Special tool for grinding first-stage sun gear sleeve

A technology for special tools and sun gears, applied to gear teeth, components with teeth, belts/chains/gears, etc., can solve the problems of unstable transmission and low bonding rate, and reduce the workload of grinding and manufacture The effect of low cost and improved degree of meshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

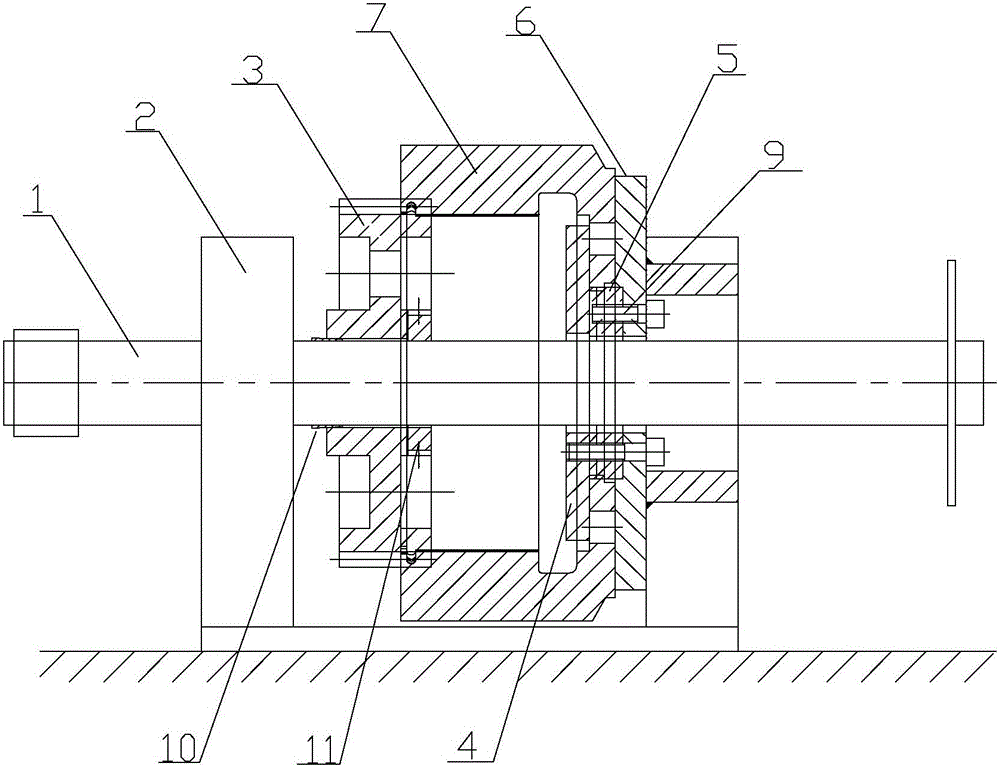

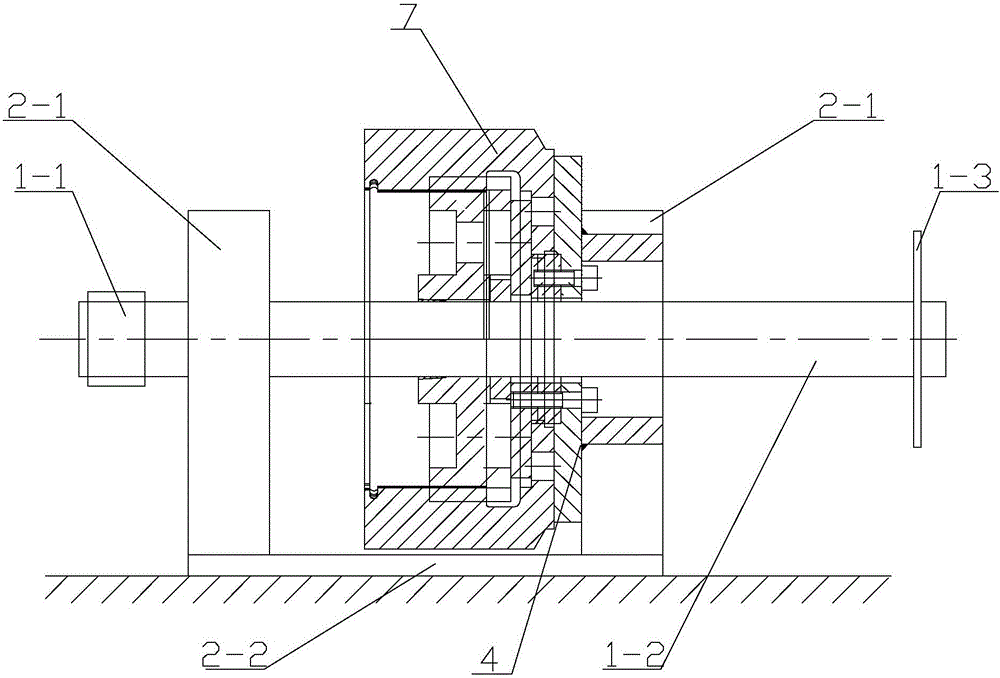

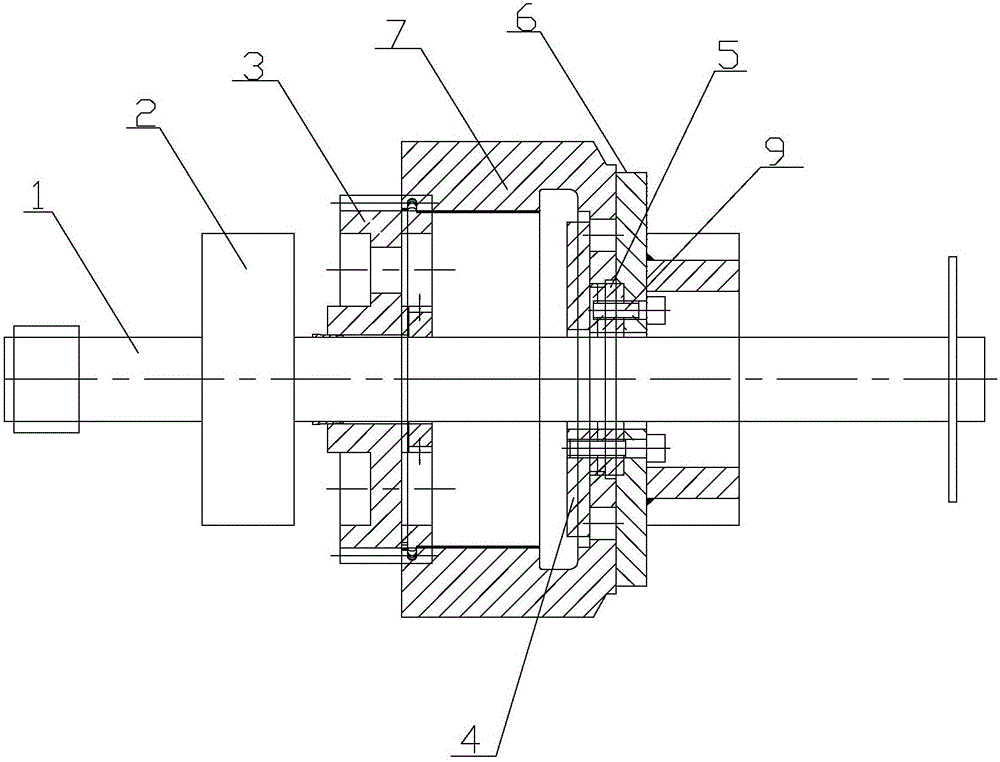

[0017] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Describe this embodiment, this embodiment includes pull rod 1, support frame 2, grinding gear 3, tightening flange 4, positioning flange 5 and support flange 6, and described support frame 2 includes base 2-2 and two positioning Block 2-1, the base 2-2 is arranged horizontally, two positioning blocks 2-1 are arranged side by side on the base 2-2 and each positioning block 2-1 is fixedly connected with the base 2-2, and the grinding gear 3 , the tensioning flange 4, the positioning flange 5, the primary sun gear sleeve 7 and the support flange 6 are arranged coaxially between the two positioning blocks 2-1 in turn, and the tensioning flange 4 is arranged on the primary In the built-in central hole 7-1 of the sun gear sleeve 7, the positioning flange 5 is set in the positioning hole 7-2 of the first-stage sun gear sleeve 7, and the support flan...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 4 This embodiment will be described. In this embodiment, the wheel surface of the grinding gear 3 is uniformly processed with a plurality of lightening holes 8 along its axial direction.

[0023] The setting of a plurality of lightening holes 8 in this embodiment is to effectively reduce the weight of the grinding gear 3 itself, which is conducive to the portability of its movement. one-third. Other unmentioned structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 , figure 2 , Figure 4 , Figure 5 , Figure 6 and Figure 7 Describe this embodiment, the tooth shape of the external teeth in the grinding gear 3 in this embodiment is a straight tooth, the number of teeth of the external teeth of the grinding gear 3 is consistent with the number of internal teeth of the first-stage sun gear sleeve 7, the grinding The shape of the external teeth of the gear 3 is consistent with the shape of the internal teeth of the primary sun gear sleeve 7 .

[0025] In this embodiment, the parameter of the number of teeth of the grinding gear 3 is consistent with the parameter of the number of teeth of the first-stage sun gear sleeve 7 . The addendum height coefficient of the grinding gear 3 is 1, the modulus M is 5, the addendum coefficient is 0.25, the pressure angle is 20°, and the normal displacement coefficient is 0. Other unmentioned structures and connections are the same as tho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com