Planer type milling machine capable of strengthening workpiece positioning

A gantry milling machine and workpiece technology, which is applied to milling machines, positioning devices, milling machine equipment, etc., can solve the problems of unguaranteed quality of workpieces, surface damage of workpieces, and small thickness of edges and corners, so as to improve the processing quality and quality. The effect of prolonging the service life and improving the levelness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

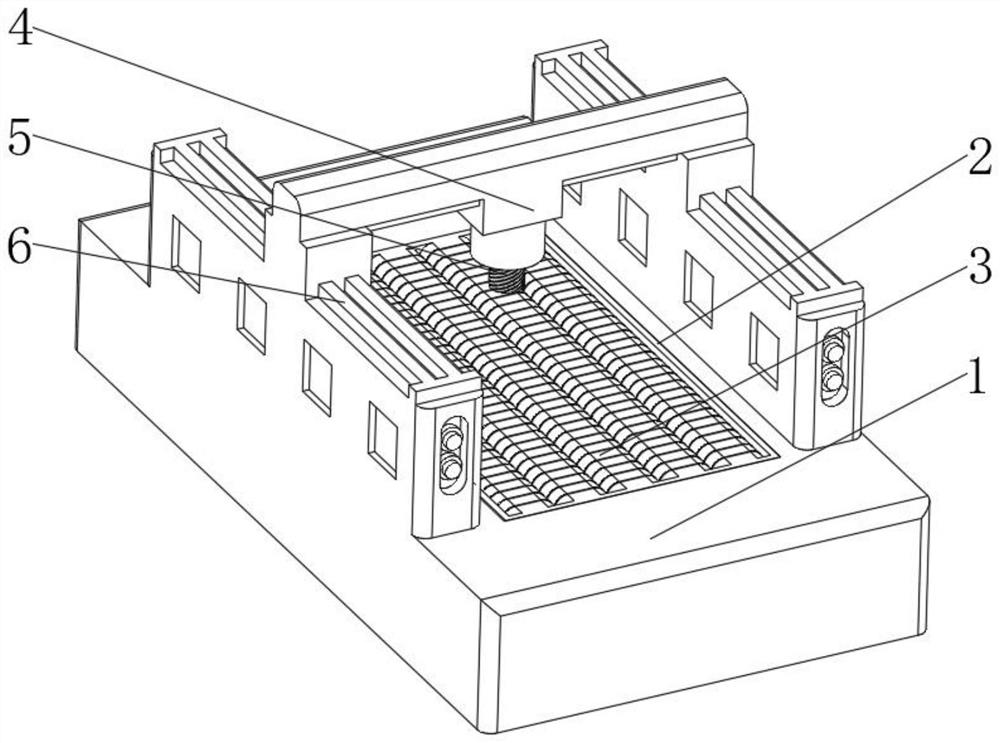

[0037] see Figure 1-2 , the present invention provides a technical solution: a gantry milling machine with enhanced workpiece positioning, specifically comprising:

[0038] Milling machine seat 1, this milling machine seat 1 has back-shaped seat plate, and the mosaic hole groove 2 that is offered at the middle position of the back-type seat plate top, and is installed in the positioning mechanism 3 of mosaic hole groove 2 bottoms;

[0039] Milling machine processor 4, this milling machine processor 4 has processing motor, and the milling machine tool 5 that is installed on the output end of processing motor, and is installed on the rail frame 6 on processing motor top, positioning mechanism 3 comprises:

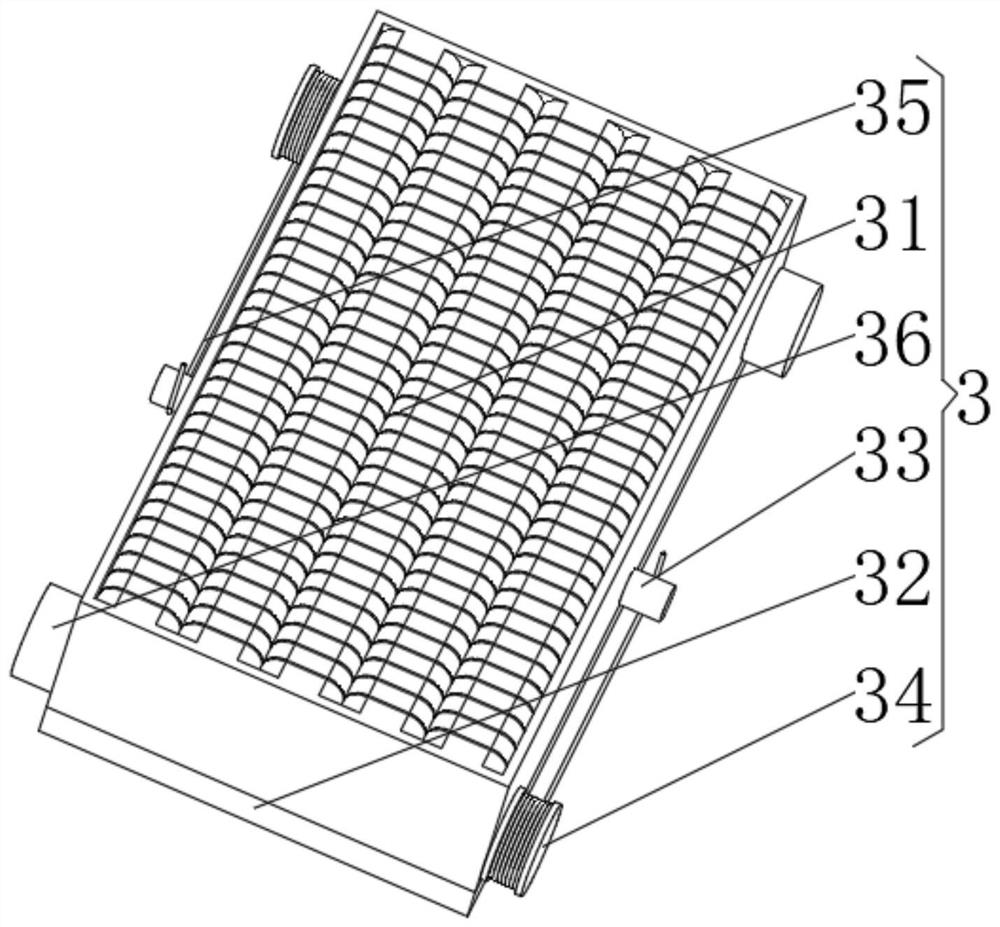

[0040] Fixing mechanism 31, this fixing mechanism 31 has a box-shaped main body, and a lifter 32 installed on the bottom of the box-shaped main body, and a reversing wheel 33 arranged at the middle position on both sides of the box-shaped main body;

[0041]Winding wheel 34...

Embodiment 2

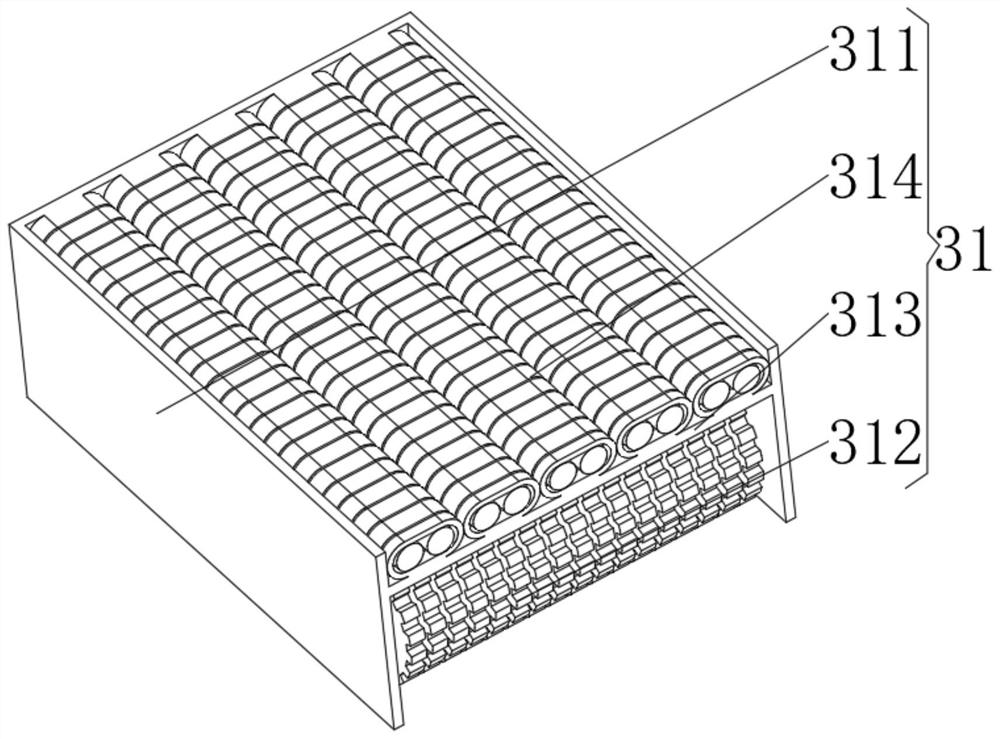

[0045] see Figure 1-3 , on the basis of implementing one, the present invention provides a technical solution: the fixing mechanism 31 includes:

[0046] Box 311, the box 311 has a square box, and an electromagnetic mechanism 312 installed at the bottom of the square box cavity, and an elastic partition 313 fixed on the square box cavity above the electromagnetic mechanism 312, and installed in the square box The cavity is located at the positioning mechanism 314 above the elastic partition 313 . Through the design of the elastic partition 313, the internal components are isolated from each other, avoiding the mutual contact of the components, and protecting them when the positioning mechanism 314 and the electromagnetic mechanism 312 move with each other. Perform offset absorption.

[0047] The bottom of the box body 311 is installed on the lifter 32 , the electromagnetic mechanism 312 is located directly above the lifter 32 , and the positioning mechanism 314 is located a...

Embodiment 3

[0050] see Figure 1-5 , on the basis of implementation one and embodiment two, the present invention provides a technical solution: The electromagnetic mechanism 312 includes:

[0051] Rotary column A1, the rotating column A1 has a cylinder, and the two ends of the cylinder pass through the box body 311 and extend to the outer surface of the box body 311;

[0052] Magnetic wheel A2, the magnetic wheel A2 has a central column, and a permanent magnet rod A3 fixed on the outer surface of the central column, and a contact gear A4 fixed on the outer end of the permanent magnet rod A3. Through the mutual cooperation of the traction wire 35 and the spring coil 36 in the first embodiment, the components of the rotating column A1 are driven, and the magnetic field transformation generated by the rotation of the magnetic wheel A2 and the permanent magnet rod A3 is used to realize the change of the magnetic force of the equipment , while providing the initial fixing force, the adsorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com