Plastic midsole for shoes for women and processing method for plastic midsole

A technology for plastic and women's shoes, applied in soles, footwear, apparel, etc., can solve problems such as increasing modification costs, damage to the midsole, and appearance problems of the midsole, reducing modification costs, modification time, and structural strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

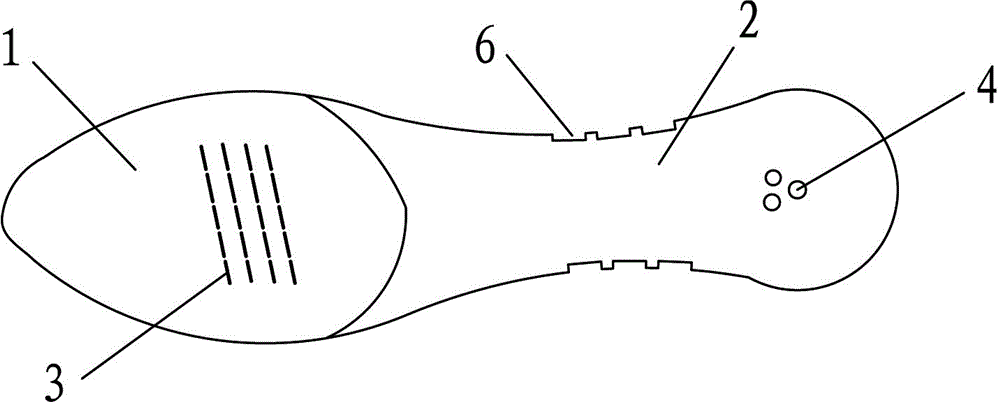

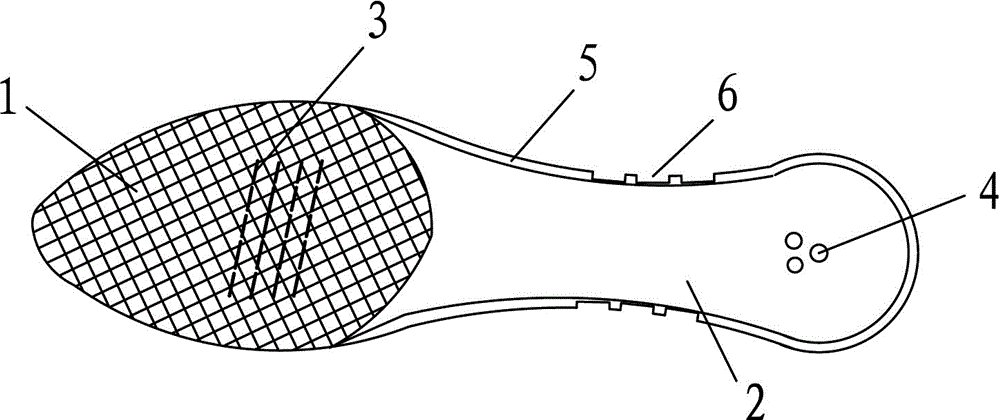

[0032] Such as figure 1 As shown, the midsole of the shoe is composed of a forefoot part 1 and a heel part 2;

[0033] The forefoot part 1 and the heel part 2 are integrated to form a shoe midsole similar to the shape of the foot;

[0034] The front palm part 1 is formed by pressing multiple layers of cardboard, and the lower surface is pasted with a square-hole cotton net composed of interlaced cotton threads;

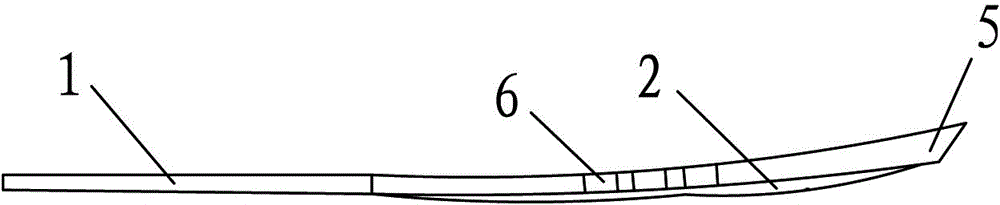

[0035] There are four rows of parallel pre-folded hole groups along the upper edge of the front part of the palm 1, and each group of pre-folded hole groups is composed of five evenly spaced pre-folded holes 3;

[0036] The heel part 2 is made of plastic injection molding, the outer peripheral side is inclined from top to bottom, the upper surface is concave downward in an arc shape, and the lower surface is convex downward in an arc shape;

[0037] The heel part 2 is provided with a plurality of fixing holes 4 for fixing and matching with the outsole of the shoe; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bump height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com