Shell-and-tube heat exchanger adopting copper heat exchange tube

A shell-and-tube heat exchanger and heat exchange tube technology, applied in the direction of heat exchanger shell, heat exchange equipment, evaporator/condenser, etc., can solve the problem of large space occupation, low heat exchange efficiency and large heat exchanger volume. and other problems, to achieve the effect of reducing elongation, increasing the bonding rate and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

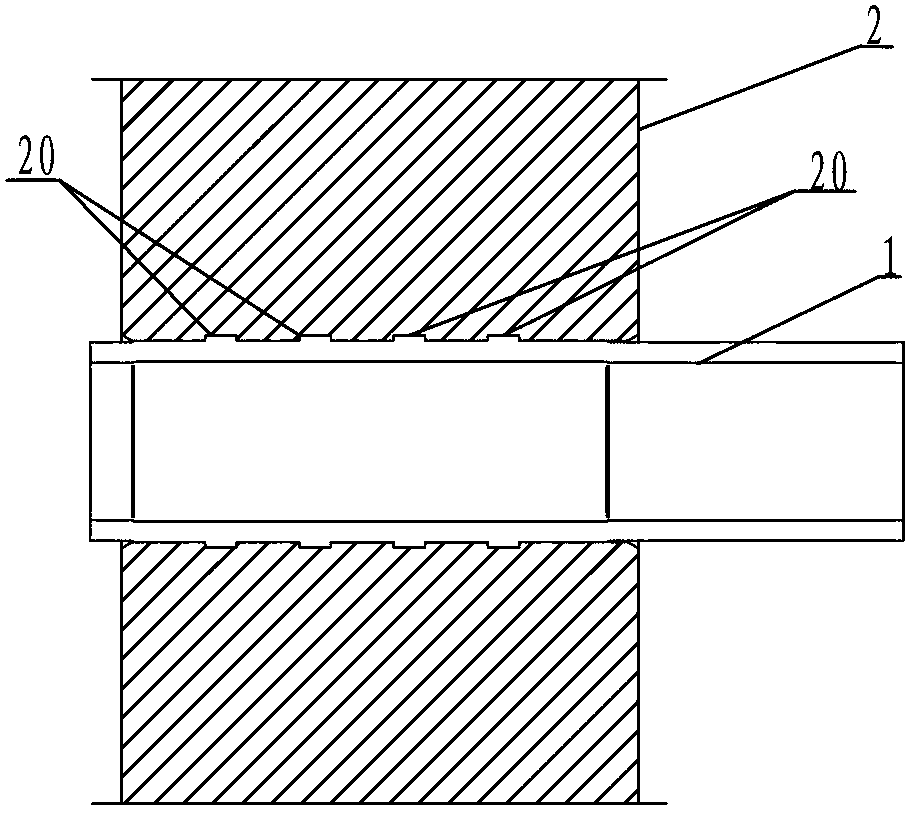

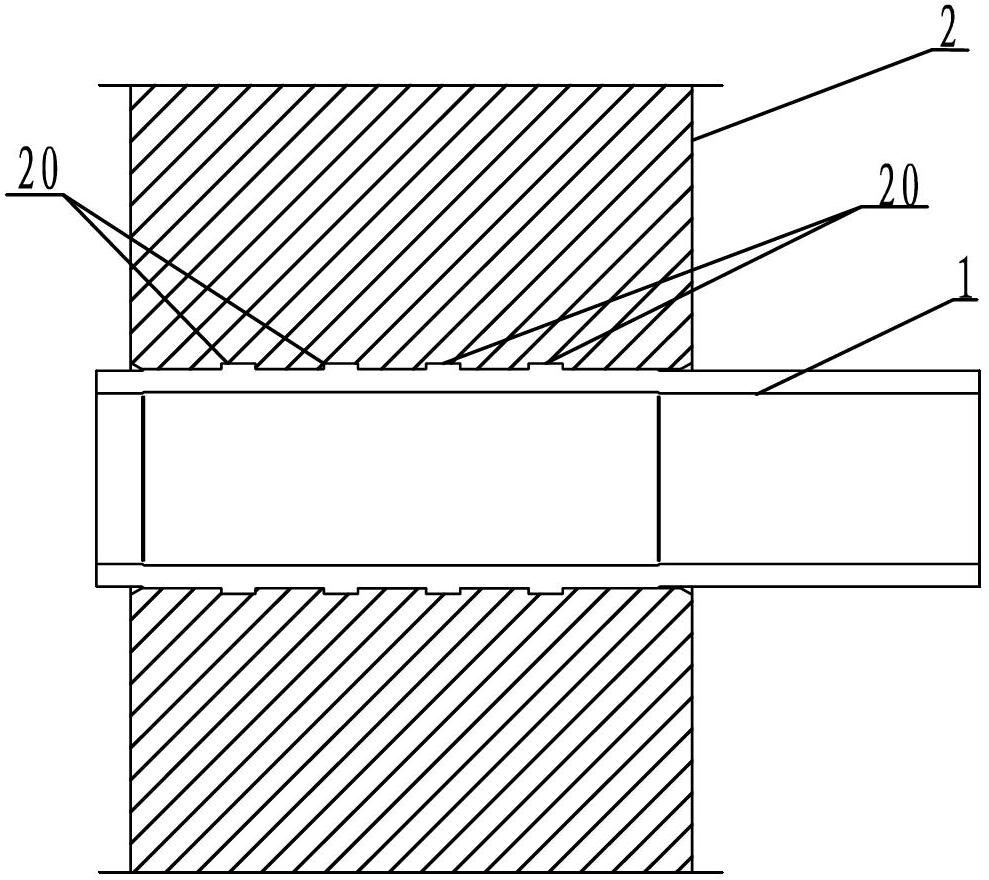

[0016] This embodiment provides a shell-and-tube heat exchanger using copper heat exchange tubes. Such as figure 1 As shown, the shell-and-tube heat exchanger includes a copper heat exchange tube 1 and a carbon tube plate 2, and the copper heat exchange tube 1 and the carbon tube plate 2 are expanded together. On the inner wall of the hole of the carbon tube plate 2 , there are four grooves 20 distributed at intervals along the extending direction of the centerline of the hole of the carbon tube plate 2 . The depth of the groove 20 is 0.5 mm, and the distance between two adjacent grooves is 10 mm. The distance between the outermost groove 20 on the sealing surface and the edge of the carbon tube sheet 2 is 8-10 mm.

[0017] The shell-and-tube heat exchanger provided in this embodiment breaks through the limitations of traditional heat exchangers that the design pressure of expansion tubes is less than or equal to 4.0Mpa, and can ensure strength and sealing under a desig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com