Polycarbonate-organosiloxane copolymer material capable of selectively transmitting near-infrared rays

An organosiloxane and polycarbonate technology, which is applied in the field of near-infrared transmission materials, can solve the problems of affecting the mechanical properties of materials, poor low-temperature impact resistance, etc., and achieves good processing performance, excellent low-temperature impact resistance, and heat resistance. Excellent effect of oxygen aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

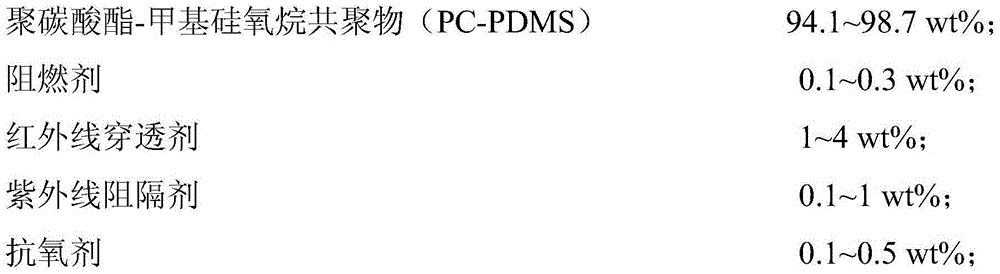

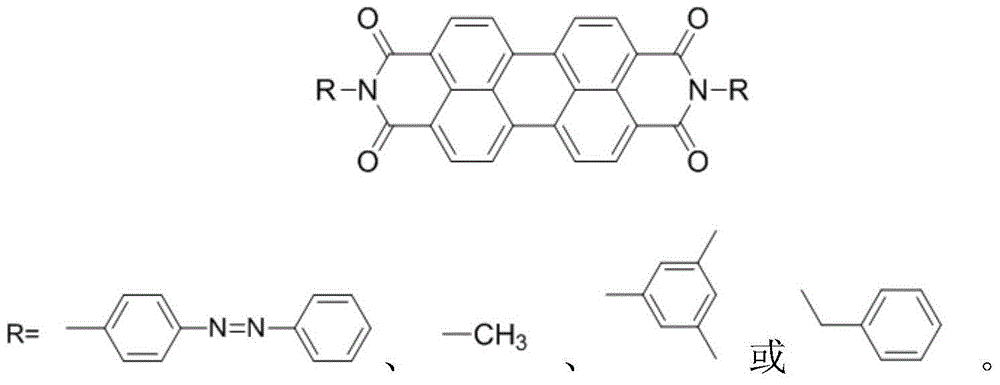

[0040] Polycarbonate-organosiloxane copolymer (Tarflon Neo Rc1700, silicone copolymerization rate 3%) 97wt%, flame retardant 0.1wt% (Dyneon-FR2025), infrared penetrating agent perylene red (Bai Lingwei reagent, particle diameter is 1100nm) 2wt%; UV blocker 0.6wt% (UV1164), antioxidant 0.2wt% (phosphonite antioxidant 168), lubricant 0.1wt% (pentaerythritol stearate).

[0041] Test results: product color: red; normal temperature and low temperature notched impact strength test: 64KJ / m 2 , 52KJ / m 2 (-30°C); flame retardant test: meet the flame retardant UL94V-1 grade at a thickness of 1.6mm; visible light transmittance (350-760nm): ≤3%; initial penetration wavelength: 723nm; infrared transmittance (800 -1500nm): 89%.

Embodiment 2

[0043] Polycarbonate-organosiloxane copolymer (Tarflon Neo AG2530, silicone copolymerization rate 9%) 97wt%, flame retardant 0.1wt% (Dyneon-FR2025), infrared penetrating agent perylene red (Bai Lingwei reagent, particle diameter is 1100nm) 2wt%; UV blocker 0.6wt% (UV1164), antioxidant 0.2wt% (phosphonite antioxidant 168), lubricant 0.1wt% (pentaerythritol oleate).

[0044] The test results show: product color: red; normal temperature and low temperature notched impact strength test: 65KJ / m 2 , 57KJ / m 2 (-30°C); flame retardant test: meet the flame retardant UL94V-1 grade at a thickness of 1.6mm; visible light transmittance (350-760nm): ≤3%; initial penetration wavelength: 723nm; infrared transmittance (800 -1500nm): 75%.

Embodiment 3

[0046] Polycarbonate-organosiloxane copolymer (Tarflon Neo Rc1700, silicone copolymerization rate 3%) 98wt%, flame retardant 0.1wt% (Dyneon-FR2025), infrared penetrating agent perylene red (Bai Lingwei reagent, particle diameter is 1100nm) 1wt%; UV blocker 0.6wt% (UV1164), antioxidant 0.2wt% (phosphonite antioxidant 168), lubricant 0.1wt% (pentaerythritol stearate).

[0047] The test results show: product color: red; normal temperature and low temperature notched impact strength test: 68KJ / m 2 , 59KJ / m 2 (-30°C); flame retardant test: meet the flame retardant UL94V-1 grade at a thickness of 1.6mm; initial penetration wavelength: 723nm; visible light transmittance (350-760nm): ≤10%, infrared transmittance (800 -1500nm): 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com