Special tools for grinding primary sun gear bushings

A special tool and sun gear technology, applied in the field of mechanical processing, can solve problems such as low lamination rate and unstable transmission, and achieve the effects of low manufacturing cost, reduced grinding workload, and convenient and quick use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

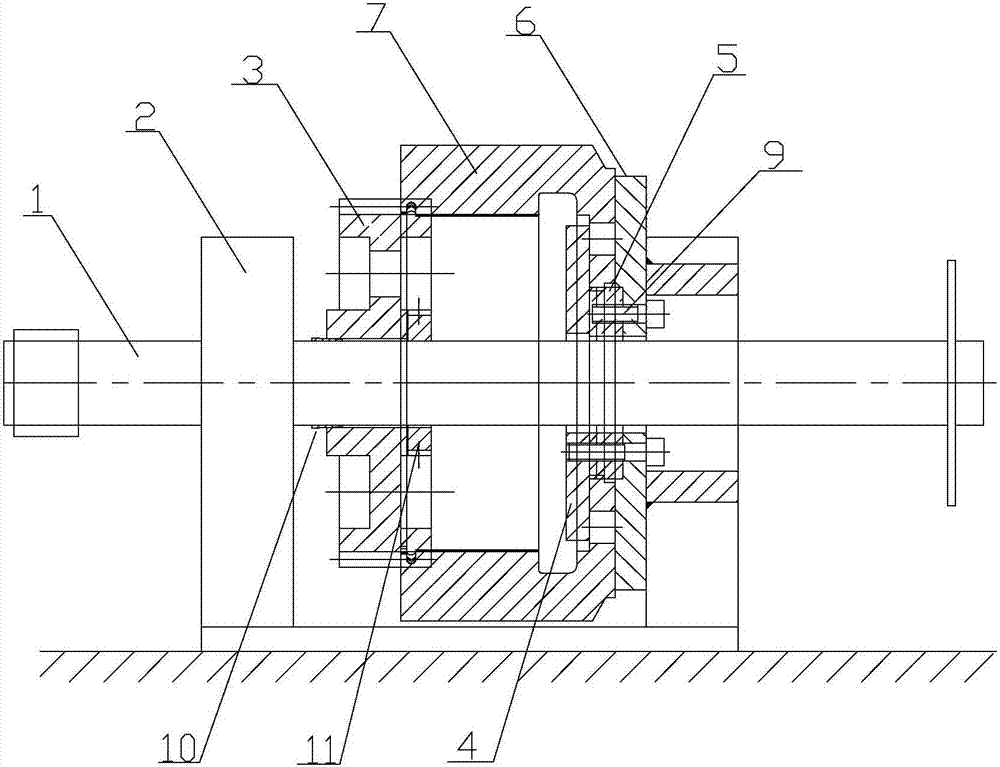

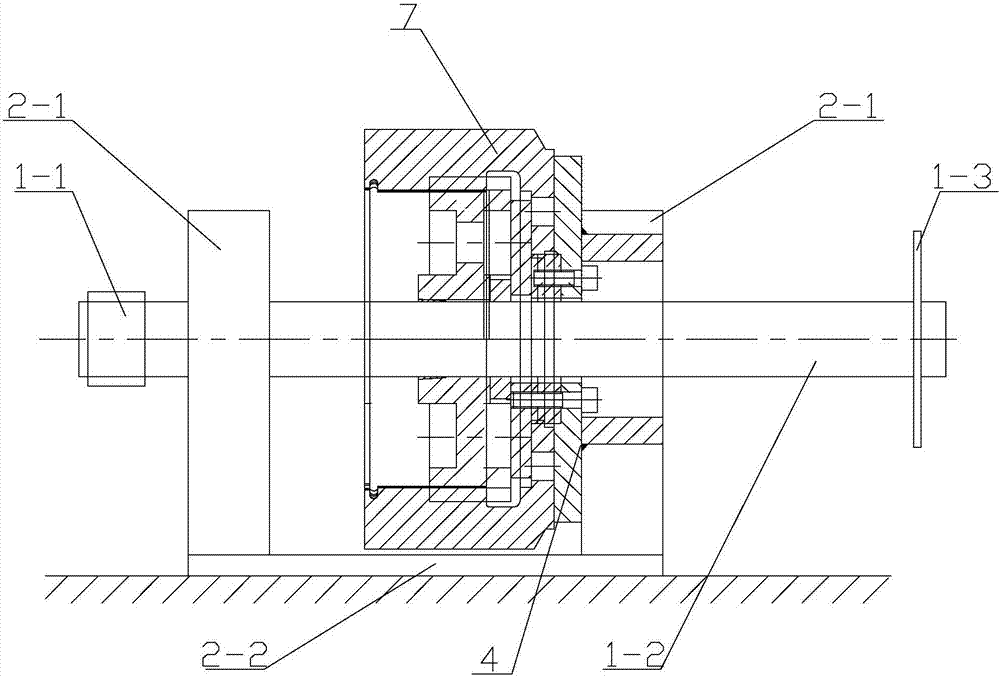

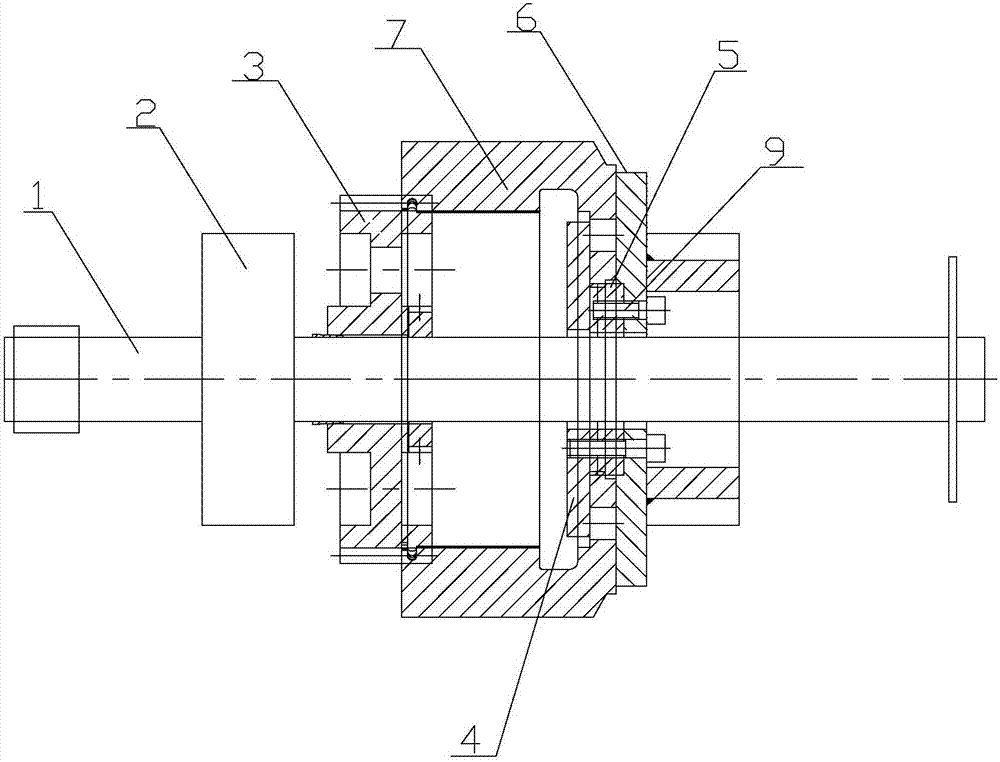

[0017] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7 Describe this embodiment, this embodiment includes pull rod 1, support frame 2, grinding gear 3, tightening flange 4, positioning flange 5 and support flange 6, and described support frame 2 includes base 2-2 and two positioning Block 2-1, the base 2-2 is arranged horizontally, two positioning blocks 2-1 are arranged side by side on the base 2-2 and each positioning block 2-1 is fixedly connected with the base 2-2, and the grinding gear 3 , the tensioning flange 4, the positioning flange 5, the primary sun gear sleeve 7 and the support flange 6 are arranged coaxially between the two positioning blocks 2-1 in turn, and the tensioning flange 4 is arranged on the primary In the built-in central hole 7-1 of the sun gear sleeve 7, the positioning flange 5 is set in the positioning hole 7-2 of the first-stage sun gear sleeve 7, and the support flan...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination Figure 4 This embodiment will be described. In this embodiment, the wheel surface of the grinding gear 3 is uniformly processed with a plurality of lightening holes 8 along its axial direction.

[0023] The setting of a plurality of lightening holes 8 in this embodiment is to effectively reduce the weight of the grinding gear 3 itself, which is conducive to the portability of its movement. one-third. Other unmentioned structures and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0024] Specific implementation mode three: combination figure 1 , figure 2 , Figure 4 , Figure 5 , Image 6 with Figure 7 Describe this embodiment, the tooth shape of the external teeth in the grinding gear 3 in this embodiment is a straight tooth, the number of teeth of the external teeth of the grinding gear 3 is consistent with the number of internal teeth of the first-stage sun gear sleeve 7, the grinding The shape of the external teeth of the gear 3 is consistent with the shape of the internal teeth of the primary sun gear sleeve 7 .

[0025] In this embodiment, the parameter of the number of teeth of the grinding gear 3 is consistent with the parameter of the number of teeth of the first-stage sun gear sleeve 7 . The addendum height coefficient of the grinding gear 3 is 1, the modulus M is 5, the addendum coefficient is 0.25, the pressure angle is 20°, and the normal displacement coefficient is 0. Other unmentioned structures and connections are the same as tho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com