Positive plate of lithium ion power battery as well as manufacturing method and laser etching device of positive plate

A power battery and laser etching technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of electrolyte infiltration and slow absorption, affecting production efficiency, electrolyte distribution, injection efficiency and low absorption speed, etc. , to achieve the effect of improving consistency, improving cycle life and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

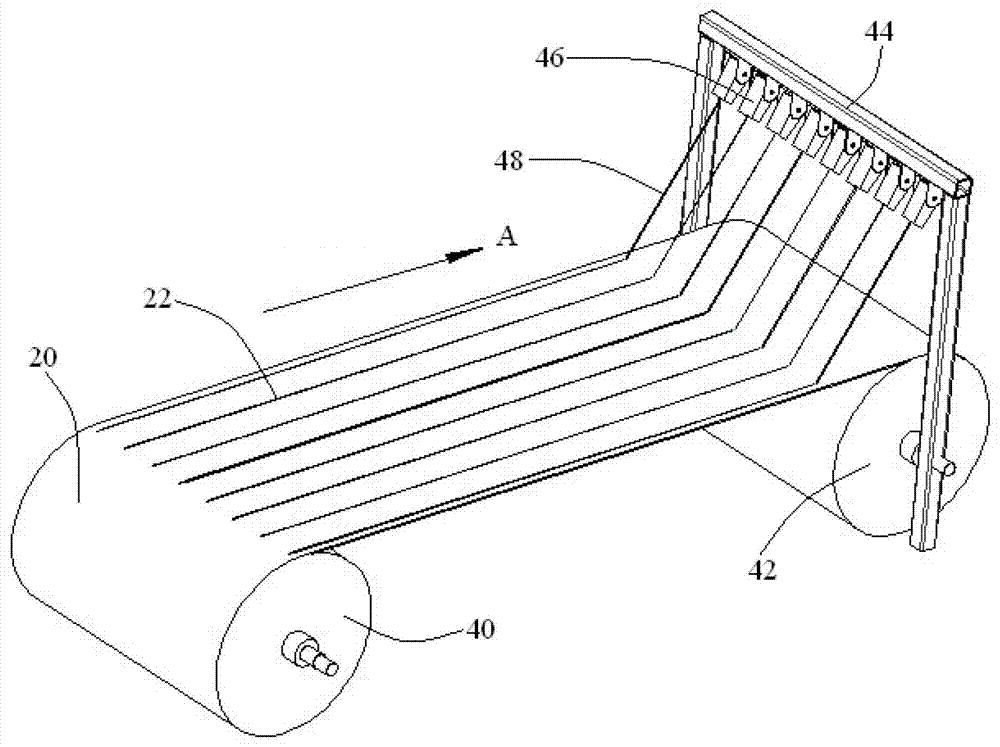

Image

Examples

Embodiment Construction

[0018] The positive electrode sheet of the lithium ion power battery of the present invention includes a positive electrode current collector and a positive electrode diaphragm coated on the positive electrode current collector, wherein the positive electrode current collector is aluminum foil, and the active material in the positive electrode diaphragm is mainly nano-scale lithium iron phosphate particles . The production process of the above-mentioned positive electrode sheet is to first mix the active material and the binder to form a slurry, and then coat the uniformly mixed slurry on the surface of the aluminum foil, then bake at high temperature to remove the solvent component in the slurry, and finally pass cold pressing A positive electrode sheet with a certain compacted density is obtained.

[0019] Since the above-mentioned positive electrode sheet is a cold-pressed product, the surface is dense and smooth, and its wettability to the electrolyte is extremely poor. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com