Rotating target binding method capable of removing oxides, computer readable storage medium and binding device

A technology of rotating target and oxide, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problem of low bonding rate between indium and target material/back tube, and achieve the goal of improving the bonding rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

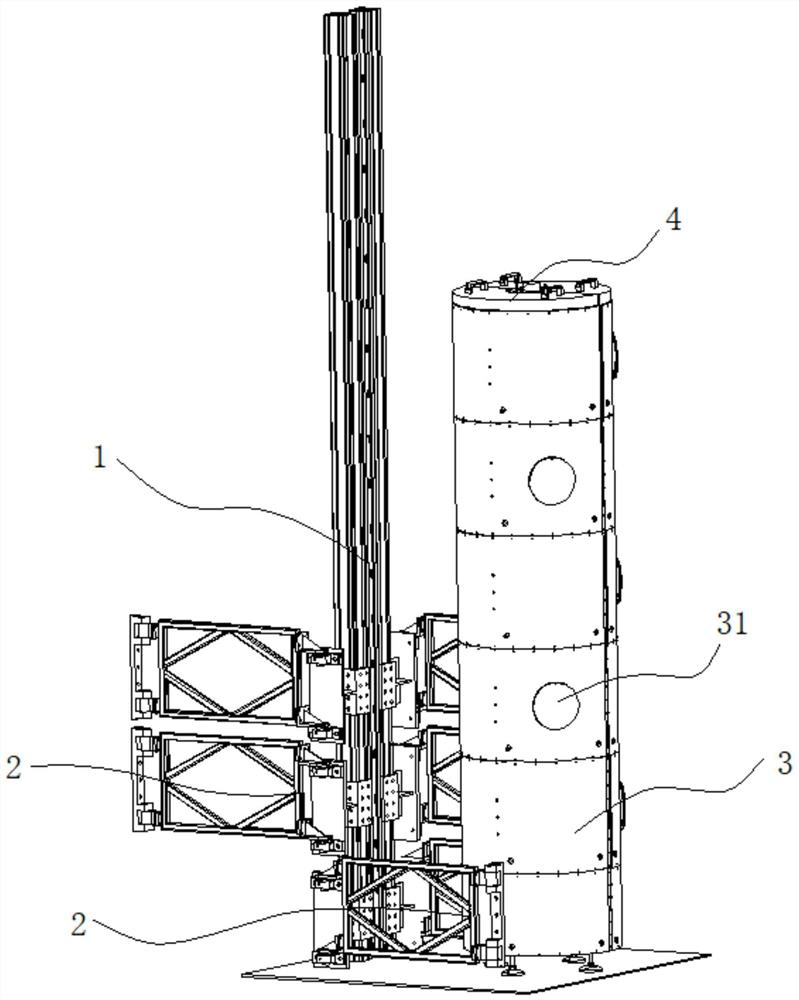

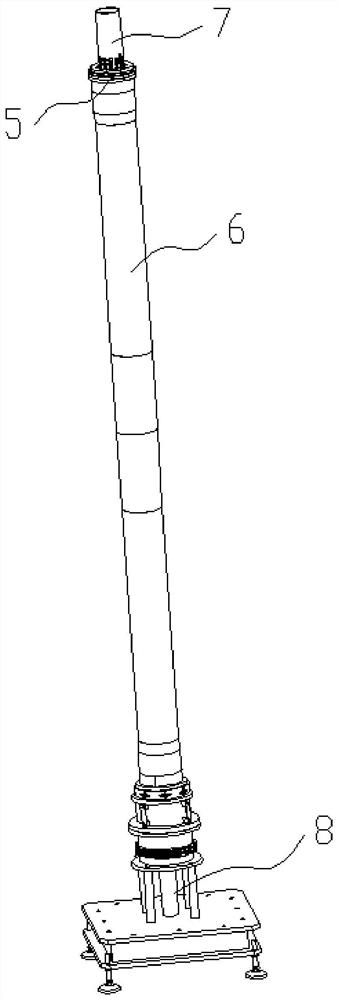

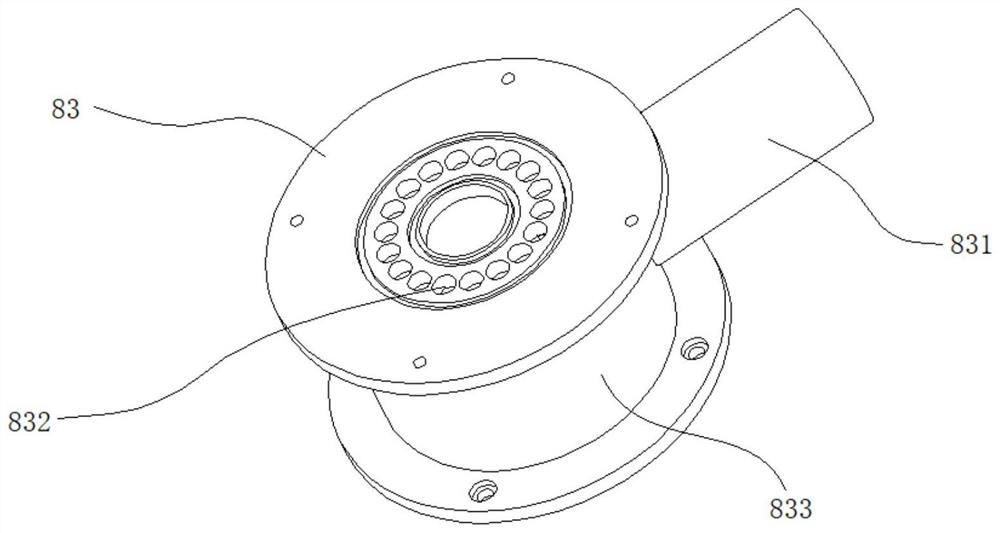

[0026] The binding heating device of the rotating target in this embodiment is as follows: figure 1 with 2 As shown, the rotating target includes a back tube 5 and multiple target tubes 6 , and the binding process is the process of fitting and fixing each segment of the target tube 6 to the outer wall of the back tube 5 in a thermally and electrically conductive manner. In this embodiment, the binding is achieved by pouring indium liquid (binding material) between the back tube 5 and the target tube 6, in which the indium liquid needs to be heated to keep it flowing. The binding heating device used in this embodiment for figure 1 The external heating structure shown in . The external heating structure includes a plurality of ring-shaped heating mantles 3 and heating pipes respectively installed on the inner walls of each heating mantle 3, and multiple heating mantles 3 are coaxially stacked through the bracket 1 and the rotatable clamping part 2, preferably including for Th...

Embodiment 2

[0039] The difference between this embodiment and Embodiment 1 is that another binding device is used, see Figure 4 , the top of the binding device has a large-capacity excess indium solution accommodating cavity 7 . In the binding step, excessive indium liquid is injected so that the washed indium liquid containing oxides floats on the uppermost layer and enters the accommodating chamber 7. After the indium liquid cools down, the indium liquid that falls back to the gap still does not contain The pure indium of the oxide, containing the oxide and / or other impurities floating on the upper layer of the indium liquid remains in the excess indium liquid holding chamber 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com