Method for improving performance of rare-earth permanent magnetic material by high temperature compressive stress

A rare earth permanent magnet and material performance technology, applied in the manufacture of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problem of affecting the dispersion uniformity of rare earth elements, the overall coercivity of the magnet is not obvious, and the coercivity improvement effect limited problems, to achieve good control accuracy, solve the problem of diffusion consistency, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

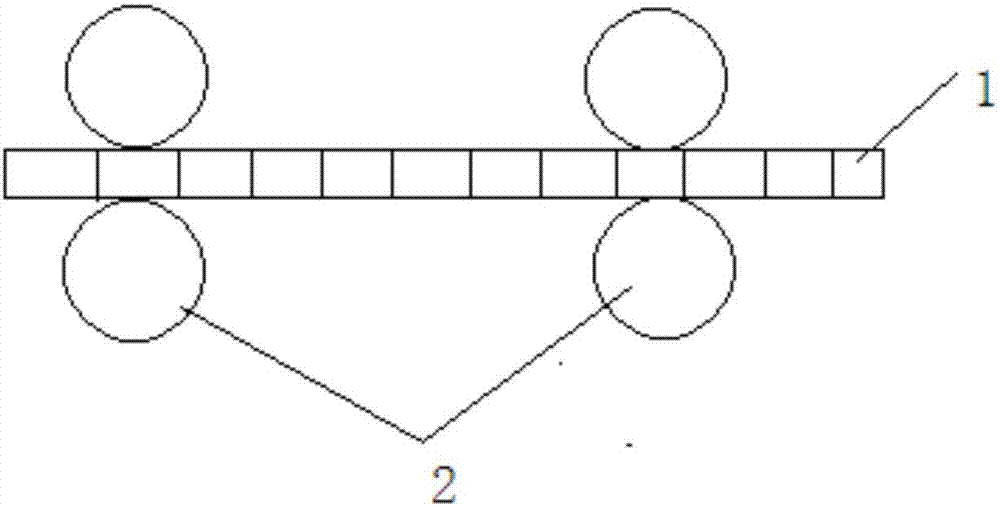

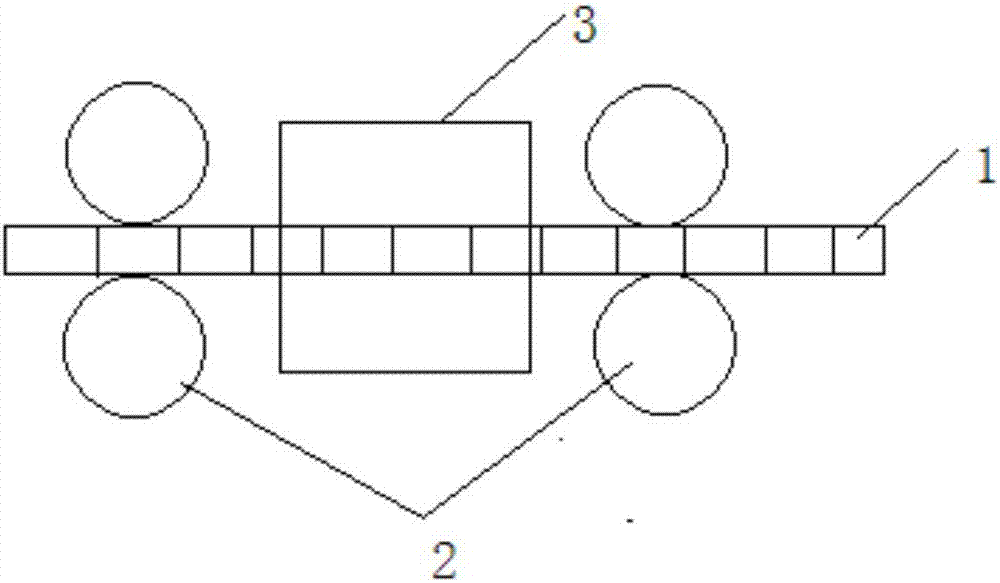

[0029] In this embodiment, the method for improving the properties of rare earth permanent magnet materials by high temperature compressive stress includes at least the following steps: attaching heavy rare earth compounds to the surface of the sintered magnet, heating and applying compressive stress at high temperature to obtain the magnet.

[0030] Different from the above-mentioned embodiments, in the method for improving the performance of rare earth permanent magnet materials under high temperature compressive stress: when the heavy rare earth compound is attached to the surface of the magnet, the protective gas atmosphere (the protective gas atmosphere is a nitrogen atmosphere or a helium atmosphere or an argon atmosphere or a nitrogen atmosphere) Argon mixed gas atmosphere or nitrogen-helium mixed gas atmosphere or helium-argon mixed gas atmosphere or nitrogen, helium, argon mixed gas atmosphere, the atmosphere pressure is preferably 1 atm, the same below).

[0031] Diff...

specific Embodiment 1

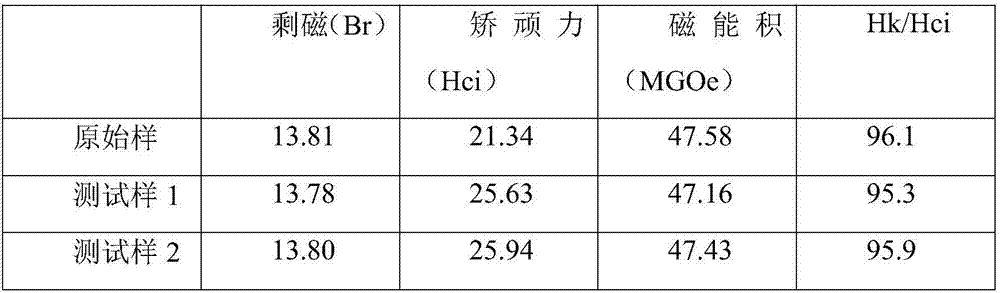

[0051] In the manufacturing method of the rare earth permanent magnet in this embodiment, the prepared NdFeB magnet is cut into thin slices, degreased, pickled, and dried, and the heavy rare earth compound is evenly adhered to the magnet by a cemented carbide roller. The surface was dried at high temperature and then passed through the internal heating high-temperature roller to apply a certain compressive stress. After cooling, the magnet was taken out and subjected to aging treatment to obtain test sample 1 and test sample 2.

[0052] The preparation of the above-mentioned NdFeB magnets includes smelting, hydrogen breaking, jet milling, molding, sintering and other treatments. The magnet is not subjected to high-temperature aging treatment, and is cut into a large square magnet of 50mm*60mm*10mm (this magnet is used as the original sample for comparison).

[0053] The thickness of the sheet magnet is controlled to be 10mm, and after degreasing, pickling, and drying, the surf...

specific Embodiment 2

[0061] In the manufacturing method of the rare earth permanent magnet in this embodiment, the prepared NdFeB magnet is cut into thin slices, degreased, pickled, and dried, and the heavy rare earth compound is evenly adhered to the surface of the magnet through a stainless steel roller. After high-temperature drying, the stainless steel high-temperature rollers are used to apply a certain compressive stress. After cooling, the magnets are taken out and subjected to aging treatment to obtain test samples 1 and 2.

[0062] The preparation of the above-mentioned NdFeB magnets includes smelting, hydrogen breaking, jet milling, molding, sintering and other treatments. The magnet is not subjected to high-temperature aging treatment, and is cut into a large square magnet of 50mm*60mm*10mm (this magnet is used as the original sample for comparison).

[0063] The thickness of the sheet magnet is controlled to be 10mm, and after degreasing, pickling, and drying, the surface is kept free ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

| compressive stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com