Antibacterial desalting pipe and application thereof to salt-alkali soil desalting

A salt draining pipe and saline-alkali land technology, applied in antibacterial salt draining pipe and its application in saline-alkali land salt draining, can solve the problem of low plant survival rate, high salt content, high alkalinity soil conductivity, low antibacterial rate, etc. problems, to achieve the effect of high plant survival rate, strong disease resistance, and strong resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

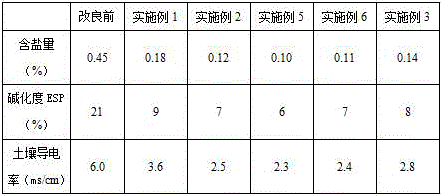

Embodiment 1

[0034] Embodiment 1 An antibacterial salt discharge pipe, including a dark pipe and a water-permeable layer,

[0035] The dark tube is processed from the following raw materials in parts by weight:

[0036] 112 parts of ethylene propylene rubber, 73 parts of low density polyethylene, 6.8 parts of polyisobutylene, 2.7 parts of chitosan, 2.1 parts of ethanolamide, 1.5 parts of methyltriethoxysilane, 2.0 parts of hexamethylphosphoric triamide, hard 1.3 parts of calcium fatty acid, 3.6 parts of di-n-octyl phthalate, 2.1 parts of graphene, 1.8 parts of guaiac resin, 8.0 parts of maleic anhydride grafted polyethylene.

[0037] The concealed pipe is a corrugated pipe, the maximum cross-sectional diameter of the concealed pipe is 100 mm in diameter, the minimum cross-sectional diameter of the concealed pipe is 92 mm in diameter, and a rectangular water-permeable gap is arranged on the pipe wall corresponding to the minimum cross-sectional diameter of the concealed pipe , the length o...

Embodiment 2

[0052] Embodiment 2 An antibacterial salt discharge pipe, including a dark pipe and a water-permeable layer,

[0053] The dark tube is processed from the following raw materials in parts by weight:

[0054] 115 parts of ethylene propylene rubber, 75 parts of low density polyethylene, 7.3 parts of polyisobutylene, 3.0 parts of chitosan, 2.5 parts of ethanolamide, 2.0 parts of methyltriethoxysilane, 2.5 parts of hexamethylphosphoric triamide, hard 1.8 parts of calcium fatty acid, 4.0 parts of di-n-octyl phthalate, 2.5 parts of graphene, 2.2 parts of guaiac resin, 8.5 parts of maleic anhydride grafted polyethylene.

[0055]The concealed pipe is a corrugated pipe, the maximum cross-sectional diameter of the concealed pipe is 110 mm in diameter, the minimum cross-sectional diameter of the concealed pipe is 102 mm in diameter, and a rectangular water-permeable gap is arranged on the pipe wall corresponding to the minimum cross-sectional diameter of the concealed pipe , the length o...

Embodiment 3

[0070] Embodiment 3 An antibacterial salt discharge pipe, including a dark pipe and a water-permeable layer,

[0071] The dark tube is processed from the following raw materials in parts by weight:

[0072] 118 parts of ethylene propylene rubber, 77 parts of low density polyethylene, 7.8 parts of polyisobutylene, 3.3 parts of chitosan, 2.9 parts of ethanolamide, 2.5 parts of methyltriethoxysilane, 3.0 parts of hexamethylphosphoric triamide, hard 2.3 parts of calcium fatty acid, 4.4 parts of di-n-octyl phthalate, 2.9 parts of graphene, 2.6 parts of guaiac resin, and 9.0 parts of maleic anhydride grafted polyethylene.

[0073] The concealed pipe is a corrugated pipe, the maximum cross-sectional diameter of the concealed pipe is 120 mm in diameter, the minimum cross-sectional diameter of the concealed pipe is 112 mm in diameter, and a rectangular permeable gap is arranged on the pipe wall corresponding to the minimum cross-sectional diameter of the concealed pipe , the length of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com