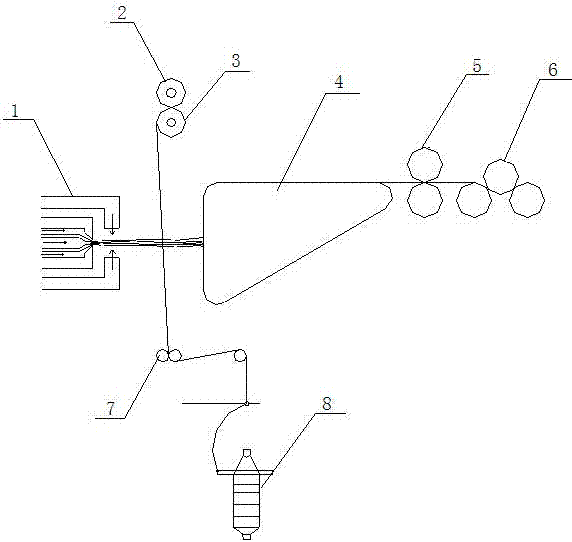

Micro-nano fiber yarn spinning device with high spinning efficiency and its spinning process

A micro-nanofiber, high-efficiency technology, applied in fiber processing, yarn, textiles and papermaking, etc., can solve the problems of inability to cover nanofibers, nanofiber peeling, inconvenient operation, etc., achieve reasonable structure and process design, and high work efficiency , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A single-hole melt-blown testing machine is used, the width of the air groove is 0.65mm; the angle of the air groove is 30°; the diameter of the spinneret hole is 0.42mm, and the spinneret process is: the temperature of the polymer melt is 260°C, and the temperature of the hot air is 280°C , the air pressure is 0.3MPa, the receiving distance is 10cm, the melt flow rate of the PP polymer used is 900g / 10min, and the diameter of the spinning fiber is between 0.6-1.1μm.

[0032] Spinning process parameters: polyester DTY 30D / 48f filament is used, the feeding speed is 1500mm / min, and the rubbing speed of the rubbing roller is 100r / min. For the twisting part, the ring is PG1-4254, the traveler is 772 2 / 0, and the spindle speed is 3000r / min. The spinning number is 18.5tex.

Embodiment 2

[0034] A single-hole meltblown test machine is used, the air groove width is 0.65mm; the air groove angle is 30°; the spinneret hole diameter is 0.42mm. The spinning process is as follows: the polymer melt temperature is 240°C, the hot air temperature is 280°C, the air pressure is 0.3 MPa, the receiving distance is 15cm, the melt flow rate of the PP polymer used is 900g / 10min, and the average diameter of the spinning fiber is is 1.2 μm.

[0035] Spinning process parameters: polyester DTY 70D / 96f filament is used, the feeding speed is 3000mm / min, and the rubbing speed of the rubbing roller is 200r / min. For the twisting part, the ring is PG1-4254, the traveler is GS 3#, and the spindle speed is 4500r / min. The spinning number is 29.5tex.

[0036] In the spinning device of the present invention, when the micro-nano fibers ejected from the melt-blown spinning spinneret are sprayed to the yarn that moves downward and rotates by itself, the yarn that is fed is continuously rotated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com