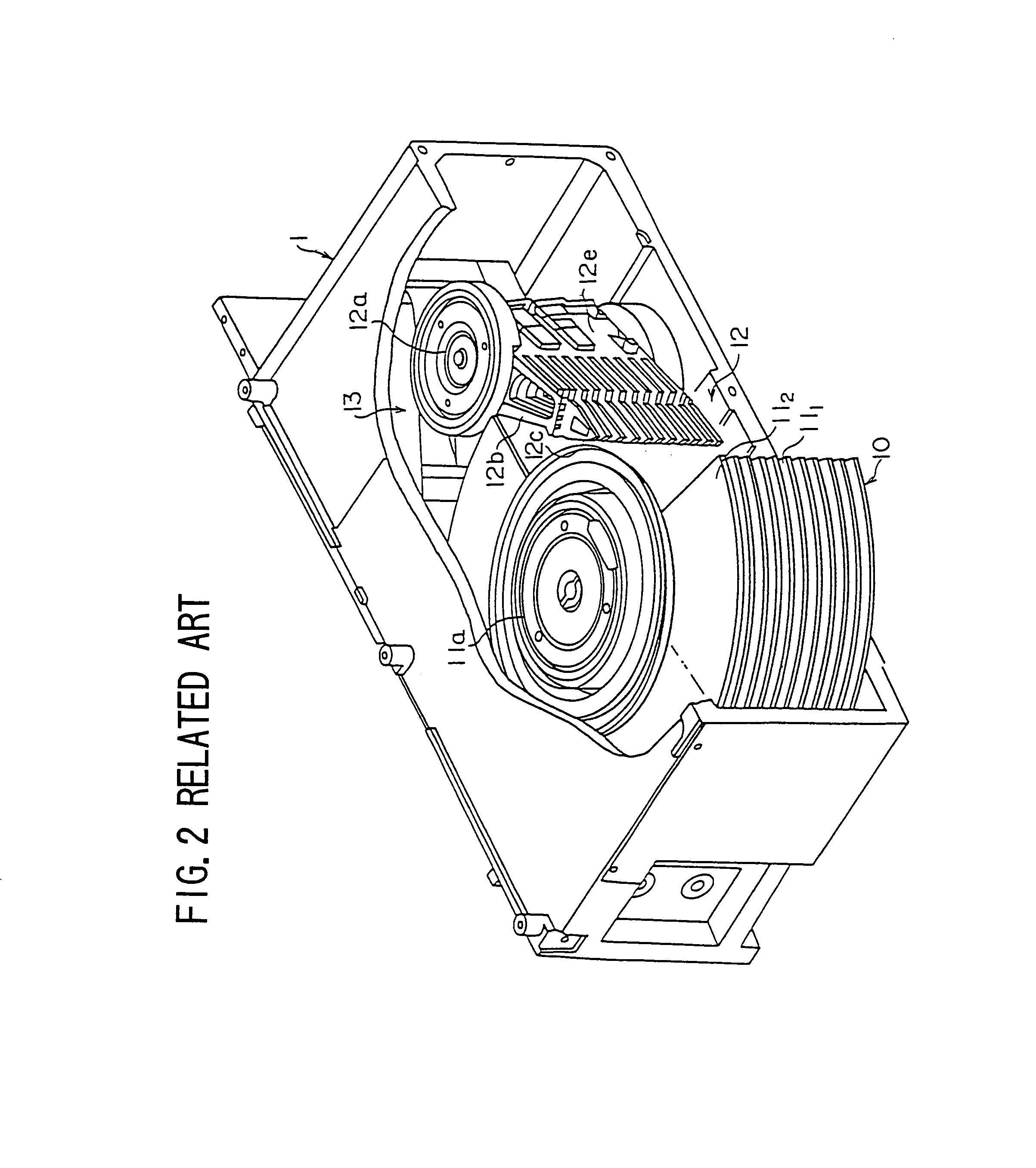

Magnetic disk drive having a surface coating on a magnetic disk

InactiveUS7081277B1Increase binding rateStrong adhesionVacuum evaporation coatingPretreated surfacesEnd-groupOxygen

A magnetic disk is produced with improved yield by forming a DLC protective film by a d.c. magnetron sputtering process conducted in a sputtering atmosphere containing oxygen. The magnetic disk carries a lubricating film on the DLC film wherein a fluorocarbon resin constituting the lubricating film contains photocrosslinking groups. A lubricating film having non-polar end groups is also disclosed.

Owner:KK TOSHIBA

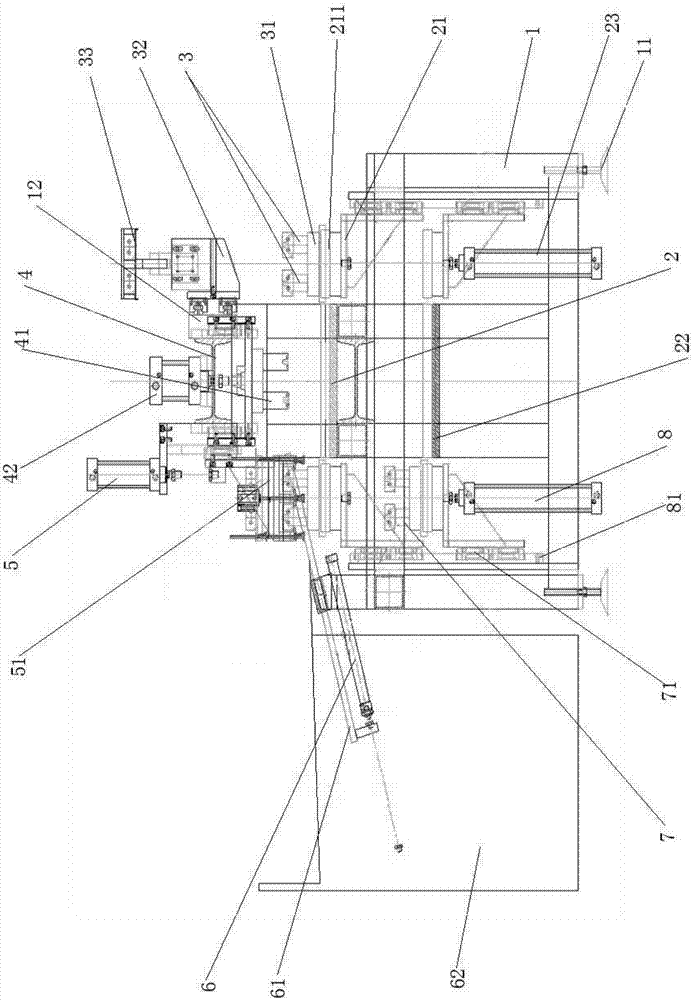

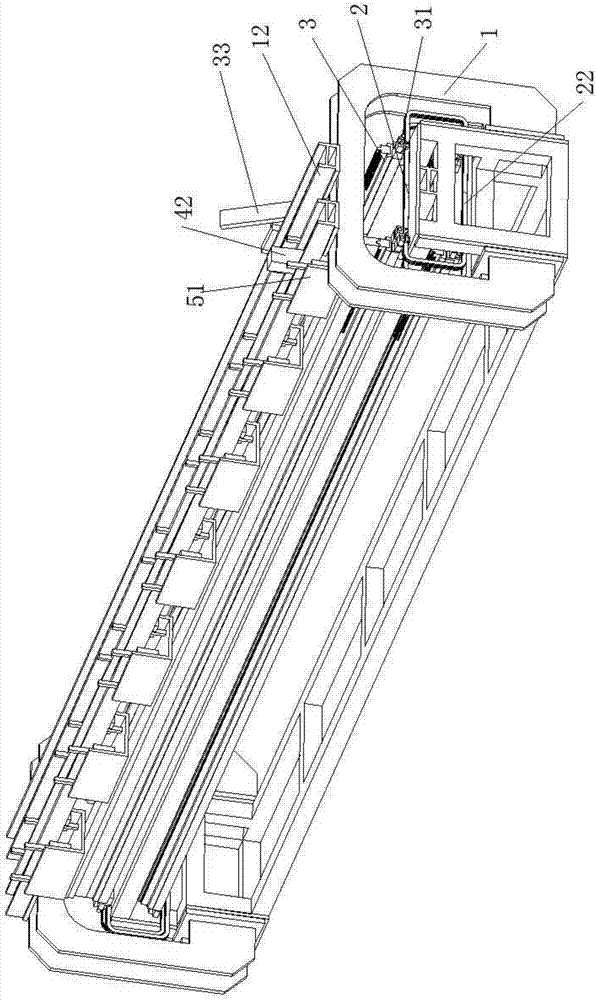

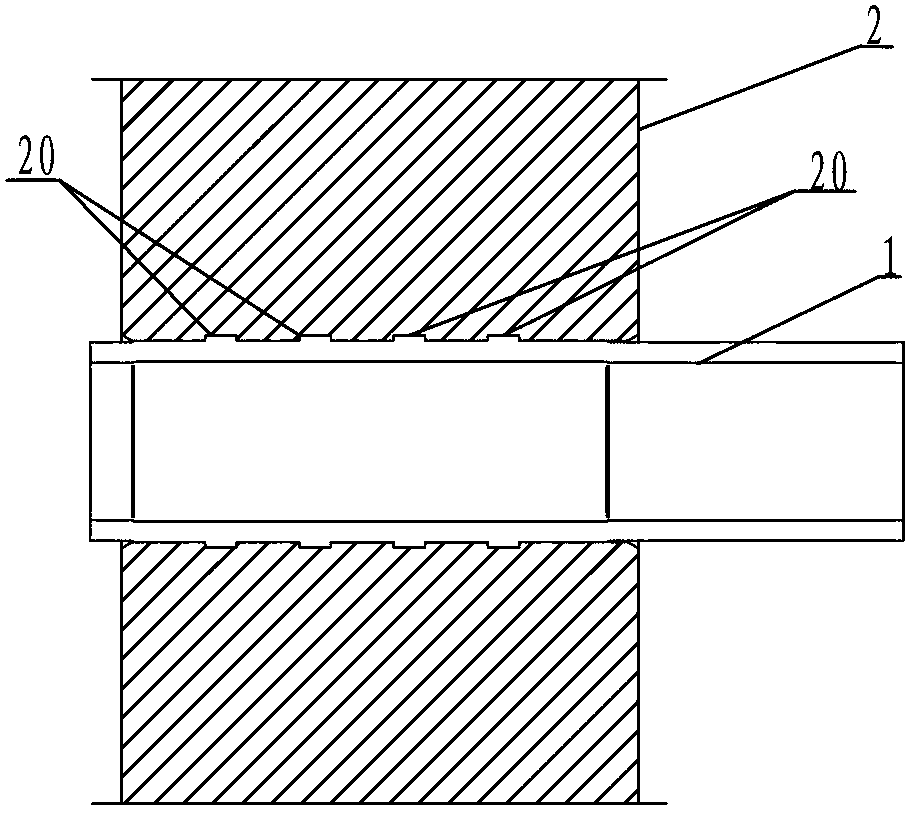

Hydraulic pressure tube expanding device

PendingCN107570614AImprove stabilityAvoid restrictionsHeat exchange apparatusEngineeringScrew thread

The invention relates to cooling part machining equipment, in particular to a hydraulic pressure tube expanding device. According to the hydraulic pressure tube expanding device, a water swelling gunhead is driven by an air cylinder to be inserted into a drain tube end port, the high impermeability can be ensured, meanwhile, the stability of tube expanding is increased, and the phenomenon of falling off is avoided. Through direct compressing connection of the water swelling gun head and the drain tube end, repeated connection and disassembly can be carried out. Meanwhile, according to the hydraulic pressure tube expanding device, restriction on a drain tube is reduced, tube expanding can be conducted on the multiple models of drain tubes, and the range of application of the device is enlarged. Through hydraulic pressure tube expanding, heat produced from tube expanding can be taken away while tube expanding is conducted. The tube wall temperature does not rise basically after tube expanding, and thermal stress can not be generated. Tube expanding is conducted by means of a water expanding mode, and the attaching rate of a fin and the drain tube is greatly improved. Inner screw threads on the inside wall of the drain tube are not destroyed, the tube expanding precision is improved, and the product quality and performance are ensured.

Owner:常州恒创热管理有限公司

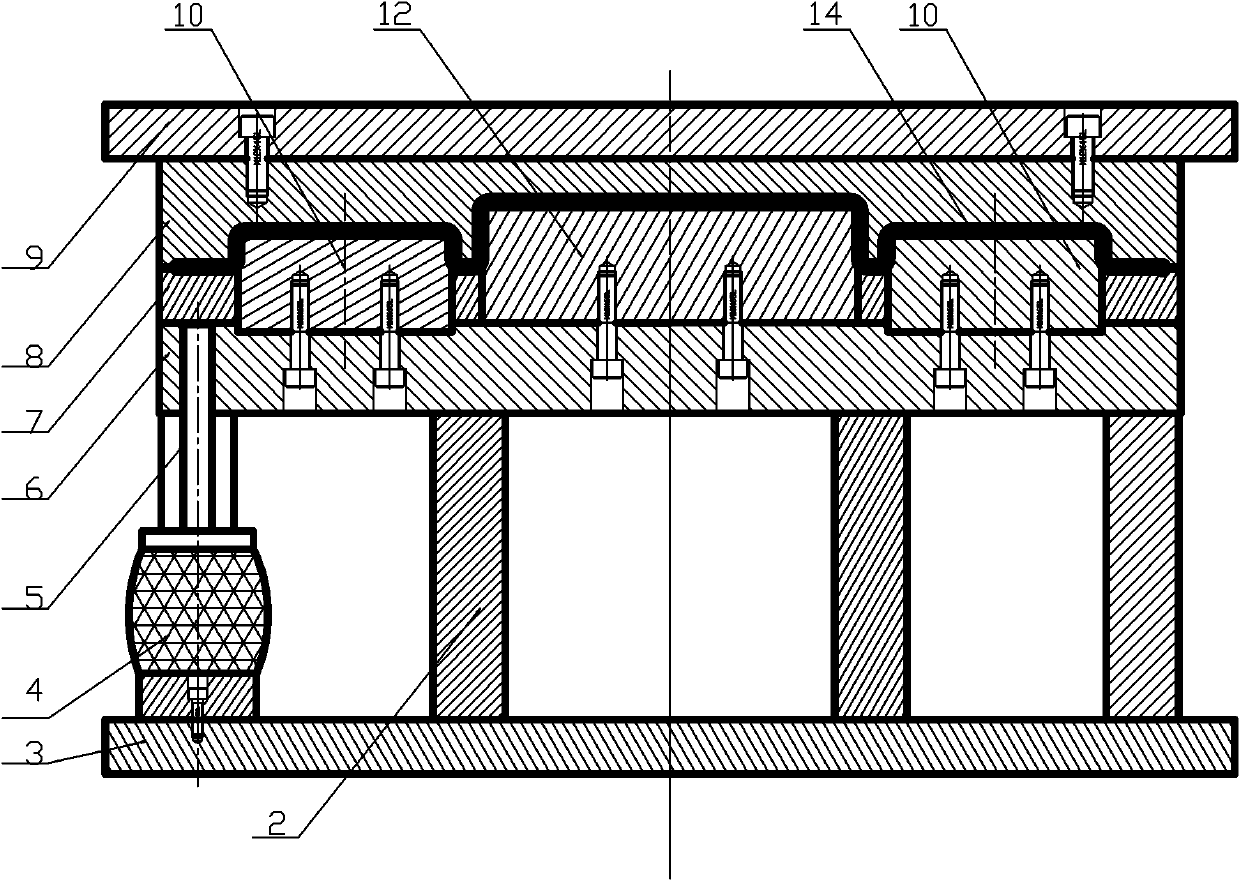

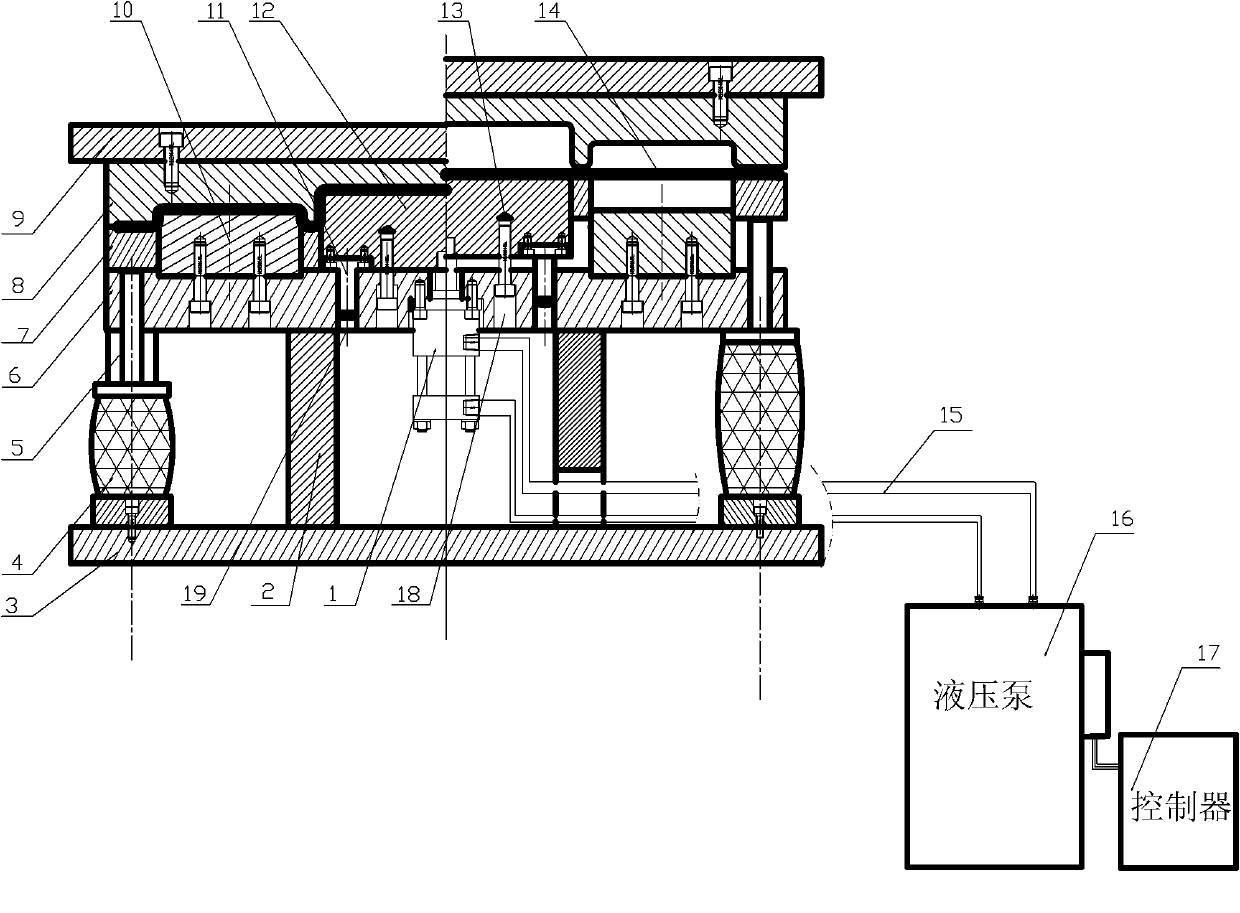

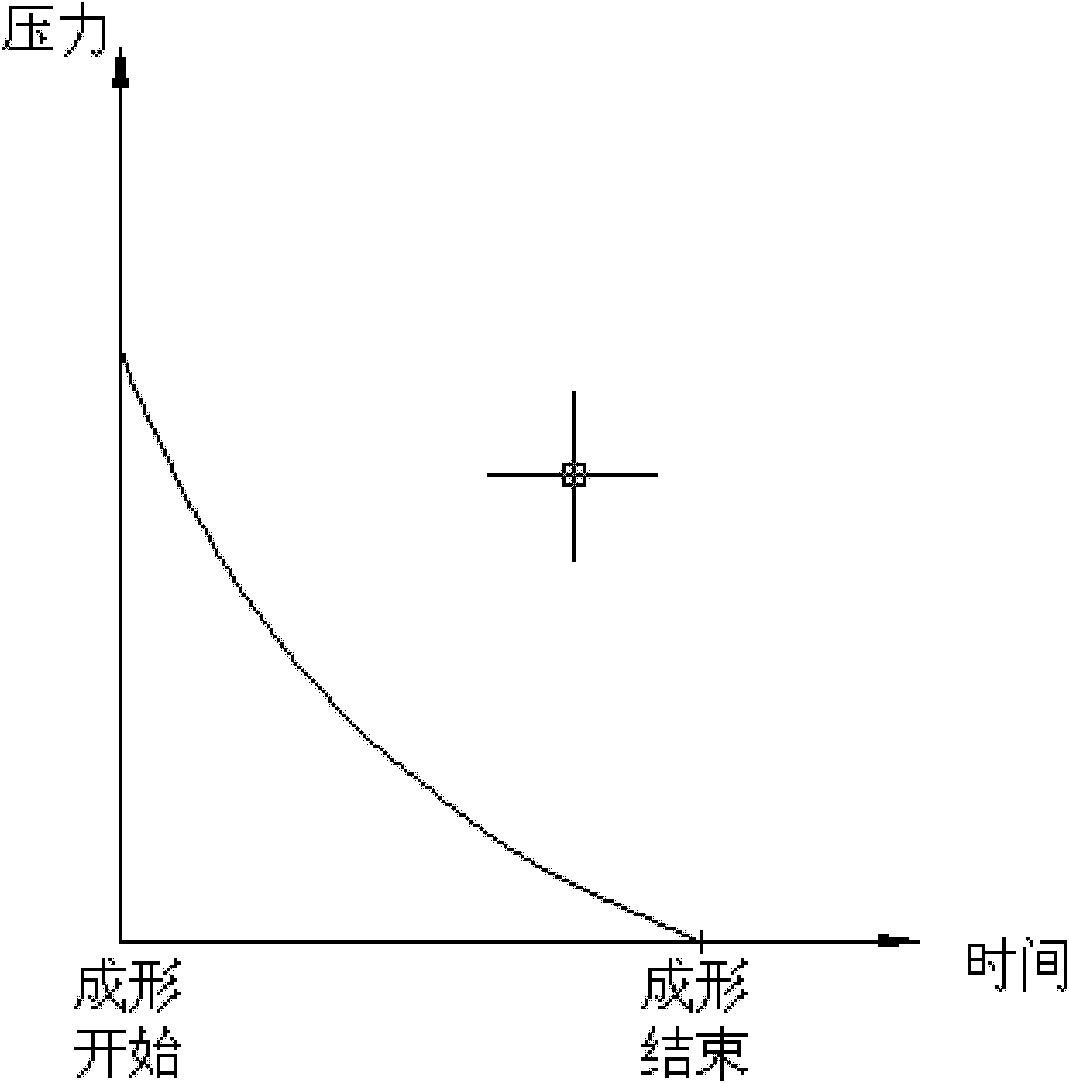

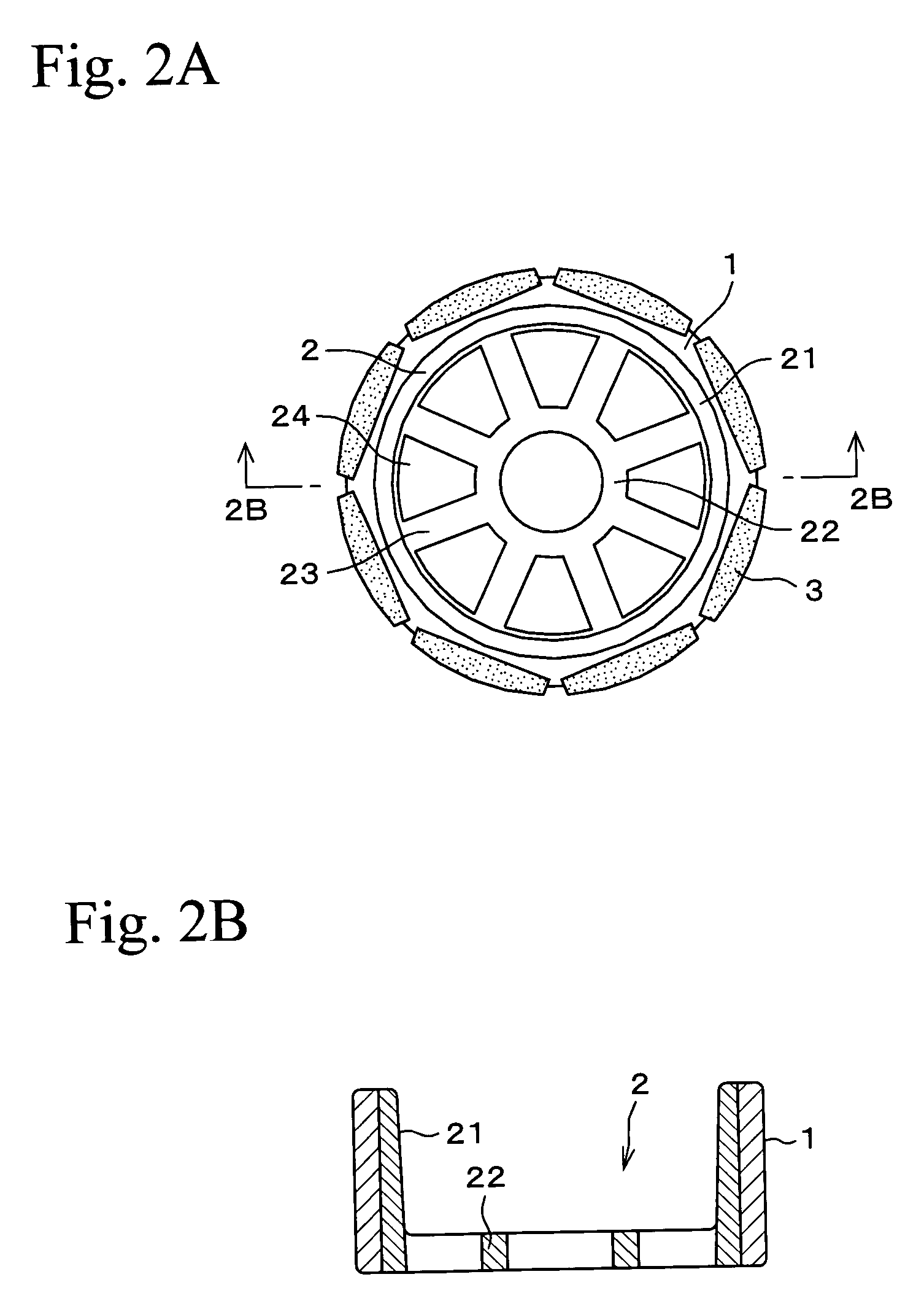

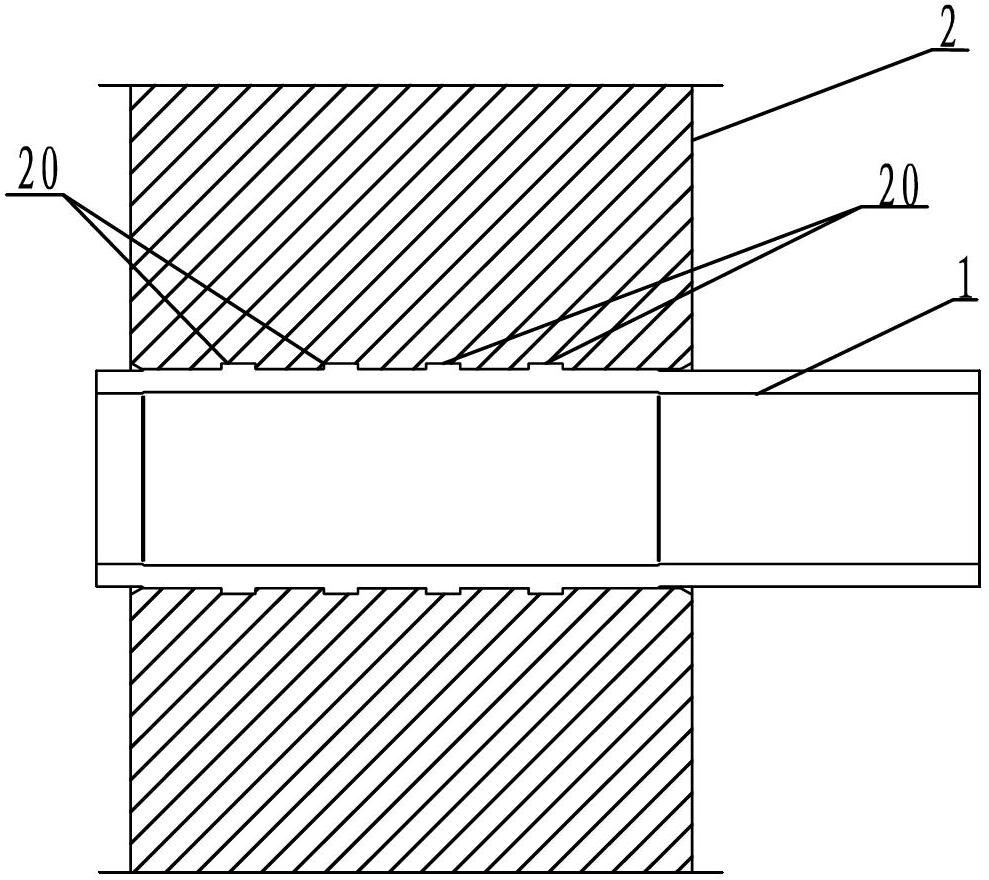

Die extending structure and die extending method using hydraulic moveable male die

InactiveCN102166600AIncrease flow dynamicsIncreased drawing depthShaping toolsHydraulic cylinderEngineering

The invention discloses a die extending structure and a die extending method using a hydraulic moveable male die. The die structure comprises an elastic polyurethane supporting component, a supporting plate, a male die base plate, an edge-pressing ring, a moveable male die, a small male die, a female die and an upper die base, wherein the elastic polyurethane supporting component and the supporting plate are fixed on a lower die base; the male die base plate is supported on the elastic polyurethane supporting component and the supporting plate; the edge-pressing ring is positioned on the maledie base plate; the moveable male die and the small male die are embedded into the edge-pressing ring; the female die is positioned on the edge-pressing ring, the moveable male die and the small maledie and a groove is formed on the female die; the upper die base is fixed on the female die; a jacking rod used for vertically jacking the edge-pressing ring and passing through the male die base plate is fixedly arranged at the top end of the elastic polyurethane supporting component; a metal plate which is molded by extending is placed between the upper surfaces of the edge-pressing ring, the moveable male die and the small male die and the lower surface of the female die; and a hydraulic system used for jacking the moveable male die is arranged on the male die base plate. The method comprises the following steps of: jacking the moveable male die to a set position through a hydraulic force of a hydraulic cylinder; descending the upper die base and descending the female die by pressing the female die on the plate; and after molding, jacking the molded manufactured piece out. Cracks generated in a deep drawing process are prevented.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

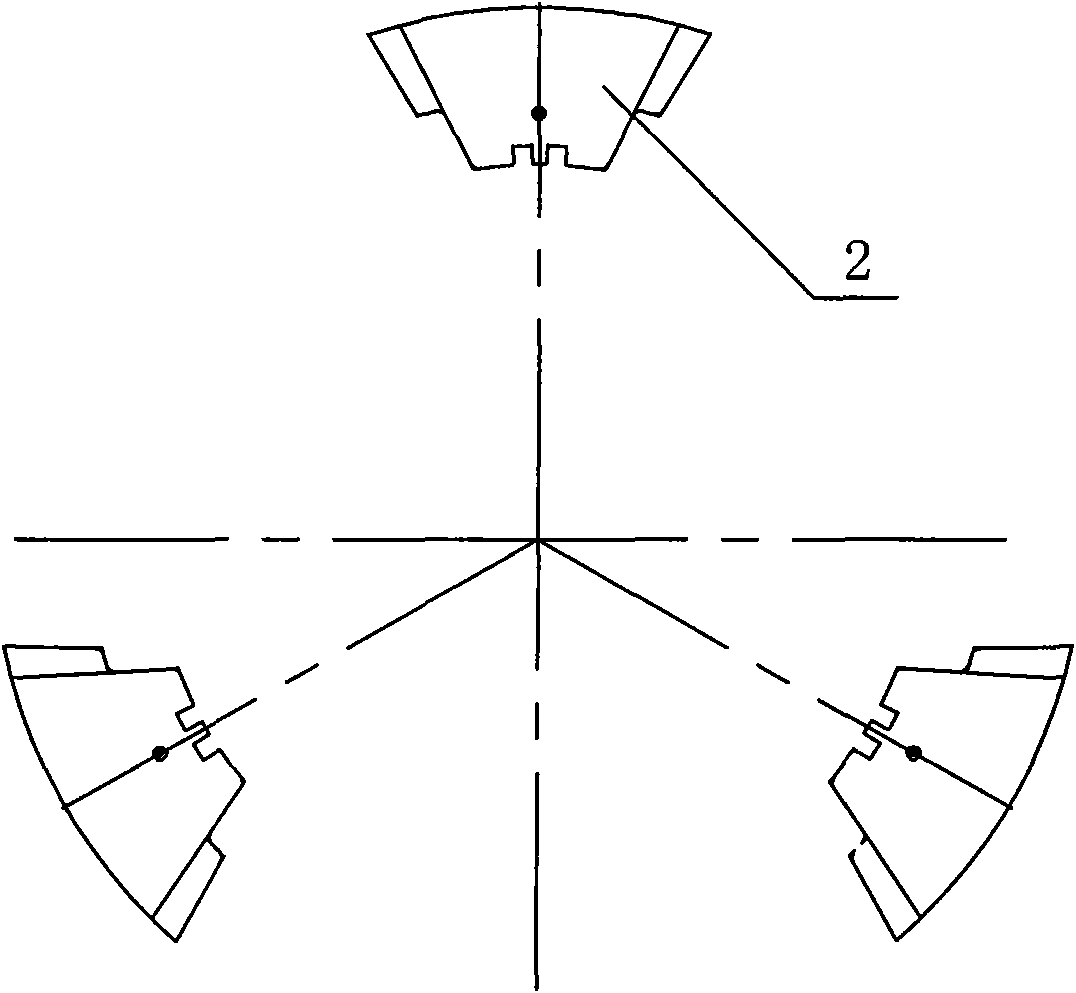

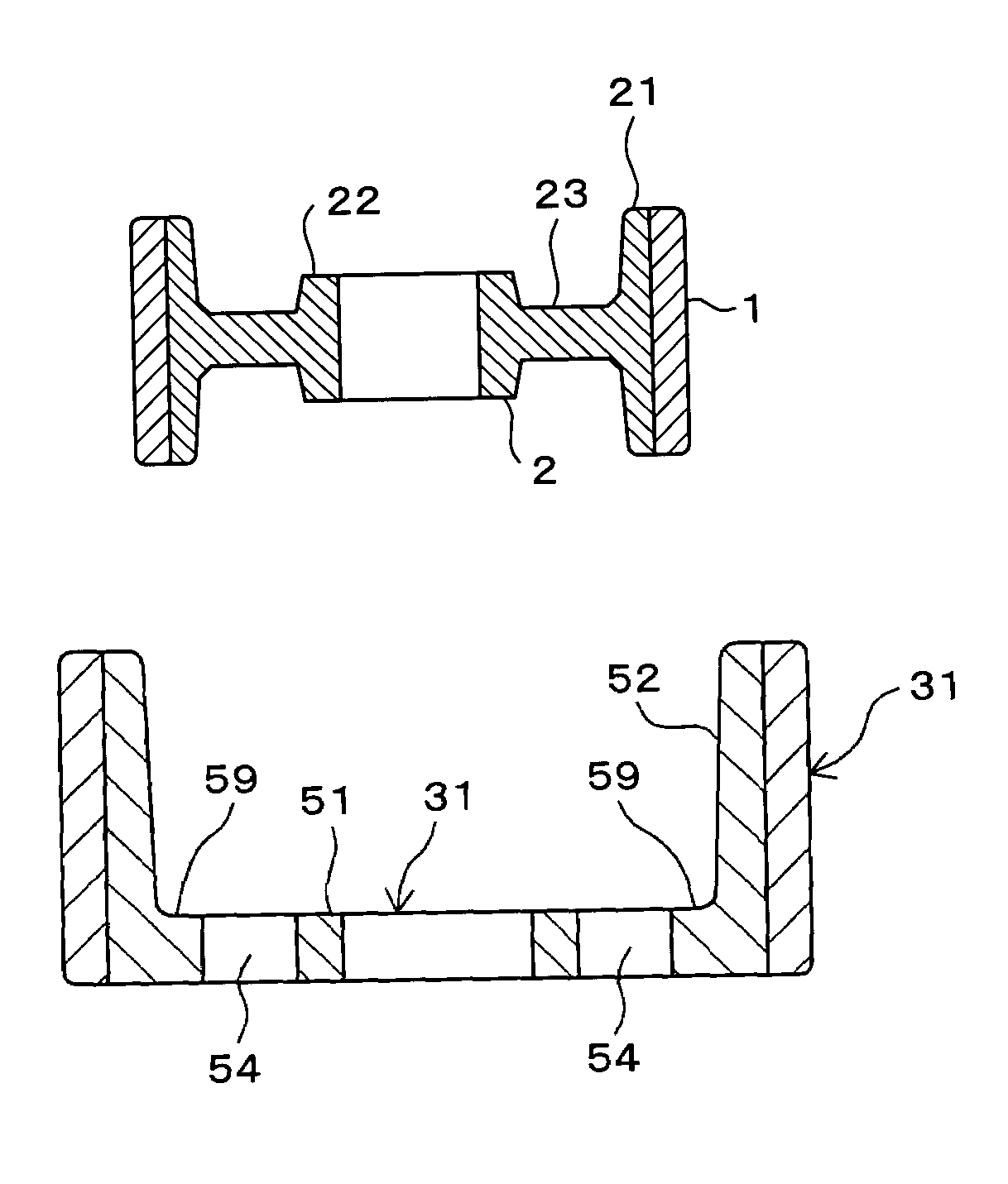

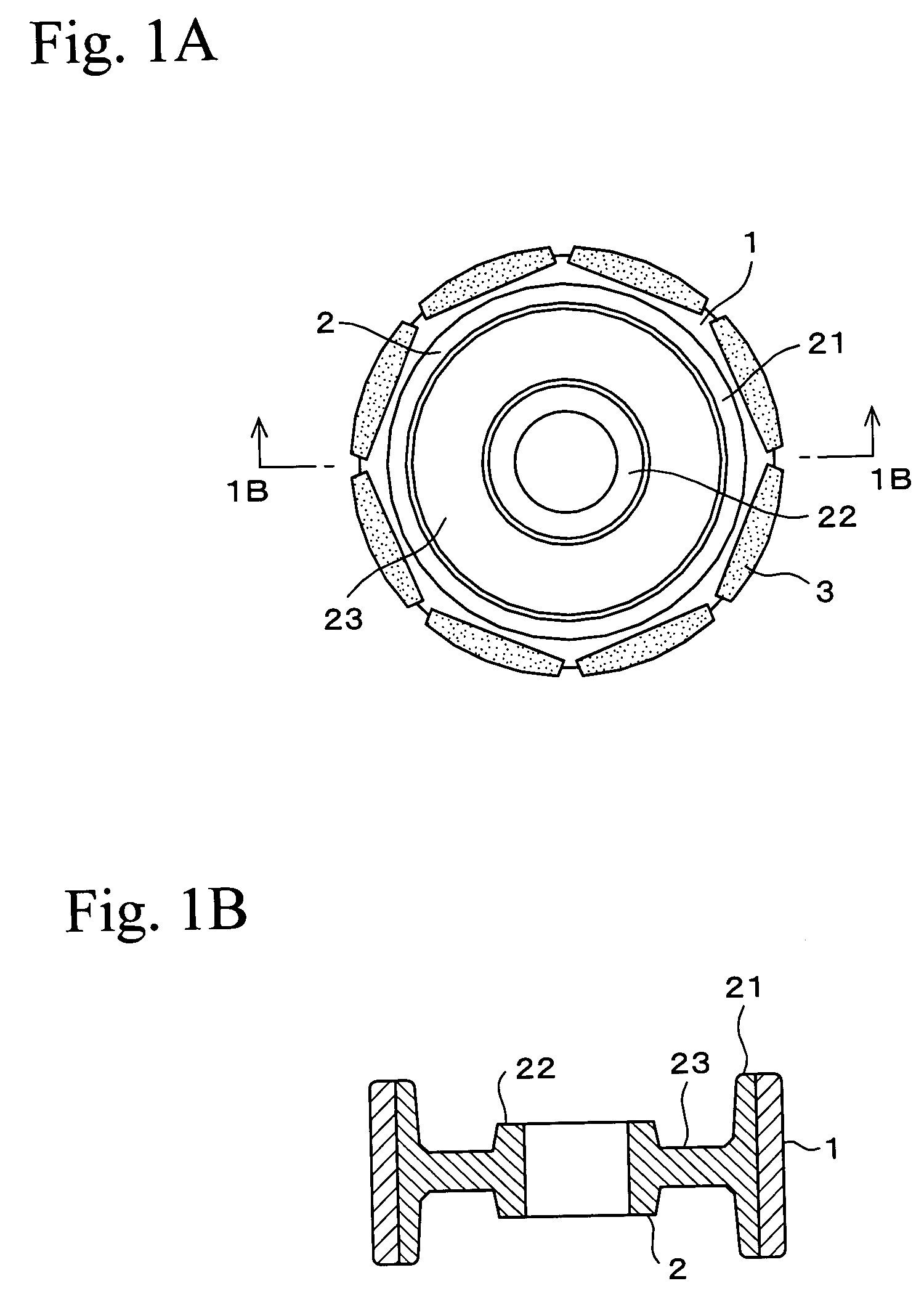

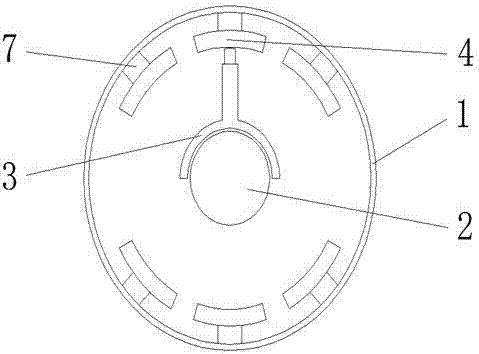

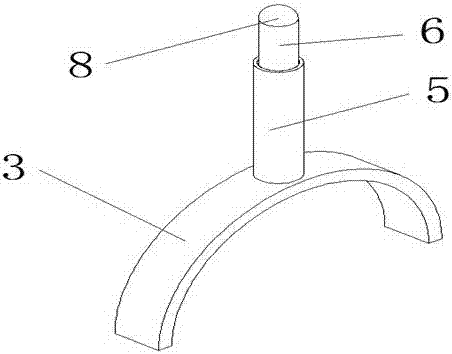

Permanent magnet type rotor and method of manufacturing the rotor

InactiveUS7151334B2Reducing magnetic characteristicReduce weightMagnetic circuit rotating partsInductances/transformers/magnets manufactureEngineeringMechanical engineering

A permanent magnet type rotor comprises an inner member 2 having an outer ring portion 21; an approximately annular outer member 1 having soft magnetism and an inner circumference contacting with an outer circumference of the outer ring portion; and plural permanent magnets 3 disposed at equal intervals on the outer circumference of the outer member toward the circumferential direction. At least one of the inner member 2 and the outer member 1 is made from a sintered material, and the inner member 2 and the outer member 1 are mutually sintered and bonded. Thickness and weight of a dynamotor itself can be reduced and high output and high efficiency can be achieved.

Owner:HITACHI POWDERED METALS COMPANY +1

Shell-and-tube heat exchanger adopting copper heat exchange tube

InactiveCN102706041AImprove the bonding rateFulfil requirementsEvaporators/condensersHeat exchanger casingsCopperMechanical engineering

The invention discloses a shell-and-tube heat exchanger adopting a copper heat exchange tube, which comprises the copper heat exchange tube and a carbon tube plate. The heat exchanger is characterized in that the copper heat exchange tube is in expanded connection with the carbon tube plate; at least four grooves which are distributed at intervals along the extending direction of the center line of a hole of the carbon tube plate are formed on the inner wall of the hole of the carbon tube plate; the depths of the grooves are 0.4 to 0.6mm; and the distance between each two adjacent grooves is 8 to 12mm. By forming at least four grooves with specific depths on the inner wall of the hole of the carbon tube plate and limiting the distance of each adjacent grooves, the sealing performance is improved during the tube expansion, the conjoint ratio of the heat exchange tube and the tube plate is increased, and the purpose that a tube head of the heat exchanger is not exposed under high pressure can be achieved. In addition, by adopting the structure, the extending length of the heat exchange tube is effectively reduced after the expanded connection, so that the heat exchanger can totally meet the requirements of underground air-conditioning unit heat exchangers in the coal mine field.

Owner:苏州利玛特能源装备有限公司

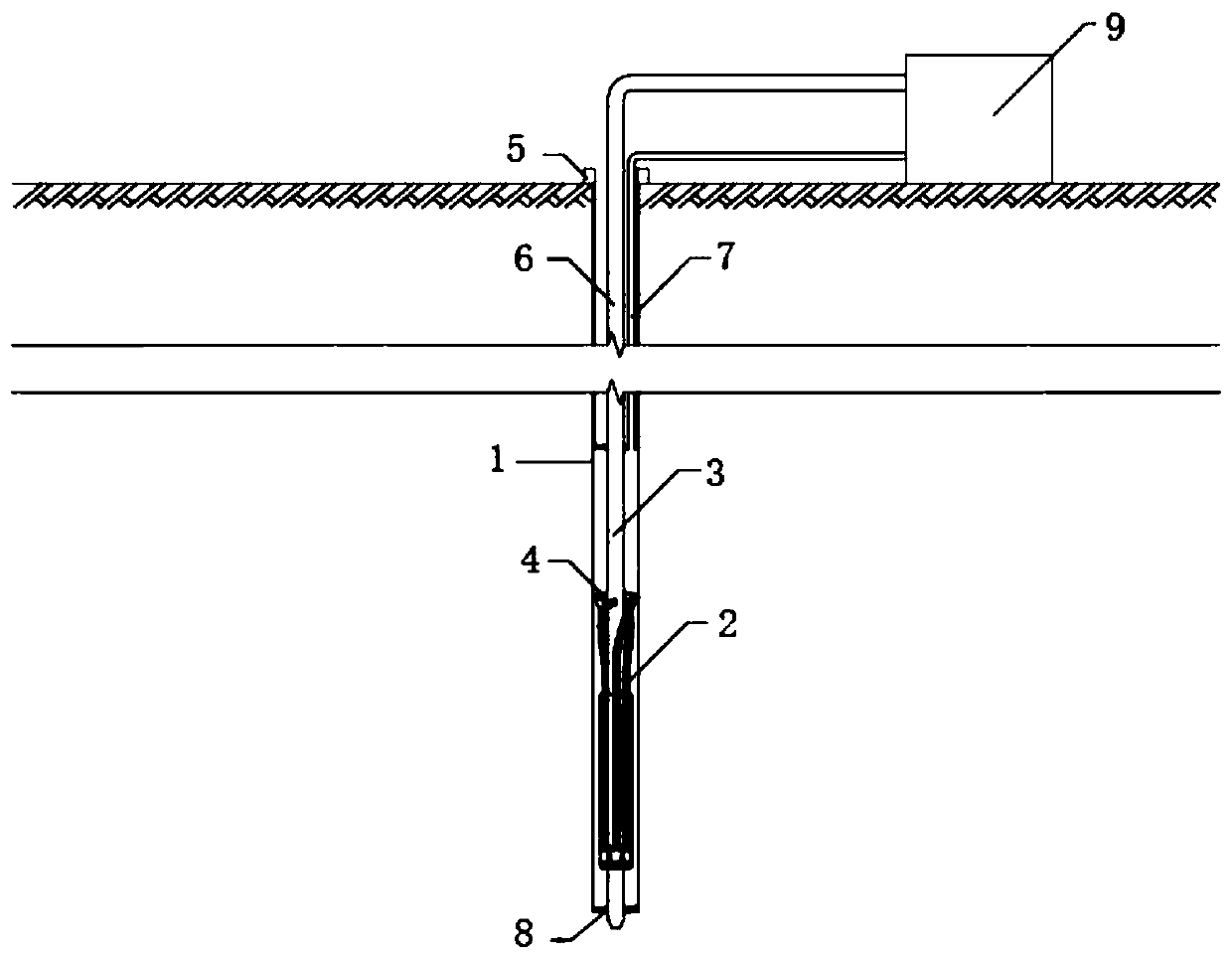

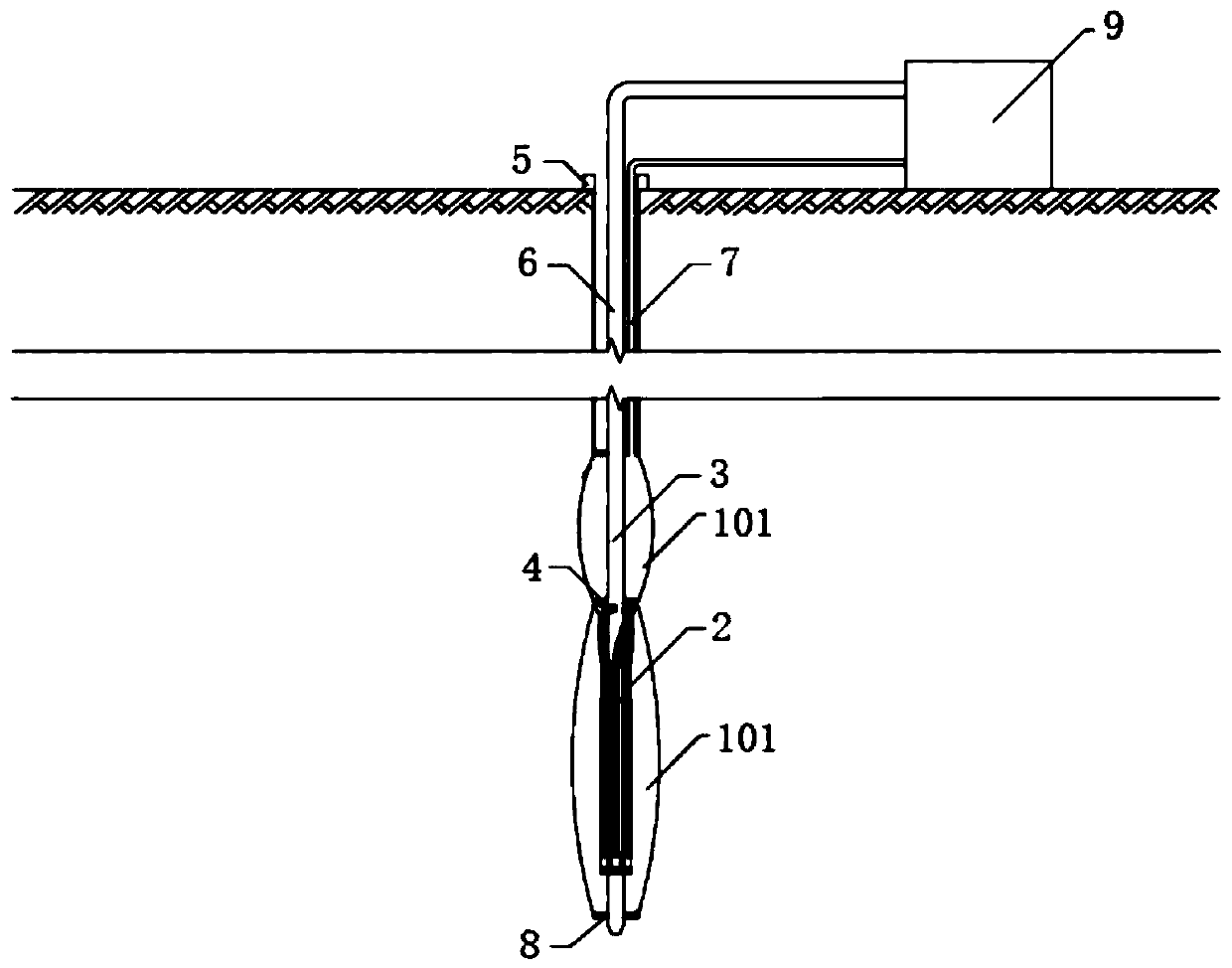

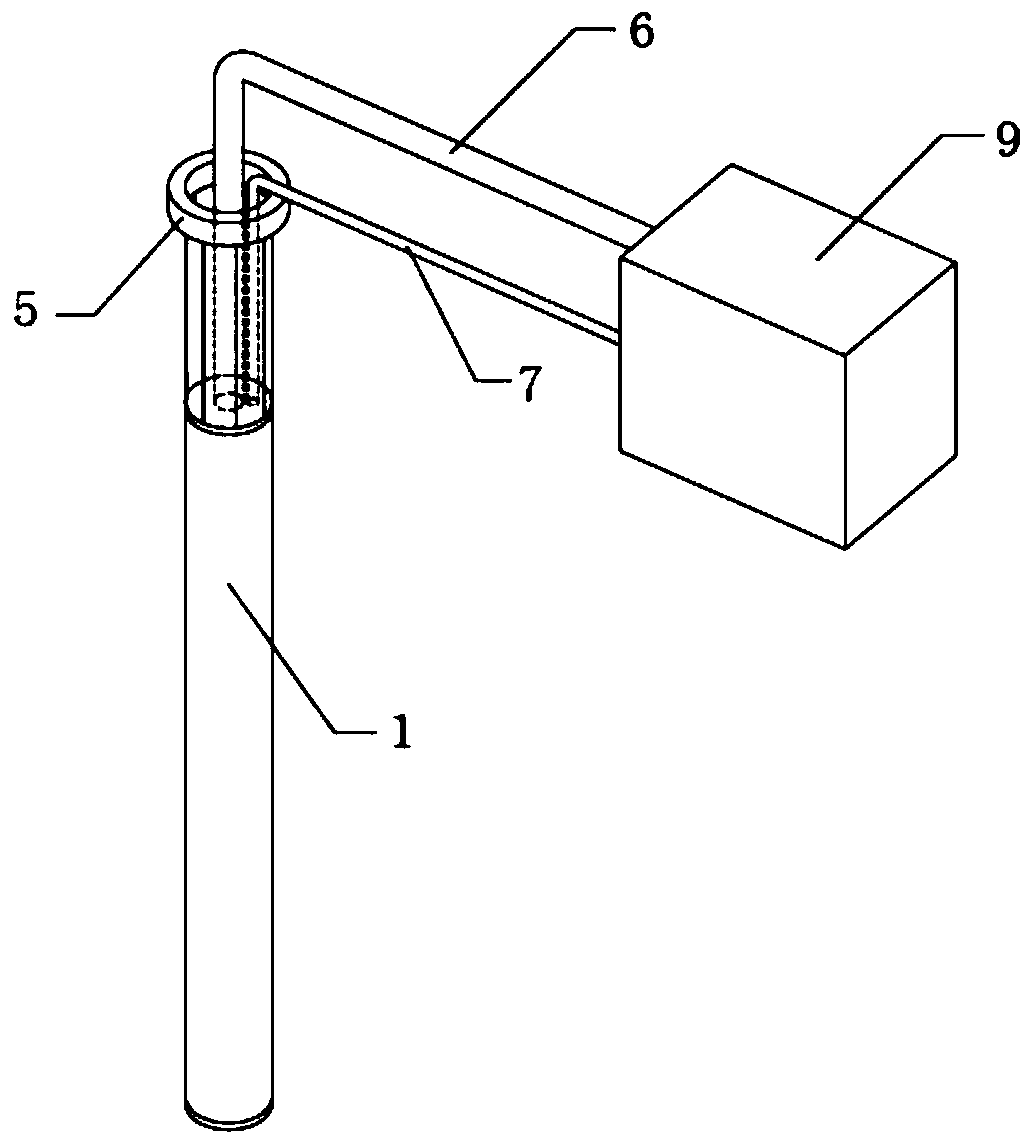

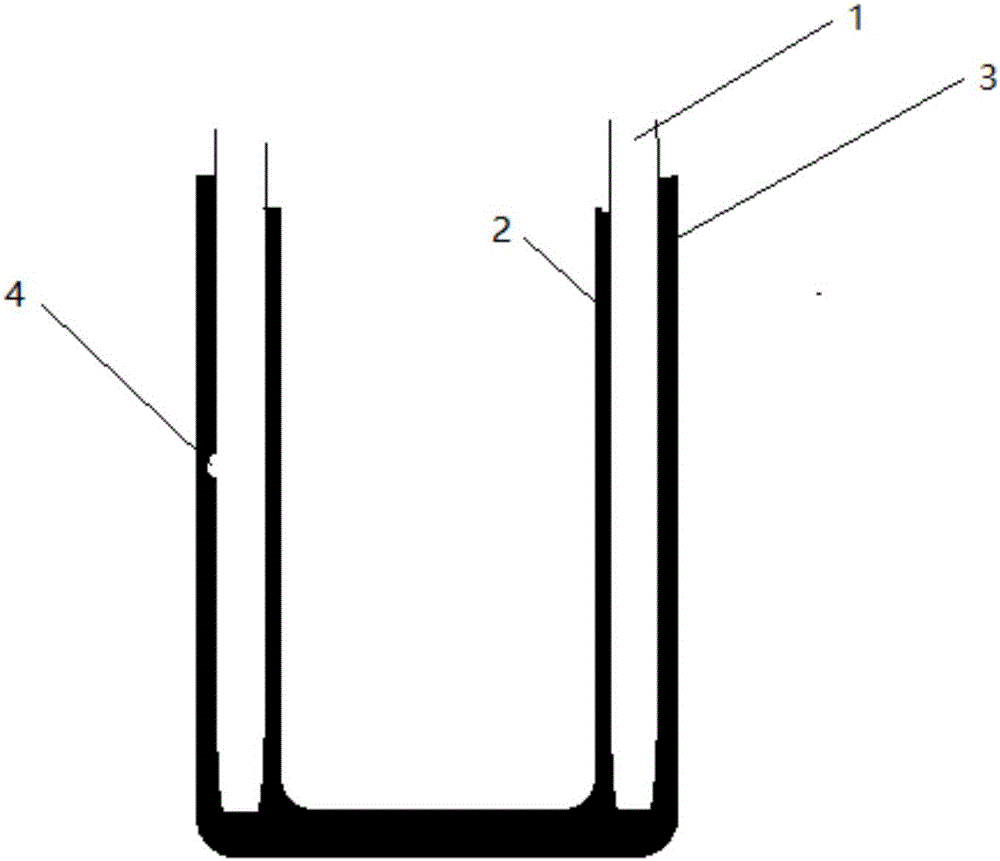

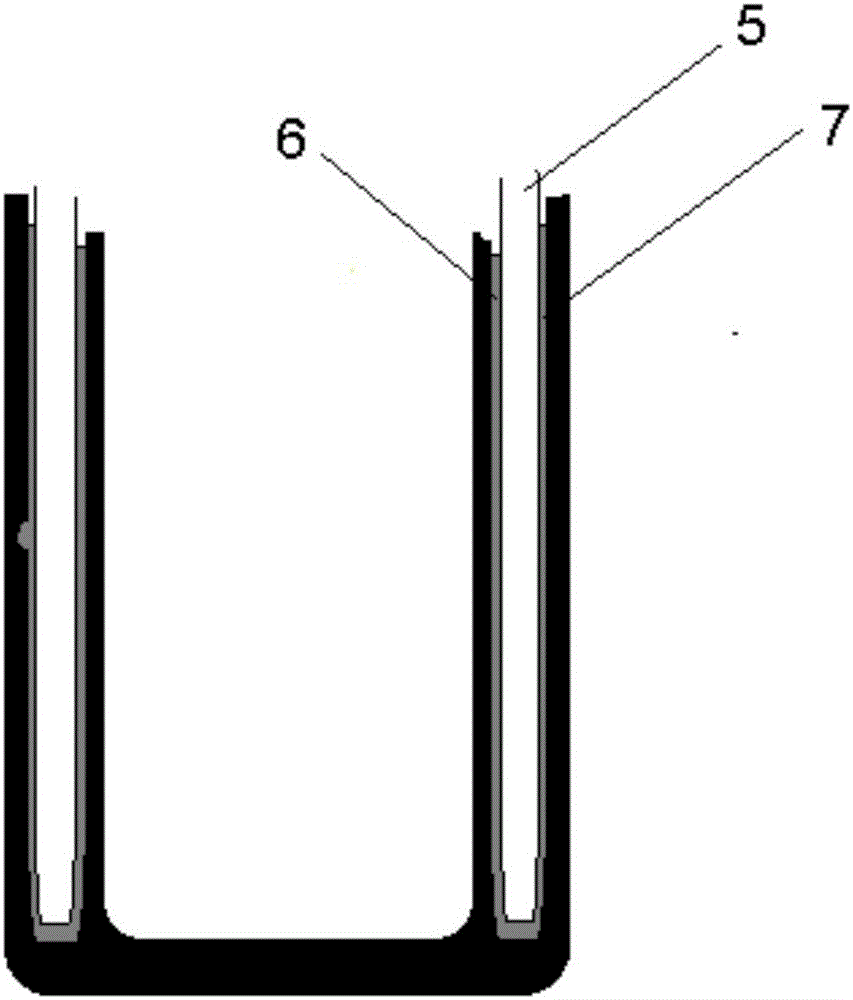

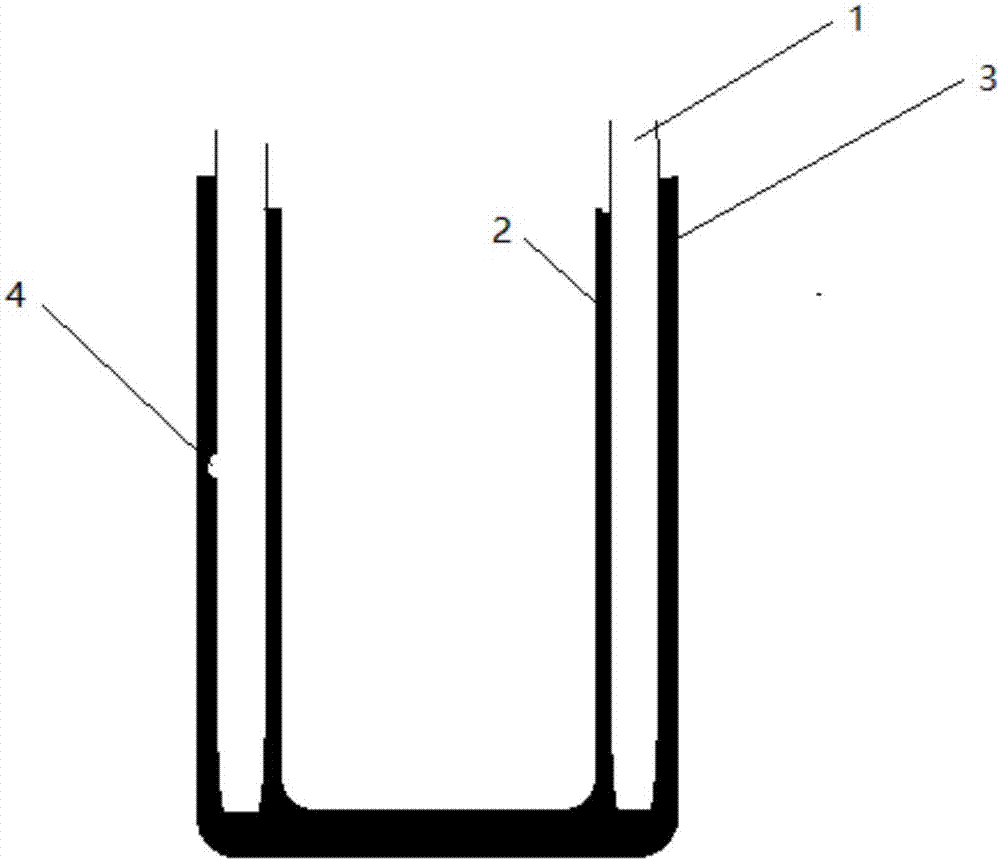

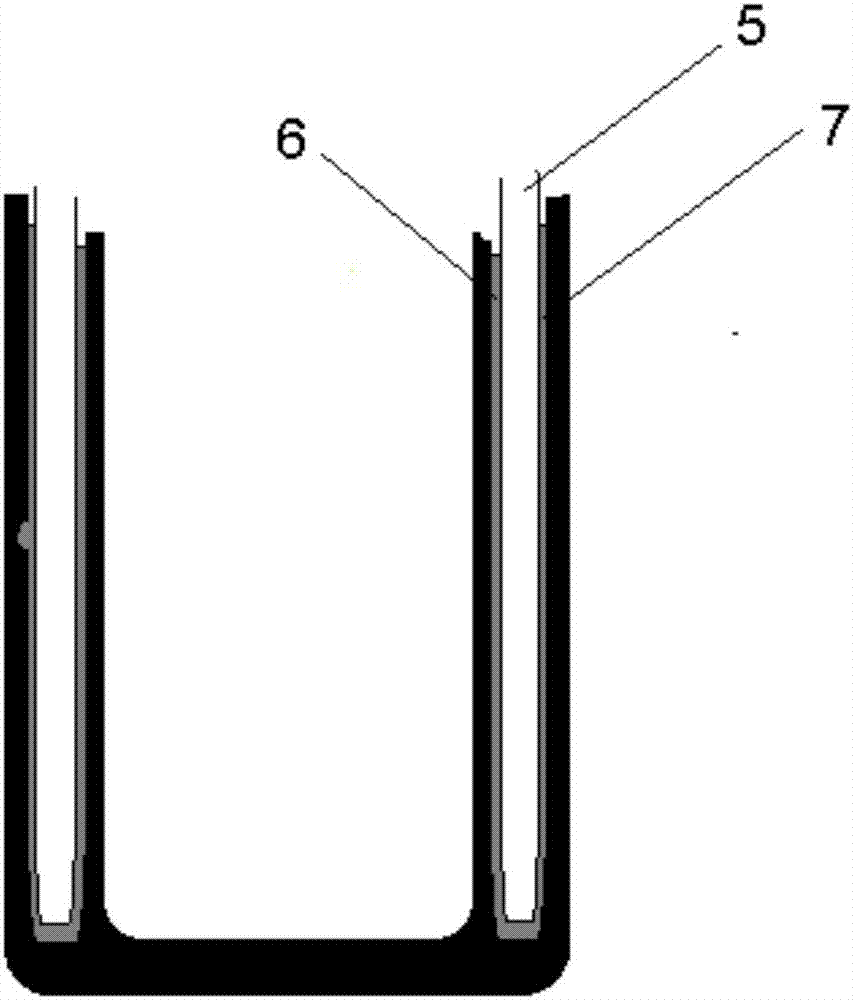

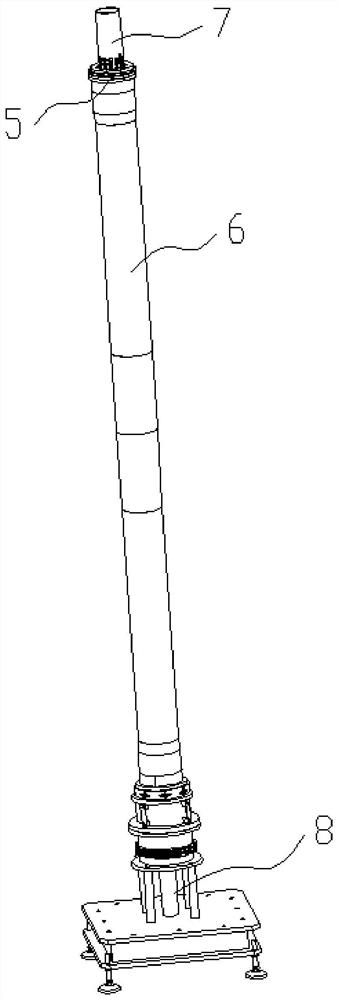

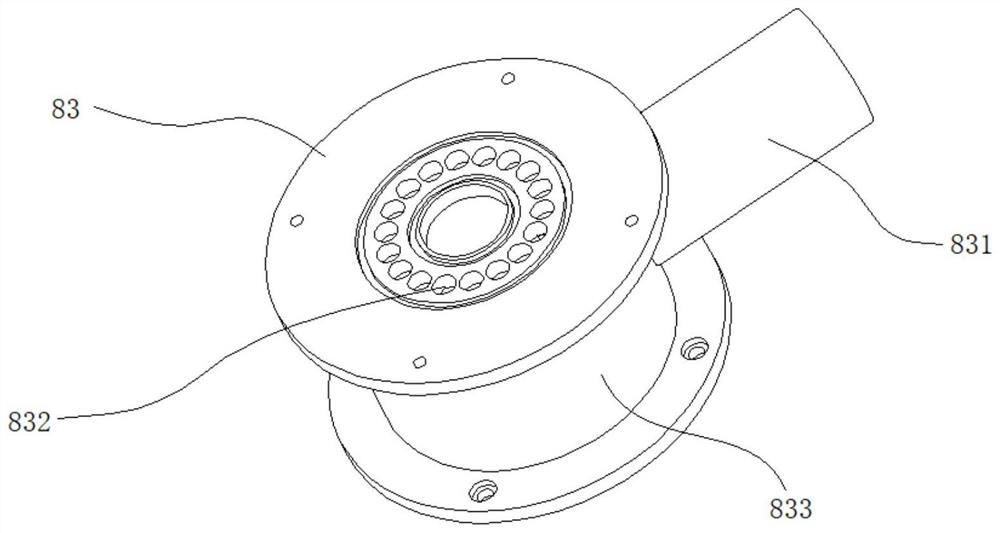

Crushed zone anti-blocking plug, slurry stopping system for preventing out-hole slurry returning and slurry stopping method

ActiveCN110984130AImprove the bonding ratePrevent slurrySoil preservationSlurryMechanical engineering

The invention discloses a crushed zone anti-blocking plug and a slurry stopping system for preventing out-hole slurry returning. The slurry stopping system comprises a slurry stopping rubber barrel, adrilling device, a slurry injection channel, a barrel protection device, a slurry injection pipe and a water injection pipe. The barrel protection device is arranged at the upper end of the slurry stopping rubber barrel. The slurry injection channel is arranged in the slurry stopping rubber barrel, the slurry injection channel penetrates through an inner cavity of the whole slurry stopping rubberbarrel and extends to the outside of the lower end of the slurry stopping rubber barrel. The slurry injection pipe communicates with the slurry injection channel. The water injection pipe communicates with the slurry stopping rubber barrel. According to the slurry stopping system, an underground slurry soil stone body horizontal baffle can be formed near the depth of the slurry injection channel,the problems that under the condition that the stratum is crushed, slurry returns out of a ground surface hole, and the barrel wall of the slurry stopping rubber barrel and a crushed rock wall are inpoor contact are solved, upper end falling stone is prevented from blocking a slurry injection hole through a semi-rigid protection barrel, and the problem that a slurry stopping plug is hard to recycle is solved.

Owner:湖南楚湘矿山工程有限公司

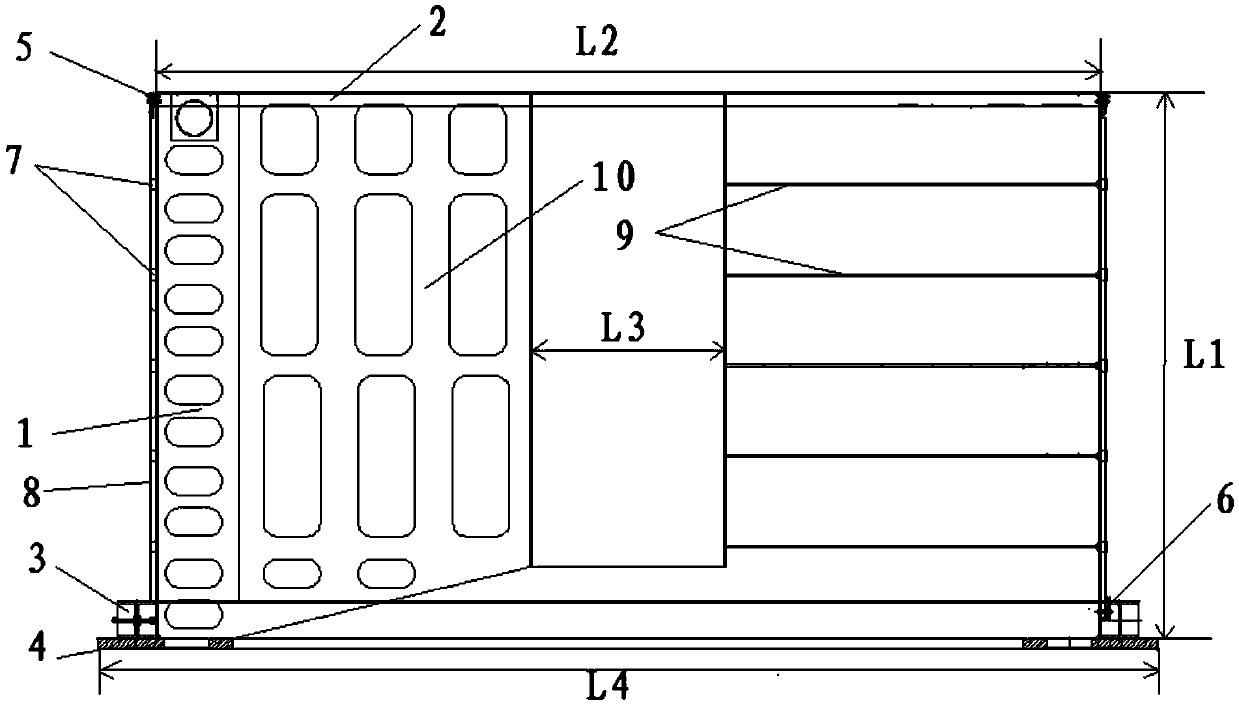

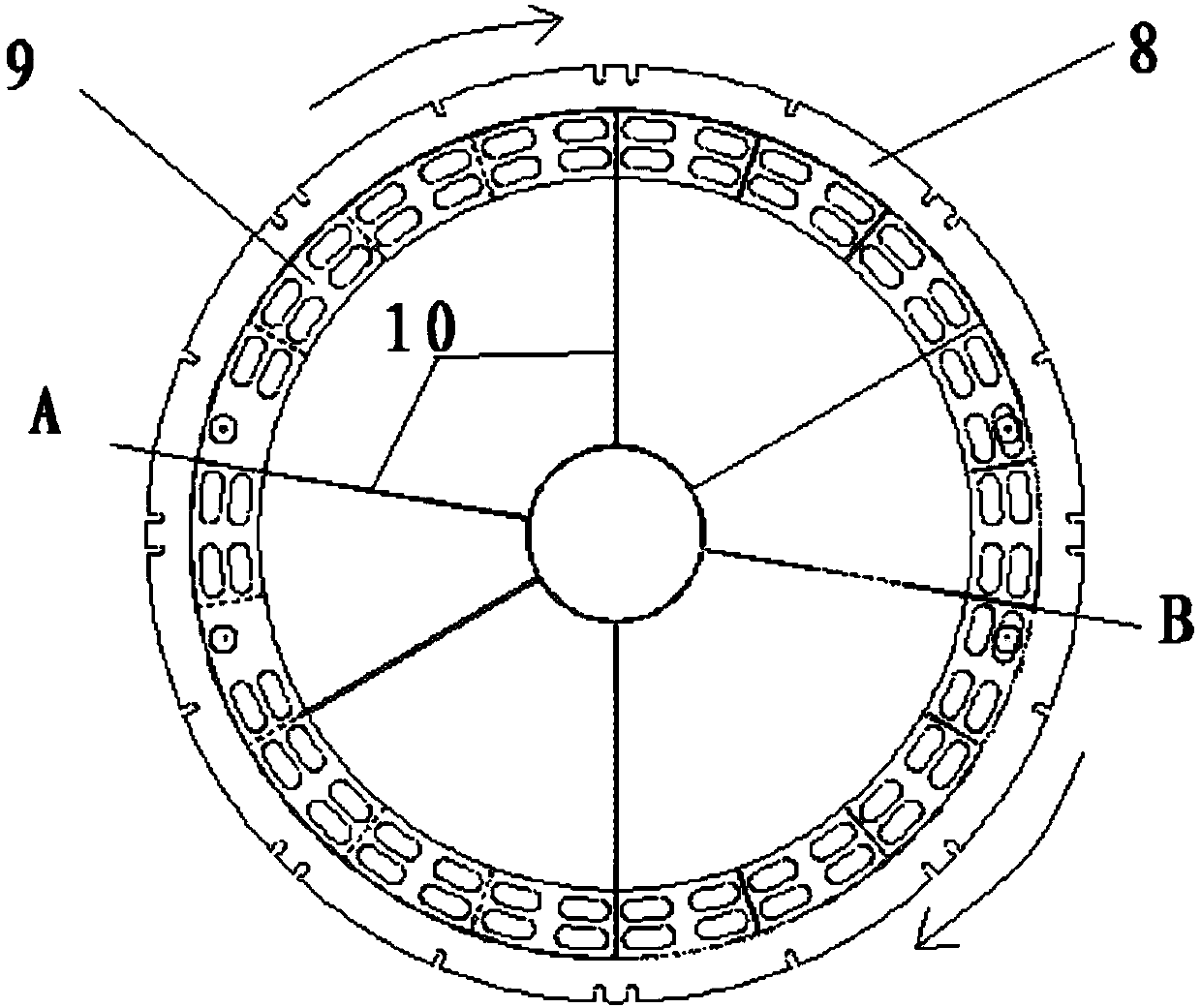

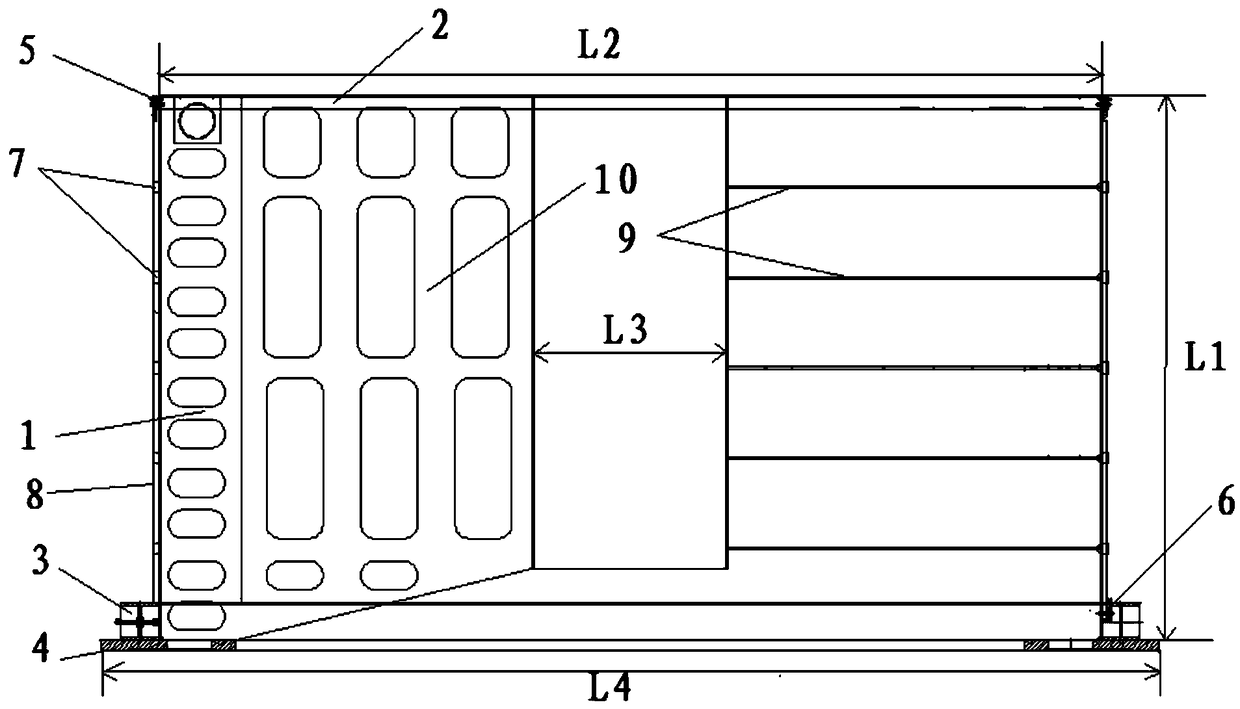

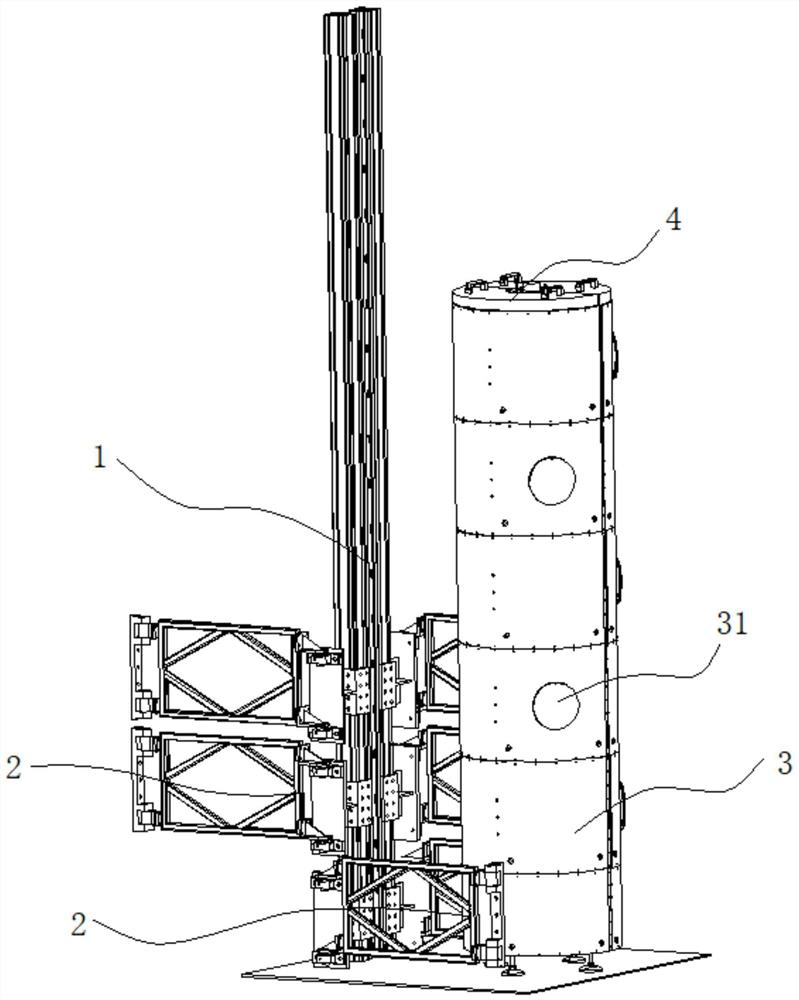

Large-diameter nonmetal skin turning device

ActiveCN107812959AImprove rigidityReduce weightWork clamping meansTurning machinesSkin structureMachine tool

The invention relates to the field of large launcher tail section skin outer circle machining, in particular to a large-diameter nonmetal skin turning device. The large-diameter nonmetal skin turningdevice comprises a blank body, an upper end plate, a pedestal set, a bottom plate, an upper pressing plate set, a lower pressing plate set and a fastening device set. The blank body is of a hollow cylindrical structure which is vertically placed, and the upper end plate is of a circular plate structure and is concentrically fixedly mounted at the axial top end of the blank body. The bottom plate is of a ring structure and is concentrically fixedly mounted at the axial bottom end of the blank body, and the pedestal set is fixedly mounted on the connecting position of the blank body and the bottom plate. The outer wall of the blank body is wrapped with an outer skin structure, and the upper pressing plate set is fixedly mounted on the side wall of the top end of the outer skin structure. Thelower pressing plate set is fixedly mounted on the side wall of the bottom end of the outer skin structure, and the side wall of the outer skin structure is sleeved with the fastening device set. According to the large-diameter nonmetal skin turning device, the current impending technological problem of tail section skin outer circle turning is solved, and essential data and design thoughts are provided for machining tools needed in the subsequent new model development process.

Owner:CAPITAL AEROSPACE MACHINERY +1

Nickel alloy/tungsten composite rod preparation method

The invention provides a nickel alloy / tungsten composite rod preparation method, which comprises (1) subjecting a tungsten rod to surface cleaning treatment; (2) placing the cleaned tungsten rod and nickel alloy powder into a press mold, putting into a cold isostatic press, and pressing to give a nickel alloy / tungsten composite rod blank with nickel alloy porosity of 35%-45%; (3) vacuum sintering in a vacuum sintering furnace to reduce the nickel alloy porosity to be lower than or equal to 5%; and (4) drawing to obtain a finished product of nickel alloy / tungsten composite rod. The inventive method is simple in process, low in equipment investment, short in production cycle, free of pollution to environment, high in yield and capable of batch production. Nickel alloy in the nickel alloy / tungsten composite rod prepared by the inventive method has uniform thickness, low porosity and high finished product dimension precision, and the metal bonding rate of the nickel alloy and the tungsten rod is higher than or equal to 98%, or up to 100% after process optimization.

Owner:XIAN REFRA TUNGSTEN & MOLYBDENUM

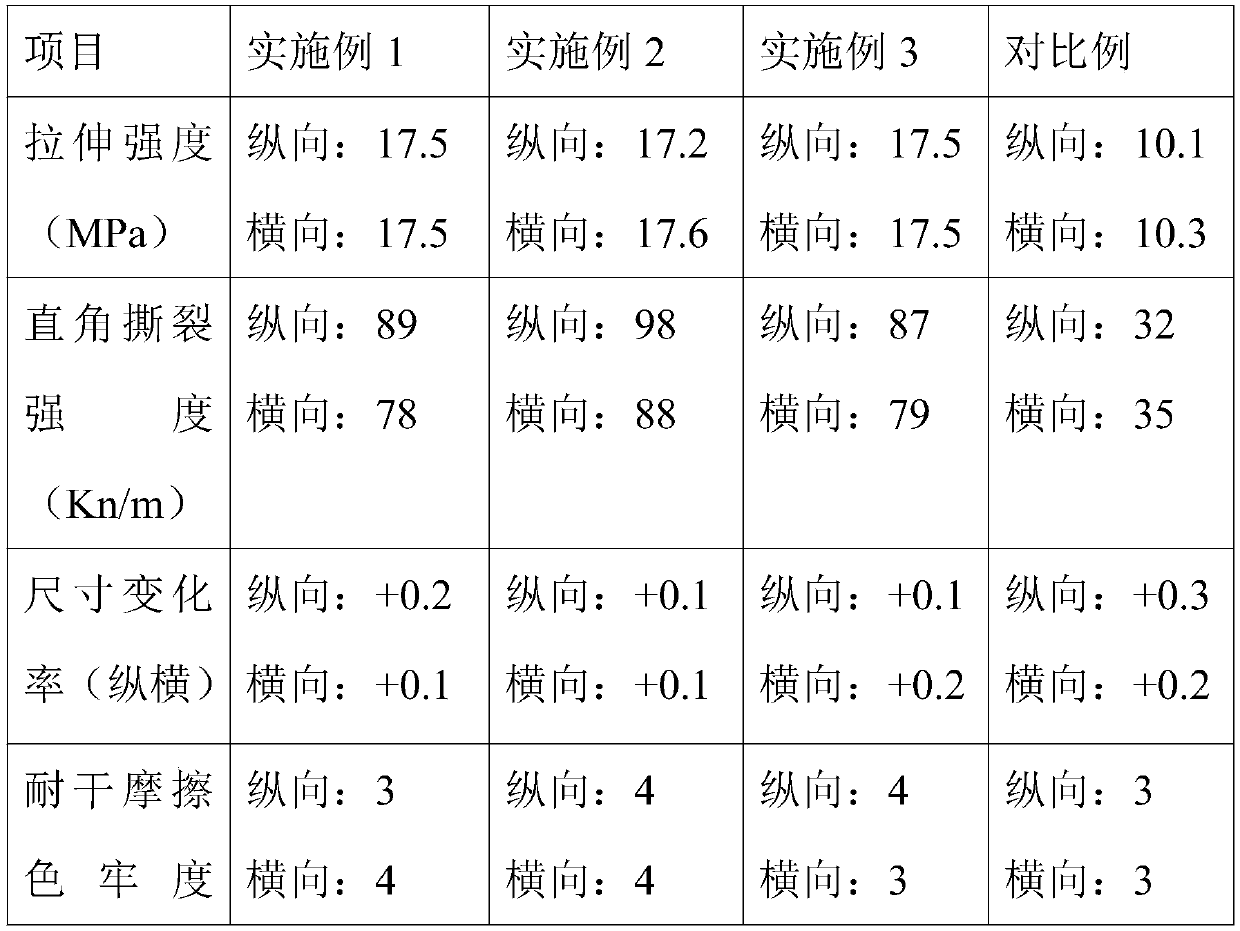

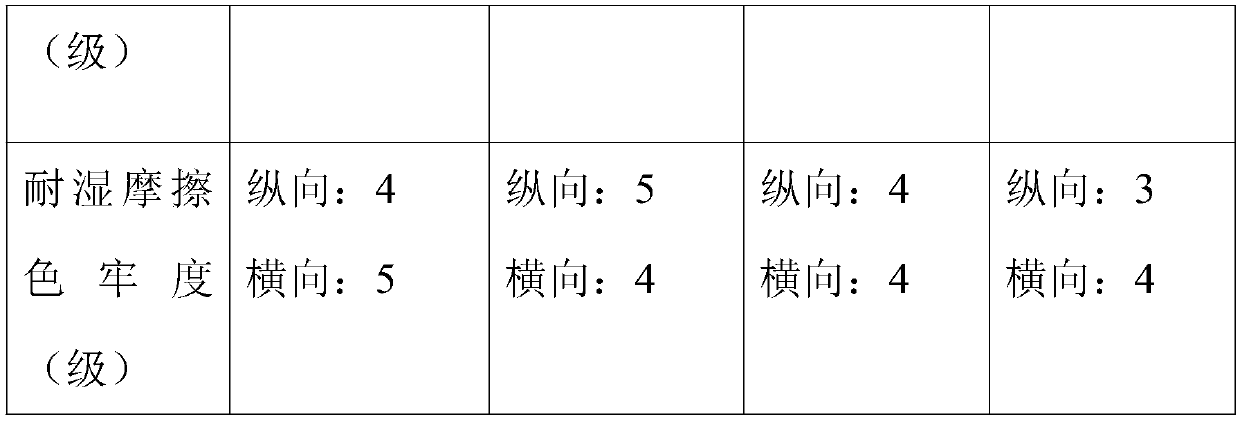

Liquid friction-increasing rubber for shoe plate of rear-drum brake and preparation method thereof

ActiveCN104327607AImprove the bonding rateImprove comfortConjugated diene hydrocarbon coatingsVulcanizationBenzoyl peroxide

The invention relates to liquid friction-increasing rubber for a shoe plate of a rear-drum brake and a preparation method thereof. The preparation method comprises the following steps: 1, dissolving silicon carbide, antimony sulfide, benzoyl peroxide, sulphur, quartz powder and Buna-N rubber in ethyl acetate and fully stirring; 2, smearing the above mixture onto the surface of a processed shoe plate by a brushing method or an infiltration method; 3, standing and air-drying; 4, placing the shoe plate in a constant-temperature vulcanization box to fully vulcanize rubber; and 5, cooling the vulcanized shoe plate and directly applying the shoe plate in assembling of the brake. The invention has the following beneficial effects: as the friction-increasing formula is blended into a liquid state, the liquid friction-increasing rubber is convenient to smear, can produce productivity and is suitable for mass production; the surface coating is uniform so as to effectively cancel influence of processing precision and raise conjoint ratio; as NRB (Buna-N rubber) is used as a base material, elasticity and buffer performance are enhanced and noise is reduced effectively; and as quartz powder is used to replace emery, the friction-increasing material is easier to distribute uniformly, hard lumps and hard spots are eliminated, and comfortability of drivers is improved.

Owner:ZHEJIANG WANXIANG SYST +1

3D overprinting and casing pressure decorative film production process, application and intermediate product

ActiveCN109532178AImprove surface strengthImproves scratch and oil resistanceCeilingsCovering/liningsFiberSurface layer

The invention discloses a 3D overprinting and casing pressure decorative film and a production process and application thereof. The decorative film successively comprises a staple fiber non-woven paper layer, a twin-block composite rubber layer, a PET transparent film layer, a release agent layer, a composite rubber layer and a PVC calendaring film layer. The process comprises the following steps:preparing a bottom PET composite layer: compounding the softened PVC calendaring film and the bottom PET composite layer to obtain an intermediate product; printing, pre-softening the intermediate product, embossing, cooling and rolling; wherein the pre-softening process is gradient heating softening. According to the product, the PVC calendaring film layer is arranged to replace the compoundingprocess of surface layer PVC and PVC base film. Since the PVC calendaring film layer is high-density PVC, surface strength of the 3D overprinting and casing pressure decorative film is greatly increased, and scratch resistance and oil fouling resistance are improved. Furthermore, the separation and delamination rate of the surface layer PVC coating and the bottom PVC calendaring film composite layer in the traditional process is reduced.

Owner:浙江锦盛装饰材料股份有限公司

Clamping ring checking tool

InactiveCN107192320AEasy to holdSpin easilyMechanical counters/curvatures measurementsEngineeringScrew thread

The invention discloses a clamping ring checking tool. The clamping ring checking tool comprises a forming machine clamping ring, a belt and tread drum main shaft, and a checking tool semicircular ring. A clamping pad is inserted in the forming machine clamping ring, and the outer side of the clamping pad is connected with a telescopic cylinder by a bolt. The telescopic cylinder is connected with the outer side of the forming machine clamping ring by the bolt. The belt and tread drum is disposed in the forming machine clamping ring in an inserted way, and the checking tool semicircular ring is disposed on the belt and tread drum main shaft in a clamped and buckled way. The top part of the checking tool semicircular ring is in a threaded connection with an adjusting rod outer sleeve, and the inner part of the adjusting rod outer sleeve is in the threaded connection with an adjusting rod inner sleeve, the top part of which is provided with an arc-shaped sliding block. The clamping ring checking tool has advantages of simple structure, convenient operation, and ability of measuring and checking out of roundness of forming machine clamping ring easily.

Owner:SHANDONG FENGYUAN TIRE MFG

Special tool for grinding first-stage sun gear sleeve

ActiveCN105710453AEffective multi-directional positioningRealize multi-directional positioningGear teethRadial positionReduction drive

The invention provides a special tool for grinding a first-stage sun gear sleeve, and relates to a special tool for grinding a gear sleeve. In a process of engaging a first-stage sun gear sleeve in a speed reducer of a steam turbine with a sun gear, low conjoint ratio is liable to cause, and unstable transmission is caused. A tensioning flange is positioned in a built-in central hole of the first-stage sun gear sleeve, a positioning flange is positioned in a positioning hole of the first-stage sun gear sleeve, a supporting flange is arranged on an end surface, which is away from a grinding gear, in the first-stage sun gear sleeve, an outer gear surface of the grinding gear is matched with an inner gear surface of the first-stage sun gear sleeve, one end of a pull rod is arranged on a positioning block in a penetrating manner, the other end of the pull rod sequentially penetrates through the grinding gear, the tensioning flange, the positioning flange and the supporting flange, the grinding gear fixedly sleeves the pull rod, and the pull rod is separately in sliding fit with an axial positioning central hole of the tensioning flange, a radial positioning central hole of the positioning flange and a limiting central hole of the supporting flange. The special tool is used for grinding the first-stage sun gear sleeve.

Owner:HARBIN TURBINE +1

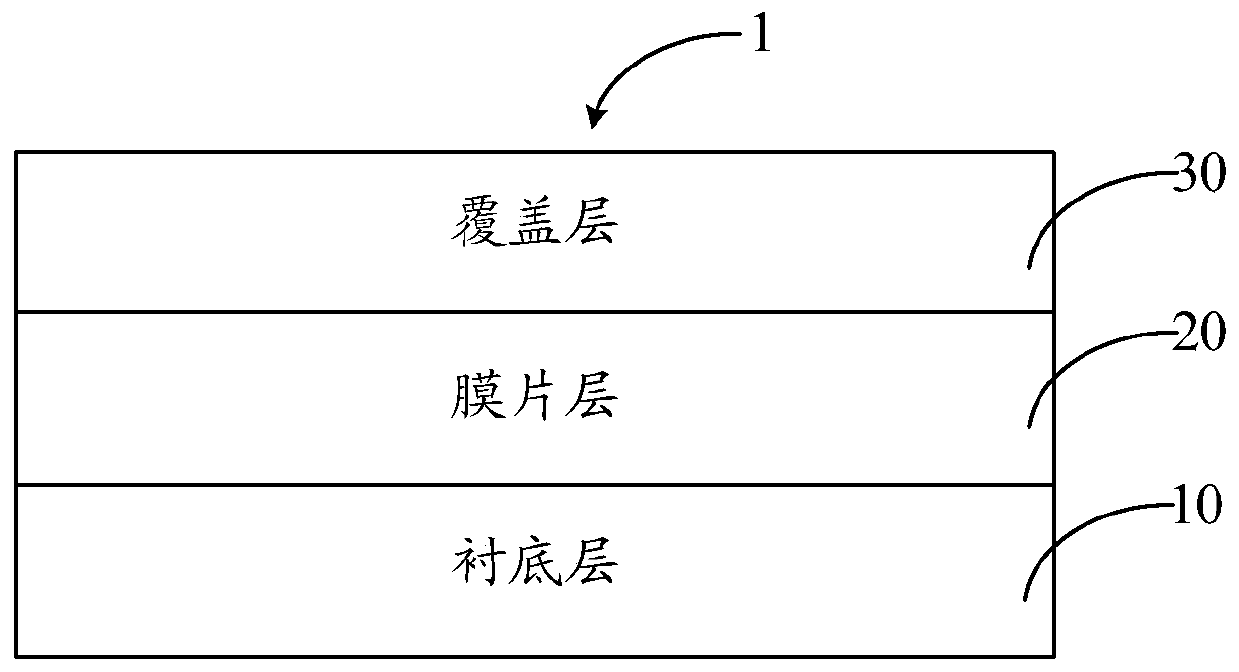

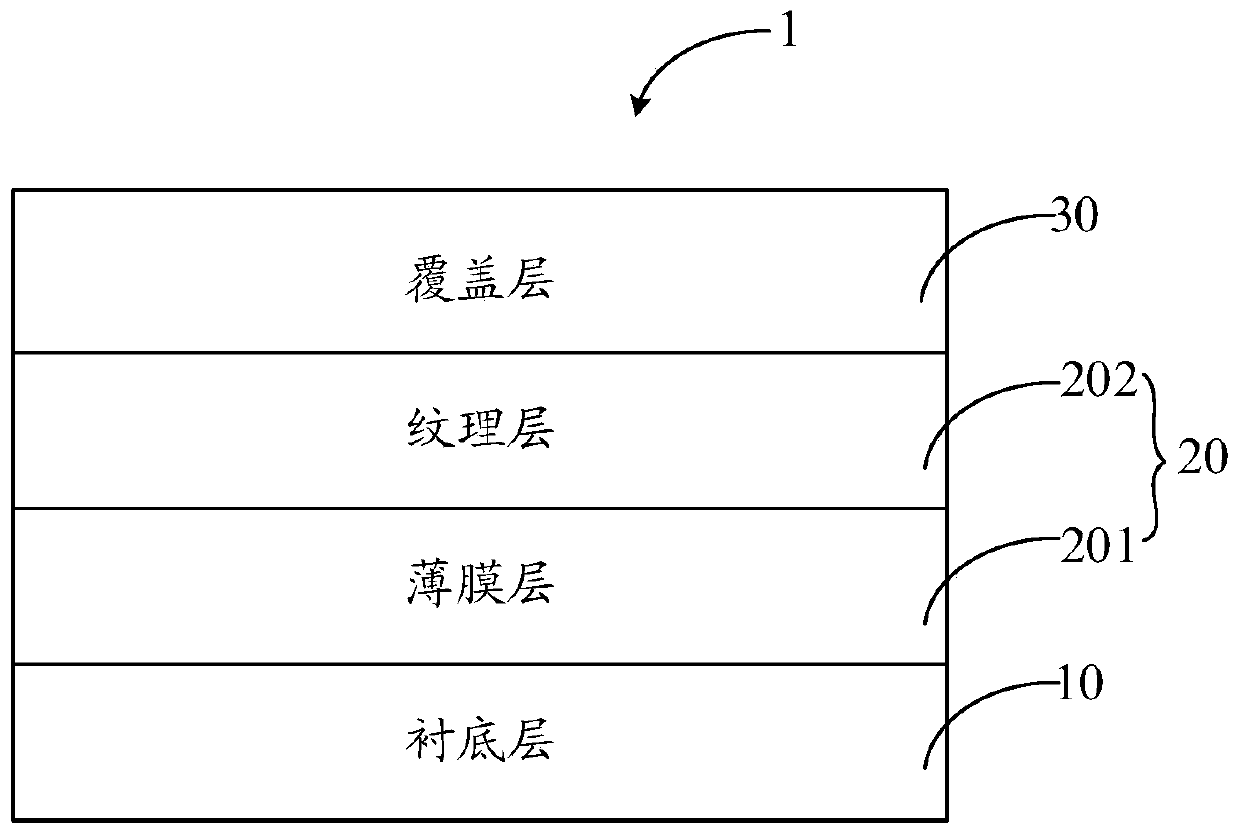

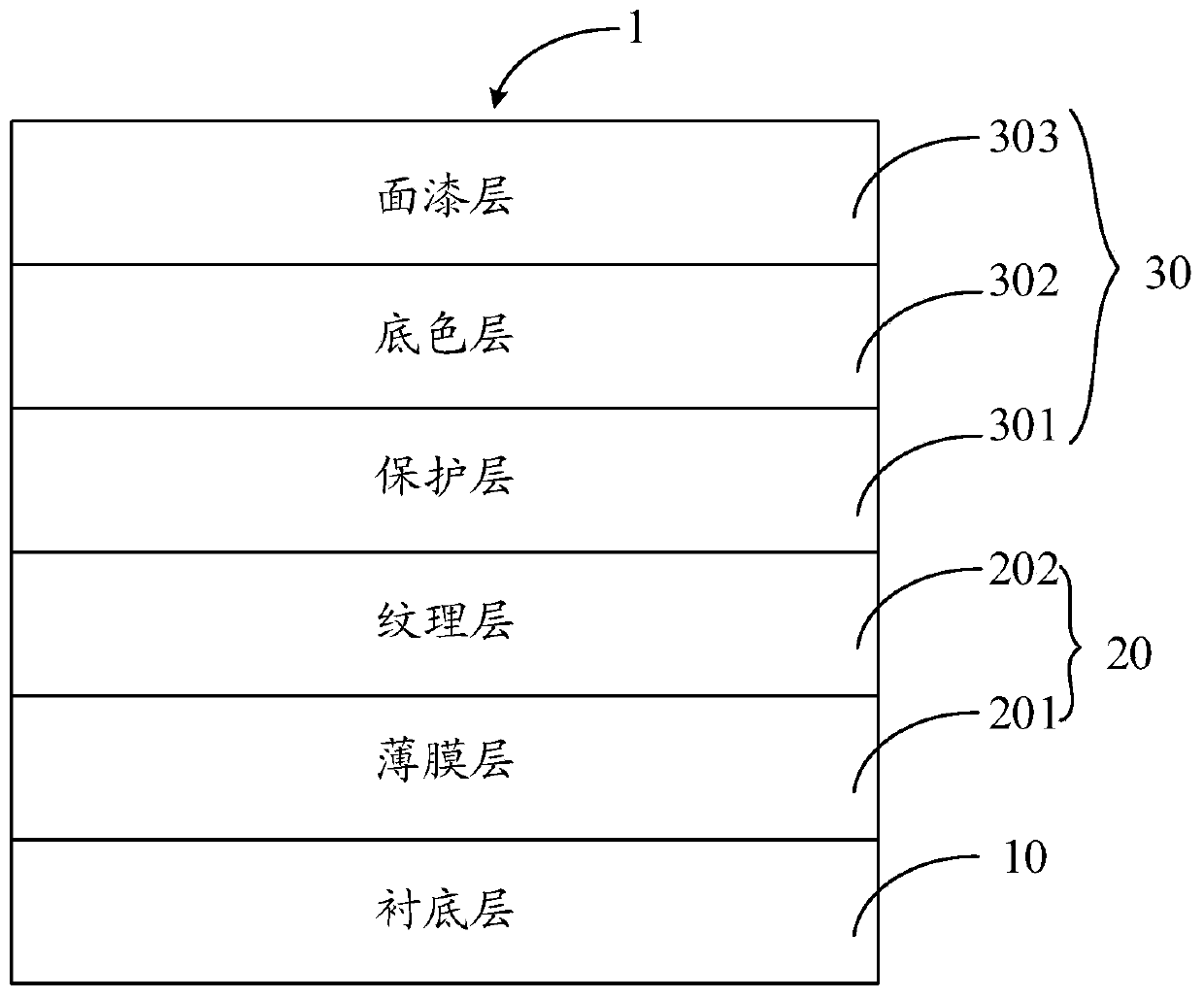

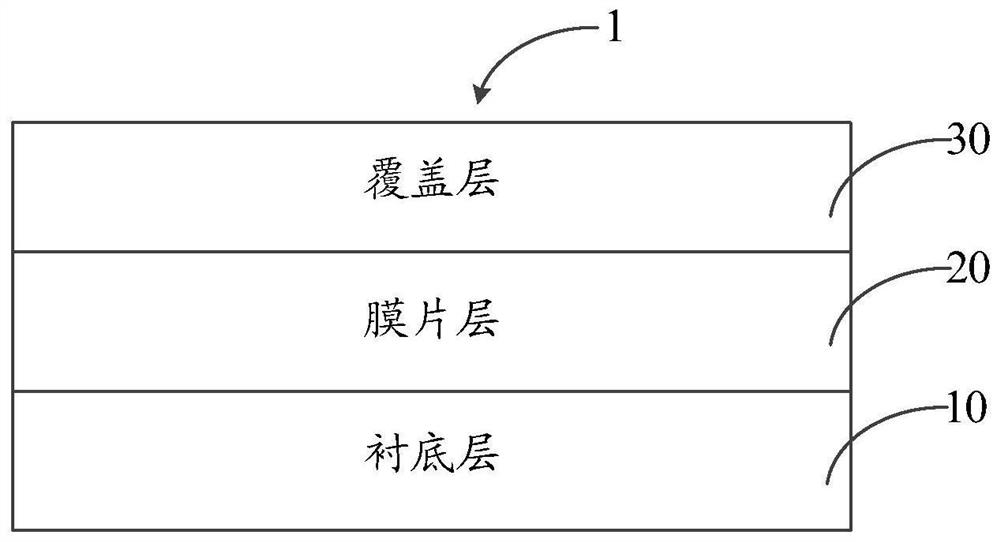

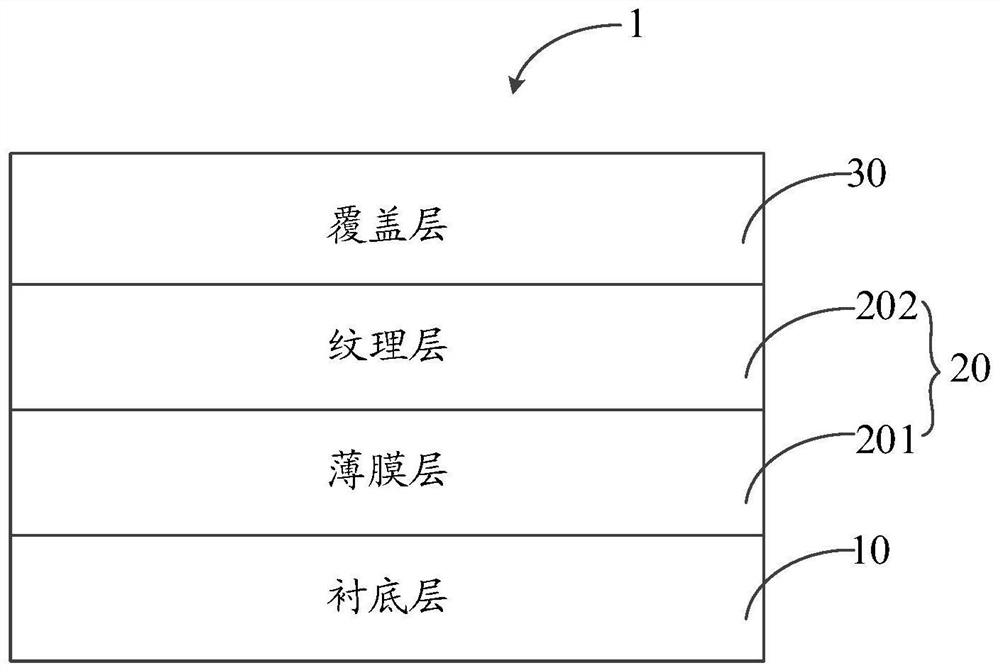

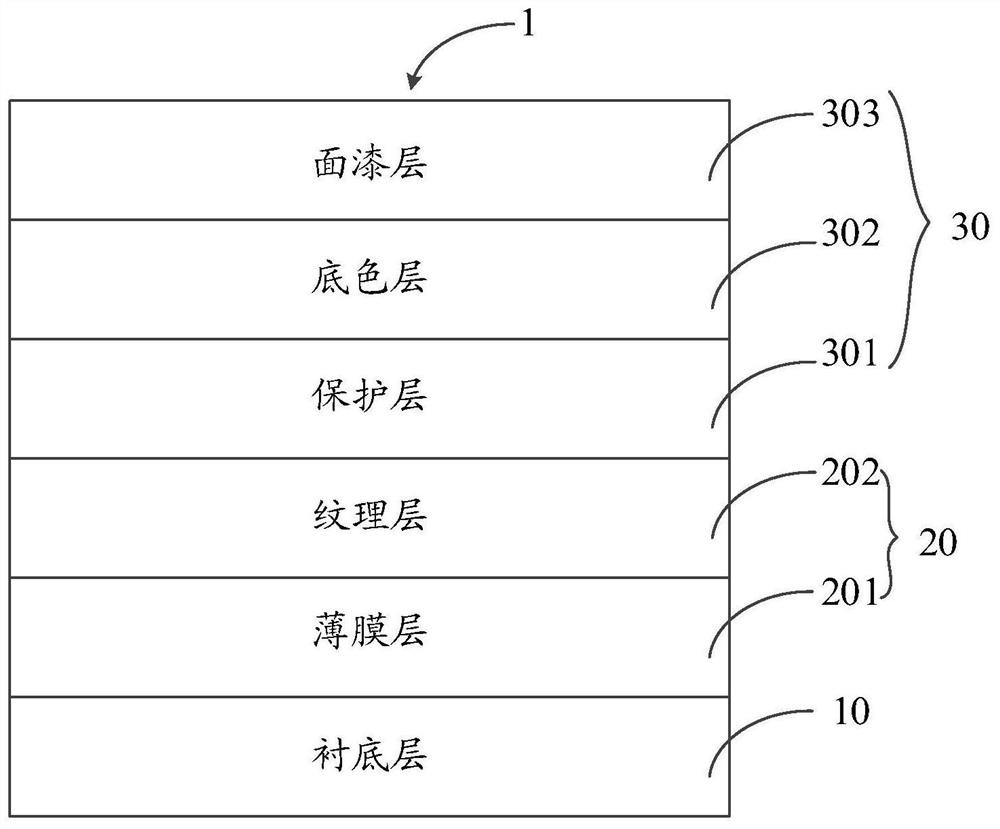

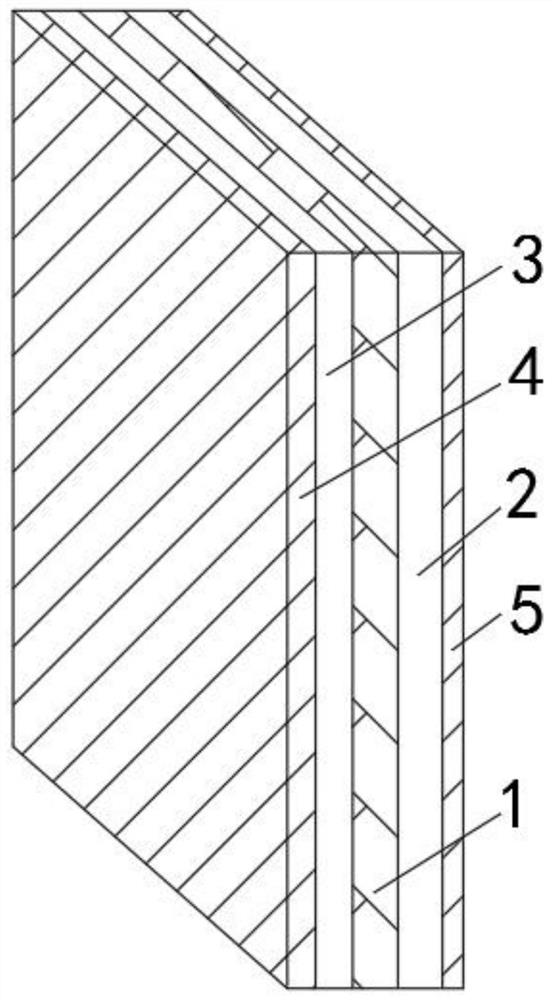

Shell, manufacturing method of shell and electronic equipment

ActiveCN110719707AImprove the bonding rateReduce process complexityOrnamental structuresCasings/cabinets/drawers detailsThin membraneEngineering

The embodiment of the invention discloses a shell, which comprises a substrate layer, a diaphragm layer arranged on the upper surface of the substrate layer, and a cover layer arranged on the upper surface of the diaphragm layer, wherein the diaphragm layer comprises a film layer and a texture layer arranged on the upper surface of the film layer. The embodiment of the invention further disclosesa manufacturing method of the shell and electronic equipment.

Owner:LENOVO (BEIJING) LTD

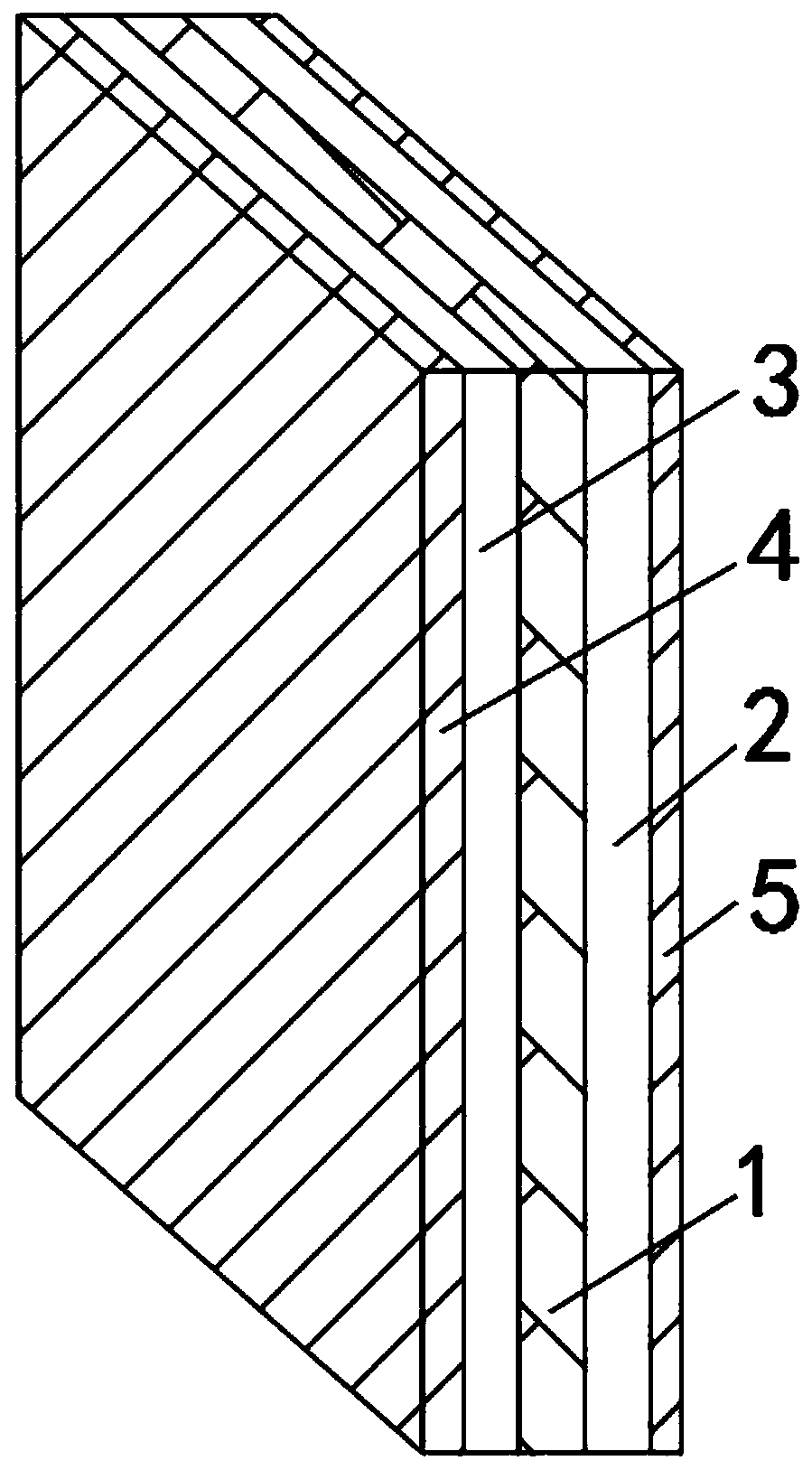

Environmental-protection multi-functional composite plate material and processing equipment for composite plate material

ActiveCN110629952AImprove adsorption capacityReduce weightCovering/liningsNon-rotating vibration suppressionAgricultural engineeringHardness

The invention discloses an environmental-protection multi-functional composite plate material and processing equipment for the composite plate material. The environmental-protection multi-functional composite plate material comprises a polythene base layer plate, the two side walls of the polythene base layer plate are provided with a first bamboo charcoal plate and a second bamboo charcoal platecorrespondingly, the outer side walls of the first bamboo charcoal plate and the second bamboo charcoal plate are provided with a second log base plate and a first log base plate correspondingly, andthe side walls of the first bamboo charcoal plate and the second bamboo charcoal plate are both provided with a plurality of sets of insert grooves in clamping connection with clamping connection columns. The environmental-protection multi-functional composite plate material is environmentally friendly and has good anti-collision and noise reduction effects, the composite plate material is high inoverall hardness, and the processing equipment is adopted to process the plate material, plate material cut mouths are made to keep smooth, the fit rate of multiple sets of the plate materials in later-period coordination use is effectively increased, gaps between the plate materials are reduced, furthermore, damage caused to the composite plate material in plate material processing positioning is effectively avoided, and the quality of the composite plate material is guaranteed.

Owner:安徽群升建筑工程有限公司

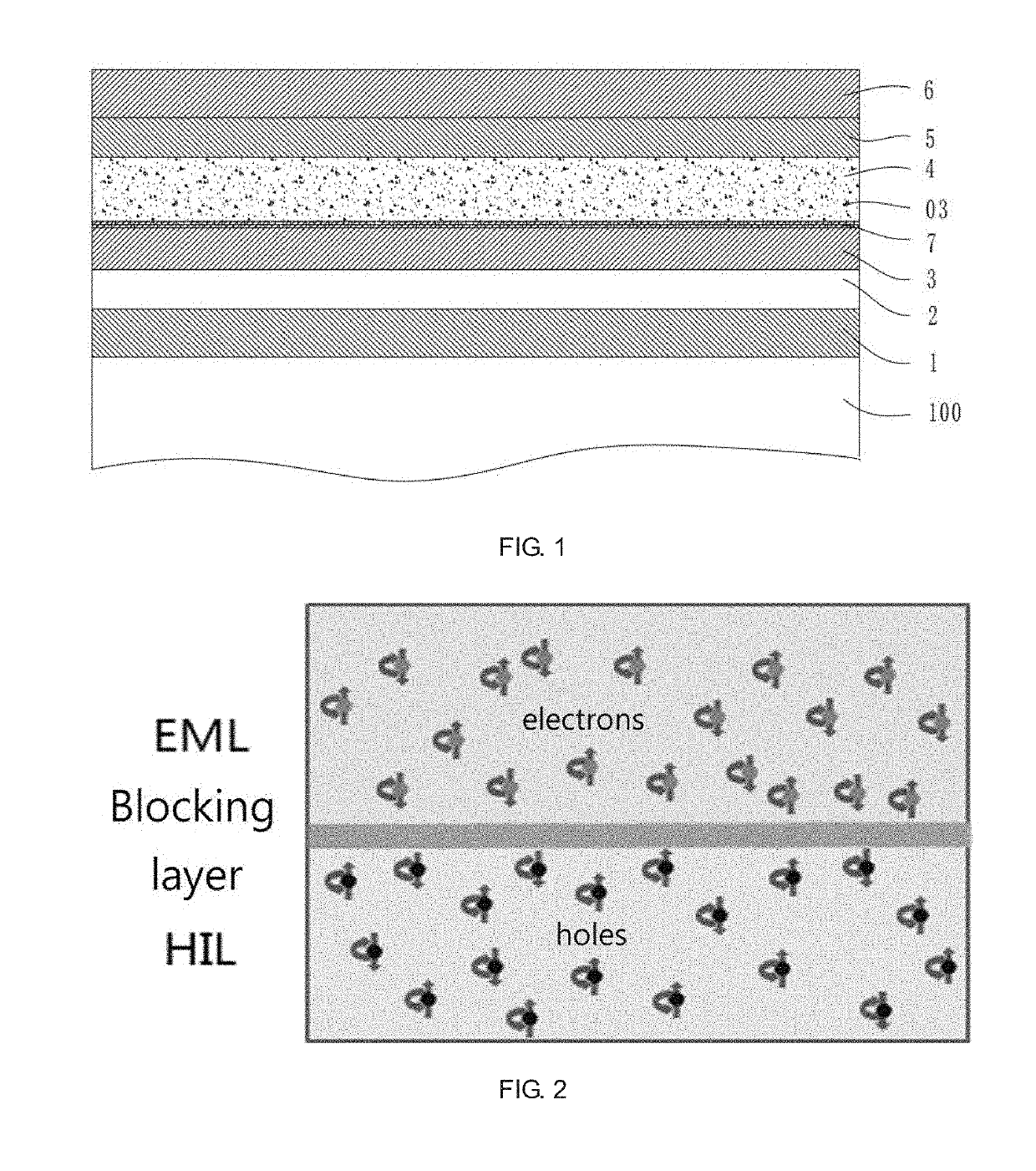

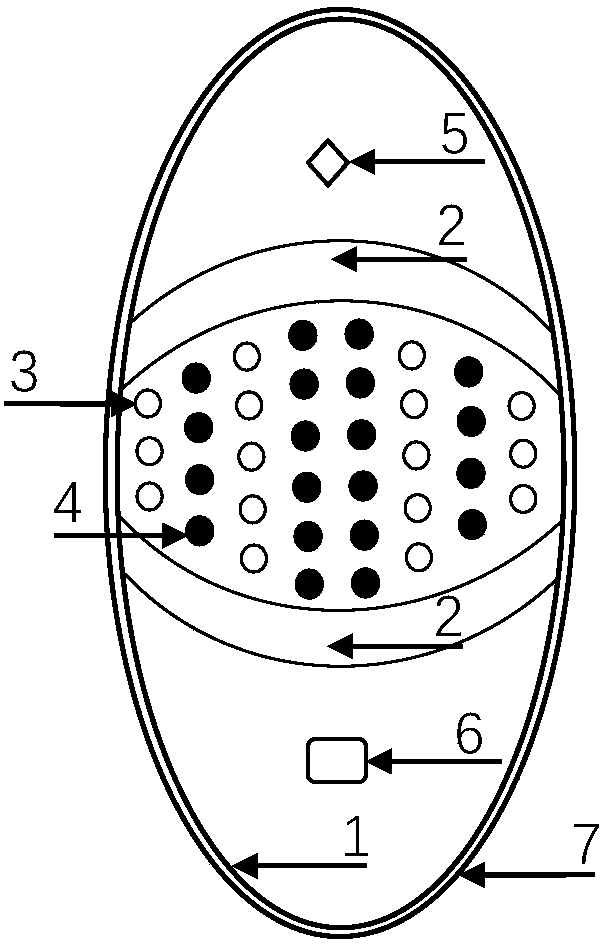

OLED panel, OLED display and manufacturing method of OLED panel

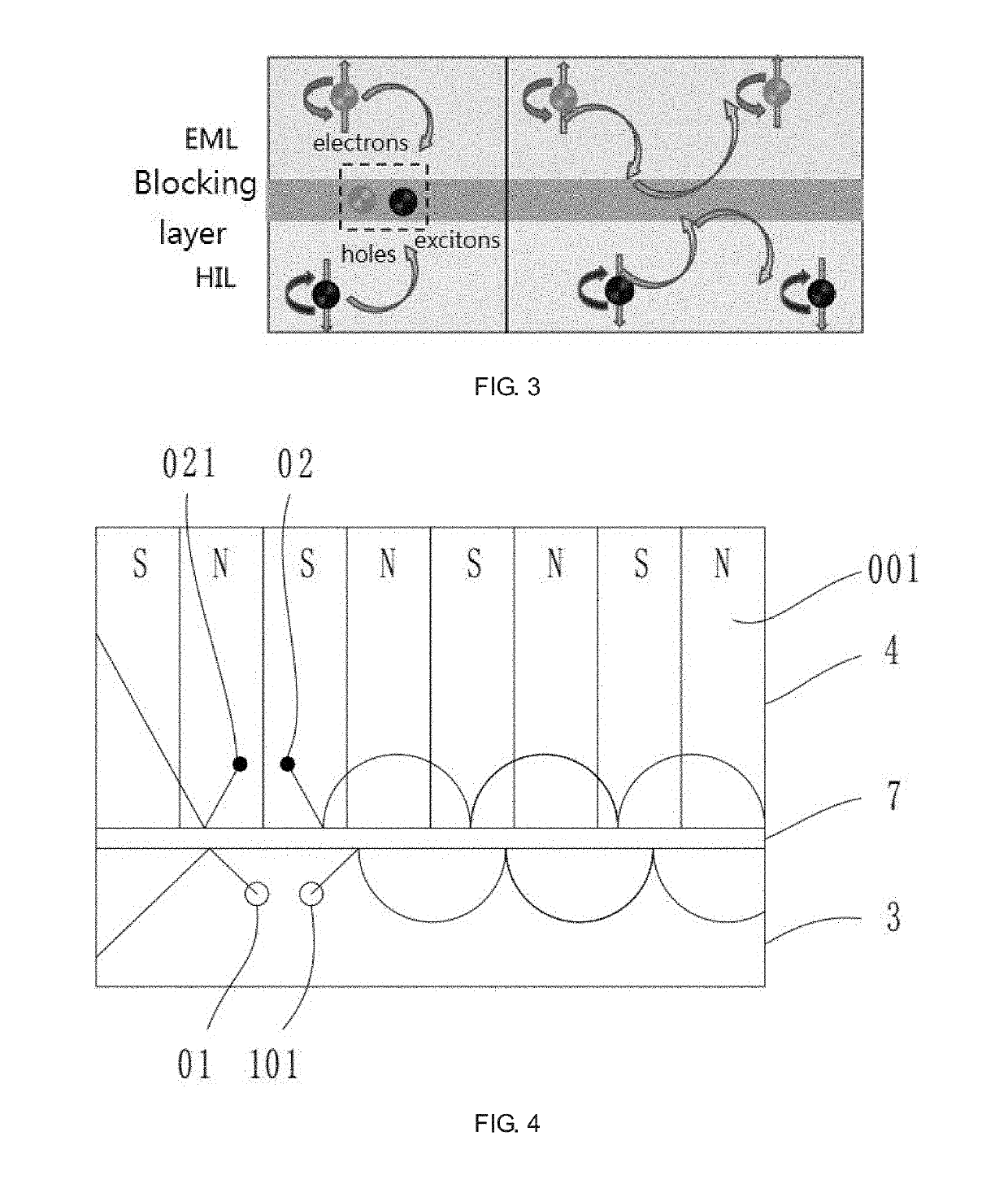

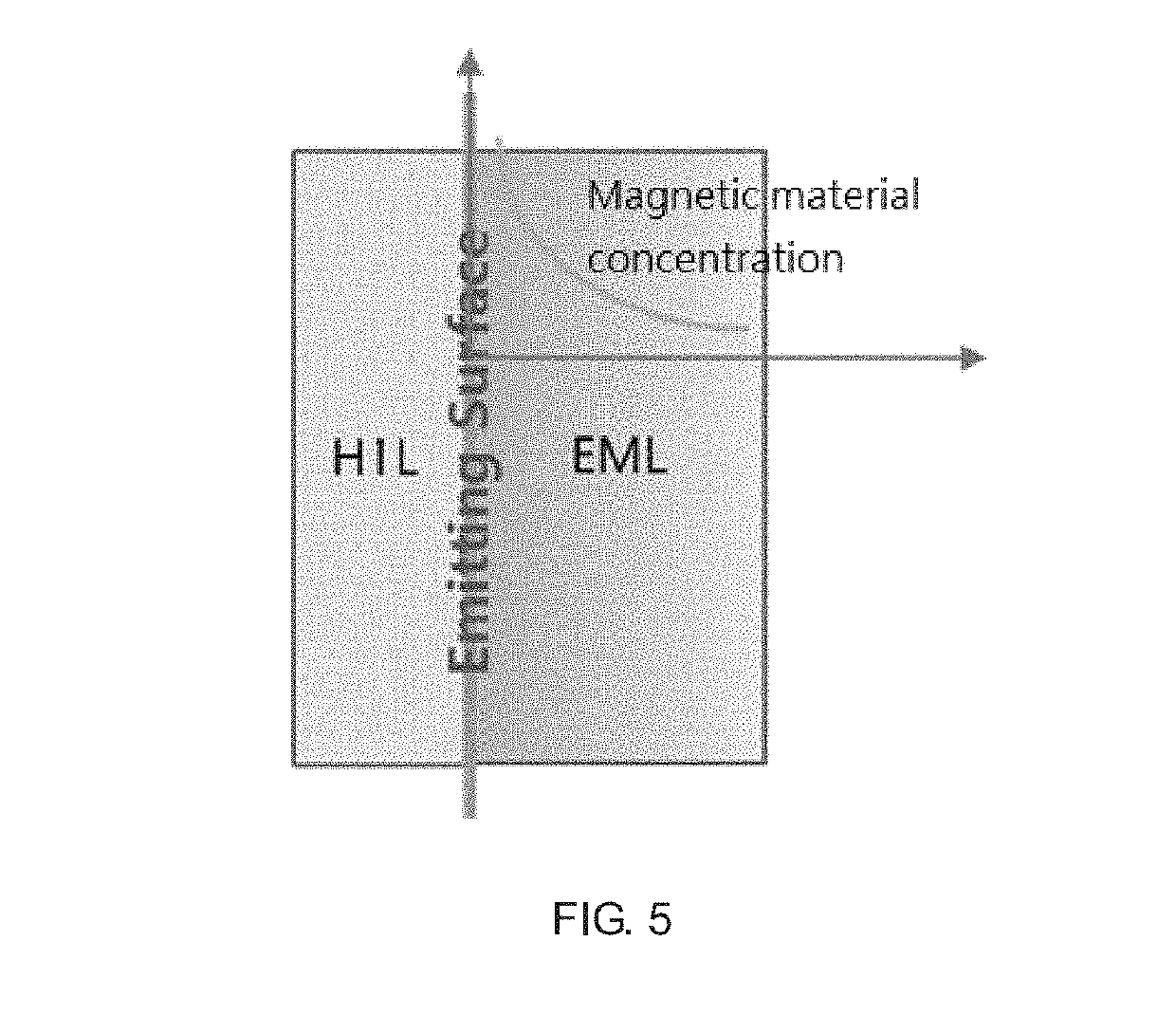

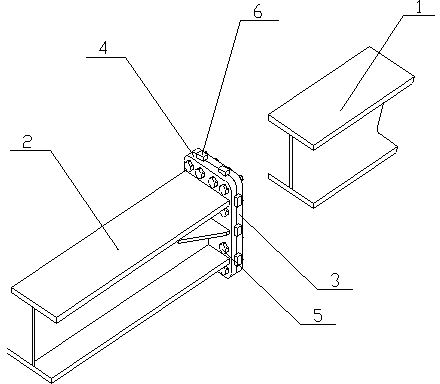

ActiveUS20190115552A1Simple structureImprove internal quantum efficiencySolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencyHole injection layer

The present disclosure relates to an OLED display panel and a manufacturing method of the same. The OLED panel includes an anode, a hole injection layer, a hole transport layer, a light-emitting layer, an electron transport layer and a cathode disposed on a substrate. The anode transporting holes to the hole injection layer, the holes penetrating the hole injection layer into the hole transport layer, the cathode transporting electrons to the electron transport layer. The electrons pass through the electron transport layer and enter the light-emitting layer. Magnetic particles are provided in the light-emitting layer and generate a magnetic field on the barrier layer where the hole transport layer and the light-emitting layer intersect to change trajectories of electrons and holes that fail to normally enter the barrier layer and rebound, moving it again to the blocking layer for bonding, thereby increasing the internal quantum efficiency of the OLED assembly.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

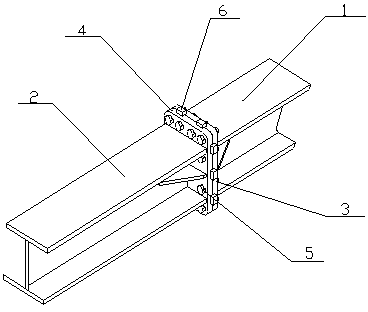

Special flange for derrick upright posts and attaching method of special flange

InactiveCN104389871AImprove flatnessImprove the bonding rateRod connectionsGas flame welding apparatusEngineeringWelding deformation

The invention relates to a special flange for derrick upright posts and an attaching method of the special flange. The flange is connected between an upper upright post and a lower upright post, and mainly comprises an upper flange plate welded with the bottom of the upper upright post, and a lower flange plate welded with the top of the lower upright post, wherein the upper flange plate is attached and connected with the lower flange plate in a back-to-back way, the flange surfaces of the upper flange plate and the lower flange plate are fixedly connected through screw bolts, and the periphery of an attaching seam of the upper flange plate and the lower flange plate is welded and fixed through a horse plate. According to an attaching method between flanges of the special flange for the derrick upright posts, firstly, a boring-milling machine is adopted for processing the front side and the back side of each of the upper flange plate and the lower flange plate, and the surface flatness is enabled to reach the drawing requirements; then, the two flanges are rigidly fixed through screw bolts and the horse plates arranged on the periphery. The special flange has the advantages that according to the special flange for the derrick upright posts and the attaching method of the flange, the welding deformation can be effectively controlled, the attaching rate among the flange plates is ensured, the cost is reduced, and the work efficiency is improved.

Owner:NANTONG ZHENHUA HEAVY EQUIP MFG

Lead layer squeeze casting method for depleted fuel storage tank

The invention discloses a lead layer squeeze casting method for depleted fuel storage tank. The method includes the following steps: choosing a cylindrical die-casting punch for the basic lead layer to pour the lead solution for squeeze casting, and obtaining the basic lead layer after solidification; embedding the thermocouple; choosing a cylindrical die-casting punch to cement the lead layer; pouring lead solution for squeeze casting; thus the cemented lead layer can be obtained after solidification. Annular punch is used for die-casting to form a thin lead layer on both the enclosure of the stainless steel inner tank and the inner shell of the stainless steel outer tank of the shielding layer of the depleted fuel storage tank, and the lead layer and stainless steel wall can fit together closely; the lead layer squeeze casting method has the advantages of a simple process flow and high efficiency, and can apply lead automatically.

Owner:SHANGHAI JIAO TONG UNIV

Shell, shell manufacturing method and electronic device

ActiveCN110719707BImprove the bonding rateReduce process complexityOrnamental structuresCasings/cabinets/drawers detailsThin membraneStructural engineering

The embodiment of the present application discloses a casing, which includes: a substrate layer, a diaphragm layer, and the diaphragm layer is arranged on the upper surface of the substrate layer; wherein, the diaphragm layer includes a film layer and a A texture layer on the upper surface of the film layer; the substrate layer and the film layer have the same material; and a covering layer, the covering layer is arranged on the upper surface of the film layer. The embodiment of the present application also discloses a manufacturing method of the housing and electronic equipment.

Owner:LENOVO (BEIJING) LTD

A green and environmentally friendly multifunctional composite board and processing equipment for the composite board

ActiveCN110629952BImprove adsorption capacityReduce weightCovering/liningsNon-rotating vibration suppressionProcess engineeringComposite plate

The invention discloses a green and environment-friendly multifunctional composite board and processing equipment for the composite board, comprising a polyethylene base board, the two side walls of the polyethylene base board are respectively provided with a first bamboo charcoal board and a second bamboo charcoal board, The outer sidewalls of the first bamboo charcoal board and the second bamboo charcoal board are respectively provided with a second log substrate and a first log substrate, and the side walls of the first bamboo charcoal board and the second bamboo charcoal board are provided with several groups of clamping columns. The slots that are engaged with each other; the composite board in the present invention is green and environmentally friendly, and has good anti-collision and noise reduction effects. It is smooth, which effectively improves the lamination rate of multiple groups of plates when they are used together in the later stage, reduces the gap between the plates, and effectively avoids damage to the composite plates when the plates are processed and positioned, ensuring the composite plates. quality.

Owner:安徽群升建筑工程有限公司

Nickel alloy/tungsten composite rod preparation method

The invention provides a nickel alloy / tungsten composite rod preparation method, which comprises (1) subjecting a tungsten rod to surface cleaning treatment; (2) placing the cleaned tungsten rod and nickel alloy powder into a press mold, putting into a cold isostatic press, and pressing to give a nickel alloy / tungsten composite rod blank with nickel alloy porosity of 35%-45%; (3) vacuum sintering in a vacuum sintering furnace to reduce the nickel alloy porosity to be lower than or equal to 5%; and (4) drawing to obtain a finished product of nickel alloy / tungsten composite rod. The inventive method is simple in process, low in equipment investment, short in production cycle, free of pollution to environment, high in yield and capable of batch production. Nickel alloy in the nickel alloy / tungsten composite rod prepared by the inventive method has uniform thickness, low porosity and high finished product dimension precision, and the metal bonding rate of the nickel alloy and the tungsten rod is higher than or equal to 98%, or up to 100% after process optimization.

Owner:XIAN REFRA TUNGSTEN & MOLYBDENUM

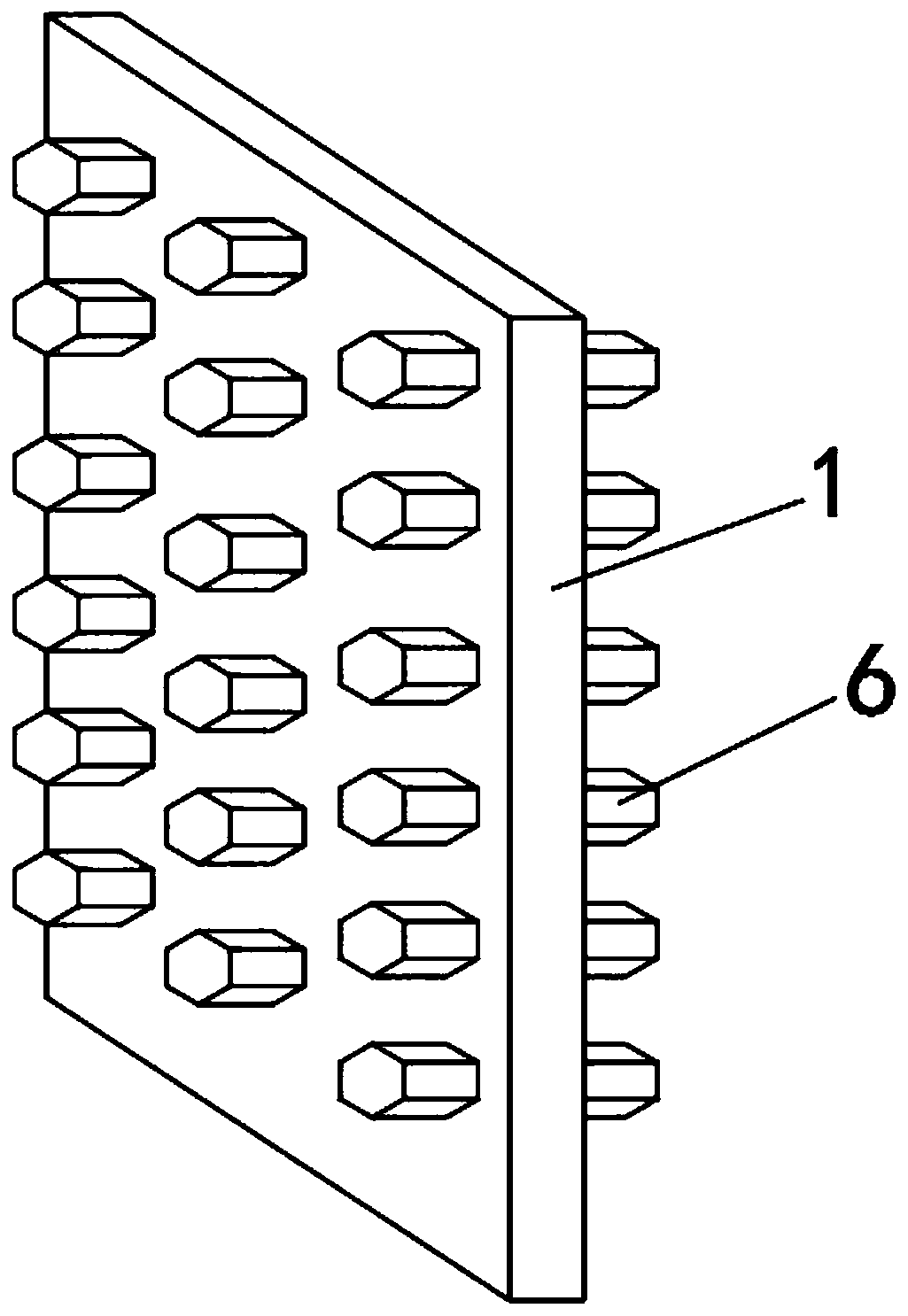

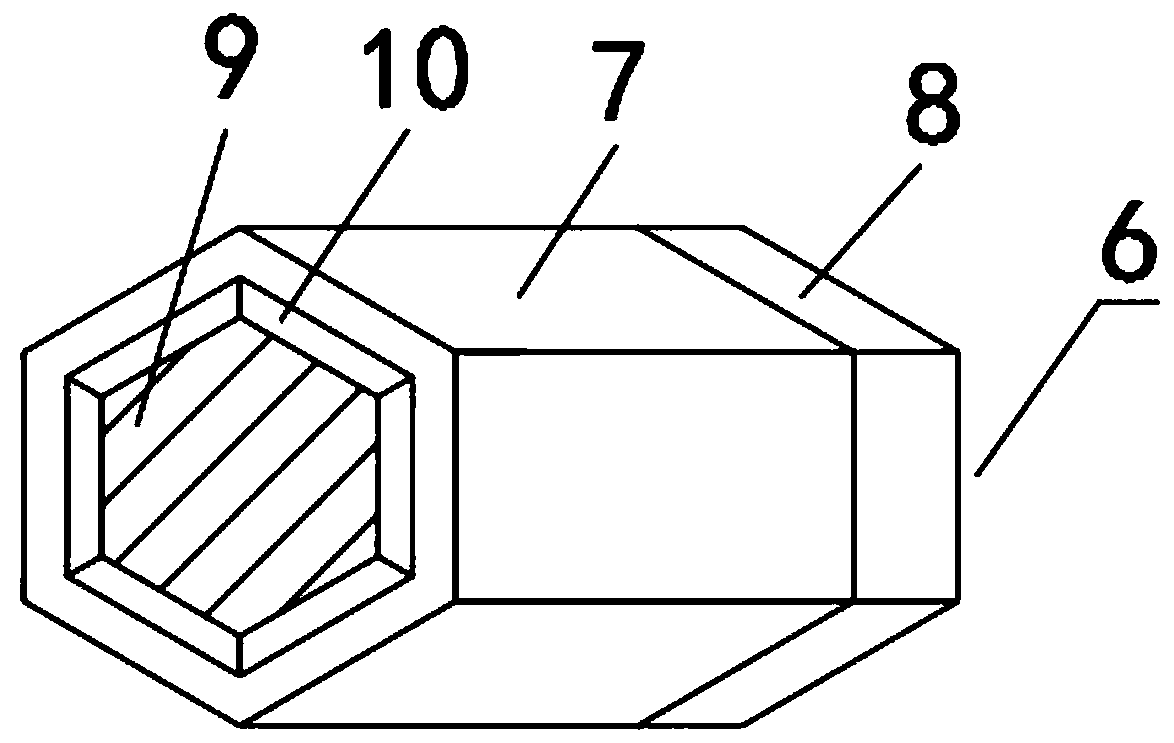

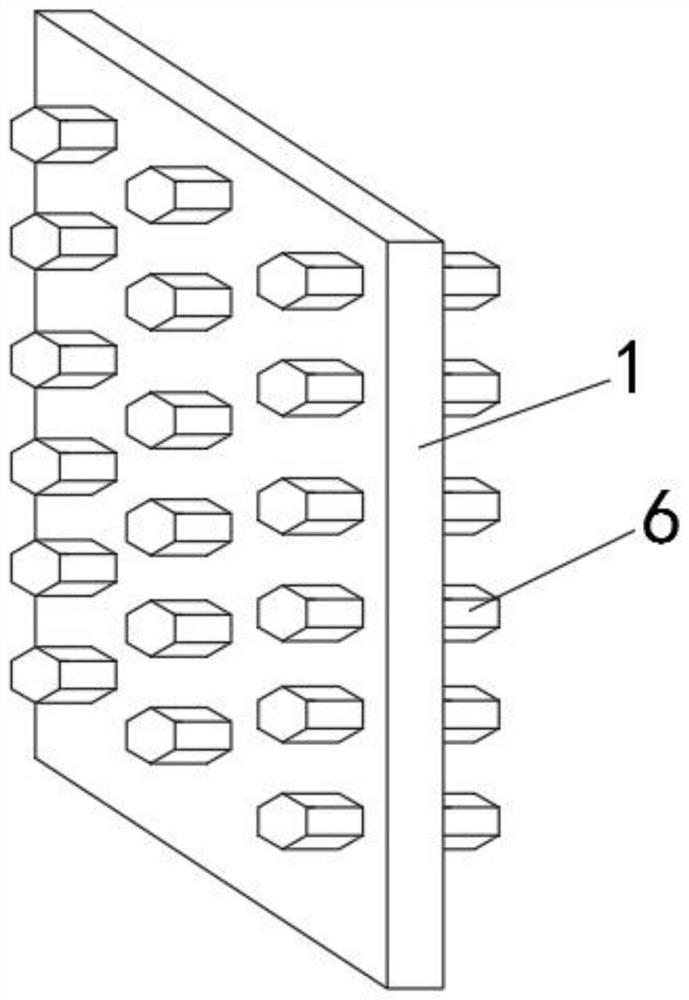

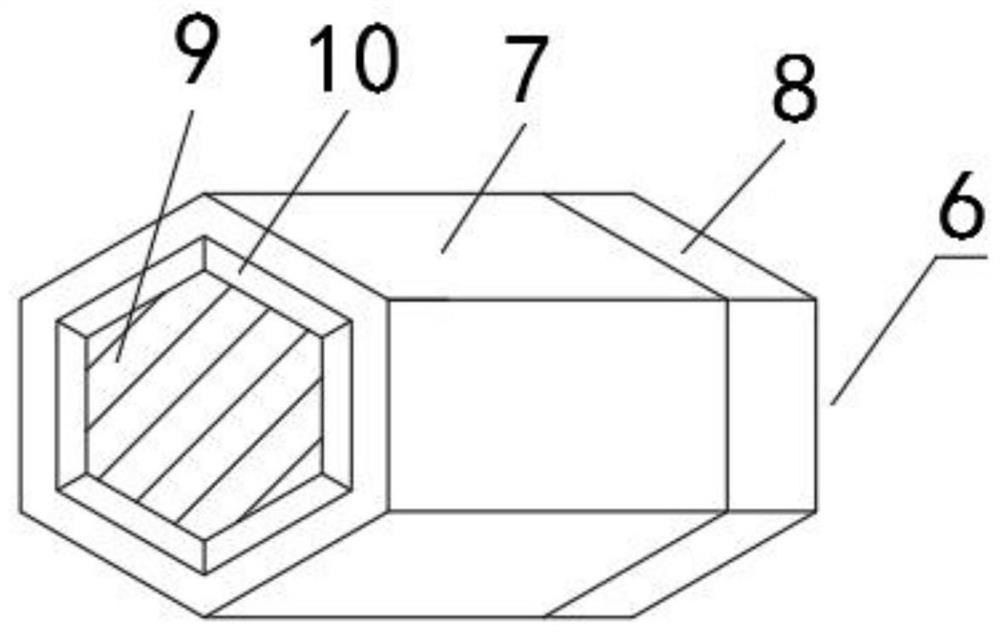

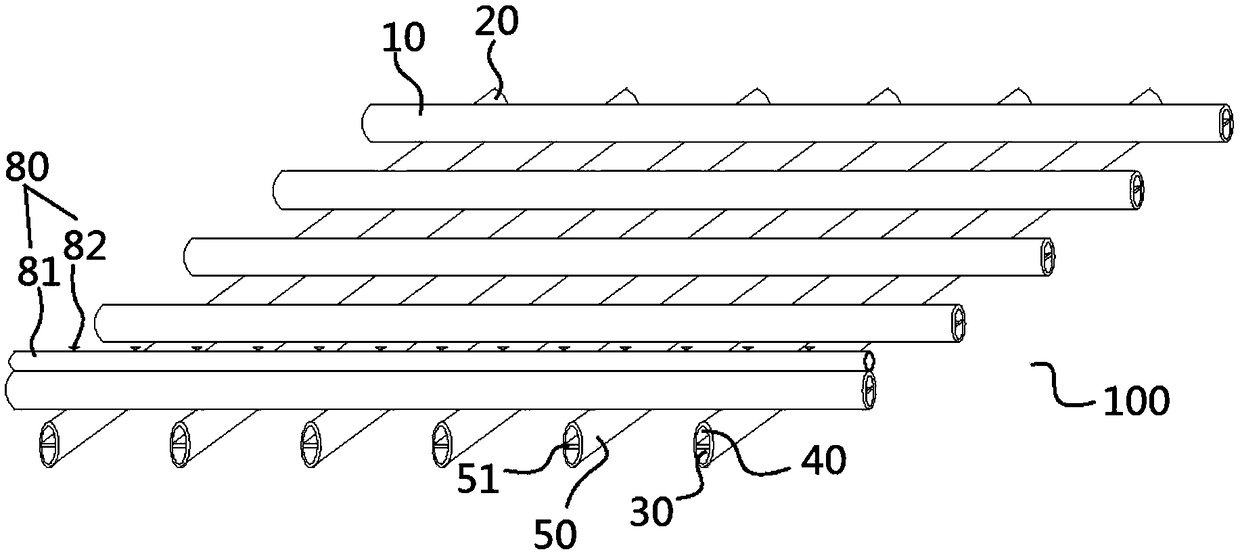

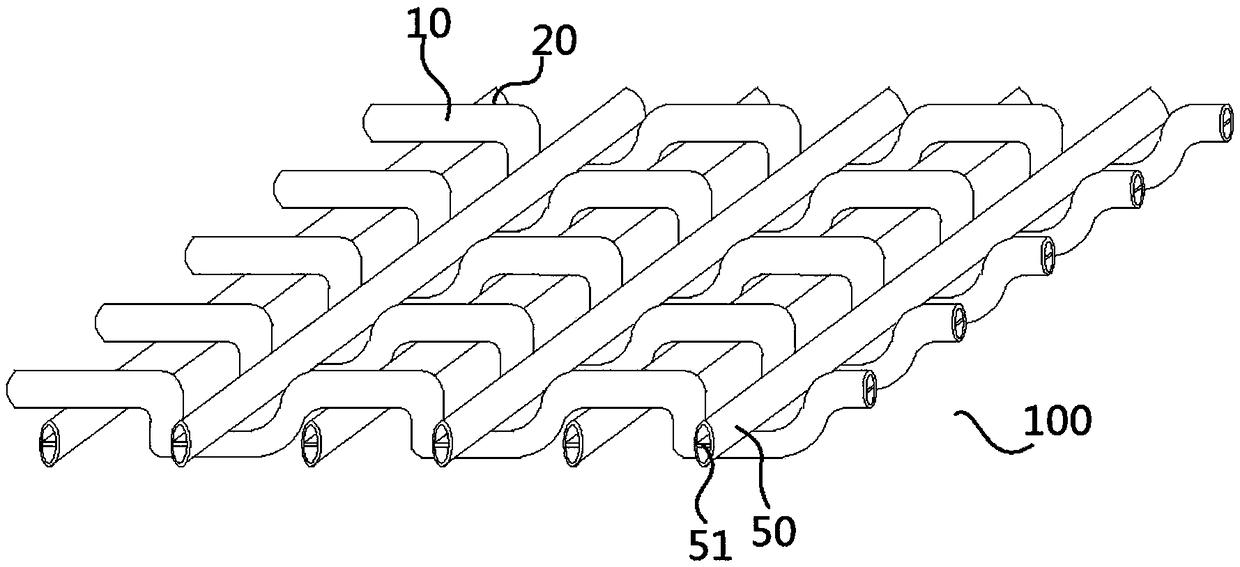

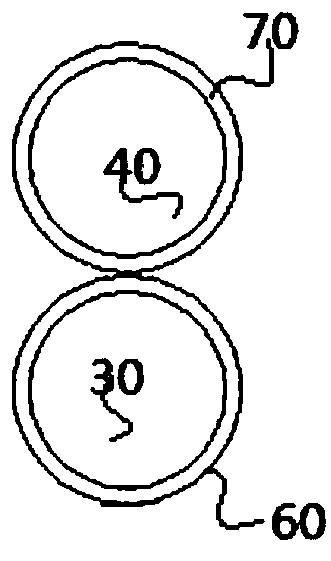

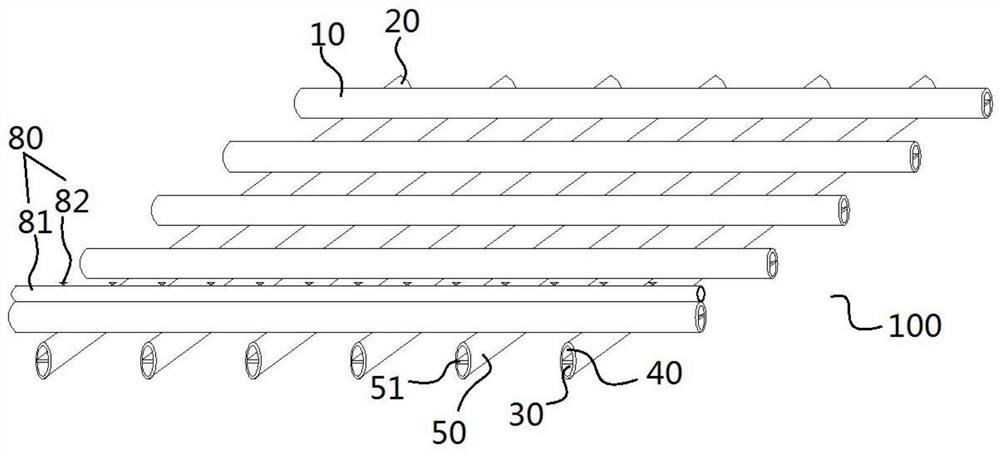

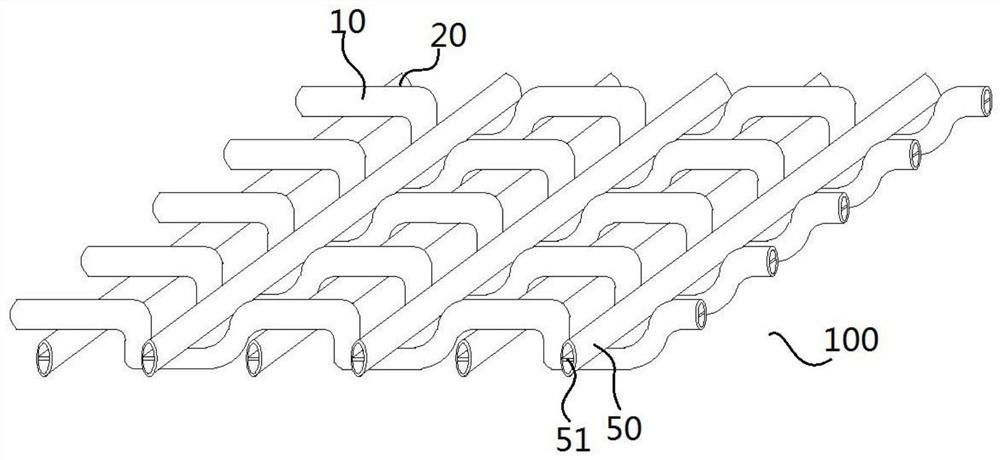

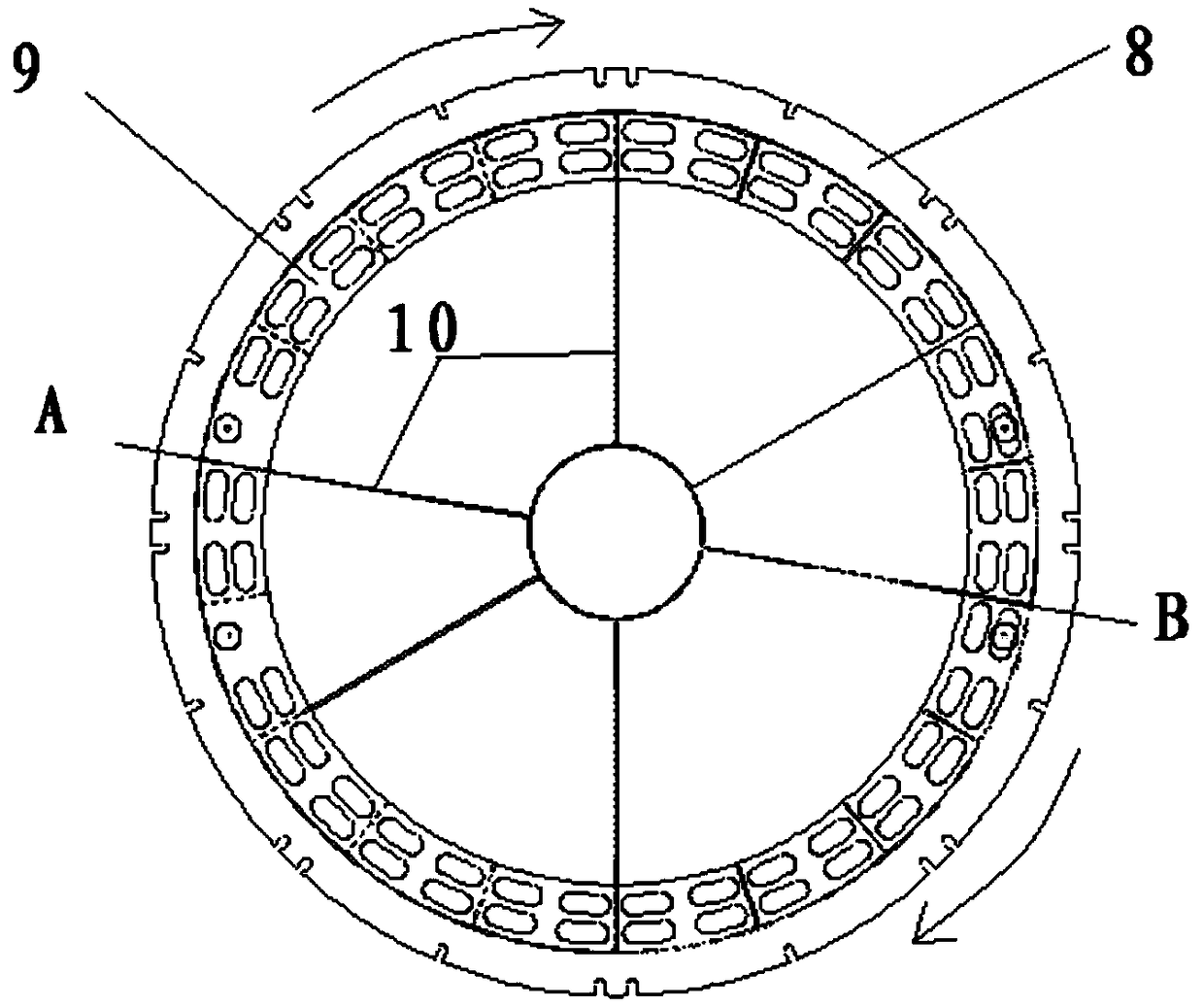

Latticed flexible manipulator

ActiveCN108502533AImprove the bonding rateImprove grip and adsorptionConveyor partsEngineeringManipulator

The invention provides a latticed flexible manipulator. The reticular flexible manipulator comprises at least one row of first direction control assemblies and at least one row of second direction control assemblies, wherein a plurality of first direction control assemblies are included in each row of first direction control assemblies, and a plurality of second direction control assemblies are included in each row of second direction control assemblies; the first direction control assemblies and the second direction control assemblies are connected to form a flexible latticed structure; eachdirection control assembly comprises a first containing cavity and a second containing cavity, and each second direction control assembly comprises a first containing cavity and a second containing cavity; each first containing cavity contains first fluid; each second containing cavity contains second fluid; the second containing cavities and the first containing cavities are connected; the volumeof the first fluid and the volume of the second fluid are different; the direction control assemblies are bent towards the small-volume sides. Through the combined structure of deformation plates andthe direction control assemblies, the latticed flexible manipulator provided by the invention can achieve both bending deformation and wavy deformation, and the contact area of the latticed flexiblemanipulator and a grabbed object is increased. Moreover, the latticed flexible manipulator further has the advantages of being simple in structure and convenient to operate.

Owner:NANJING CHENGUANG GRP +1

Rear drum brake shoe liquid friction-increasing rubber and preparation method

ActiveCN104327607BImprove the bonding rateImprove comfortConjugated diene hydrocarbon coatingsVulcanizationBenzoyl peroxide

The invention relates to a liquid friction-increasing rubber for a rear drum brake shoe and a preparation method thereof, comprising: 1. dissolving silicon carbide, antimony sulfide, benzoyl peroxide, sulfur, quartz powder, and nitrile rubber in ethyl acetate , and stir well; 2. Apply the above mixture to the surface of the processed hoof by brushing or soaking hair; 3. Let it stand to dry; 4. Put the hoof in a constant temperature vulcanization box to fully vulcanize the rubber ; 5. The vulcanized shoe can be directly used for brake assembly assembly after cooling. The beneficial effects of the present invention are: the invention adjusts the friction-increasing formula into a liquid state, which is convenient for painting, can form productivity, and is suitable for mass production; the surface coating is uniform, which can effectively offset the influence of processing accuracy and improve the lamination rate; Rubber (Nitronitrile Rubber) is used as the base material to increase elasticity and cushioning performance, effectively reducing noise; using quartz powder instead of corundum, the friction-increasing material is easier to distribute evenly, eliminating hard spots and improving the driver's comfort.

Owner:ZHEJIANG WANXIANG SYST +1

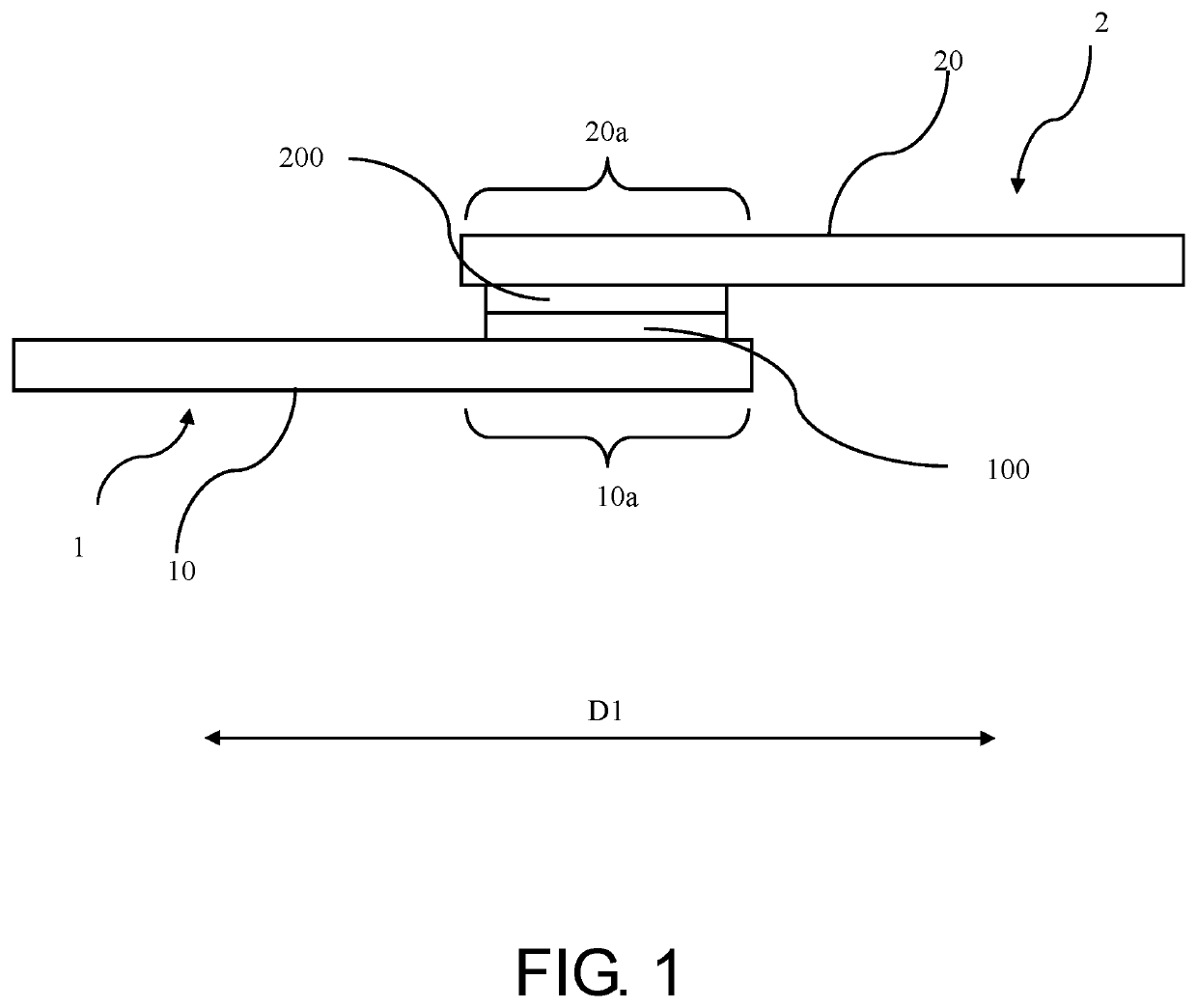

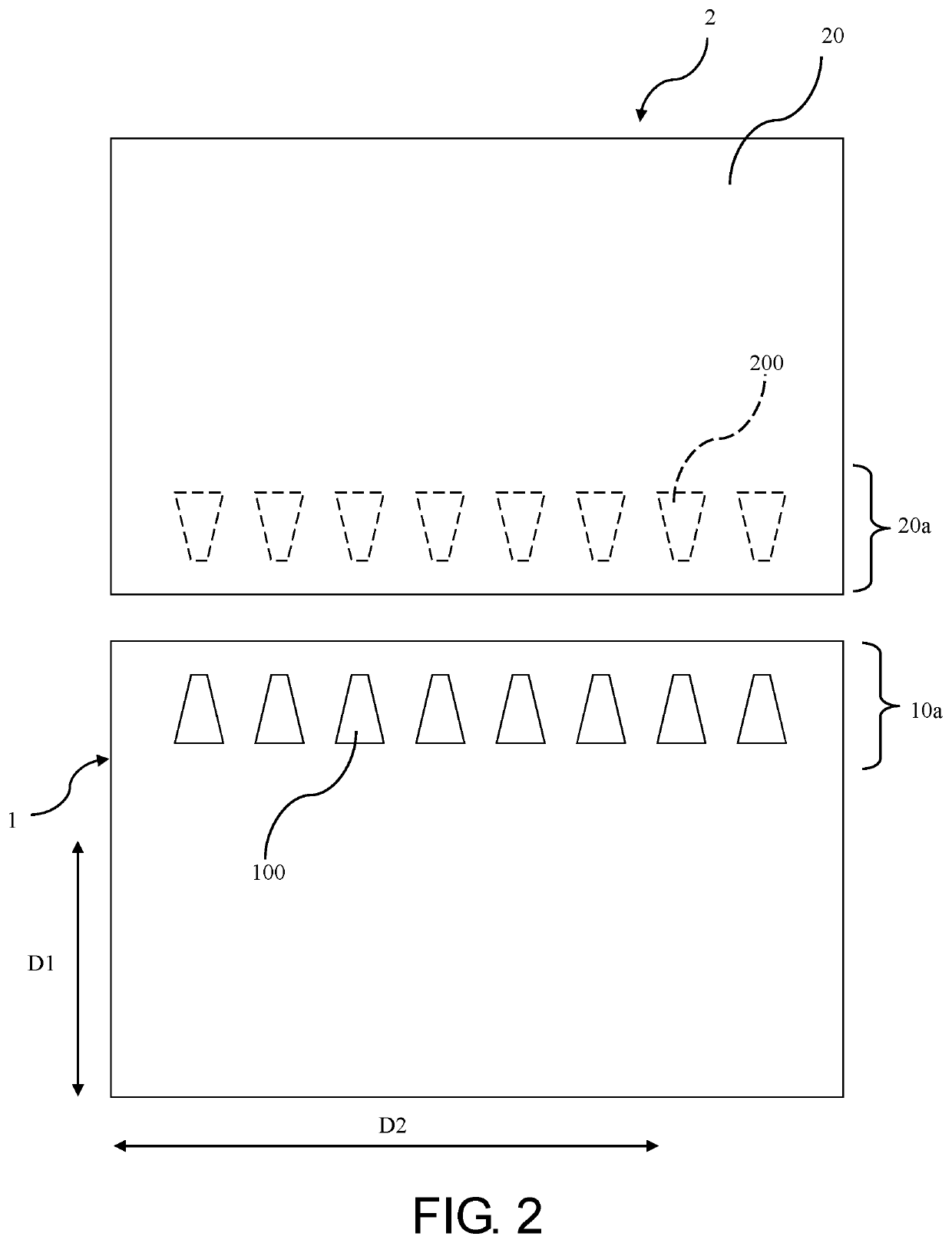

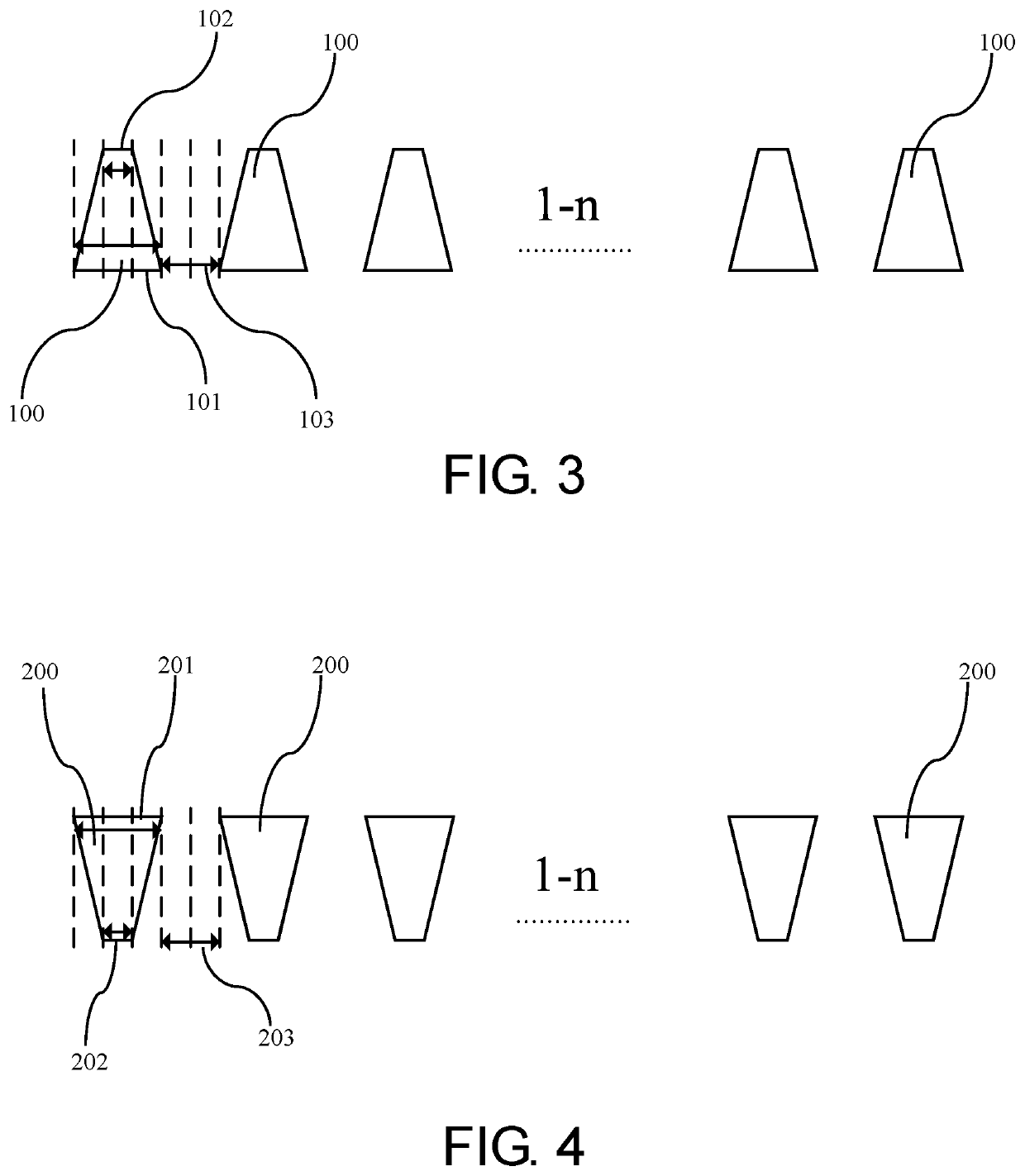

Display panel and chip-on-film (COF) package bonding structure, panel bonding pins, package bonding pins, and display panel and cof package bonding method

ActiveUS20210212213A1Improve the bonding rateImprove yieldPrinted circuit aspectsDigital processing power distributionStructural engineeringMaterials science

A display panel and chip-on-film (COF) package bonding structure is provided and includes a display panel including a panel substrate and a plurality of panel bonding pins. The panel bonding pins are disposed on the panel substrate and are arranged along a lateral direction. Each of the panel bonding pins is trapezoidal and is directed along a longitudinal direction. A COF package is bonded to the display panel and includes a package substrate and a plurality of package bonding pins. The package bonding pins are disposed on the package substrate, are arranged along the lateral direction, and are bonded to the panel bonding pins respectively. Each of the package bonding pins is trapezoidal and along the longitudinal direction. The trapezoidal panel bonding pins and package bonding pins can be aligned with and contacts each other.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Solar sports patch based on myoelectricity stimulation

InactiveCN108309567ARealize power supplySave energyElectrotherapyPlastersElectricityMuscular fatigue

The invention discloses a solar sports patch based on myoelectricity stimulation, comprising a patch base. A glue layer is applied to the skin side, and release paper is provided. The patch base is made of a flexible electronic material; a microprocessor unit, a wireless signal receiver, a solar power layer, a myoelectricity stimulation electrode array and a flexible microcircuit connected with the components are built in the patch base. The patch base is provided with an intelligent control terminal; the intelligent control terminal may set low-frequency pulse of specific parameters for the patch base. The patch base is provided with pores around electrode points. The solar sports patch based on myoelectricity stimulation saves energy, is portable and small in size, and has high fitting rate and good breathability. Low-pulse myoelectricity stimulation modes of different parameters can be autonomously set and can be combined with different application methods in order to achieve the purposes, such as relieving local muscular fatigue and improving local muscular strength.

Owner:BEIHANG UNIV

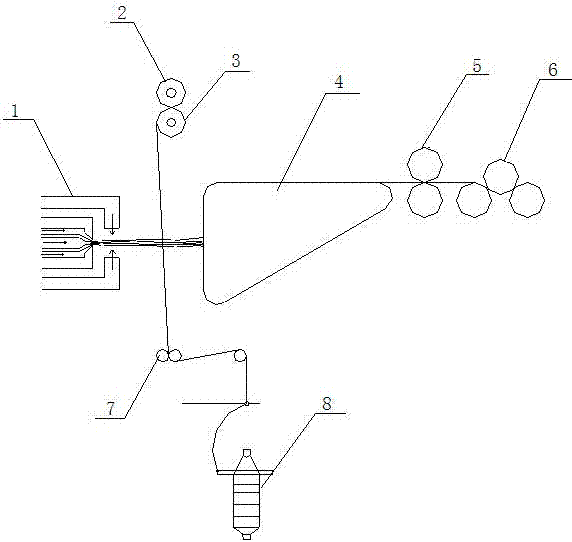

Micro-nano fiber yarn spinning device with high spinning efficiency and its spinning process

The invention discloses a micro-nano-fiber yarn spinning device high in spinning efficiency and a spinning process thereof. The spinning device comprises a spinning head, a yarn feeding system, a fiber collection mechanism, a roller twisting mechanism and a twisting mechanism, the spinning head is constituted by a hot air pipeline, a polymer melt pipeline and a cold air pipeline, the yarn feeding system is constituted by yarn and a roller, the fiber collection mechanism is constituted by a receiving curtain, compressing rollers and winding rollers, the roller twisting mechanism is constituted by two roller twisting rolling wheels, and the yarn penetrates through the space between the two roller twisting rolling wheels. The micro-nano-fiber yarn spinning device is reasonable in structure and process design, convenient in practical operation, capable of spinning micro-nano-fibers into the yarn and achieving 360-degree complete cover, in particular to the surface of the yarn and high in fitting rate and work efficiency, redundant nano-fibers can be re-utilized, and the produced yarn has the functions of antisepsis, thermal insulation, sound absorption, filtration, adsorption and the like.

Owner:南通吉瑞雅纺织有限公司

A lead layer extrusion casting hanging method for spent fuel storage tank

The invention discloses a lead layer squeeze casting method for depleted fuel storage tank. The method includes the following steps: choosing a cylindrical die-casting punch for the basic lead layer to pour the lead solution for squeeze casting, and obtaining the basic lead layer after solidification; embedding the thermocouple; choosing a cylindrical die-casting punch to cement the lead layer; pouring lead solution for squeeze casting; thus the cemented lead layer can be obtained after solidification. Annular punch is used for die-casting to form a thin lead layer on both the enclosure of the stainless steel inner tank and the inner shell of the stainless steel outer tank of the shielding layer of the depleted fuel storage tank, and the lead layer and stainless steel wall can fit together closely; the lead layer squeeze casting method has the advantages of a simple process flow and high efficiency, and can apply lead automatically.

Owner:SHANGHAI JIAO TONG UNIV

A mesh flexible manipulator

ActiveCN108502533BImprove the bonding rateImprove grip and adsorptionConveyor partsRobot handControl engineering

The present invention provides a network flexible manipulator, comprising: at least one row of first direction control components, each row of first direction control components is multiple; at least one row of second direction control components, each row of second direction control components There are multiple direction control components, the first direction control component and the second direction control component are connected to form a flexible grid structure; the first direction control component and the second direction control component are both provided with: a first accommodation chamber, a second The first fluid is provided in a housing chamber; the second fluid is provided in the second housing chamber, the second housing chamber is connected with the first housing chamber, the volumes of the first fluid and the second fluid are different, and the direction is controlled Components are bent towards the small side. According to the embodiment of the present invention, the net-shaped flexible manipulator utilizes the combined structure of the deformation plate and the direction control component, which can not only realize bending deformation, but also realize wave-shaped deformation, increase the contact area with the grasped object, and have a structural Simple, easy to operate and other advantages.

Owner:NANJING CHENGUANG GRP +1

A large-diameter non-metallic skin turning device

ActiveCN107812959BImprove rigidityReduce weightWork clamping meansTurning machinesSkin structureMachine tool

The invention relates to the field of large launcher tail section skin outer circle machining, in particular to a large-diameter nonmetal skin turning device. The large-diameter nonmetal skin turningdevice comprises a blank body, an upper end plate, a pedestal set, a bottom plate, an upper pressing plate set, a lower pressing plate set and a fastening device set. The blank body is of a hollow cylindrical structure which is vertically placed, and the upper end plate is of a circular plate structure and is concentrically fixedly mounted at the axial top end of the blank body. The bottom plate is of a ring structure and is concentrically fixedly mounted at the axial bottom end of the blank body, and the pedestal set is fixedly mounted on the connecting position of the blank body and the bottom plate. The outer wall of the blank body is wrapped with an outer skin structure, and the upper pressing plate set is fixedly mounted on the side wall of the top end of the outer skin structure. Thelower pressing plate set is fixedly mounted on the side wall of the bottom end of the outer skin structure, and the side wall of the outer skin structure is sleeved with the fastening device set. According to the large-diameter nonmetal skin turning device, the current impending technological problem of tail section skin outer circle turning is solved, and essential data and design thoughts are provided for machining tools needed in the subsequent new model development process.

Owner:CAPITAL AEROSPACE MACHINERY +1

Rotating target binding method capable of removing oxides, computer readable storage medium and binding device

PendingCN113174579AImprove the bonding rateVacuum evaporation coatingSputtering coatingPhysicsChemistry

The invention relates to the technical field of magnetron sputtering target preparation, in particular to a rotating target binding method capable of removing oxides, a target binding device and a computer readable storage medium. According to the rotating target binding method capable of removing the oxides, a hard corrugated sheet extends into a gap between a back tube and the target tubes, the hard corrugated sheet is lifted to scrape the outer surface of the back tube and / or the inner surface of the target tube, indium liquid is injected into the gap upwards from the bottom of the gap between the back tube and the bottommost target tube, and the speed of injecting the indium liquid is controlled, so that the highest point of the indium liquid in the gap is lower than the lowest point of the hard corrugated sheet. According to the rotating target binding method capable of removing the oxides, the indium liquid is injected from bottom to top, the hard corrugated sheet extends into the gap between the back tube and the target tube before the indium liquid is injected, the outer surface of the back tube and the inner surface of the target tube are scraped by utilizing corners of the hard corrugated sheet, and indium oxide layers or other oxides on the back tube and the target tube are removed, so that the laminating rate of indium and the target / back tube is increased.

Owner:广州市尤特新材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com