Hollow bowl-shaped silicon dioxide nanoparticles, preparation method and application thereof

A nanoparticle, silica technology, applied in the field of materials, can solve problems to be developed and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

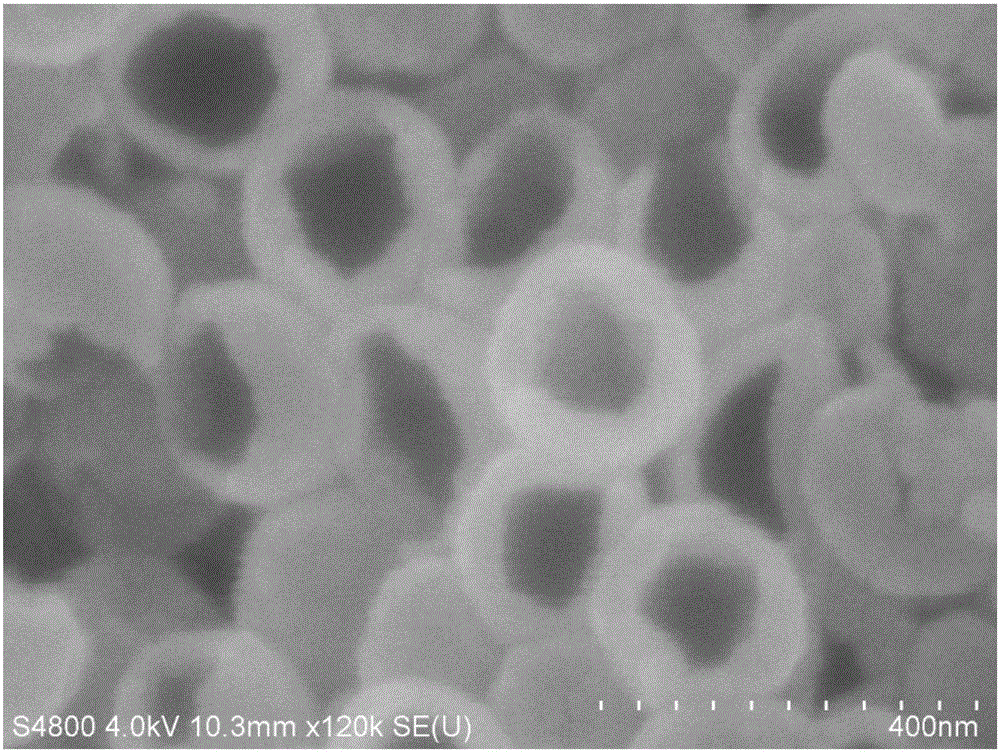

[0053] The invention provides a method for preparing hollow bowl-shaped silicon dioxide nanoparticles, the method comprising the steps of:

[0054] 1) providing a first mixed solution, a catalyst, a silicon source, and a first solvent, wherein the first mixed solution includes polymer nanoparticles and a second solvent;

[0055] 2) under stirring conditions, mix the first mixed liquid and the catalyst, and react to obtain the second mixed liquid;

[0056] 3) under stirring conditions, mixing the second mixed solution and the silicon source, and reacting to obtain a third mixed solution containing silica-coated polymer nanoparticles;

[0057] 4) coating the third mixed solution on the substrate, and drying to obtain a substrate coated with a silica-coated polymer nanoparticle coating;

[0058] 5) Soak the product obtained in step 4) in the first solvent, take out the matrix, and dry to obtain the hollow bowl-shaped silica nanoparticles.

[0059] In the present invention, the ...

Embodiment 1

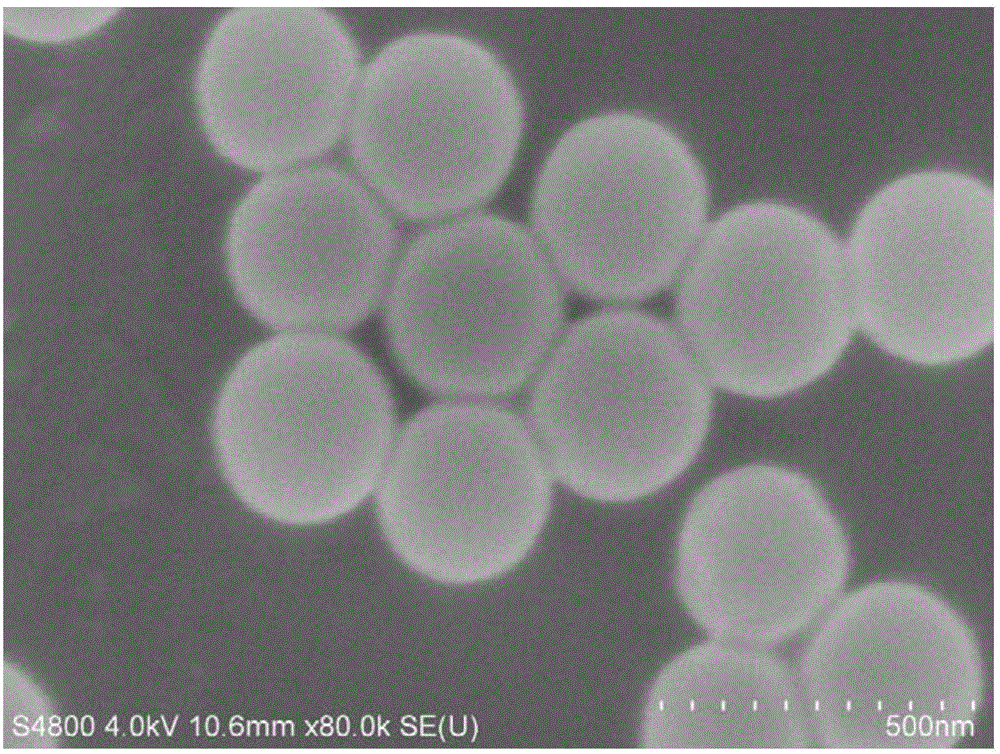

[0115] Embodiment 1 Hollow bowl-shaped silica nanoparticle 1

[0116] Take 1.5g of polyvinylpyrrolidone (average relative molecular weight 58000), 0.35g of azobisisobutylamidine hydrochloride, 100mL of distilled water, mix and stir at room temperature, after the solution is clarified, add 11mL of styrene monomer, and pass into N 2 2h; then at 70°C, stirring at a speed of 200rpm, stirring for 24h to obtain polystyrene nanoparticles 1 with an average particle diameter of about 240nm.

[0117] Take 5.0 g of the polystyrene nanoparticles 1 obtained above, dissolve them in 40 mL of absolute ethanol, and ultrasonically dissolve them for 30 min to obtain a 7.0 wt % suspension; at 50 ° C, the stirring speed is 200 rpm, Add 5mL of ammonia water to the suspension, and after 5min, add 1.5mL of silicon source, the silicon source is tetraethyl orthosilicate and methyltriethoxysilane with a volume ratio of 1:3, and react for 3h to obtain the average particle size Silica-coated polystyrene...

Embodiment 2 2

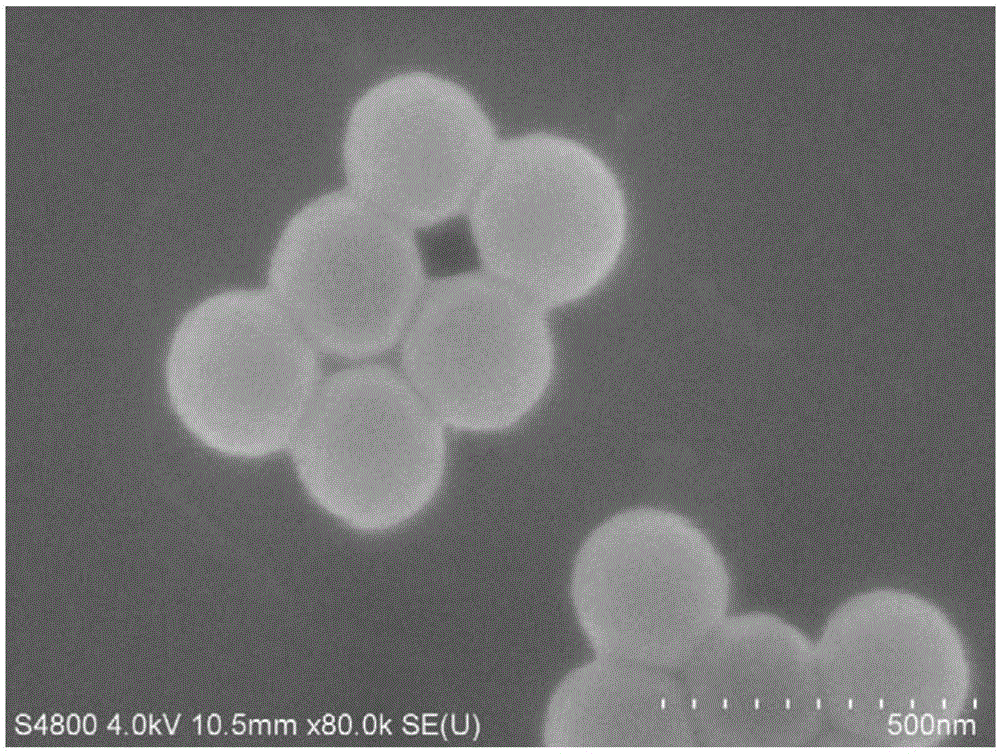

[0126] Embodiment 2 Silica nanoparticles 2

[0127] Take 0.1g of polyvinylpyrrolidone (average relative molecular weight 58000), 0.05g of potassium persulfate, 100mL of distilled water, mix and stir at room temperature, after the solution is clarified, add 2mL of styrene monomer, and pass through N 2 0.5 h; then at 40° C. with a stirring speed of 500 rpm for 12 h to obtain polystyrene nanoparticles 2 with an average particle diameter of about 100 nm.

[0128] Take 0.71g of the polystyrene nanoparticles 2 obtained above, dissolve them in 40mL of methanol, and ultrasonically disperse them for 30min to obtain a 1.0wt% suspension; at 20°C, the stirring speed is 500rpm, and Add 2mL of ammonia water to the suspension, and after 5min, add 0.5mL of silicon source, the silicon source is methyl orthosilicate and methyltrimethoxysilane with a volume ratio of 2:1, and react for 0.5h to obtain an average particle size of 110nm 2 left and right silica-coated polystyrene nanoparticles.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com