Contactor vacuum tube air leakage and contact abrasion online monitoring device and method

A monitoring device and vacuum tube technology, which is applied in measuring devices, liquid tightness measurement using liquid/vacuum degree, testing of machine/structural components, etc. It can solve problems such as mine explosion, vacuum tube air leakage, and affecting normal underground production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

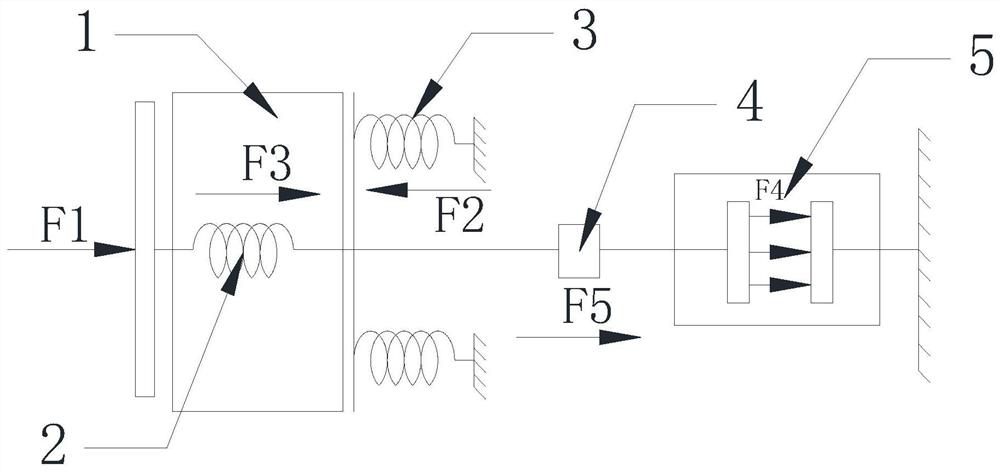

[0023] Such as figure 1 The on-line monitoring device for air leakage and contact wear of a contactor vacuum tube is shown, which includes an electromagnet 1, an overtravel spring 2, a counter force spring 3, a miniature tension pressure sensor 4, and a vacuum tube 5, and the miniature tension pressure sensor 4 is fixed on the electromagnetic Between iron 1 and vacuum tube 5.

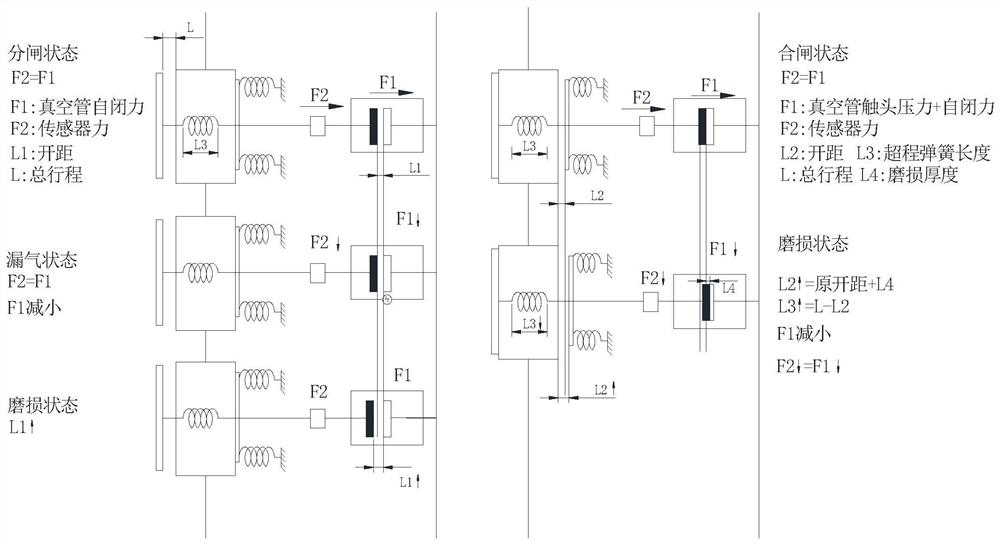

[0024] Such as figure 2 As shown, according to the relationship between the breakdown voltage of the vacuum tube and the degree of vacuum (Baschen curve), the air pressure is less than 10 -3 Above Pa, the breakdown voltage drops sharply. For vacuum tubes, the pressure inside the tube is maintained below 10 -3 Below Pa, and the higher the vacuum degree, the better, and the lower the pressure in the tube, the better; as the vacuum tube is used and leaks, the vacuum degree in the tube decreases, the pressure in the tube increases, the difference between the atmospheric pressure and the pressure in the t...

Embodiment 2

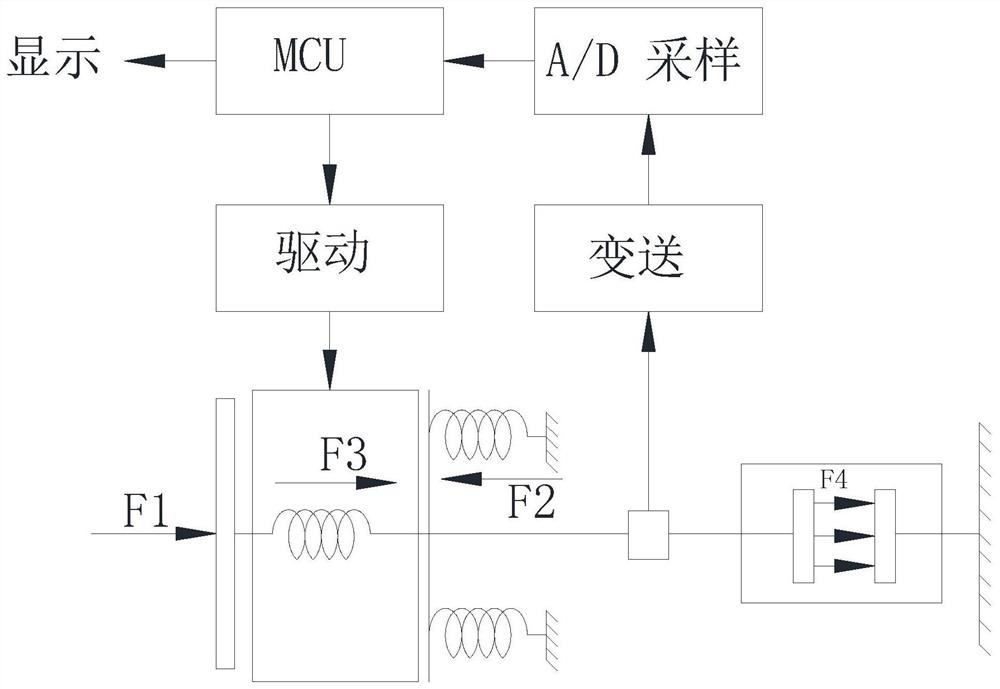

[0029] Such as image 3 As shown, on the basis of Example 1, the sensor transmission module, A / D sampling module, MCU and electromagnet drive module are added, and the miniature tension and pressure sensor is installed axially, and the secondary signal passes through the transmission module and is converted into a standard After the linear voltage signal is sent to the MCU through the A / D acquisition module, the MCU outputs the signal to the electromagnet drive module after logical judgment to realize the closing and opening of the vacuum tube.

Embodiment 3

[0031] The contactor vacuum tube air leakage and contact wear monitoring method of the present invention is as follows: Figure 4 As shown, after power on, set the vacuum tube air leakage blocking value Fk and contact wear value Fm; when the contactor is opened, judge whether the sensor pressure -Fz is less than the air leakage blocking value Fk; when -Fz=Fk, MCU judges that there is no air leakage, monitor the sensor force -Fz in real time, and display the force value; when the contactor is closed, Judging whether the contactor contact pressure Fz is less than the contact wear value Fk; when Fz=Fk, the MCU judges that the contact is worn Within the allowable range, the contact pressure Fz is monitored in real time, and the force value is displayed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com