Modification method for establishing water channel by utilizing molybdenum disulfide to enhance water flux of polyamide reverse osmosis membrane

A technology of molybdenum disulfide and reverse osmosis membrane, which is applied in chemical instruments and methods, permeation/dialysis water/sewage treatment, semi-permeable membrane separation, etc., can solve problems that cannot meet practical applications, and improve water flux and salinity Interception performance, improvement of water permeability, and improvement of penetration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

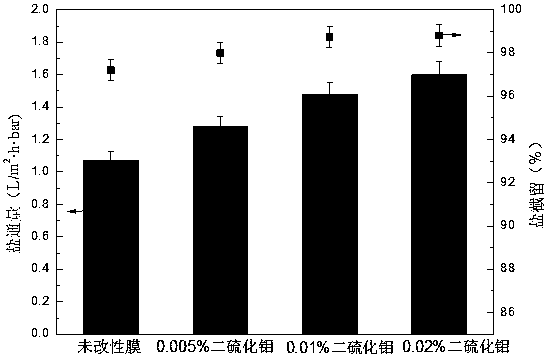

[0018] Specific embodiment 1: What this embodiment records is a kind of modification method that utilizes molybdenum disulfide to establish water channels to enhance the water flux of polyamide reverse osmosis membranes. The specific steps of the method are as follows:

[0019] Step 1: Prepare a mixed solution of molybdenum disulfide and 1-3% m-phenylenediamine with a mass fraction of 0.005%~0.2%;

[0020] Step 2: Pour the mixed solution prepared in Step 1 on the surface of the polyethersulfone base membrane and keep it for 10 minutes;

[0021] Step 3: remove the mixed solution on the surface of the polyethersulfone base membrane in step 2, and dry it with nitrogen for 5 minutes;

[0022] Step 4: Pour the 1,3,5-trimesoyl chloride n-hexane solution with a mass fraction of 0.1% on the surface of the polyethersulfone base membrane obtained in step 3 to make the 1,3,5-trimesoyl chloride n-hexane solution Fully react with polyethersulfone base membrane for 1min;

[0023] Step 5: ...

specific Embodiment approach 2

[0025] Specific embodiment two: a kind of modification method that utilizes molybdenum disulfide to establish water channels to enhance the water flux of polyamide reverse osmosis membrane described in specific embodiment one, in step one, the mass fraction of described molybdenum disulfide is 0.005% ~0.05%.

specific Embodiment approach 3

[0026] Specific embodiment three: a kind of modification method that utilizes molybdenum disulfide to establish water channels to enhance the water flux of polyamide reverse osmosis membrane described in specific embodiment one, in step one, the mass fraction of described m-phenylenediamine is 2 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com