Leather softening equipment

A leather softening and equipment technology, applied in the field of clothing, can solve the problems of wasting resources, endangering the surrounding safety, and prone to splashing, etc., to achieve the effect of avoiding waste, improving uniformity, and ensuring the quality of leather softening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

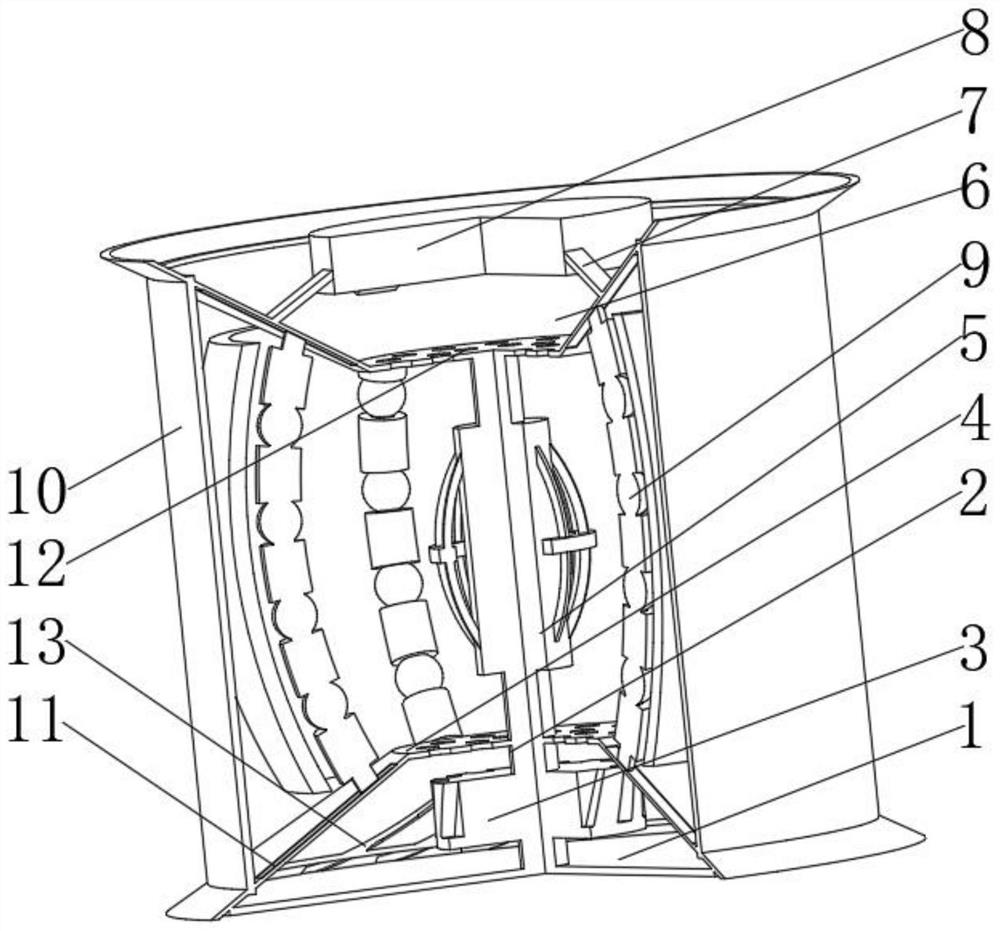

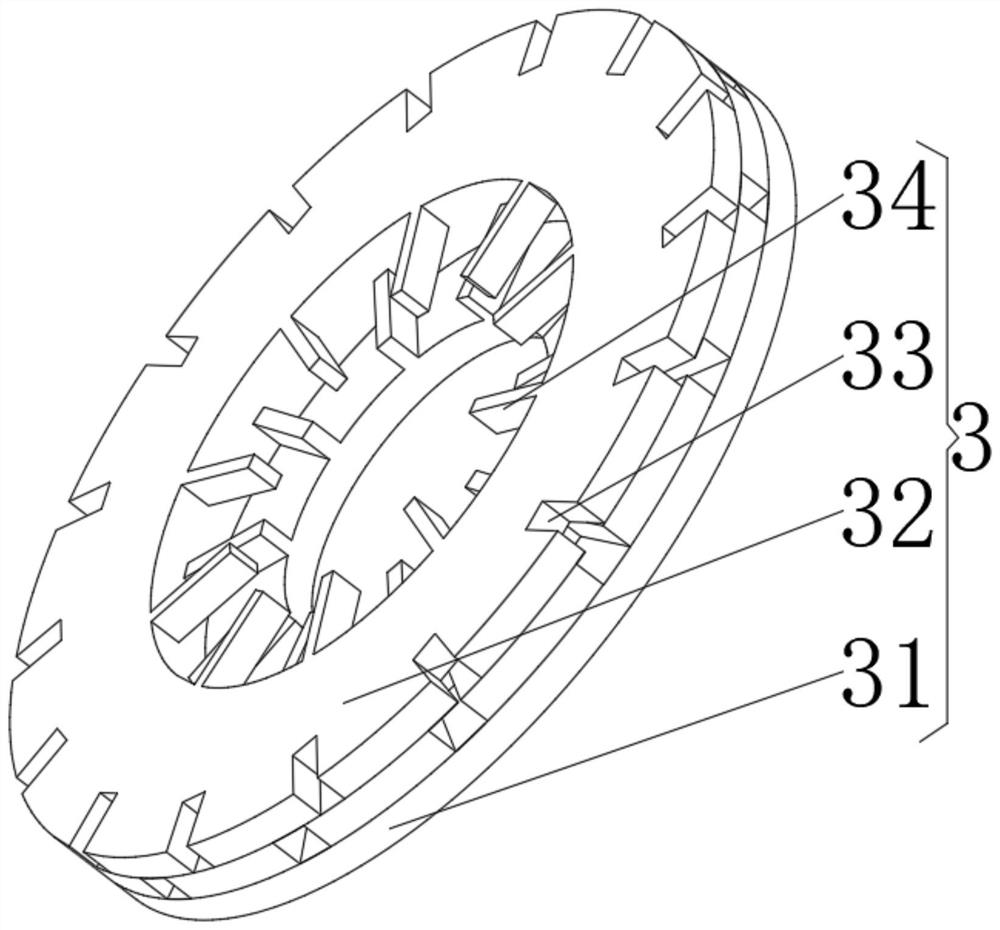

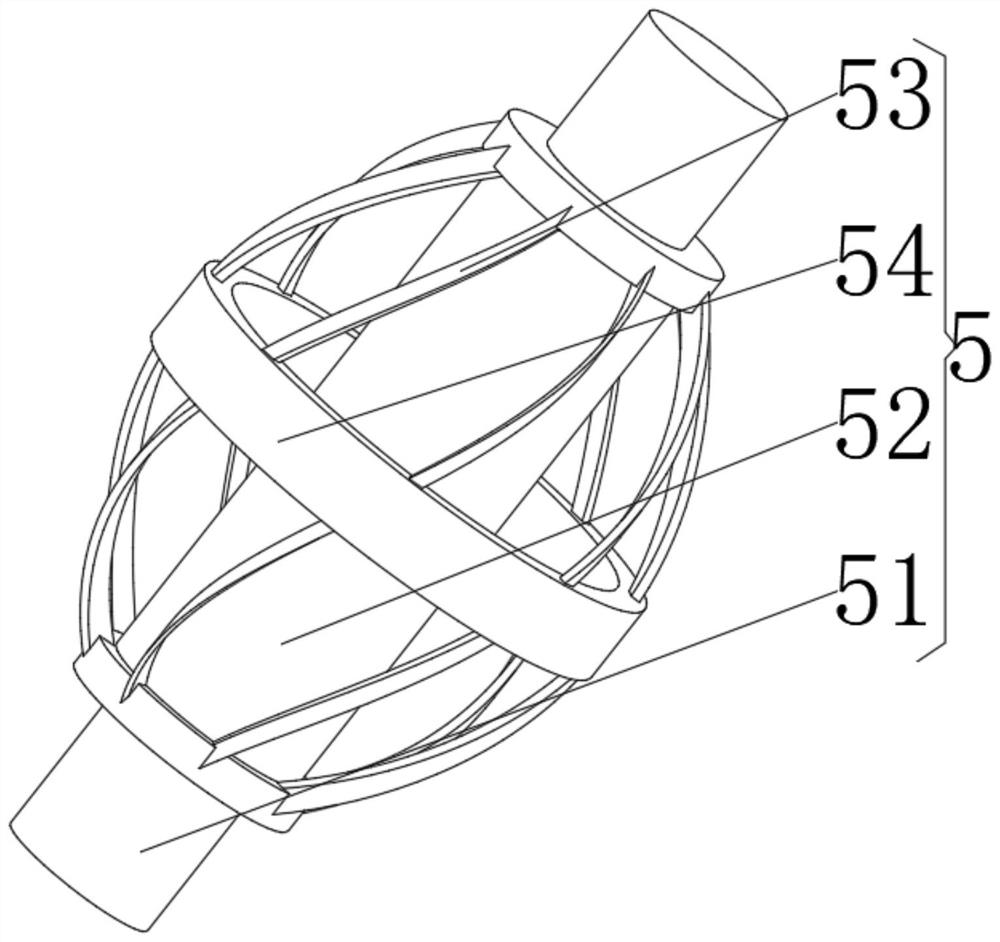

[0037] see Figure 1-6, the present invention provides a technical solution: a leather softening device, including a placement base 1, a support shaft 2 is fixedly connected to the middle position of the top of the placement base 1, and a guide fan wheel 3 is flexibly connected to the middle position of the outer surface of the support shaft 2, and the support The bottom cover 4 is fixedly connected to the side of the rotating shaft 2 away from the placement seat 1, the self-heating mechanism 5 is fixedly connected to the middle position of the top of the bottom cover 4, and the top cover 6 is fixedly connected to the end of the self-heating mechanism 5 away from the bottom cover 4, and the top cover 6 The top is fixedly connected with a placement frame 7, and the end of the placement frame 7 away from the top cover 6 is fixedly connected with an adding mechanism 8. The top cover 6 and the bottom cover 4 are close to each other and are movably connected with an arc-shaped rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com