A lead layer extrusion casting hanging method for spent fuel storage tank

A spent fuel extrusion casting technology, applied in the field of extrusion casting lead coating, can solve the problems of inefficiency, complex lead filling process, high cost, etc., and achieve the effect of simple process flow, dense thin lead layer and high bonding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

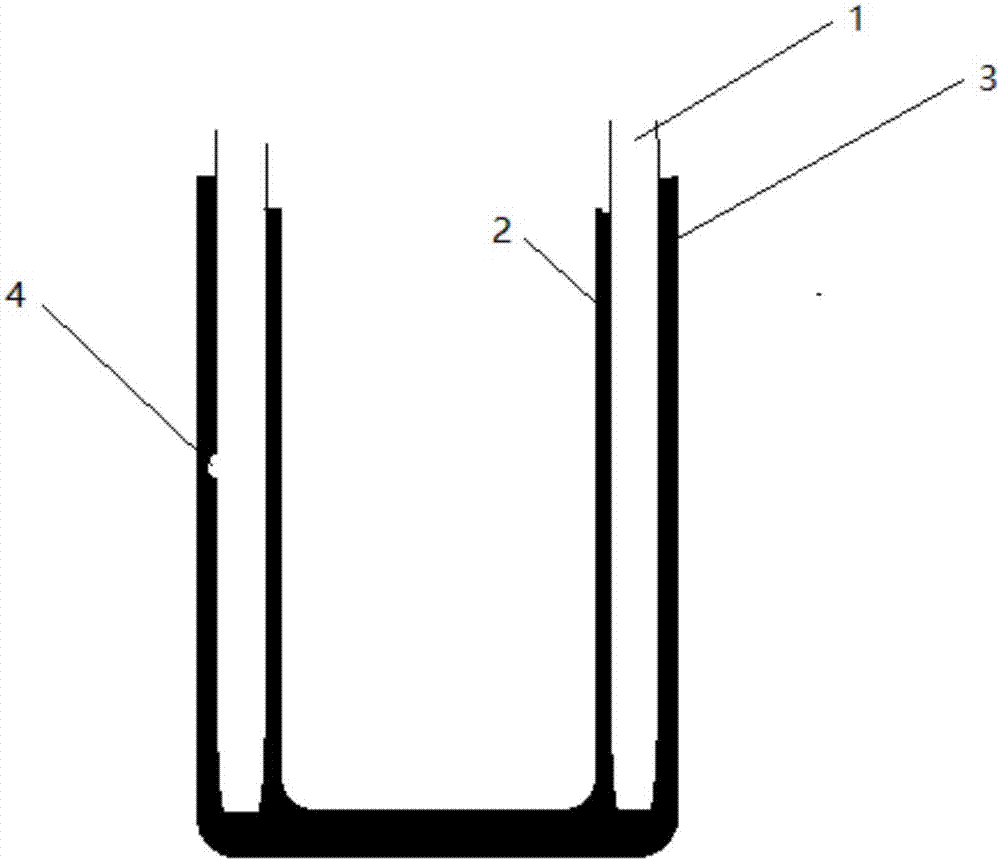

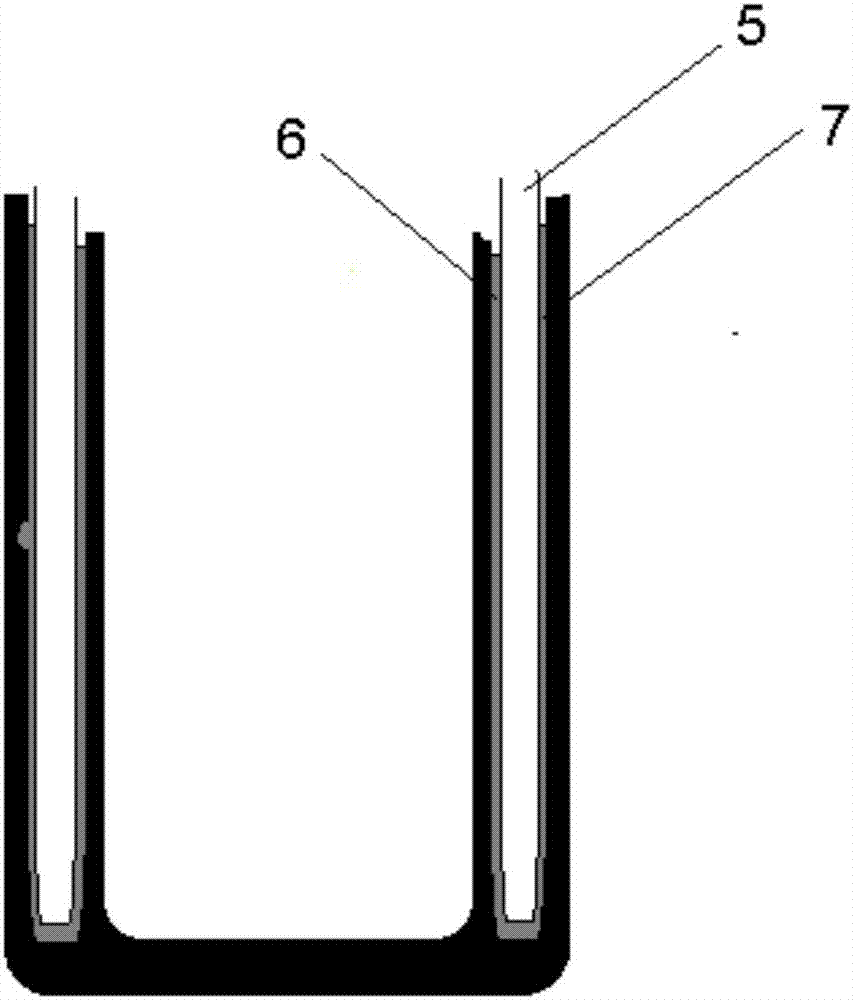

[0026] Before hanging lead, carry out necessary pickling on the stainless steel surface of the inner and outer tanks in the gap of the shielding layer of the storage tank, preheat (70-90°C), and apply a certain amount of tin or tin-lead metal layer. exist figure 1 In the process, first pour an appropriate amount of lead liquid into the gap between the surface of the inner shell of the spent fuel storage tank and the surface of the inner shell of the outer tank, and when it cools to a semi-solid state, press down the basic lead layer with a ring-shaped punch 1 to carry out extrusion casting Hanging, so that the semi-solid liquid lead is squeezed and solidified under pressure. After the solidification is completed, a basic lead layer is simultaneously obtained on the surface of the inner shell of the storage tank and the inner shell of the outer tank. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com