Method and system for determining and penetrating underground coal gasification passage

A coal gasification and determination method technology, which is applied in coal gasification, underground mining, construction, etc., can solve the problems of low penetration efficiency of gasification channels, inability to penetrate gasification channels, and low penetration efficiency, so as to improve penetration efficiency and reduce The effect of small drilling investment and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

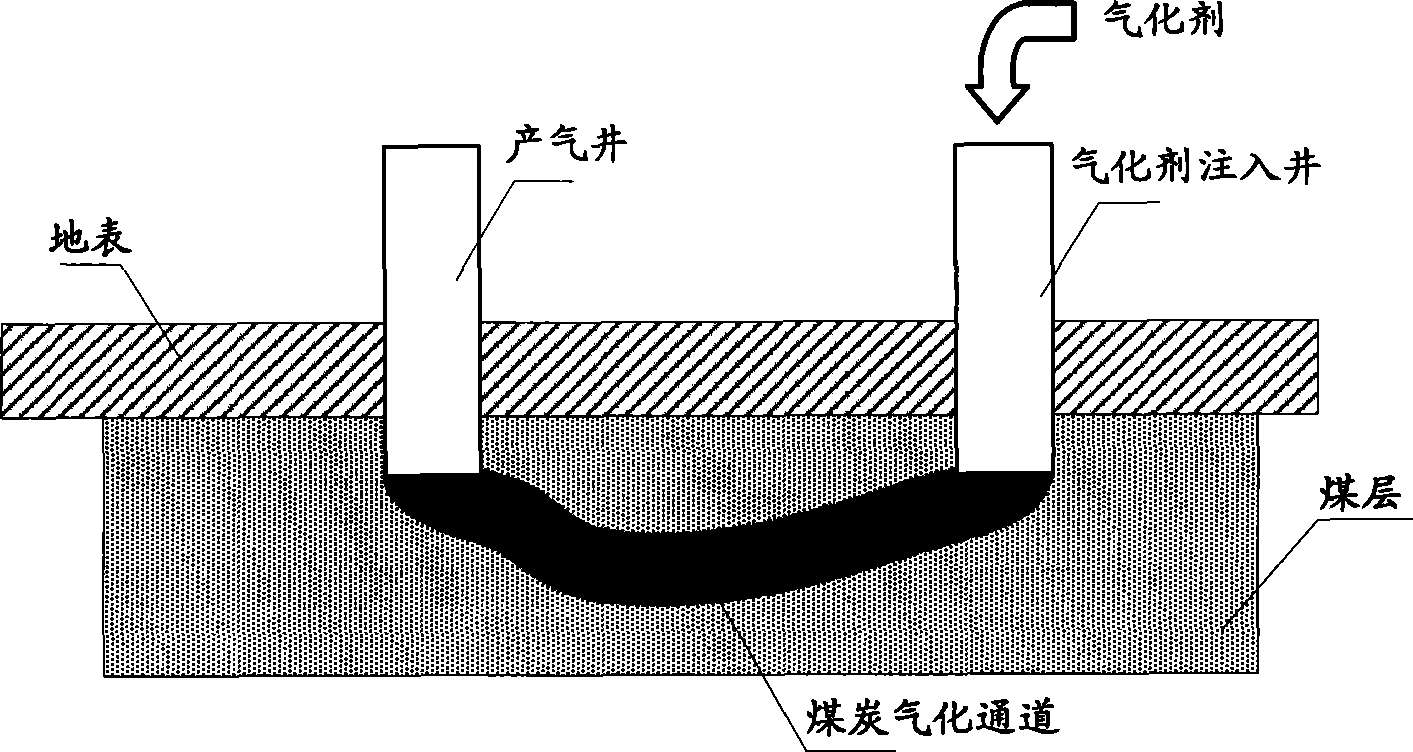

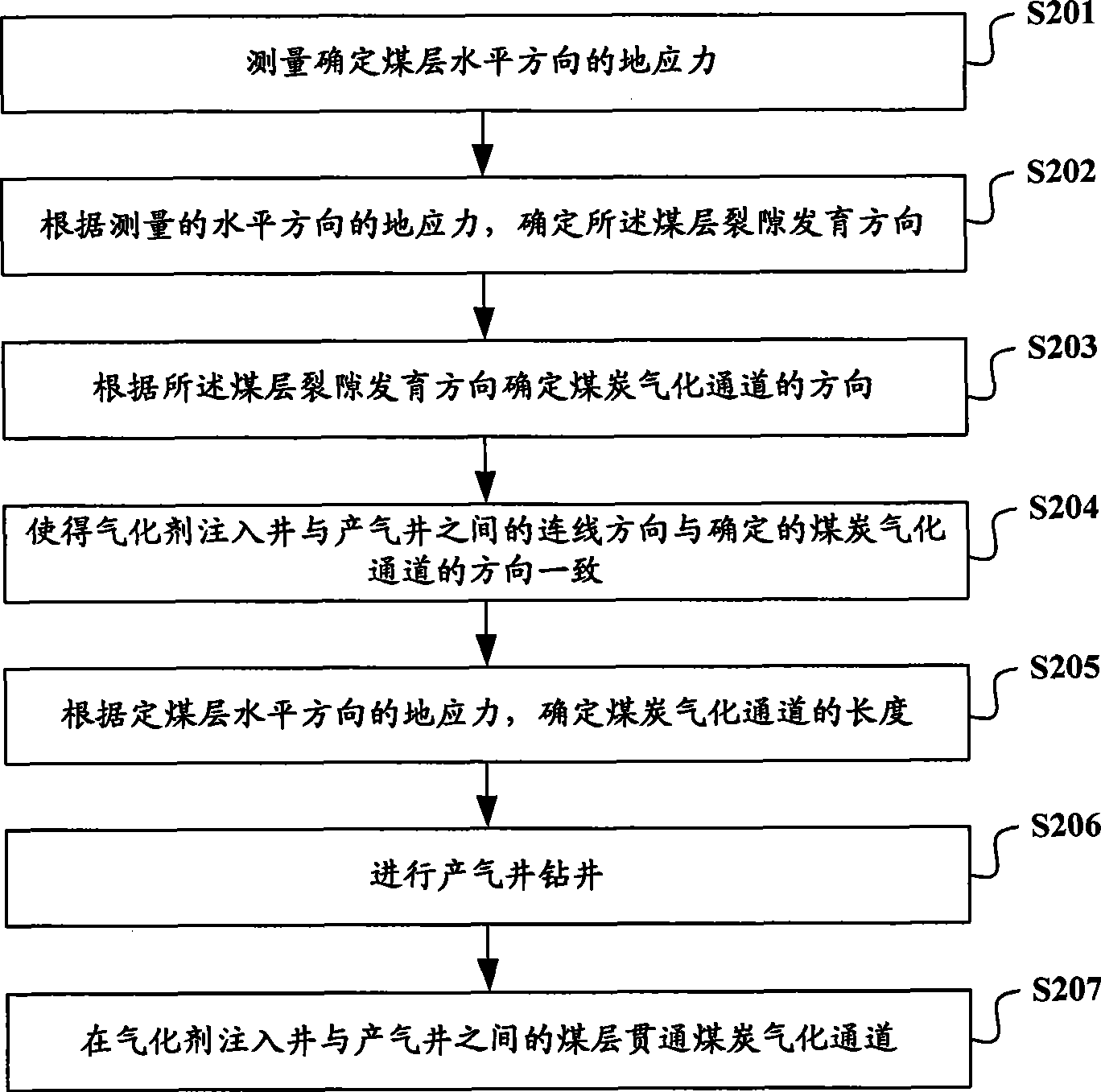

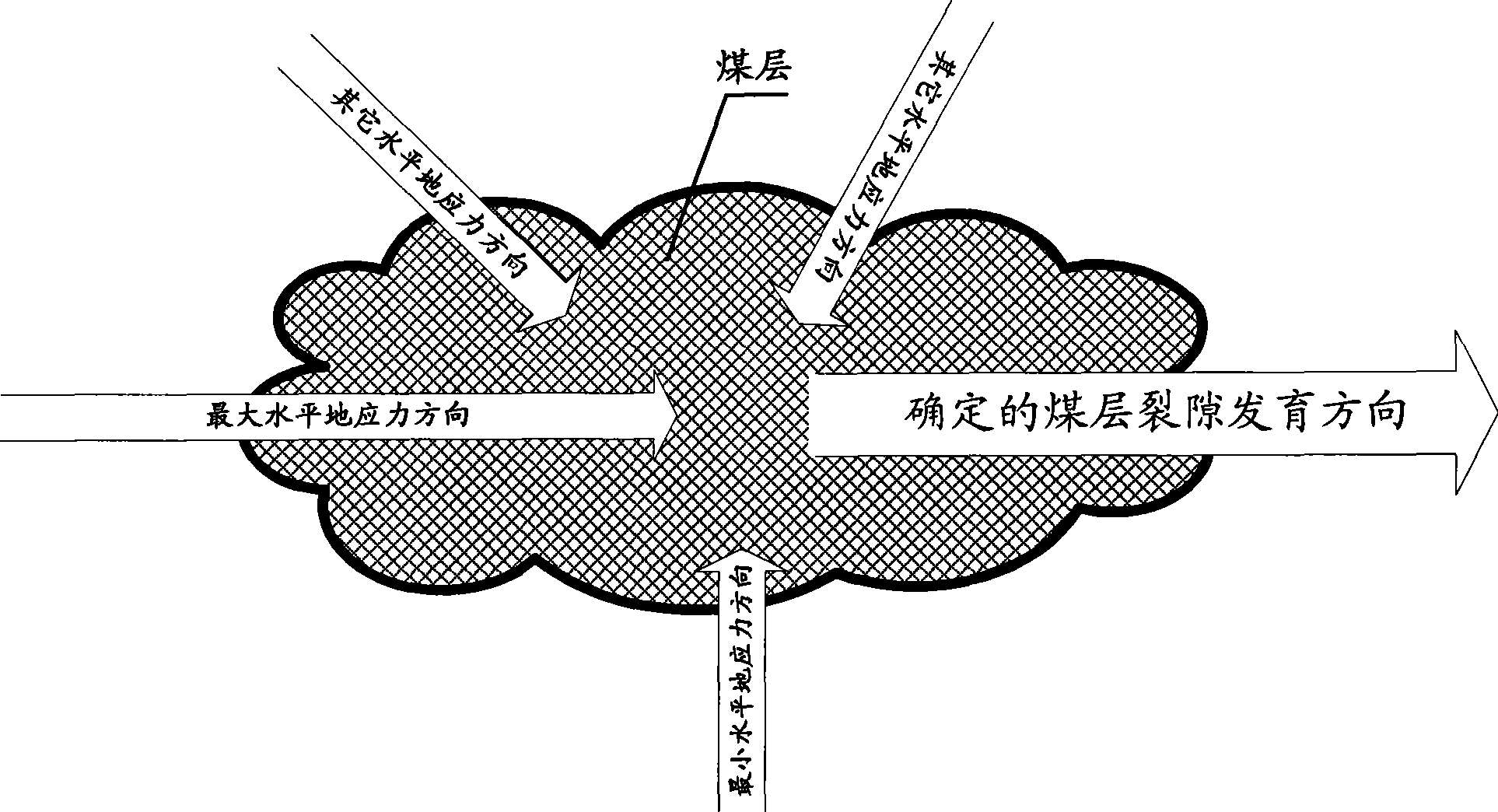

[0038] The inventor of the present invention considers that there are often fissures in the coal seam, and the naturally formed fissures can provide effective penetration channels. Therefore, the embodiment of the present invention uses the cracks in the coal seam to select and penetrate the coal gasification channel. Specifically, the development direction of the cracks in the coal seam (ie, the direction of the cracks) can be determined according to the measured in-situ stress in the horizontal direction of the coal seam, and the direction of the coal gasification channel can be determined according to the development direction of the coal seam cracks. In this way, the development of coal gasification channels along the development direction of coal seams can make the gasification channels reach the same permeability, and the required external force is small, thereby improving the penetration efficiency of the gasification channels; or applying the same external force, you can I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com